8 Warranty and Service

Each Wöhler Rotary Viper Vent will be tested in all

functions and will leave our factory only after ex-

tensive quality control testing.

If used properly, the warranty period for the Wöh-

ler Rotary Viper Vent will be twelve month from

the date of sale.

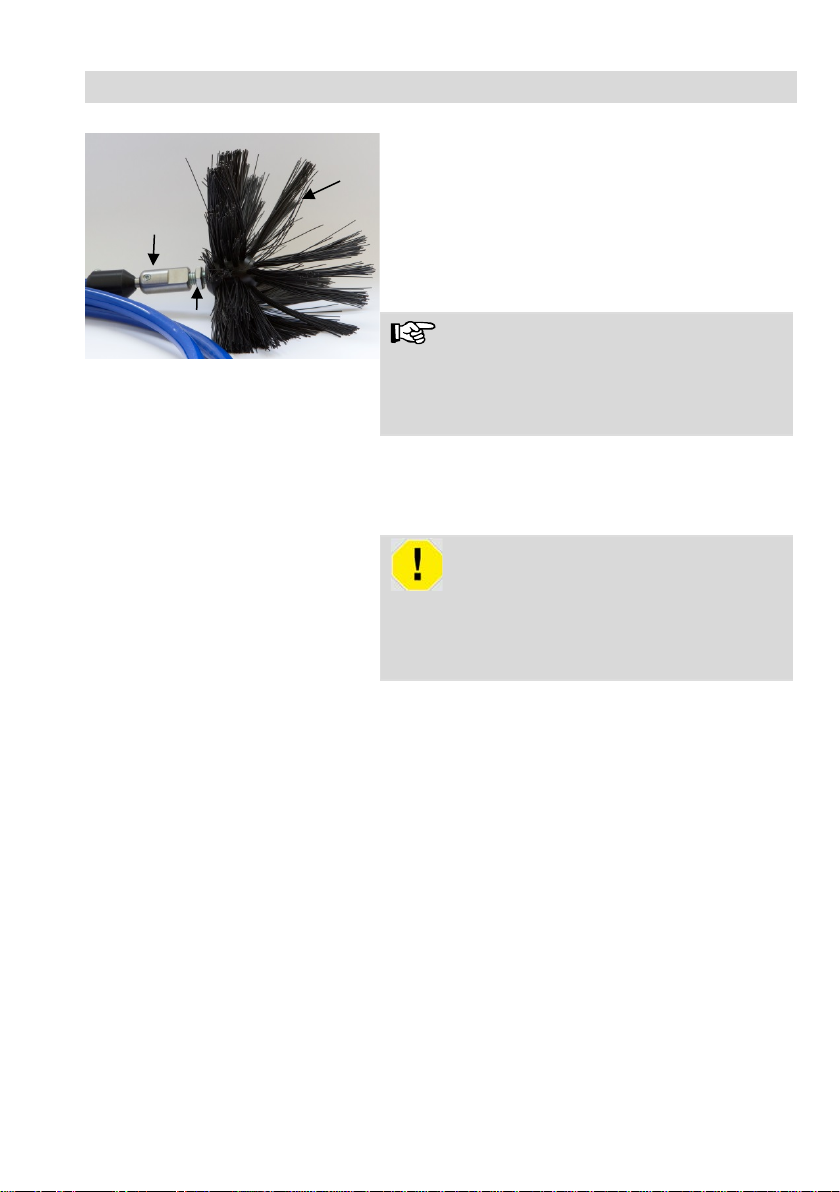

Not covered by the warranty are cleaning attach-

ments (brush head made of Perlon or threaded

brush), because they are consumables.

This warranty does not cover the freight and pack-

ing costs when the device is sent to the factory for

repair.

Service by non authorized personnel or making

modifications to the analyzer voids any warranty.

Wöhler has built our reputation on excellence in

customer service. Therefore, of course, we are

readily available to assist you after the warranty

period ends.

Send us the device and we will repair it and

return it to you with our package service.

Immediate help is provided by our technical

staff over the telephone.

9 Accessories

Brush Head, Perlon 12,5 cm Ø, M 10

Brush Head, Perlon 18 cm Ø, M 10

Brush Head, Perlon 25 cm Ø, M 10

Threaded Brush, Perlon, 30 cm Ø, M 10

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com