Tiso ASTM F2656 M50 User manual

Page. -1-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Original guideAUTOMATIC HIGH SECURITY ROAD BLOCKERASTM F2656, M50 series of RB332, RB333, RB334OPERATING MANUAL. PART ІPage. -1-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global

Page. -2-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Warning -This symbol tells you that the sections concern safety issuesАttribution - This symbol tells you to read the section with particular careСaution - This symbol indicates that the sections warn of problems with the release of high pressure oilСaution -This symbol tells you that the sections concern pressure hazardСaution - Moving parts and crush hazard - mind your handsDefinition - This symbol tells you to describe abbreviations for conventionsIMPORTANT INSTALLATION, SAFETY INSTRUCTIONSџCAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLYџTHIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERSџTO ENSURE THE SAFETY OF PEOPLE, IT IS IMPORTANT THAT YOU READ ALL THE FOLLOWING INSTRUCTIONS.џINSTALLATION, CONNECTION AND COMMISSIONING WORKS SHALL BE PERFORMED BY SPECIALISTS OF THE APPROPRIATE QUALIFICATION.џPERSONNEL INVOLVED IN MAINTENANCE OF EXISTING ELECTRICAL INSTALLATIONS OR COMMISSIONING, ELECTRICAL INSTALLATION, REPAIR WORK, MAINTENANCE AND INSTALLATION SHALL BE TRAINED TO WORK WITH THIS MODEL OF THE DEVICE! TRAINING SHALL BE CARRIED OUT AT THE MANUFACTURER'S REPRESENTATIVES' OR AT THE MANUFACTURERS' OF THE PRODUCT.Due to regular improvement of the product its design can be modified without degradation of the product features and quality not covered by this Operation Manual.

Page. -3-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Contents:1. General Guidelines............................................................................................................... 52. Product Description .............................................................................................................. 83. Purpose ............................................................................................................................... 94.Technical Features ...............................................................................................................105.Product Specification ........................................................................................................... 136. Road Blocker Installation ................................................................................................... 147. Connection of Road Blocker Utilities................................................................................... 238. Precommissioning .............................................................................................................. 299. Operation Regulations ........................................................................................................ 3210. Hydraulic System............................................................................................................... 3811. Notes ................................................................................................................................ 43The Manual is provided for joint use with the Operation Manual. Part II. Wiring of Road Blockers (RB series) џThis manual is an integral part of the product and shall be handed over to the customer. The manual shall be kept for future use and to be consulted, if appropriate.џIf the road blocker is resold, handed over to another owner or transported to another place, make sure that this manual is enclosed to the product to be used by new owner and/or maintenance staff during installation and/or operation The following abbreviation are used in this Manual: џM - Maintenance;џHU - Hydraulic Unit;џHC - Hydraulic Cylinder;џR.s.l - Road surface level (reference point + 0.000).

Page. -4-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global DECLARATION OF CONFORMITY OF EQUIPMENT There is confirmed the compliance with the basic safety requirements of following EU Directives:- 2006/42/ EC;- 2014/30/EC;- 2014/35/EC;

Page. -5-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Rising blockerџTiSO" ensures its best effort for guarantee and correctness of this Manual and reflecting material changes in the design. However, a policy of continuous improvement can lead to insignificant differences between the equipment supplied and the description in this document.џThe Manual to be kept for future use. џDo not allow children and unauthorized persons to stay near operating equipment. The manufacturer shall bear no responsibility for violation of safety rules.џAny actions that are not explicitly listed in these instructions shall be prohibited.џSafety devices shall protect potentially hazardous areas.1.The traffic area regulated by the shall contain road blocker appropriate warning signs effective for the territory of the country (see clause 6.5)! For safe operation of the the other warning sign road blocker,shall be installed at a distance of at least 50 m according to the current traffic regulations! In the event of violation of the operating rules and the requirements of the operational documentation, the road blocker may present a dan-ger to human life and health by virtue of high voltage and moving parts of the product! Transportation of the product shall be ensured in the lowered state only!Personnel involved in maintenance of existing electrical installations or commissioning, electrical installation, repair work, maintenance and installation shall be trained to work with this model of the device! Training shall be carried out at the manufacturer's representatives' or at the manufacturers' of the product. The Manual should be scrutinized prior to the equipment installationand operation to ensure the human safety. Safety is not ensured incase of improper operation or use.General safety provisions.Warning sign (conditionally)

Page. -6-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 1.1 Instructions to the installer:1. For your safety, follow the installation instructions;2. The product shall be installed in accordance with applicable regulations and rules, in compli-ance with safety precautions during installation work;3. Installation of the equipment shall be carried out with the power supply disconnected;4. Packaging materials shall be disposed of in accordance with applicable standards;5. Strictly observe the sequence of operations for assembling the blocker specified in the instruction;џIt is forbidden to make changes to the arrangement of equipment and use of materials and components that are not included in the contents of delivery and are not provided for in this manual.џDo not install this equipment during a lightning storm, heavy rain or snow, in an explosive atmosphere and in poor visibility. Mounting zone is equipped according to the current standards.џInstallation, connection and commissioning works shall be performed by specialists of the appropriate qualification.6. If faults or defects are detected, contact the supplier's service desk.7. The installer shall provide the user with the necessary information on the operation of the system in manual mode in the event of an emergency.8. The manufacturer is not responsible for the operation of the equipment in the following cases:џ non-compliance with the installation technology,џuse of non-standard materials and components,џperformance of work by unqualified personnel9. The manufacturer is not responsible for the safety measures when installing the equipment by personnel not involved in the company's service desk.

Page. -7-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Make sure of availability of the plate with manufacturer's details:1.2 Instructions to user:1. The operation regulations, prescribed by this Manual, shall be strictly observed.2. No modifications of the equipment components shall be made.3. The equipment shall be used for intended purposes, specified by the manufacturer.4. Don't try to repair or adjust the road blocker on your own. The relevant service department shall be referred to. Breaking of seals shall cancel the manufacturer's warranty liabilities.5. The road blocker control units (panels) shall be beyond the reach of outsiders.6. The company "TiSO" shall not be liable for improper operation of equipment and violation of safety measures by the user.џ The Road Blocker must be installed, precommissioned and serviced by the certified professionals having the relevant qualification and being familiar with the product design and instruction manuals:- Installation and operation manual (Part І, Part ІІ);- Datasheet;- Instruction manuals for components.џTechnical inspections, maintenance, adjustment and repair shall be per-formed only when the road blocker is deenergized.џThe device, designed and manufactured in accordance with directives of the European Union, shall be marked according to CE standards.

Page. -8-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

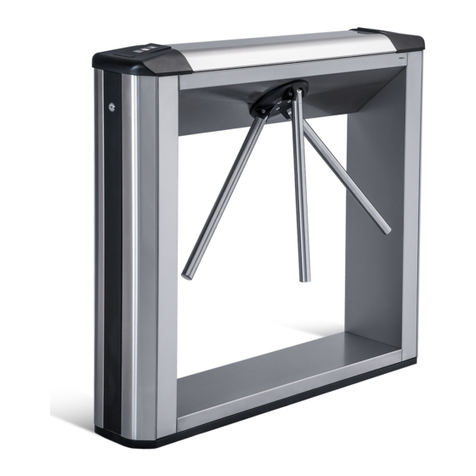

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 2.1 The automatic hydraulically-operated antiramming road blocker is a fixed platform withbuilt-in anticrossing element (raising platform). In down position it is located on theroadbed level and does not obstruct the vehicle traffic. In up position the road blockerprevents the unauthorized vehicle access.2.2 Coating - warning paint (black and yellow);2.3 Actuator - hydraulic with external hydraulic (oil) unit;2.4 The road blocker can be controlled:• from wire or wireless remote control panel;• automatically via access control system;• manually (manual sinking in case of power failure).Independent control of two road blockers from one control unit and parallel (simultaneous) group control of more than two road blockers are possible.2.5 The road blocker is equipped with visual alarm;2.6 Additional options:• road blocker heating (for low winter temperature climatic regions);• induction loops;• audible alarm siren;• auxiliary remote control devices.2. DescriptionDownUp

Page. -9-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 3. Product Purpose3.1 The antiramming retractable road blockers are used at governmental, commercial and private facilities for unauthorized vehicle access control, vehicular traffic management and regulation at sites and adjacent areas as well as parking lots and spaces. мест.3.2 The road blockers are recommended for passenger transport facilities, approaches to sports facilities and government facilities, to be installed in front of shops, hotels, shopping malls and office centers, health care facilities, at the approaches to cottages and cottage settlements, at central urban and historical sites, industrial and special facilities.объектах.OFFICEBUILDINGS PLANTSSPORTS ANDLEISURE CENTERSHAULAGECOMPANIESPPPPARKING LOTS

Page. -10-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Technical Features4. 4.1 Technical Features of the road blocker К12 of RB332, RB333, RB334 seriesTable 1. Automatic antiramming road blocker technical features

Technical Features*:

Road Blocker model

RB 332

RB 333

RB 334

Installation type Submersible Actuator type Hydraulic Actuator layout External Blocking width 2000 mm 3000 mm 4000 mm Anticrossing platform lift height 1200 mm Dimensions (LxWxH) 2295x2168x600 mm 2295x3168x600 mm 2295x4168x600 mm Weight 2250 kg 3190 kg 4200 kg Power consumption 5,5 kW 5,5 kW 7,5 kW Raising time ( ±1 s) 3,5 s (1,5 s with EFO) Sinking time ( ±1 s) 3,5 s Installation depth 600 mm Maximum axle weight limit 15 t (by default), 30 t / 50 t (optional)** Penetration resistance 1843,5 kJ Power supply 50/60 Hz; 3Ph- 400 V Road Blocker index of protection IP 67 Control box index of protection IP54 (by default), IP65 (optional) Temperature range - 10° С / + 40° С Temperature range*** (optional) - 40° С / + 65° С Material Structural steel Ñ22 Coating Zink + RAL 9005 Black / RAL 1003 Yellow Use intensity high Maximum length of high pressure hydraulic hoses up to 25 meters Electronic control unit and integration with third-party systems through PLC (PCB) controller Options: Light indication built-in LEDs + (RYG) Road Blocker manual sinking Manual release mechanical device + Additional options: Audible alarm + Cooling system (for hydraulic unit) + Forced drainage + Induction loop controllers + Wireless remote control radio controller + Remote control panel + Road Blocker heating + * Technical features can be changed without prior notice **Drawings of foundation for 30 and 50 tons axle load to be provided upon request ***For temperatures below -10 °C heating system to be used

h = 1200 mm

s (km/h)M (kg)

500 mm

R.s.l. ±0.000

Page. -11-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 4.2 Dimensions of the Road Blocker К12 of RB332, RB333, RB334 series W

HhL

Dimensions Model Product length (L) , mm Product width (W), mm Product height (H), mm Blocking height (h) , mm Road blocking width (V), mm RB 332 2295 2168 600 1200 2000 RB 333 3168 3000 RB 334 4168 4000

Table 2 - Road Blocker dimensionsWV

L (2295)

H (600)h (1200 mm)

1914

Page. -12-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 4.3 Road Blocker К12 of RB332, RB333, RB334 series and reinforcement cage assembly dimensions

Model Road Blocker dimensions (L x W x H) Road Blocker and reinforcement cage assembly* (l х w х h) RB 332 2295 x2168 х 600 6150 х 3100 х 600 RB 333 2295 x 3168 х 600 6150 х 4100 х 600 RB 334 2295 х 4168 x 600 6150 х 5100 х 600

Reinforcement cage and Road Blocker assembly dimensions:Reinforcement cage dimensions:Table 3 - Road Blocker and reinforcement cage assembly dimensions

w (3100/4100/5100)527

l (6150)

W (2168 / 3168 / 4168)w (3100/4100/5100)

L (2295)1928l(6150)

Vehicle traffic directionVehicle traffic direction*Drawing is for standard 15 tons axle load; Drawings of Road Blocker and reinforcement cage assembly for 30 and 50 tons axle load to be provided upon request.

Page. -13-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 5.1 Road Blocker major components and scope of delivery: (on the example of the Road Blocker RB333)5.Product SpecificationLegend: 1. Static part (SP) - Road Blocker assembly;2. Dynamic part (DP) - Anticrossing platform;3. Utility insertion point;4. Front installation plate;5. Control box;• Hydraulic unit (HU);• Electronic control unit(ECU);6. Remote control panel;7. Mains cable; 32145HUECU5.2 General appearance of the Road Blocker and reinforcement cage assembly:21Legend:1. Road Blocker assembly;2. Reinforcement cage (optional);400 V- 3 phase(230 V- 1 phase)*50/60 Hz 7631

Page. -14-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 6.1 Arrangement of installation site:џArrangement of installation site must comply with requirements of the applicable regula-tions and standards.џInstallation area shall be fenced along perimeter with temporary security fencing orcaution tape at the distance of 3 meters from the installation site.џThe appropriate warning signs ISO 7010:2011 shall be installed in front of the installation site.џMake sure that there are no underground utilities at the installation site!џKeep outsiders away from the installation site!џSafety regulations must be observed during installation!6.2 Installation sequence:џPreparation of installation pit;џArrangement of conrete base (foundation);џAssembling of reinforcement cage*;џInstallation of utility conduits**;џInstallation of the Road Blocker assembly in the design position;џInstallation of hydraulic unit in the design position;џConnection of utilities.* - Reinforcement cage may be delivered as additional option along with the product or to be manufactured bythe work performer according to the company drawings** - Light and sound indication, road blocker heating, forced drainage may be provided as additional options6.3 Installation procedure:6.3.1 Layout of pit:6.Road Blocker installation

Road Blocker model

Pit dimensions А, mm B, mm C, mm

RB 332

6500 3350 800***

RB 333

6500 4350

RB 334

6500 5350 Table 4. Pit dimensions

mm ,A

Vehicle traffic direction

С,mm

***Size is for standard 15 tons axle load. Drawings of foundation for 30 and 50 tons axle load to be provided upon request.

Page. -15-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 6.3.2 Preparation of installation pit:1. The required marking according to the design solutions to be made;2. The roadbed to be removed, if appropriate;3. A pit with А х B dimensions and 800 mm depth to be dug according to the installation pit layout of the Road Blocker relevant model (See Table 4);4. 50 mm sand cushion to be made;5. Geotextile to be put on the pit bottom;6. Water discharge to be installed** (The recommended water discharge diagram is shown in p. 6.5);7. 360 mm depth trench to be dug for utility conduit installation.8. The pit to be filled with 10-20 mm grain size gravel to 100 mm height;9. 50 mm concrete layer to be poured (Concrete С25/30).џ Make sure that soil absorbs water. For this purpose about 40 liters of water to be poured into the pit and its complete absorbtion into soil in less than 30 minutes to be checked! џIn case of insufficient soil permeability or abundant groundwater it is advised to use pumps of forced water discharge into the existing sewage system or earth (The recommended water discharge diagram is shown in p. 6.5)* The pit size to be determined by the installer in case of loose soils. Size is for standard 15 tons axle load. Drawings of foundation for 30 and 50 tons axle load to be provided upon request.** Water dischage system into the existing drainage system or soil. to be provided, if applicable. The use of the forced water discharge systems (pumps) is allowed.*** The road blocker utility conduit outlet side to be determined by the installer.

+

0.000

R.s.l.

800*С (pit depth)

DrainageUtility conduit***B (pit width)АView А W (2168 / 3168 / 4168)The recommended pit layout for the road blocker with reinforcement cage:

Reinforced concrete(С25/30 ENV206), 600 mm layer; Road BlockerSoil;

Geotextile(EN 13256-2009);

10-20 mm grain size gravel(BS EN 13043), 100 mm layerConcrete (С25/30 ENV206), 50 mm layer;

10050600800*50

Sand cushion, 50 mm layer

336296

For hydraulic hose outletFor cable outletForced draining pipe

Page. -16-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global џReinforcing and concreting to be performed according to the applicable standards;џSoil to be compacted based on soil mechanical parameters according to the applicable design regulatory documents;џIt is advised to use the relevant concrete vibro-shrinking means;џIt is advised to use waterproof additives to obtain water-resistant concrete;џIt is advised to use a formwork for concrete pouring; 6.3.3 Road Blocker installation in the design position:џThe Road Blocker to be installed by means of handling equipment;џSafety regulations to be observed according to the applicable standards during handling operations!џSlinging must be performed by the properly qualified slingers having the appropriate permit to work;џPresence of unauthorized persons at the installation site during handling operations is PROHIBITED!а) Sequence of operations in case of the Road Blocker installation in the designposition and joining with reinforcement cage in the pit:1. The product to be unpacked;2. Outside condition and configuration to be checked;3. The road blocker to be slinged by hooking for assembly bracket (4 pcs) and to be installed in the design position by means of handling equipment;View А

<1 t

WL<1 t

А

Assembly bracketLoad size: The road blocker horizontal position and compliance with the design reference marks shall be checked by builder's level.± 0.000 is accepted as conventional level of the road surface of the site. Vehicle traffic direction

Page. -17-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 4. The prepared front and rear parts of the reinforcement cage to be joined and then the reinforcement cage side parts - 2 pcs. to be joined. Every rib to be welded;5. Formwork to be installed;6. Utility conduits and water discharge pipes to be installed;7. The pit with the Road Blocker and reinforcement cage assembly to be filled with 600 mm* concrete layer up to theroadbed level (C25/30 strengthgrade of concrete according toENV-206); Vehicle traffic direction Vehicle traffic direction FormworkEvery rib to be welded; Vehicle traffic direction Utility conduitsConcrete С25/30џRebar welding to be performed according to EN 10138;џThe reinforcement cage drawing is shown in Annex to this Manual;џThe entire structure of reinforcement cage and the road blocker to be securely fixed with each other (to be welded);*Size is for standard 15 tons axle load. Drawings of foundation for 30 and 50 tons axle load to be provided upon request.

Page. -18-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global b) Sequence of operations whenthe Road Blocker and reinforcementcage assembly is installed into the pit:1. The product to be unpacked;2. Outside condition and configuration tobe checked;3. The front and rear reinforcement cageto be joined with the road blocker, thenthe side one (2 pcs) and every rib to bewelded.4. The road blocker to be slinged by hookingfor assembly bracket (4 pcs) and to bedropped along with reinforcement cage inthe prepaired pit by means of handlingequipment;џThe Road Blocker to be installed by means of handling equipment;џSafety regulations to be observed according to the applicable standards during handling operations!џSlinging must be performed by the properly qualified slingers having the appropriate permit to work;џThe presence of unauthorized persons at the installation site during handling operations is PROHIBITED!The reinforcementcage to bewelded to the road blocker along the entire perimeterџReinforcing to be performed according to the applicable standards;џRebar welding to be performed according to EN 10138;џThe reinforcement cage drawing is shown in Annex to this Manual;џThe entire structure of reinforcement cage and the road blocker to be securely fixed with each other (to be welded);

А

Vehicle traffic direction Vehicle traffic directionView АAssembly bracket

Page. -19-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 6. Utility conduits and water discharge pipes to be installed;7. The pit with the Road Blocker and reinforcement cage assembly to be filled with 600 mm* concrete layer up to the roadbed level (С25/30 strength grade of concrete according to ENV-206);џConcreting to be performed according to the applicable standards;џIt is advised to use waterproof additives to obtain water-resistant concrete;џAfter concrete is dry the road surface around the road blocker to be restored and the installation area (site) to be arranged;џComplete drying of concrete foundation takes at least 28 days.Vehicle traffic directionConcrete С25/30Utility conduits***Drawing is for standard 15 tons axle load. Drawings of foundation for 30 and 50 tons axle load to be provided upon request.**The design position of the utility conduit outlet is possible on different sides.8. Control cabinet with hydraulic unit to be installed in the design position:1) Control cabinet to be opened;2) Inner protective plates (4 pcs.) tobe removed;3) Protective plates (4 pcs.) tobe inserted on outside of controlcabinet and make sure offixation security;Fixation plates to be removed fromcontrol cabinet and protective plates tobe installed on inside of control cabinetafter handling operations;132АProtective plate(removable)Fixation plateInstalled fixation plateControl cabinetView А

Page. -20-

Size А4

Installation and Operation Manual

Revision 3.1.2 11.2023

HIGH SECURITY ROAD BLOCKER

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global 9. To be connected to the Road Blocker (See details in Section 7):џelectric cables to be connected to the Road Blocker inspection box;џhydraulic unit hydraulic hoses to be connected to the Road Blocker;Loctite 542 is advised for fixation of sealing of metal screwed pipe joints!џMake sure of the road blocker installation accuracy and attachment security prior to its connection;џTake a close look at the hydraulic system and power supply connection diagrams.Loctite 542 Front installation plate;30,7 internal33,7 external50,7 external47,8 internal

336296238

This manual suits for next models

3

Table of contents

Other Tiso Turnstile manuals