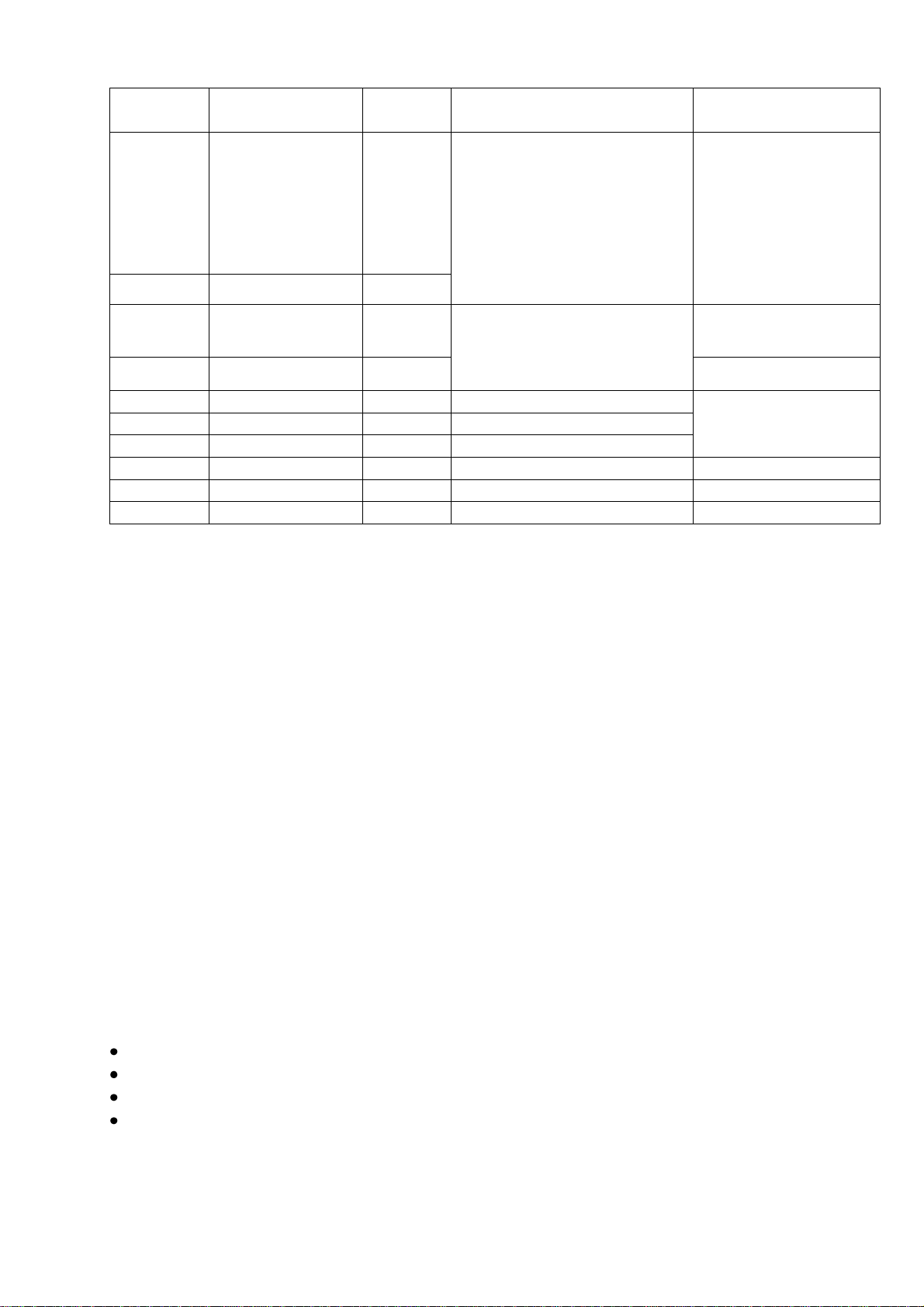

13 АUIА.427.00.00.00-02 OM

Delay of «WAITING FOR START OF ACCESS»is initiated.

Controller energizes solenoid and thus unlocks rotor in the relevant direction.

LED display corresponding to authorized access is switched from red to green.

If during delay of «WAITING FOR START OF ACCESS»rotor rotation has started, then further

behaviour of controller depends on the angle of rotor rotation:

6º of rotor rotation –LED display is switched from red to green indicating

occupation of access. The output signal «START OF ACCESS А/В» («OUT1»or

«OUT2») assumes active status. Delay of «WAITING FOR START OF ACCESS»is

cancelled.

10º of rotor rotation –status of the relevant input «AIRLOCK A/B»is verified. If

command is active, controller goes to the mode «SINGLE ACCESS IN ONE DIRECTION

WITH AIRLOCK FUNCTION». If by this moment the command «AIRLOCK»of the

relevant direction has not come, then controller further operates in the mode «SINGLE

ACCESS IN ONE DIRECTION WITHOUT AIRLOCK».

58º of rotor rotation –the signal «START OF ACCESS A/B»(«OUT1»or «OUT2»)

is cancelled and the signal «AIRLOCK POINT A/B»(«OUT5») appears.

60º of rotor rotation –when this point is entered rotor can’t be returned to the point

0º (in opposite direction) without the command «RETURN»(«INP1») being given or

actuation of the «FREE ACCESS»mode via RS-485 in opposite direction.

64º of rotor rotation –the signal «DETECTION OF ACCESS А/В» («OUT3»or

«OUT4») is generated.

70º of rotor rotation –the relevant solenoid is deenergized preparing rotor for locking

in the point 120º (0º for next access).

120º of rotor rotation –the signals «AIRLOCK POINT A/B»(«OUT5») and the

relevant signal «DETECTION OF ACCESS А/В» («OUT3»or «OUT4») are cancelled and

after that availability of the command «OPEN A/B»(«OUT3»or «OUT4») corresponding

to the current direction of access is verified and if command by that moment is active then

controller goes to the «FREE ACCESS»mode.

1.8.3.3 «SINGLE ACCESS IN ONE DIRECTION WITH AIRLOCK FUNCTION»

In this mode controller unlocks rotor via solenoid in one direction with possibility of its rotation to

60º. After that rotor can be unlocked in any direction that enables to arrange the second level of

identification and authorize completion of access or exit in opposite direction according to

identification results.

Controller goes to the mode «SINGLE ACCESS WITH AIRLOCK FUNCTION», if in «INITIAL

STATE»the command «AIRLOCK A/B»(«INP2»or «INP3») is active. In this case controller,

received the relevant command «OPEN A/B», goes to the mode «SINGLE ACCESS IN ONE

DIRECTION WITH AIRLOCK FUNCTION».

Controller also goes to the mode «SINGLE ACCESS WITH AIRLOCK FUNCTION», if the

turnstile has started to operate in one of directions in the «SINGLE ACCESS»mode, and when

rotor reaches 10º angle the command «AIRLOCK»is activated in the direction of current access

and later on access will be with airlock function.

Difference of controller operation in this mode from the mode «SINGLE ACCESS IN ONE

DIRECTION WITHOUT AIRLOCK»is as follows:

When rotor reaches the position 10º controller deenergizes the solenoid of current access and

the solenoid of opposite direction, if in opposite direction «FREE ACCESS»is turned on.

Rotor gets to 60º with two deenergized solenoids that results in its locking.

After that rotor can be unlocked again in straight direction (the direction of continued access)

by cancellation of the relevant command «AIRLOCK»(«INP2»/ «INP3») or by giving via

RS-485 the command «FREE ACCESS»in the current direction. The difference is that having

received via RS-485 the command «FREE ACCESS»rotor will not be locked in the current

direction in the point 120º.