TIS 600 User manual

Introduction of Instrument

TIS 600 is a handheld safety tester which is mainly used for safety performance

tests of household appliances and industrial equipment (otherwise known as a

Portable Appliance Tester),

Its main functions are as follows:

Safety CLASS I test;

Safety CLASS II test;

Cord/Polarity test;

230V/110V Sub-Leakage test functionality

12V battery-powered, with automatic power-off function so that it will automatically

shut down if there is no operation within 5 minutes.

It has a backlight display function and will be automatically shut down within 30s.

Warning: Read this manual carefully before use and follow the relevant procedures

during the operation.

This kit includes:

※TIS 600 safety tester 1 PCS

※CORD mains test cord 1 PCS

※Crocodile clip test cord (including a removable crocodile clip)1 PCS

※Probe 1 PCS

※AA lithium battery 1.5V 8 PCS

※Instructions 1 PCS

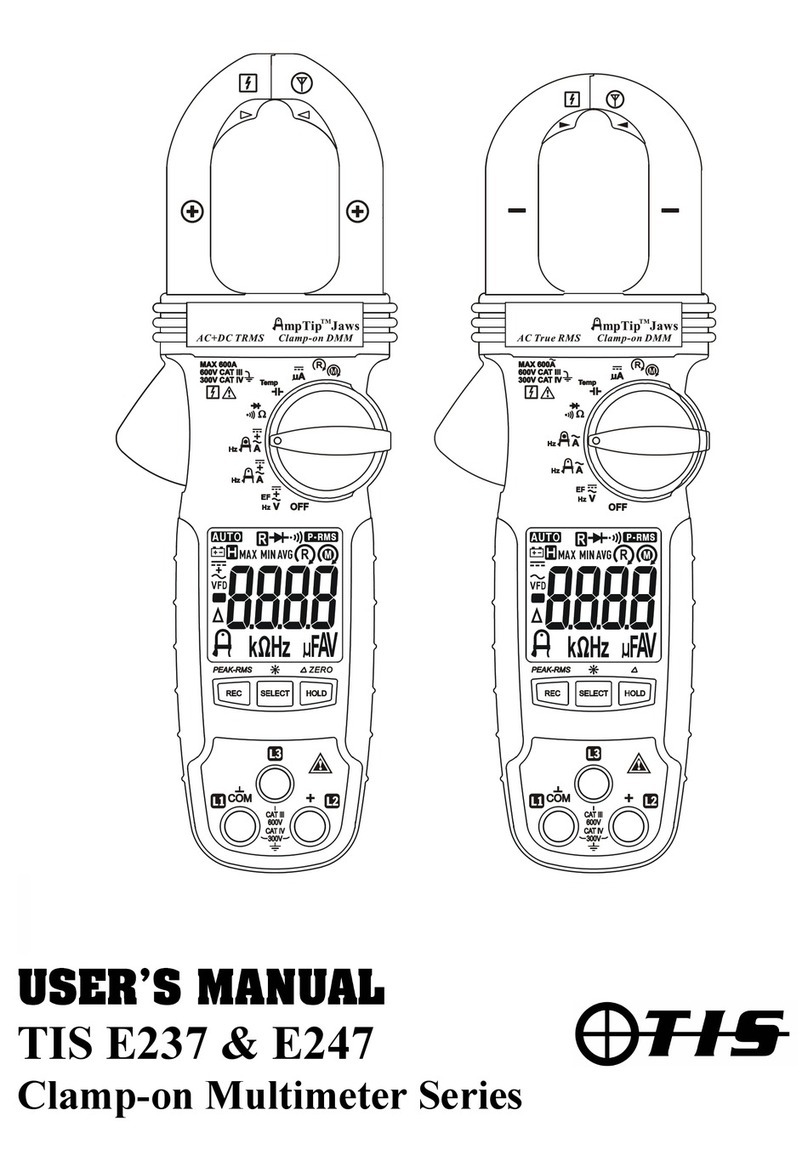

Instrument Description

1) LCD

2) F key

3) ▲ key

4) A key

5) POWER key

6) B key

7) ☀key

8) ▼ key

9) C key

10) Output socket

11) Input socket

12) Protective grounding resistance test terminal

13) 12VDC power connector

3.1 Introduction of functions of each part

1) LCD: Display the test content and data

2) F key: Function key. Complete the combined function in conjunction with other

keys

3) ▲ key: UP key. Turn pages when viewing the test results

4) A key: Start the CLASS I test

5) POWER key: Turn on/off the machine

6) B key: Start the CLASS II test

7) ☀Key: Turn the backlight on/off

8) ▼ key: DOWN key. Turn pages when viewing the test results

9) C key: Start the CORD test

10) Output socket: For the output of the test voltage during CLASS I, CLASS II and

CORD tests

11) Input socket: For the input of the test voltage during CORD and out-phase tests

12) Input Earth Bond Lead terminal (Aconductor for connecting external earth points

on CLASS I appliances).

13) 12VDC power connector: A power connector when an external 12VDC power is

applied

I. Operation of instrument

4.1 Turn on / off

Press POWER to turn the machine on/off;

The instrument will be automatically shut down if there is no operation within 5 minutes;

Note: When the instrument displays , this indicates a lack of power and it is

necessary to replace the battery.

4.2 Calibration

During the replacement of the test leads, including the IEC lead (used when testing

extension cables / C Type functionality) or Earth Bond leads these functions require

recalibration of the TIS 600 before use. (This calibration will compensate for the lead

resistance during testing)

①Calibrate the CLASS I test grounding resistance.

Insert the Earth bond lead into the output socket (12) with the probe supplied, insert the

probe into the earth terminal and the input socket (10). Press and hold the F (2) and A (4)

function key together until the calibration interface is enabled.

Press the A (4) key, this will then perform the lead calibration/ adjustment, Press the F (2)

to exit the calibration process.

②Calibrate the CORD/IEC test ground resistance.

Insert the CORD/IEC mains test cord into the output socket (10) and the other end into

input socket (11). Press the POWER key to turn on the instrument, and press and hold the

combination key F + A until entering the calibration interface. Press the C key to calibrate

the CORD test grounding resistance; after the calibration is completed. The resistance of

the current test cord (line) will be displayed. Press the F key to exit.

4.3 Voltage selection

In addition to selecting the output voltage (250V/500V) of the test insulation resistance in

the CLASS I/II test, the TIS 600 can select the working voltage (110V/230V) of the

equipment to be tested according to the working voltage of the equipment under test. The

setting of the working voltage (110V/230V) of the equipment to be tested will affect the

leakage current test results and the out-phase detection function.

①Setting of the output voltage of the insulation resistance test voltage.

Press the POWER key to turn on the instrument, press and hold the combination key F +

B until entering the voltage setting interface. Set the insulation resistance test voltage by

pressing ▲ or ▼ key. Switch to INSULATION, press the POWER key to select the voltage,

and switch 250V/500V through ▲ and ▼ keys. Press the POWER key to confirm and exit.

②Setting of the working voltage of the equipment to be tested.

Press the POWER key to turn on the instrument, and press and hold the combination key

F + B until entering the voltage setting interface. Set the insulation resistance test voltage

or the working voltage of the equipment to be tested by pressing ▲ or ▼ key. Switch to

LEAKAGE, press the POWER key to select the voltage, and switch 110V/230V through ▲

and ▼ keys. Press the POWER key to confirm and exit.

4.4 CLASS I test

Connect the equipment to be tested to the TIS 600 with the mains test cord supplied with

the appliance to the TIS 600 output socket and the other end to the power connector of the

equipment to be tested.

Connect the Earth bond lead to the TIS 600 (Terminal 12) then connect the other end to a

metal conductive part of the CLASS I appliance (connected to the protective conductor of

the equipment).

After correct connection, press the A key to start the CLASS I test. Ensure that the

equipment to be tested is powered on during the test. After the test is started, TIS 600 will

light the symbol at the right hand side of the LCD screen to indicate that the CLASS

I test is being performed currently. The test will be done automatically according to the

following steps:

①Grounding Test. Test the resistance between the conductive part of the equipment to

be tested and the protected area.

If the measured resistance is greater than 25Ω, the buzzer and the grounding icon flash to

indicate the grounding fault. After 5 seconds, exit and return to the main interface;

If the measured resistance is less than 25Ω, compare with the set resistance, display the

resistance and "√" or "×", and then conduct the next test.

②Insulation Resistance Test. If the power switch of the equipment to be tested is off, the

instrument may display LO LOAD to indicate that the equipment to be tested has an

insufficient load capacity. Press the A key or turn on the power switch of the equipment to

be tested to continue the insulation resistance test. Press any other key to exit and return

to the main interface.

After the test is completed, the insulation resistance is displayed. Compare it with the set

value and display the comparison result "√" or "×".

③Leakage current test.

After the test is completed, the leakage current value is displayed. Compare it with the set

value and display the comparison result "√" or "×".

④Make a final judgment based on the test results obtained in the three steps above,

display PASS or FAIL, and save the test results. Press any key to automatically exit and

return to the main interface after about 10 seconds.

4.5 CLASS II test

Connect the equipment to be tested to the TIS 600 with the mains test cord: connect one

end of the mains test cord to the TIS 600 outputsocket (10) and the other end to the power

interface of the equipment to be tested.

After correct connection, press the B key to start the CLASS II test. Ensure that the

equipment to be tested is powered on during the test.After the test is started, the TIS 600

will light the at the right hand side of the LCD screen to indicate that the CLASS II

test is being performed. If the insulation resistance test voltage used is 500V, the

marking will also be lit. The testwill be done automatically according to the following steps:

①Insulation Resistance Test. If the power switch of the equipment to be tested is off, the

instrument may display LO LOAD to indicate that the equipment to be tested has an

insufficient load capacity. Press the A key or turn on the power switch of the equipment to

be tested to continue the insulation resistance test. Press any other key to exit and return

to the main interface.

After the test is completed, the insulation resistance is displayed. Compare it with the set

value and display the comparison result "√" or "×".

②Leakage current test. After the test is completed, the leakage current value is displayed.

Compare it with the set value and display the comparison result "√" or "×".

③Make a final judgmentbased on the test results obtainedin the two steps above, display

PASS or FAIL, and save the test results. Press any key to automatically exit and return to

the main interface after about 10 seconds.

Note: The CLASS II insulation resistance test voltage is defaulted to 500VDC and can be

set to 250VDC. The specific operation is shown in 4.3.

4.6 CORD test

Connect the CORD cable to be tested to the TIS 600: Connect one end of the CORD cable

to the TIS 600 output socket (10) and the other end to the TIS 600 IEC input socket (11).

Afterthe correct connection,pressthe Ckeyto startthe CORDtest. Afterthetest isstarted,

TIS 600 will light the marking at the right side of the LCD screen to indicate

that the CORD test is being performed currently.

①Grounding Test. Detect the connectivity of the Earth terminal of the CORD cable.

If the connectivity is poor or it is not connected, the buzzer and the grounding icon flash to

indicate the grounding fault, provide an initial error prompt after the polarity analysis, and

exit and return to the main interface after 5 seconds;

If the connectivity is good, compare it with the set resistance, display the resistance and

"√" or "×", and conduct the next test.

②Insulation Resistance Test.

After the test is completed, the insulation resistance is displayed. Compare it with the set

value and display the comparison result "√" or "×".

③PolarityTest. Test whether there is an open circuit, short circuit and reverse connection,

display test results with PASS/OPEN/SHOR/CORS/FAIL to respectively indicate the

correct connection, open circuit, short circuit, reverse connection and occurrence of many

errors.

④Make a final judgment based on the test results obtained in the three steps above,

display GOOD or ERROR, and save the test results. Press any key to automatically exit

and return to the main interface after about 10 seconds.

4.7 Out-phase test

Connect the socket to be tested to the TIS 600 with the CORD main test cord: connect one

end of the IEC test cord to the TIS 600 input socket (11) and the other end to the socket to

be tested.

After correct connection, if the socket to be tested is powered on, the instrument will

automatically perform the out-phase test. Other operations will be invalid during this period

until the socket to be tested is powered off or the power cord is unplugged from the socket.

After entering the test interface, the TIS 600 will light the marking at the right

hand side of the LCD screen to indicate that the instrument is performing the out-phase

test.

Note: This test result is affected by the setting of the working voltage of the equipment

under test. The setting operation is shown in 4.3.

Test result: If it is normal, display LN "√", LE "√", NE "√";

If the Zero line is out of phase, display LN “×”, LE“√” and NE“×”;

If the ground line is out of phase, display LN “√”, LE“×” and NE“×”;

4.8 View the test results

When the instrument is in standby mode, press the ▲ key or the ▼ key to view the test

results, where a maximum of last 300 test results can be viewed. The TIS 600 only saves

the results of the CLASS I test, the CLASS II test and the CORD test, the results will only

be saved when the test is completed successfully.

For the test results, , and respectively indicate the test type

corresponding to the data displayed currently as CLASS I, CLASS II and CORD.

The test results viewed indicate data groups with 001 –300 to distinguish which data

belongs to which test result. The last test result is classified as 001; the greater the number,

the earlier the test time. Press the POWER key to view the determined final test result of

the current test result and display it in the group position.

Press the F key to exit the view page and return to the main interface.

II. Main technical parameters

Test Conditions:

Function

Range

Accuracy

Technical parameters

Earth Bond/

Earth

Resistance

test

0Ω~20Ω

±5%+3

Test current>200mA (R < 2Ω)

If 0.01~0.1Ω passed, display “√”

If 0.1~0.5Ω passed, display “√” and

flash

If 0.51~19.9 failed, display“×”

Test voltage 5VDC, test time 5S

Insulation

resistance test

Test voltage

500VDC

-

Test current> 1mA (R = 500KΩ)

Test time 5S

0.2MΩ~19.99MΩ

±5%+3

Test voltage

250VDC

-

Test current> 2mA (R = 1KΩ), test

time 5S

0.2MΩ~19.99MΩ

±5%+3

-

CLASS I

-

If ≥1MΩ passed, display “√”

CLASS II

-

If ≥2MΩ passed, display “√”

CORD

-

If ≥1MΩ passed, display “√”

Leakage

current test

0.10mA~10mA

±5%+3

Test voltage 50V rms, frequency

50Hz

Test time 5S

CLASS I

-

If 0.1~0.75mA passed, display “√”

If 0.75~3.5mApassed, display “√” and

flash

If 3.5~10.50mA failed, display “×”

CLASS II

-

If 0.1~0.25mA passed, display “√”

If 0.25~10.50mAfailed, display “×”

CORD test

Correct

connection

Display “√PASS”

L open circuit

“LN ×, LE ×, NE √, OPEN”

N open circuit

“LN ×, LE √, NE×, OPEN”

G open circuit

“LN √, LE ×, NE ×, OPEN”

L_N short circuit

“LN ×, LE √, NE √, SHOR”

L_G short circuit

“LN √, LE ×, NE √, SHOR”

N_G short circuit

“LN √, LE √, NE ×, SHOR”

L_N reverse

connection

“LN ×, LE √, NE √, CORS”

L_E reverse

connection

“LN √, LE ×, NE √, CORS”

N_E reverse

connection

“LN √, LE √, NE ×, CORS”

Multiple errors

“LN ×, LE ×, NE ×, FIAL”

Out-phase

detection

Correct

Display “LN √, LE√, NE√”

230VAC±15%

110VAC±15%

Zero cord off

Display “LN ×, LE√, NE×”

Ground cord off

Display “LN √, LE×, NE×”

Power: AA 1.5V*8 or 12VDC

Low voltage detection: ≤9.5V

6.1 CLASS I test

Grounding

performance test

Insulation

resistance test

Leakage current

test

Final test result

“√”

“√”

“√”

“PASS”

“√” flashes

“√”

“√”

“PASS” flashes

“×”

“√”

“√”

“FAIL”

“√”

“×”

“√”

“FAIL”

“√”

“√”

“√” flashes

“PASS” flashes

“√”

“√”

“×”

“FAIL”

“√” flashes

“√”

“√” flashes

“PASS” flashes

6.2 CLASS II test

Insulation resistance

test

Leakage current test

Final test result

“√”

“√”

“PASS”

“×”

“√”

“FAIL”

“√”

“×”

“FAIL”

6.3 CORD test

Grounding

performance test

Insulation

resistance test

CORD test

Final test result

“√”

“√”

“√”

“GOOD”

“×”

“√”

“√”

“ERROR”

“√”

“×”

“√”

“ERROR”

“√”

“√”

“×”

“ERROR”

Table of contents

Other TIS Test Equipment manuals

Popular Test Equipment manuals by other brands

Time Electronics

Time Electronics 1010 user manual

Vaisala

Vaisala HUMICAP HMP155 user guide

MSG Equipment

MSG Equipment MS015 user manual

Jamar

Jamar Traffic Counter Tester II user manual

Agilent Technologies

Agilent Technologies 11644A Series User's and service guide

Agilent Technologies

Agilent Technologies 8922 Supplementary User's Guide