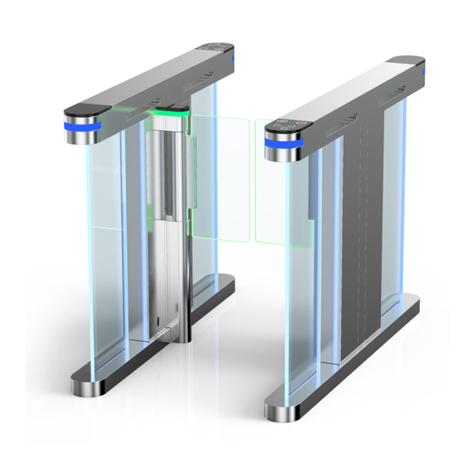

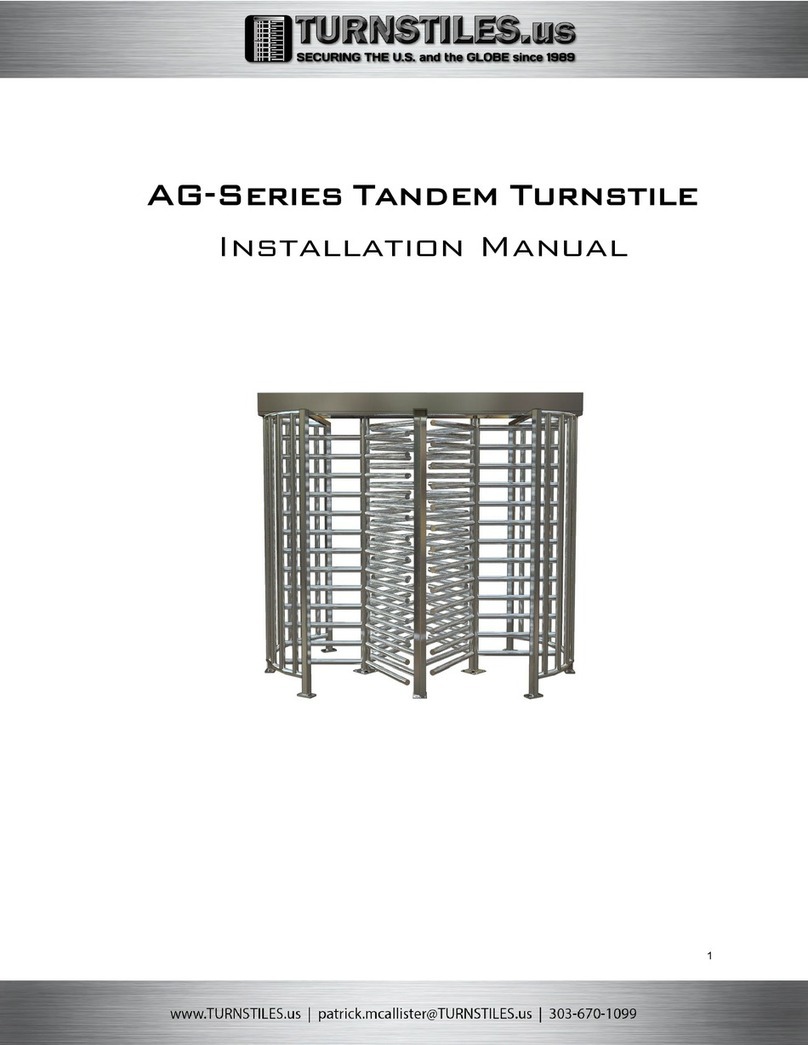

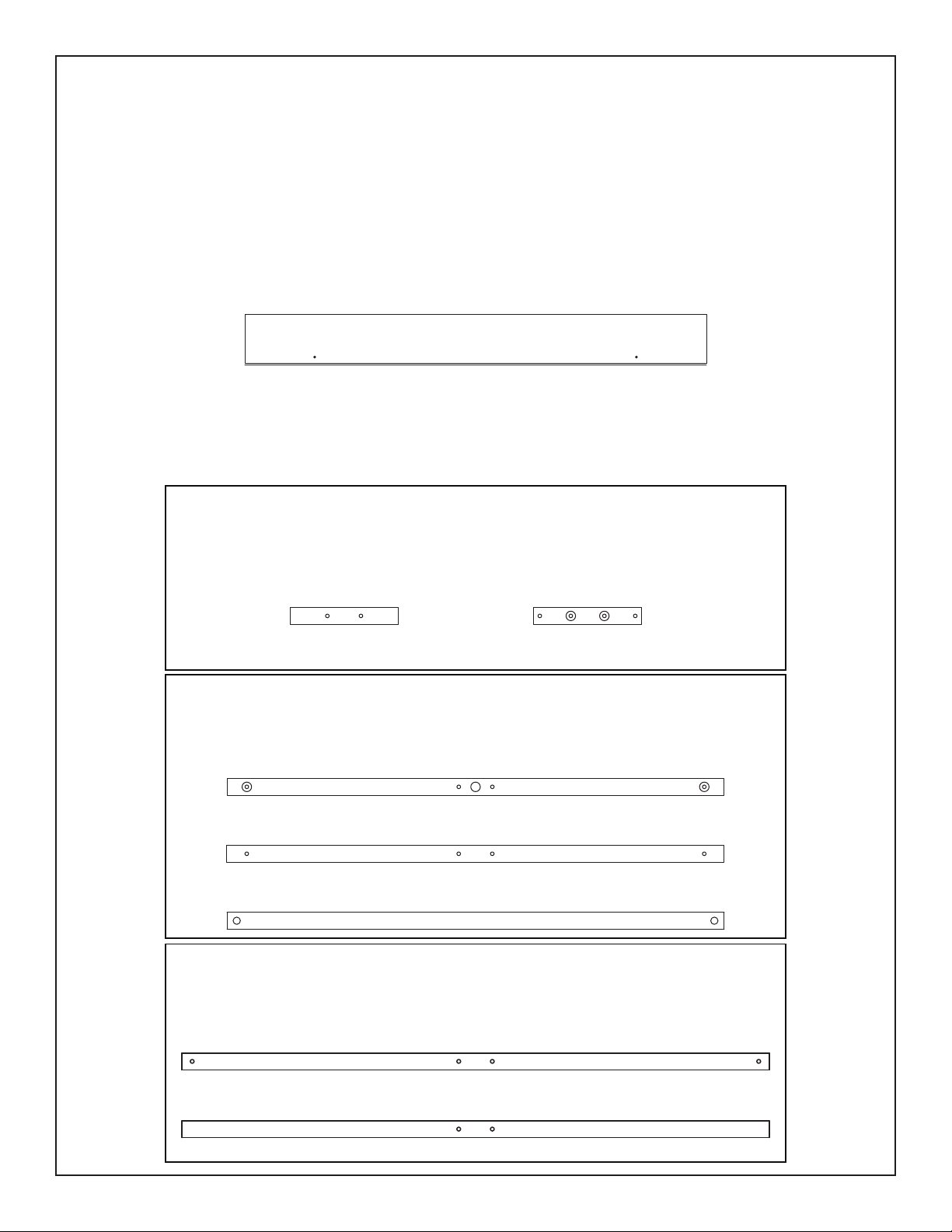

The High-Security Series HS427-S |HS430-S |HS439-S |HS448-S

Full-Height Turnstile (Single) |Interior & Exterior Application

Available Finishes:

• Hot dipped galvanized carbon steel

• Carbon steel with powder coating

(standard color is black/ other colors available upon request)

• Our signature 304 stainless steel, No. 4 satin

nish, or 316 stainless

Operation Features

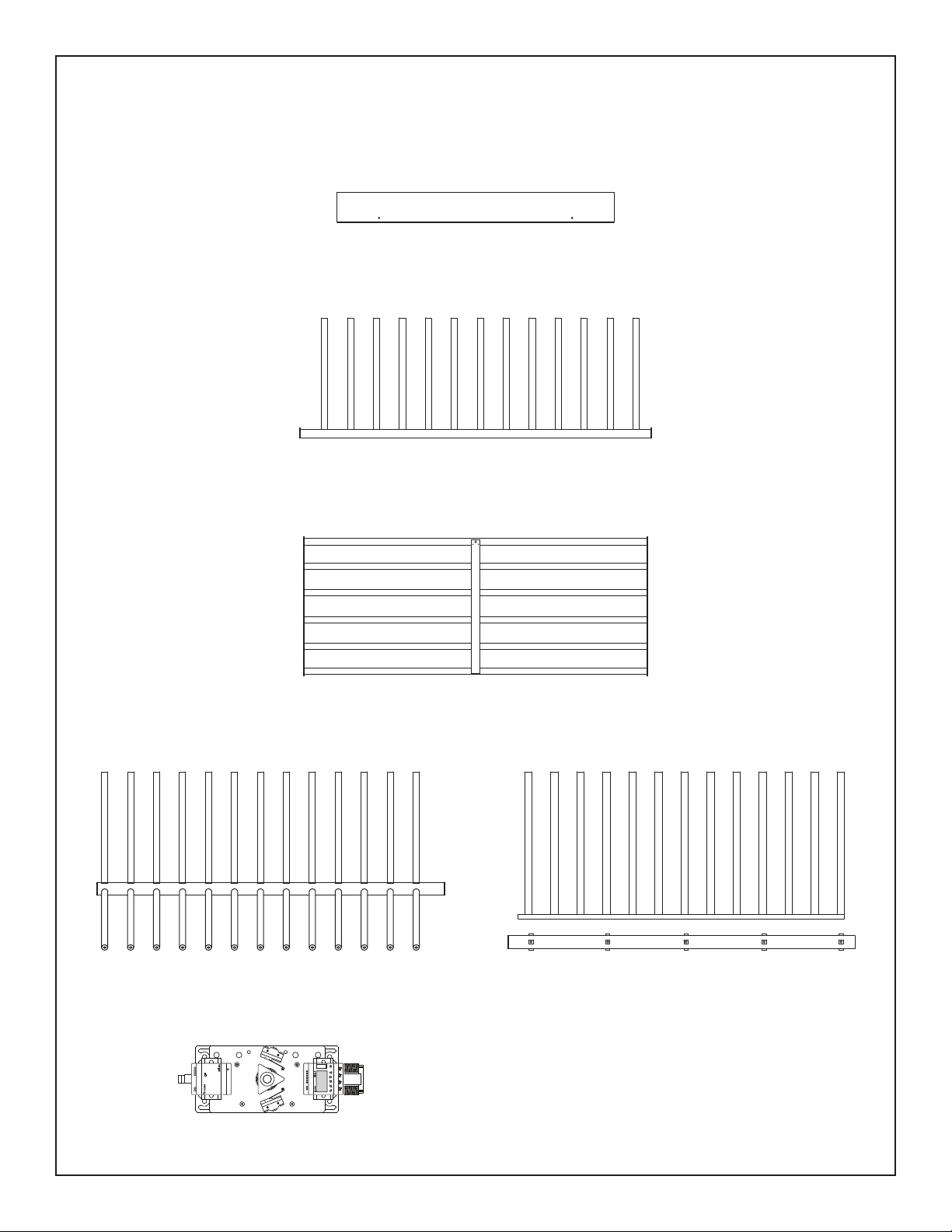

6500 Series Control Head:

• Auto-indexing (self-centering) with adjustable

hydraulic shock suppression

• Hardened tool steel locking bars, cam and

roller assemblies

• Permanently lubricated bearings

• Your choice of manual or electronic control on

both directions

• Nearly universal integration to any number of

access control systems

• Your choice on each electronic direction of

locking or unlocking on power failure

Options:

• Card reader mounting plates

• Daylight visible indicator lights

• Bi-directional key overrides

• Lockout bar (padlock not included)

• Decorative arm caps

• Stainless steel overhead full canopy

• Half canopy (covers passageway)

• 8 digit key resettable LCD counter with seven

year lithium battery

• Cold weather package, including thermostat

controlled heater and insulated mainframe

• Push button and wireless remotes

• Heel guard arm covers

• Additional options available upon request

Warranty:

Units are warranted against defects in materials

and workmanship for a period of one year from

date of delivery. See warranty information for

specic details.

Matching Swing Gate available:

(see model HS336 and model HS348 Manual

Passage Gate information)

* Dimensions are approximate based on chart on reverse side

Electrical Specications:

Input Voltage: 100-240 VAC

Input Current: 1.3 - .55 A

Frequency: 50/60 Hz

Storage Temperature: -40 to 158°F

Operating Temperature: -4 to 131°F

(Cold weather package available)

Operating Voltage: 24VDC

Operating Current: 1.2 A (typical)

Standards and Codes:

Austenitic stainless steel:

ASTM A240, A249, A276

Hot rolled steel:

AISI C-1020, AISI C-1018

Hot dipped galvanizing:

ASTM A-143, ASTM A-153-80

All fasteners provided meet IFI ANSI/

ASME Fastener Standards

American Welding Society (AWS)

Standard D 1.1

4008027

The 6500 Series Control Head

is certified to conform to the

following standards:

UL 294, UL 325, UL Subject 2593,

CAN/ULC S319 & CSA C22.2#247

Advantage International Registrar to

be an ISO 9001:2015 company

* Dimensions are subject to change without notice

Applications:

Ideal for controlling orderly ow of foot trafc in

both indoor and outdoor settings

Design & Construction:

• Designed for secure operation with

aesthetics in mind

• Featuring fully welded exterior components

• Minimal exposed stainless steel hardware

• Heavy gauge materials meeting

ASTM standards

Dimensions:

HS427-S

•Pedestrian Clearance: 27” (685.8mm)

•Width: 62” (1574.8mm)

•Depth: 57.375” (1457.3mm)

HS430-S

•Pedestrian Clearance: 30” (762mm)

•Width: 66” (1676.4mm)

•Depth: 59.250” (1505mm)

Arm & Barrier Tubing Sizes

(HS427-S & HS430-S):

• Standard: 1 1/2” (38.1mm) diameter 14 gauge

• Optional: 1 3/4” (44.4mm) diameter 14 gauge

(16 gauge – Stainless Steel models)

HS439-S

•Pedestrian Clearance: 38.5” (978mm)

•Width: 84” (2133.6mm)

•Depth: 76” (1930.4mm)

HS448-S

•Pedestrian Clearance: 49.319” (1252.7mm)

•Width: 106” (2692.4mm)

•Depth: 96.187” (2443.1mm)

Arm & Barrier Tubing Sizes

(HS439-S & HS448-S):

• Standard: 1 3/4” (44.4mm) diameter 14 gauge

All Models:

•Overall Exterior Height: 91” (2311.4mm)

•Passage Height: 84” (2133.6mm)

•Removal of Cover: Minimum of 4” needed

www.TURNSTILES.us

Patrick.McAllister@TURNSTILES.us

303-670-1099

HS400 Series Single Full Height Turnstile Service & Installation Manual