• Do not field strip or otherwise disassemble this marker while

it is pressurized with air supply.

• Dressappropriatelywhenplayingthegameofpaintball. Avoid

exposing any skin when playing the game of paintball. Even

a light layer will absorb some of the impact and protect you

from the paintballs.

• Keep exposed skin away from escaping gas when installing

orremovingairsupply cylinder or if the marker orairsupplyis

leaking. Compressedair, CO2,and nitrogen gasses are very

cold and can cause frostbite under certain conditions.

• Use only .68 caliber paintballs, never load or fire any foreign

objects.

• Avoid alcoholic beverages before and during the use of this

marker. Handling markers whileundertheinfluenceof drugs

or alcohol is a criminal disregard for public safety.

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air supply

cylinder or adaptor. Contact the air supply cylinder or adaptor

manufacturerwithanyquestions.

• Always measure your marker’s velocity before playing

paintball and never shoot at velocities in excess of 300 feet

per second (see instructions on page 7).

6

Safety Is Your Responsibility (continued from page 5)

E

N

G

L

I

S

H

Getting Started (continued on page 7)

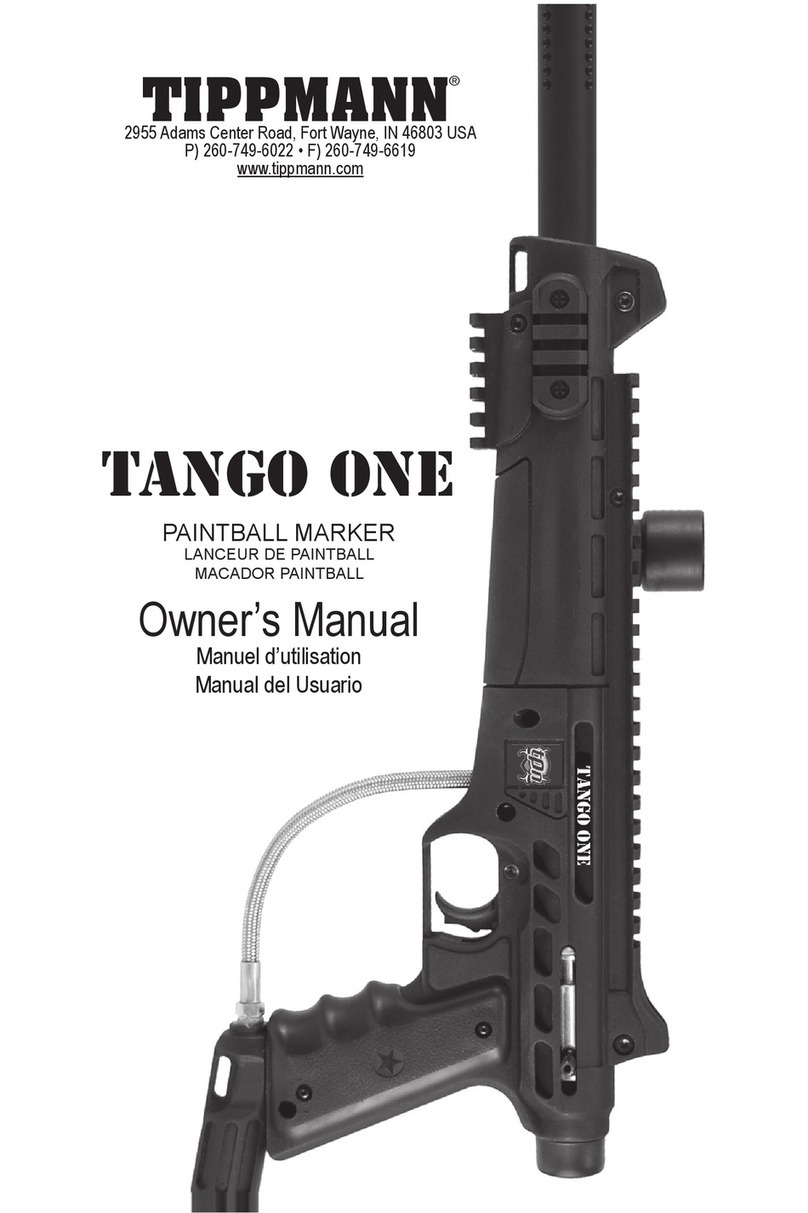

Getting Started

STEP 1) Prepare Marker for Air Supply Cylinder Installation

• ForModel:CustomProTM WithE-GRIPTM -Youmust firstinstall

battery(see instructions on page9before performing STEP 2.

• ForCustomProTM andCustomProTM ResponseTMgotoSTEP2.

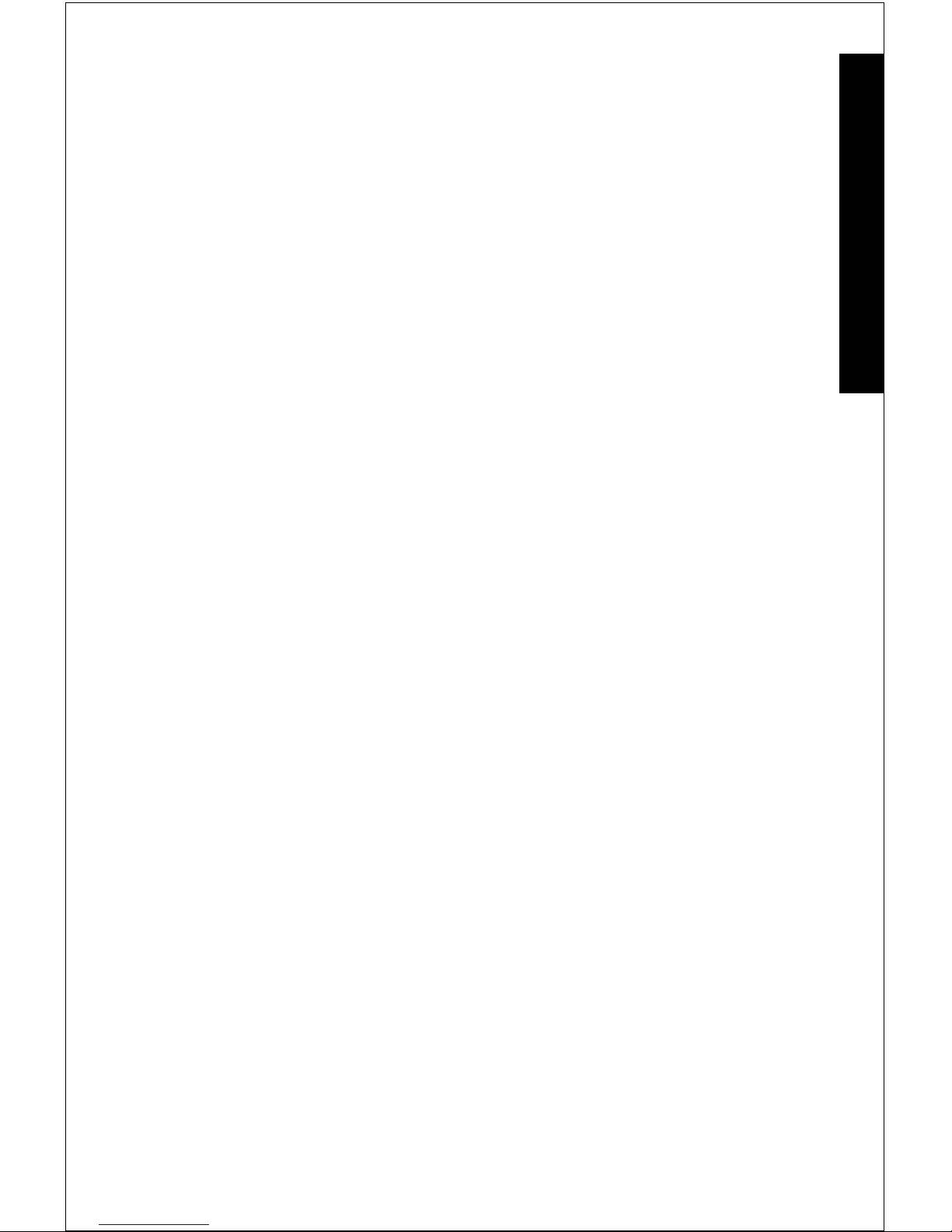

STEP 2) Air Supply Cylinder Installation

• Do not pressurize a partially assembled paintball marker.

• First install barrel sleeve (see instructions on page 2).

• NextputtriggersafetyinSafeMode(seeinstructionsonpage4).

• Next you need to cock the marker by sliding the bolt handle

all the way back until it locks into place. Always keep marker

in the cocked position when air supply is attached to marker.

This will help prevent an accidental discharge.

• To install the air supply cylinder, lubricate the cylinder valve

o-ring with a little gun oil then insert the cylinder valve end

intothe air supplyadapterat the backendof the markergrip.

Twistthecylinderclockwiseintothemarkeruntilitstops. Adjust

the butt plate if necessary. Your marker is ready to fire once

youswitchtoFireMode from SafeMode. Ifthetankisfulland

youdo not heartheair supply engage,thepin valve couldbe

too short or the pin valve seal is damaged.