E

N

G

L

I

S

H

5

CONGRATULATIONS on your purchase of a TPN™ Tango One™ paintball marker. We

believe our Tango One markers to be the most accurate and durable paintball markers

available, and are proudly manufactured by Tippmann®. All Tango One line markers will

provide many years of dependable service if cared for properly.

Please take time to read this manual thoroughly and become familiar with your Tango

One model’s parts, operation, and safety precautions before you attempt to load or re

this marker. If you have a missing or broken part or need assistance, please contact

Tippmann Consumer Relations at 1-800-533-4831 for fast friendly service.

TABLE OF CONTENTS

Barrel Sleeve Installation Instructions .....................................................................................................4

Warning/Liability Statement .....................................................................................................................5

Safety Is Your Responsibility! ..................................................................................................................6

Trigger Safety ...............................................................................................................................6

Familiarize Yourself With Safety... ................................................................................................6

Getting Started ........................................................................................................................................7

1. Install the Barrel. ......................................................................................................................8

2. Air/CO2 Cylinder Installation ....................................................................................................8

3. Loading the Hopper ..................................................................................................................9

4. Firing the Marker ......................................................................................................................9

Velocity Adjustment .................................................................................................................................9

Unloading Your Marker ............................................................................................................................9

Air/CO2 Cylinder Warnings....................................................................................................................10

Air/CO2 Cylinder Safety Tips ..................................................................................................... 11

Air/CO2 Cylinder Removal .................................................................................................................... 11

Repairing Air/CO2 Cylinder Leaks..............................................................................................12

Cleaning and Maintenance ....................................................................................................................12

Storage ..................................................................................................................................................13

Tango One Disassembly and Assembly ................................................................................................13

Marker Instructions .....................................................................................................................13

The Valve ...................................................................................................................................14

The Trigger .................................................................................................................................16

General Troubleshooting ......................................................................................................................16

Specications ........................................................................................................................................17

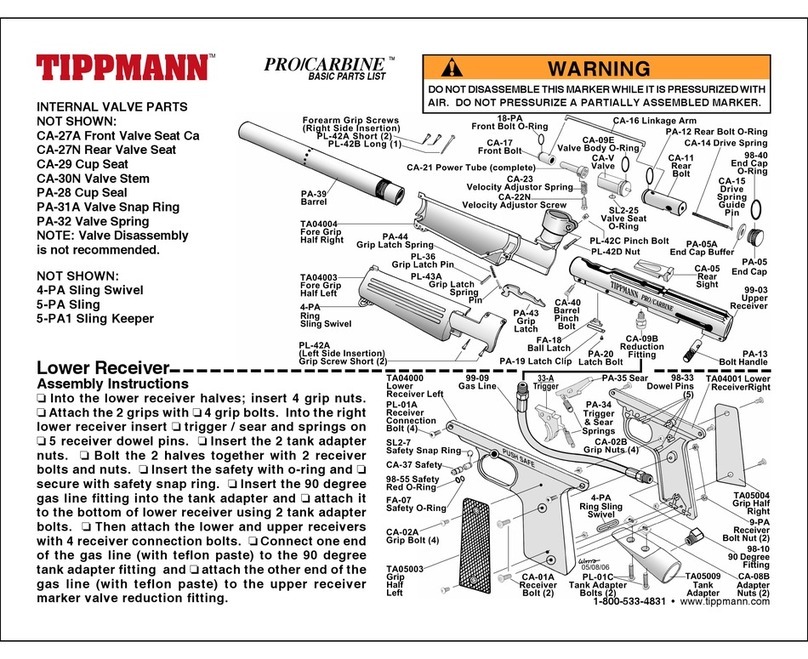

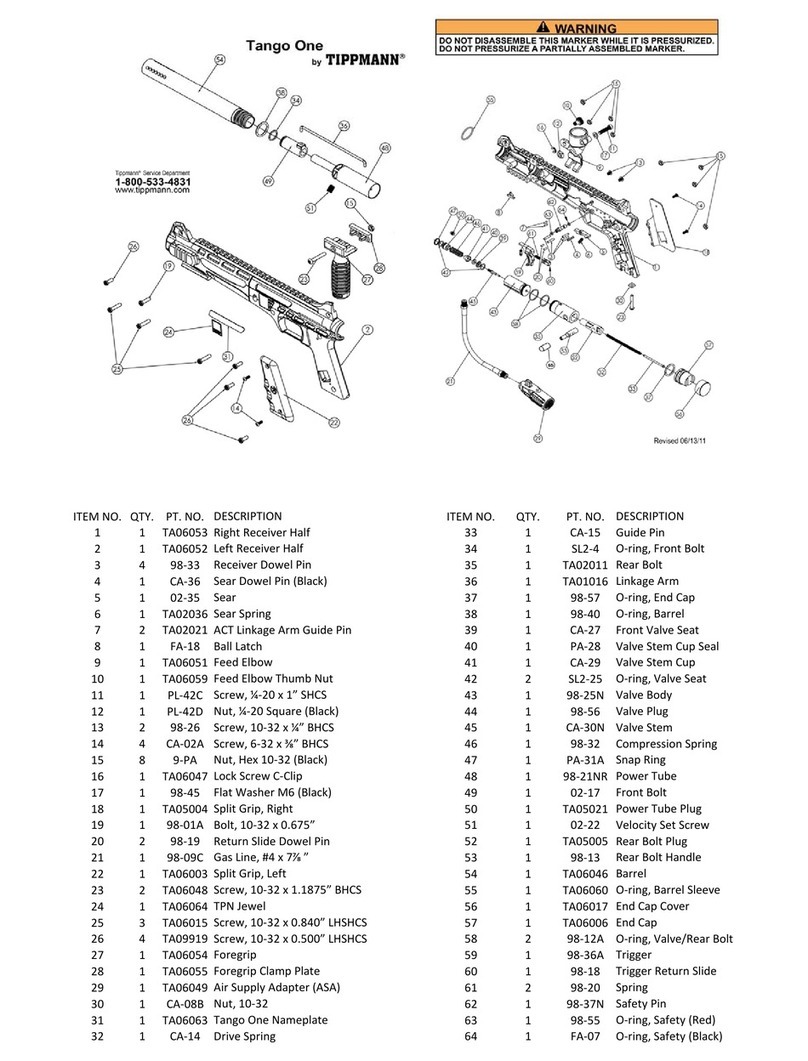

Basic Parts Diagram ..............................................................................................................................18

Parts List ....................................................................................................................................20

Warranty and Repair Information ..........................................................................................................22

TANGO ONE

by TIPPMANN®

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619 • www.tippmann.com

™