TimeTec TTS 2200B User manual

Mobile Access,

TimeTec Smart Tripod Turnstile

TTS 2200B

Installation Manual

www.timeteccloud.com

1

TS2200: Tripod Turnstile

TS2211: Tripod Turnstile with Controller and RFID Reader

TS2222: Tripod Turnstile with Controller and Fingerprint Reader with RFID function.

Please read this document carefully before installation and using the device.

1. Technical Specications

Input Voltage AC 100V ~ 120V/200~240V,

50Hz/60Hz

Max. Tolerance of Arms Center: 80 kg

End: 40 kg

Rated Power 60 W Ingress Protection Degree IP54

Operating Environment Indoor and Outdoor (shelter) Arm Length (mm) 500

Operating Temperature -28ºC ~ 60ºC Net Weight 65kg

Operating Humidity 5% ~ 85% Gross Weight 75kg

Flow Rate 25 ~ 48 passages / minute Dimension(mm) Figure 1 L = 1110, W = 320, H = 980

Input Control Signal Dry contact Package Size (mm) L = 1200, W = 440, H = 1080

"""#

$%#

&## '(# &##

$%#

'(#

"""#

)*#

&##

)*#

&##

Figure 1

2. Arm Installation and Equipment Testing

2.1 Arm Installation Method

Installation procedure

Figure 2-1

1. Using the glue and applying in the hole of the arms as well

as the one screw, as shown in gure 2-1. (This is to prevent

screws from getting loose due to vibration after being used

for a long time.) This hole shall be applied

with glue evenly.

2

Figure 2-2

2.2 Power-on Test Before the Installation of Device

1. Please make sure that the power requirements are strictly met to avoid permanent damage to the unit. Input voltage: AC 100~120V/200 ~

240V.

Note: The tripod turnstile must be connected to the ground (earth).

2. Power on and wait 30s for the tripod turnstile to nish the self-check program.

3. Lift the arms manually, as shown in gure 2-4.

4. Check whether the tripod turnstile and the LED indicators work properly.

If there is any problem, please contact the supplier.

Figure 2-3 Figure 2-4

3. Equipment Installation

3.1 Installation Conditions

The equipment must be installed on concrete ground, ensuring that expansion bolts can be secured rmly.

You are suggested to install an assistant framework or fence to form a passageway, as shown in gure 3-1.

Figure 3-1

2. Rotating the arms to the connection points until it was

fastening, and use the Hex key to fasten the one screw on

each arm, as shown in gure 2-2.

Tighten the one screw on each

arm in clockwise direction.

Power Switch

Earth Wiring Terminal

There is a power switch in the side

direction of this power supply. Lift upwards

&##

'(#

"'(#

+,,-,./0.!

12/345627

﹤%#

﹤%#

3

Notes:

1. The space at the end of the arm shall not be greater than 80mm (see figure 3-1).

2. Setting a warning line for card swiping (see figure 3-2). A warning line is suggested to prompt users to swipe cards in a distance, which

would greatly reduce the probability of equipment failure caused by improper operations.

Warning line for card swiping

Warning line for card swiping

Warning line for card swiping

Warning line

for card swiping

Assistant

framework

Figure 3-2

3.2 Cabling

There are inlets in the bottom plate for cabling, as shown in figure 3-3, the unit is millimeter. Cable protection covers are suggested to use if it is

surface mounted.

Warning: The tripod turnstile must be connected to the Ground (earth), there is wiring interface near the power switch.

Figure 3-3

3.3 Installation

1. Drilling holes.

Drill holes based on the locations of the holes shown in figure 3-3.

2. Fix the mounting plate to its original position.

Placing the mounting plate properly and apply screw securing glue on the surface and the threads of the expansion bolts, install six

expansion bolts to secure the mounting plate, and use a horizontal ruler to test the levelness of the mounting plate. If the mounting plate is

not level, adjust it by the gaskets provided. Note that all the six expansion bolts must be installed properly, as shown in figure 3-4.

Figure 3-4

3. Put the turnstile on the mounting plate and tighten the screws. Apply screw securing glue before using and putting gaskets on the screws

to adjust the direction of the turnstile. If the tripod turnstile is not level, you can place gaskets to adjust, as shown in figure 3-5.

50.00

16.00

606.00

262.00

1120.00

315.00

Screw securing glue shall

be applied on the threads.

4

Figure 3-5

4. Cable Diagram

4.1 Function Description of the Turnstile Control Board

If you are using TS2211 or TS2222, all the connections between access control and turnstile control boards are done in factory. Just plug in

communication cable to access controller and do the setting.

If you are using TS2200, you need to connect access control system to the main board, please check the content in this chapter carefully.

Warning: The third party access control system lock relay trigger time should be 1 second or less than 1 second.

Figure 4-1

Descriptions:

J2 Counter: To connect a LED screen and display the number of people passed that is generated by the push of tripod arms, each completed

push means pass one time.

J5 (Right) & J4 (Left) Indicator: To connect a LED screen and indicate whether this passage is allowed to pass.

Installation levelnessInstallation levelness

5

J3 Indicator (top): To connect a LED screen and indicate if user verication is successful and whether it is able to pass.

J-NC2 Disabled Turnstile: Short circuit NC1 and GND, the turnstile is disabled, that is to say, the turnstile is locked by force.

J7 Opening Signal Input: To receive relay signal and open the turnstile. Short circuit K1 and GND, left passing is allowed; short circuit K2 and

GND, right passing is allowed.

J6 External Alarm: Short circuit ALARM1 and GND, and the turnstile is disabled (locked) and the alarm is ringing in case there are emergencies.

J6 Drop Arm: Short circuit DOW and GND, the arm is dropped down by force in case there are res or other emergencies.

J8 Proximity Switch Signal Input: Input position signal of the arm.

J9 12V Power Supply for Access control: Control board directly provides Access Control with 12V power. (Maximum support 3A)

V1L Left Solenoid, V2R Right Solenoid & UP D50 Solenoid: Control the passage and arm dropping.

4.2 Connection Diagram of the Access Controller Device

Figure 4-2

Warning: Forbidden using an electrically charged objects to connect to any one port of Opening Signal Input, otherwise will

damage the control board.

4.3 DIP K1 Switch Conguration

Figure 4-3

Pin 1 2 3 4 5 6 7 8

Function Setting Opening Duration Direction Indicator Continue Passing Function Alarm

Default 1 1 1 0 1 0 0 0

4.3.1 Setting the Turnstile Opening Duration

Opening duration refers to the period of time from opening to closing once the turnstile receives an open signal. In the DIP switch, number 1, 2,

and 3 are used for duration setting. It can be set to dierent values from 5s to 60s according to the following chart.

Bit Setting Duration Bit Setting Duration

111 5s 011 30s

110 10s 010 40s

101 15s 001 50s

100 20s 000 60s

Note: The turnstile opening duration is set to 5s by default.

Note: The lock relay duration of access controller

device needs to be set to 1s.

6

4.3.2 Direction Indicator

It is to indicate whether the passage allows people to pass. The green arrow means passing is allowed while the red "X" means passing is

prohibited. The indicator status can be set through number 4 and 5 in the DIP switch. The description of the bit settings are as follows:

11 = One-way traffic, left passing is allowed.

10 = One-way traffic, right passing is allowed.

01 = Passing is allowed in both directions.

4.3.3 Continue Passing Function

With the Continue Passing function, the turnstile could remember at most 20 swipes of one card at one time and allows up to 20 people to pass

so they don’t have to swipe card each time, this function can be enabled or disabled through number 6 in the DIP switch. The description of the

bit settings are as follows:

In the DIP switch, number 6 is used to enabled or disabled the Continue Passing Function, number 7 is used to set the initial value of Continue

Passing Function.

number 6 number 7 Function Opening Duration

0 disabled Disabled

Continue Passing Function

Please consult 4.3.1 Setting the Turnstile Opening Duration

1

1

Enabled Continue Passing Function

The initial value is 16s, and the Opening Duration = 16 + (N -1) * 6

0 The initial value is 8s, and the Opening Duration = 8+ (N -1) * 6

4.3.4 Alarm Function (Optional)

In the DIP K1 switch, number 8 is used to enabled or disabled the Alarm Function.

1 = enabled

0 = disabled

Note: Please set to 0 when working normally, that is to say that Alarm Function is disabled.

7

5. Equipment Precautions and Maintenance

5.1 Precaution

1. It is recommended to purchase optional accessories to use in outdoor environment.

(1) It shall install optional cooling fans for the equipment if the working temperature is often above 50 ºC.

(2) It is equivalent to IP54 waterproof under proper installation. However, it cannot work in the region that may suer typhoon.

(3) If the temperature is -30ºC, a heating plate is suggested to install. It might need multiple times to power on while getting hot

automatically through the self-check program.

(4) The service life of this equipment may be shortened if it works outdoors in coastal areas or a region prone to acid rain.

2. If the power and signal cables are connected properly, this equipment can be immersed in water of 250mm deep, but it must not be

powered on for operating when it is immersed in water.

3. It is highly recommended that a card swiping warning line to set for prompting passers-by to swipe cards properly and a reasonable

passage width shall be set to prevent passers-by from squeezing in illegally.

4. It is recommended that a warning sign is placed at a conspicuous position, and prompt: "Please swipe your card outside the warning line

and pass in order. Thank you!”

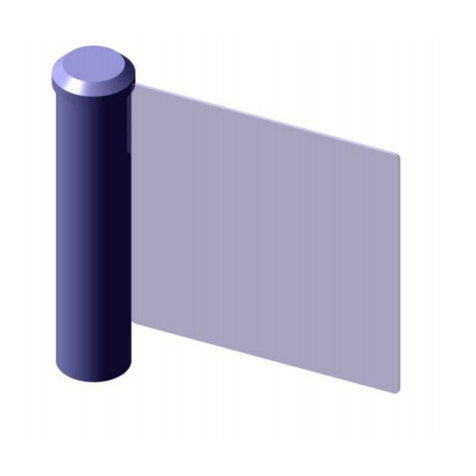

The maximum tolerance of the tripod turnstile's arms

Please note that the maximum stress tolerance at the center of the arm is 80kg and at the ends of the arm is 40kg (See gure 5-1). When the

impact force on the tripod turnstile reaches the designed limit, the arms break down rst to ensure that the whole equipment is not damaged

and the passer-by is not injured.

Figure 5-1

In case of emergencies

This equipment is designed to drop down arms automatically if there is power failure thus make the passage being open to the public. And

there is interface in the turnstile main board to connect an emergency switch (J6 Drop Arm) which would make the tripod turnstile keep open in

case of emergencies. Note after power restoration, wait for more than 6s and then lift the arms manually.

5.2 Maintenance

Forming maintenance consciousness

The tripod turnstile needs to be maintained regularly and repaired once it is damaged. It is recommended that warning signs being placed at

conspicuous positions for prompting passers-by to pass in a proper way and in good order. Reasonable maintenance consciousness helps to

guarantee long-term usage of the tripod turnstile.

Regular maintenance

Cleaning and protection liquid dedicated for stainless steel are recommended to wipe the outer shell of the equipment regularly. The tripod

turnstile used outdoors or in an environment with lots of dust must be maintained once a year at least, for example, clean up the dust and add

appropriate lubricating oil to Trilobed Wheel. Note regular maintenance should be performed after power o the equipment.

The Adjustable Tension Spring is used to adjust the tripod turnstile's elasticity and return speed. You can rotate it in clockwise direction to

enhance and in anticlockwise direction to weaken the elasticity and return speed of the tripod turnstile. See gure 5-2.

Figure 5-3 shows the mechanical and electrical structure of this equipment.

Maximum stress

tolerance: 40 kg

Maximum stress

tolerance: 80 kg

8

Figure 5-2 Figure 5-3

6. Troubleshooting

Symptom Troubleshooting

The indicator is not lighted when the equipment is

powered on.

It may be caused by the power supply or circuit.

Check whether the connection cable and power cable between are damaged, or

the wiring is loose.

The arms of the tripod turnstile cannot be lifted

manually after the equipment is powered on.

It may be caused by the problem of relative components or drop-arm solenoid.

1. Check whether the stop base and turn plate withstands each other, as shown in

gure 6-1.

2. Check whether the drop-arm solenoid is operating. Check the work status of the

solenoid, as shown in gure 6-2.

The tripod turnstile does not open after

authentication.

It may be caused by lack of permission or a circuit problem.

1. Check whether the user has the permission to open the turnstile.

2. Use a multimeter to check whether the NO and COM ports of the access control

system has a relay signal output.

3. Short

-circuit the ports "K1, GND" and "K2, GND", if the turnstile is successfully

opened, it would be the problem of controller. In this case, please refer to

Attachment 2 Connection Diagram of Mainboard and Access Control Panel to

check the cable connection of the controller.

The passing is not smooth after the turnstile is

opened, it encounters resistance when pushing the

arms, and the arms cannot return to the home

position after they rotate.

It is caused by the Adjustable Tension Spring.

Adjust the Adjustable Tension Spring, as shown in gure 5-3.

The arms drop during the use.

It may be caused by the problem of relative components or drop-arm solenoid.

1. Check whether there is any gap at the position shown in gure 6-1.

2. Check whether the drop-arm solenoid is totally closed. If not, power o the

equipment and power on it again 2 minutes later.

The turnstile allows people continue passing

one-way side during the use.

1. Check the Turnstile-opening Solenoid

2. Check whether the Turnstile-opening solenoid is operating. Check whether the

Turnstile-opening solenoid is stuck or the Metal Shrapnel is broken, as shown in

gure 5-3.

Drop-arm Solenoid

Position Sensor

Lock Rod

Adjustable Tension Spring

Turnstile-opening

Solenoid

Lock Rod

Metal Shrapnel Tri-lobed Wheel

Turnstile-opening

Solenoid

9

Figure 6-1

Figure 6-2

Attachment 1 Default Factory Settings

No. Function Default

1 Lock Driving Duration 5s

2 Door Sensor None

3 Verication Interval 1s

4 Controller Communication TCP/IP: 192.168.1.201

5 Turnstile Opening Duration 5s

6 Passing Direction Indicator Passing is allowed in both directions

7 Continue Passing Function Disabled

8 Alarm Function Disabled

Note: The Lock Driving Duration is default 5 seconds, please set to 1 second.

Normal status of the drop-arm solenoid after

being powered o

Normal status (closed) of the drop-arm solenoid

after being powered on

10

Attachment 2 Connection Diagram of Mainboard and Access Control Panel

Warning: This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be required

to take adequate measures.

11

Attachedment 3 Connection of TTS 2200B main board and TimeTec BLE 2

Power Supply

12VDC

-

+

©2018Ti me te c Com pu ti ng S dn B hd. Al l ri gh ts reser ve d • 012018