tissin TS800 Series User manual

Smart Valve Positioner

TS800 Series

Instruction Manual

Ver. PM-TS800EN-12/2020

2

Smart valve positioner

TS800 Series

tissin

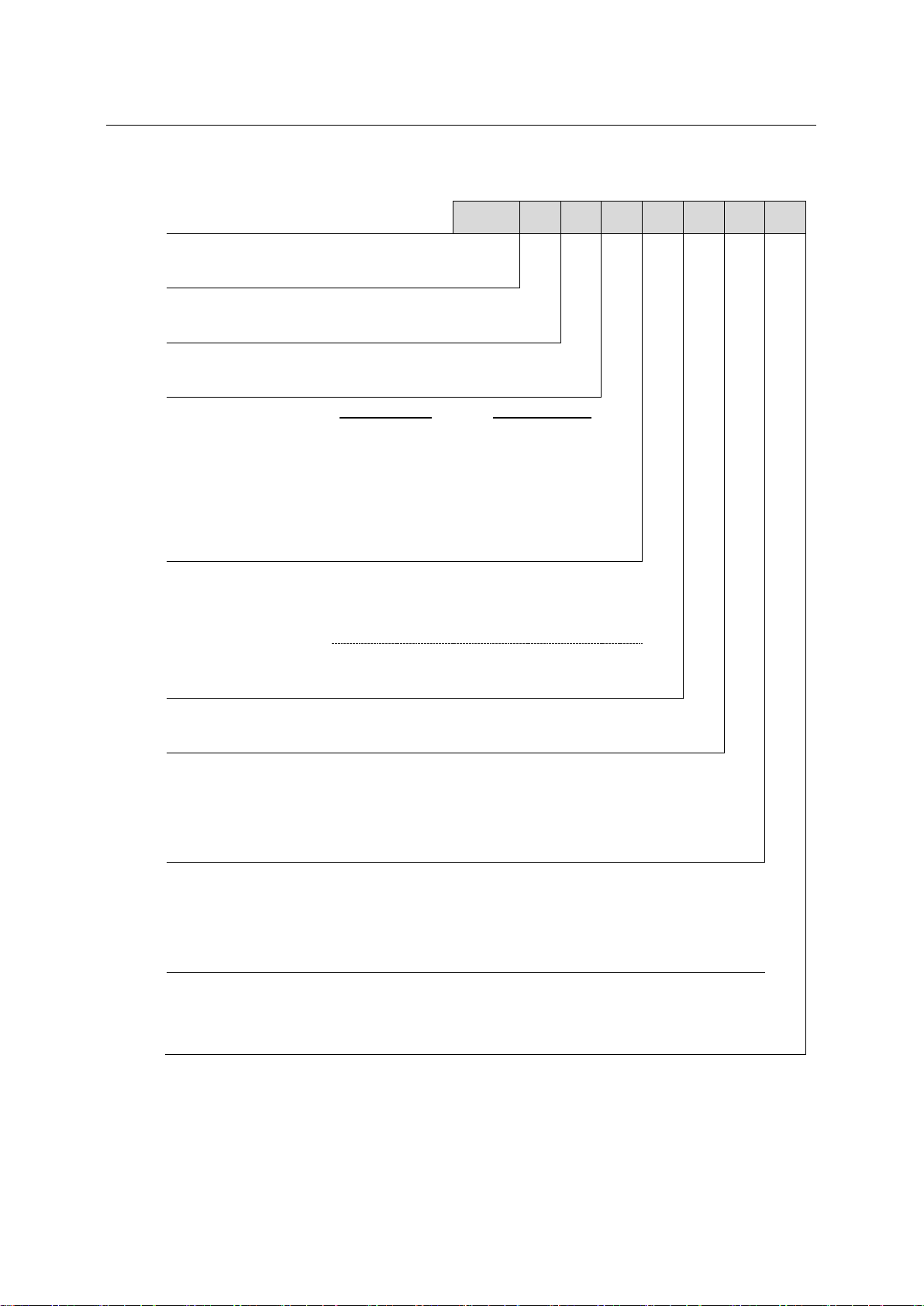

Table of Contents

1

Introduction-------------------------------------------------------------------------------------

4

1.1

General information for the user----------------------------------------------------------

4

1.2

Limited warranty and disclaimer----------------------------------------------------------

4

1.3

Requirement for safety----------------------------------------------------------------------

5

1.4

Explosion proof certificate------------------------------------------------------------------

5

1.5

Basic safety instructions for use in Ex area--------------------------------------------

6

1.6

Conditions to maintain intrinsically safety (Ex i) --------------------------------------

6

2

Product Description---------------------------------------------------------------------

7

2.1

Function---------------------------------------------------------------------------------------

7

2.2

Features---------------------------------------------------------------------------------------

7

2.3

Options----------------------------------------------------------------------------------------

7

2.4

Applications----------------------------------------------------------------------------------

7

2.5

Label-------------------------------------------------------------------------------------------

8

2.6

Product number-----------------------------------------------------------------------------

9

2.7

Specifications--------------------------------------------------------------------------------

10

2.8

Structure--------------------------------------------------------------------------------------

11

2.8.1 External structure-----------------------------------------------------------------

11

2.8.2 Internal structure------------------------------------------------------------------

12

2.9

System configuration----------------------------------------------------------------------

13

2.10

Operation Principle-------------------------------------------------------------------------

13

2.11

Approval drawings--------------------------------------------------------------------------

14

2.11.1 TS800 standard type------------------------------------------------------------

14

2.11.2 TS800 with limit switch type --------------------------------------------------

14

2.11.3 TS800 feedback shaft connection-------------------------------------------

14

3

Installation---------------------------------------------------------------------------------------

15

3.1

Before installation-----------------------------------------------------------------------------

15

3.2

TS800L installation---------------------------------------------------------------------------

15

3.2.1 Notes on installation ---------------------------------------------------------------

15

3.2.2 Effective rotation angle range of feedback lever----------------------------

16

3.2.3 Lever type and dimension -------------------------------------------------------

16

3.2.4 Bracket Installation-----------------------------------------------------------------

17

3.2.5 Dimension after installation------------------------------------------------------

17

3.3

TS800R installation---------------------------------------------------------------------------

18

3.3.1 TS800R installation examples---------------------------------------------------

18

3.3.2 TS800R bracket installation components------------------------------------

18

3.3.3 TS800R installation steps--------------------------------------------------------

19

3.4

TS820 Remote type installation-----------------------------------------------------------

21

3.5

Option module Installation------------------------------------------------------------------

22

3

Smart valve positioner

TS800 Series

tissin

3.5.1 Position transmitter module Installation---------------------------------------

22

3.5.2 HART communication module Installation-----------------------------------

22

3.5.3 Limit switch module Installation-------------------------------------------------

23

3.5.4 How to adjust limit switch cam --------------------------------------------------

24

3.6

How to adjust Auto/Manual switch -------------------------------------------------------

25

3.7

Orifice installation-----------------------------------------------------------------------------

26

4

Pneumatic connection----------------------------------------------------------------

27

4.1

Supply air pressure condition--------------------------------------------------------------

27

4.2

Pneumatic port Description----------------------------------------------------------------

27

4.3

Air connection----------------------------------------------------------------------------------

28

4.3.1 TS800L air connection------------------------------------------------------------

28

4.3.2 TS800R air connection------------------------------------------------------------

28

5

Electrical connection-------------------------------------------------------------------

29

5.1

Terminal description--------------------------------------------------------------------------

29

5.2

Wiring diagrams-------------------------------------------------------------------------------

30

5.2.1 Power and Feedback signal connection--------------------------------------

30

5.2.2 Limit switch connection------------------------------------------------------------

30

5.2.3 Alarm signal connection-----------------------------------------------------------

30

6

Calibration---------------------------------------------------------------------------------------

31

6.1

LCD description-------------------------------------------------------------------------------

31

6.2

Button description-----------------------------------------------------------------------------

32

6.3

How to quickly perform Auto calibration ------------------------------------------------

33

6.3.1 Auto calibration Steps--------------------------------------------------------------

33

6.4

Software map----------------------------------------------------------------------------------

34

6.5

Main menu Description----------------------------------------------------------------------

35

6.6

Main parameter menu Description-------------------------------------------------------

36

6.7

Submenu Description------------------------------------------------------------------------

37

6.7.1 TUNNING ----------------------------------------------------------------------------

37

6.7.2 PARAMETE--------------------------------------------------------------------------

39

6.7.3 DEVICE P-----------------------------------------------------------------------------

41

6.7.4 INFOMATN---------------------------------------------------------------------------

44

6.7.5 DIAGNOST---------------------------------------------------------------------------

45

6.7.6 EMERGNCy-------------------------------------------------------------------------

48

7

Error code and Troubleshooting --------------------------------------------

49

7.1

Error code during Auto calibration--------------------------------------------------------

49

7.2

Error code during operation----------------------------------------------------------------

51

4

Smart valve positioner

TS800 Series

tissin

1 Introduction

1.1 General information for the user

This instruction includes installation, operation, maintenance, and parts information for Tissin

TS800 Valve Positioner. Keep these instructions in a location which is easily accessible to

every user and make

Installation, commissioning and maintenance of the product can only be performed by

trained specialist personnel who have been authorized by the plant operator to do so.

Before installing or commissioning, be sure to read and thoroughly understand the

product manual and operate the product properly.

Operators must strictly observe the applicable national regulations with regards to

installation, function tests, repairs, and maintenance of electrical products.

Only trained and authorized person should operate the machinery and the equipment.

Do not use this positioner out of the range of its specifications as this can cause failure.

Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

Never handle mechanical equipment or disassemble the device until safety is

confirmed.

Before loosening the pneumatic lines and valves, turn off the pressure and vent the

pneumatic lines.

Observe applicable accident prevention and the safety regulations for electrical

equipment.

The manual can be altered or revised due to hardware of software upgrades without any prior

notice. Please visit our website ( www.tissin.co.kr ) and check the latest documentation.

1.2 Limited warranty and disclaimer

This product has been fully inspected and shipped through a thorough quality inspection

procedure. The manufacturer warranty period of the product is 18 months after the

product is shipped from Tissin in Korea.

For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided. This limited

warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

Using the device in a manner that does not fall within the scope of its intended use,

disregarding this manual, using under unqualified personnel, or making unauthorized

alterations releases the manufacturer from liability for any resulting damage. This

renders the manufacturer's warranty null and void.

5

Smart valve positioner

TS800 Series

tissin

1.3 Requirement for safety

This manual contains notices you have to observe in order to ensure your personal safety, as

well as to prevent damage to property. These safety instructions are intended to prevent

hazardous situations and/or equipment damage. For the safety, it is important to follow the

instructions in the manual.

WARNING

Failure to observe the warning may result in serious injuries or death.

CAUTION

Failure to observe this warning may result in damage to the device or personal injury.

NOTICE

Failure to observe the warning may result in damage to the device or may degrade

performance.

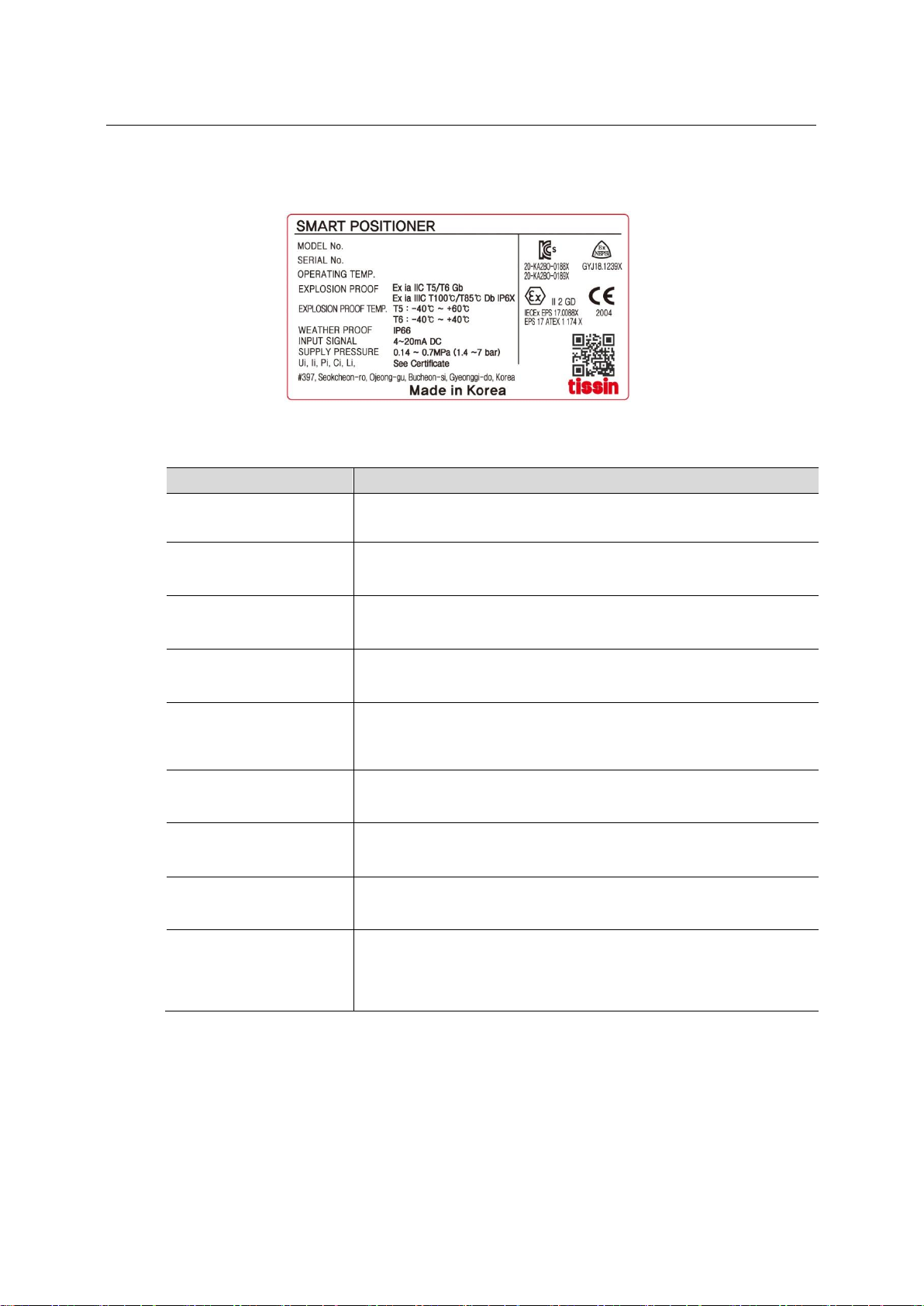

1.4 Explosion proof certificate

This product has obtained a variety of explosion-proof certification and safety level

certification. For details, please visit our website and download the corresponding explosion-

proof certificate for confirmation.

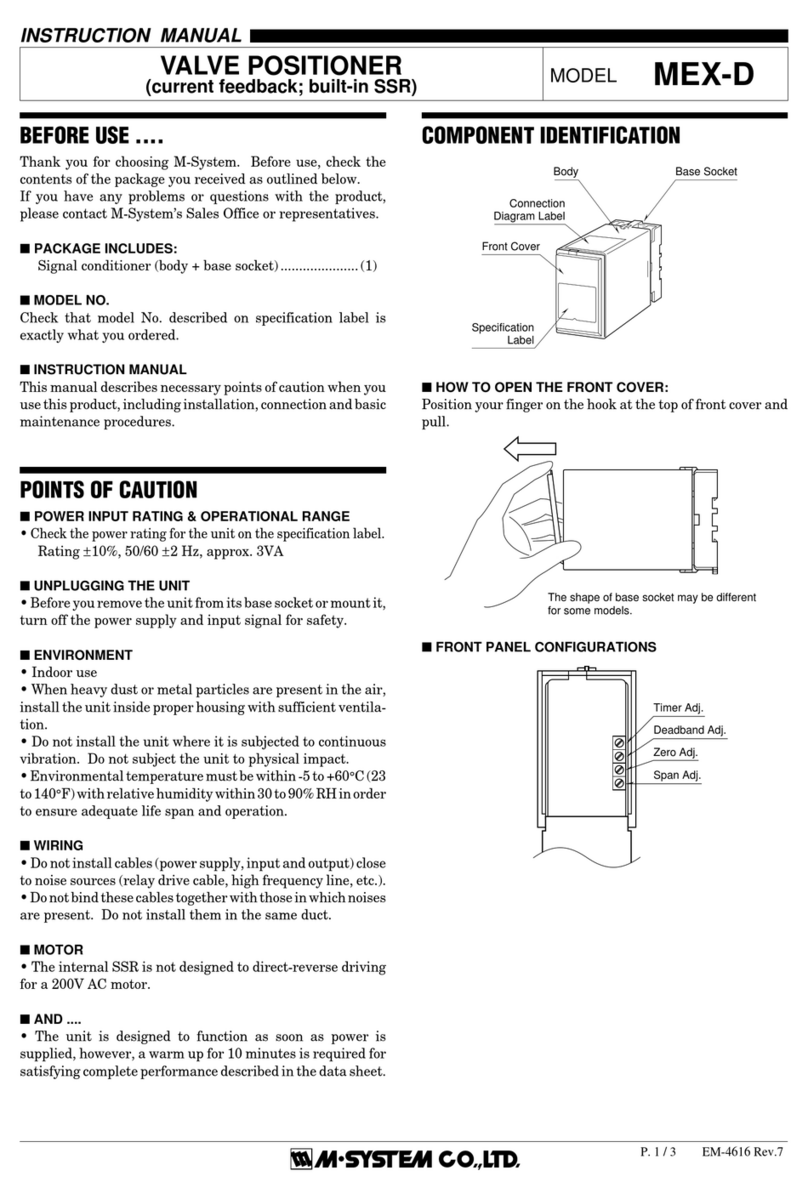

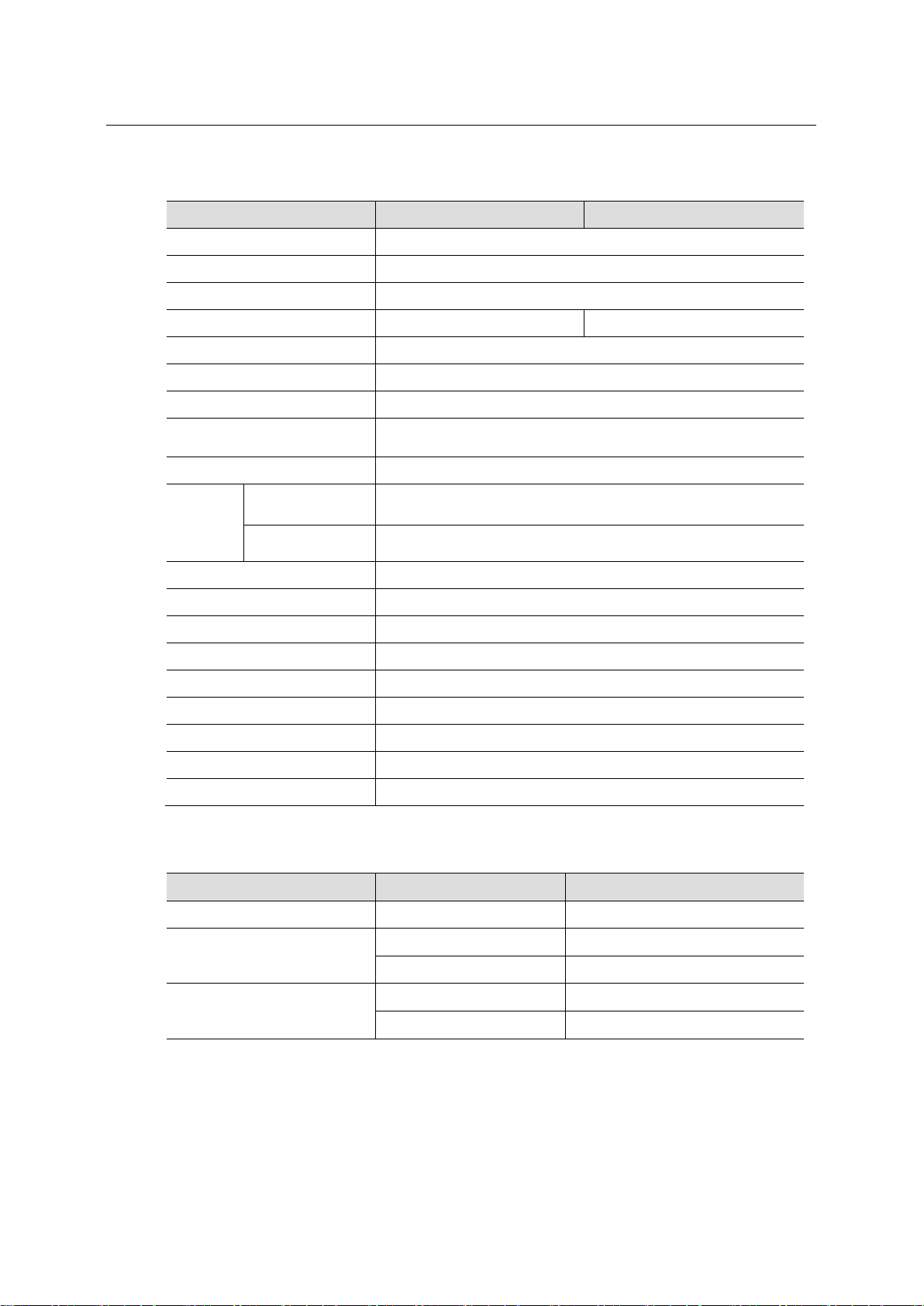

Certificate type

Certificate number

Explosion proof grade

IECEx

IECEx EPS 17.0088X

Ex ia IIC T5/T6 Gb

Ex ia IIIC T100℃/85℃Db IP6X

ATEX

EPS 17 ATEX 1 174 X

II 2G Ex ia IIC T5/T6 Gb

II 2D Ex ia IIIC T100℃/85℃Db IP6X

EAC

RU С-KR.АД07.В.01840

/20

1Ex ia IIC T5/T6 Ga X

KCS

20-KA2BO-0188X

Ex ia IIC T6/T5

20-KA2BO-0189X

Ex ia IIIC T85℃/100℃

CCC

2020322307002407

Ex ia IIC T5/T6 Gb

Ex iaD 21 T85/T100

NEPSI

GYJ18.1239X

Ex ia IIC T5/T6 Gb

SIL

SIL

FS/71/220/19/0378

(SGS TUV SAAR)

SIL2 at HFT=0

SIL3 at HFT=1

6

Smart valve positioner

TS800 Series

tissin

1.5 Basic safety instructions for use in Ex area

To prevent the risk of explosion, observe not only the basic safety instructions in the

respective operating instructions for operation in the Ex area, but also the following.

WARNING

Observe the applicable safety regulations (also national safety regulations) as well as

the general rules of technology for construction and operation.

Make sure that the device is suitable for the area of use.

Check the positioner’s certified and permitted explosion proof range.

Close all unnecessary Cable Gland with the locking screws approved by the explosion

site.

1.6 Conditions to maintain intrinsically safety (Ex i)

WARNING

Make sure to connect "Intrinsic safety" type protection device to intrinsically safe circuit

only.

Observe the specifications for the electrical data on the certificate and in technical

data.

In order to maintain intrinsically safe protection, be sure to use a barrier that meets the

following specifications.

Barrier specifications

Ui

li

Pi

Ci

Li

Main power

28V

101mA

707mW

0.6nF

6uH

Position transmitter,

Alarm1, Alarm2,

Limit Switch(Dry contact type)

28V

101mA

707mW

0.6nF

6uH

Limit Switch

(Proximity type)

16V

26mA

34mW

30nF

50uH

7

Smart valve positioner

TS800 Series

tissin

2 Product Description

2.1 Function

Smart valve positioner TS800 series controls the valve stroke in response to an input signal of

4~20mA DC from the control panel, DCS or calibrator.

2.2 Features

LCD and 4 button local control

Quick and easy calibration

PST and alarm function

Auto/Manual switch included

Built-in self-diagnostic function

Modularization of the internal parts

IP66 / NEMA4X

Improvement of valve control speed by applying large flow pilot valve

Strong vibration resistance and impact resistance

2.3 Options

Position transmitter (4~20mA DC Feedback signal)

HART communication (Ver. HART 7)

Limit switch (Mechanical or Proximity type)

Remote control type (TS820)

2.4 Applications

The TS800 is mounted on a pneumatic control valves and is used for fluid control of industrial

parts.

Oil and gas

Chemicals

Power plant

Paper

Water treatment

Pharmaceutical

Printing and dyeing processing

Food and beverage

Etc.

8

Smart valve positioner

TS800 Series

tissin

2.5 Label

Item

Description

MODEL No.

Indicate the model number.

SERIAL No.

Indicate the serial number.

EXPLOSION PROOF

Indicate the certified explosion proof grade.

OPERATING TEMP.

Indicate the allowable operating temperature.

EXPLOSION PROOF

TEMP.

Indicate the ambient temperature range for the explosion proof.

This temperature range must be observed when using in

explosion-proof areas.

WEATHER PROOF

Indicate the enclosure grade.

INPUT SIGNAL

Indicates input current signal range.

SUPPLY PRESSURE

Indicate the allowable input supply pressure range.

Ui, Ii, Pi, Ci, Li

Indicate required barrier specification for intrinsically safety circuit

configuration.

Please refer to the certificate for the detailed specifications.

9

Smart valve positioner

TS800 Series

tissin

2.6 Product number

TS800

Model

Standard type

TS800

Remote type

TS820

Acting type

Linear type

L

Rotary type

R

Explosion proof

type

Non-explosion poof

N

Ex ia IIC T5/T6

A

Connection

Conduit entry

Air connection

G(PF)1/2

PT1/4

1

G(PF)1/2

NPT1/4

2

NPT1/2

NPT1/4

3

M20

NPT1/4

4

M20

G1/4

5

Lever type

(Linear )

10~80mm

1

70~150mm

2

Adapter type (70mm)

3

Lever type

(Rotary)

M6 x 34L (Fork lever type)

1

NAMUR

5

Ambient Temp.

-30℃~85℃(Standard type)

S

-40℃~85℃

L

Communication

None

0

Position transmitter (4~20mA DC feedback)

1

HART communication

2

HART and Position transmitter (4~20mA DC feedback)

3

Limit switch

None

0

(For TS800)

Mechanical type (Dry contact NO, NC, COM)

M

Proximity type (P+F NJ1,5-F-N)

P

With Dome cover (Without Limit switch)

D

Cable length

5m

1

(For TS820)

10m

2

User define (Less than 20 meters)

X

10

Smart valve positioner

TS800 Series

tissin

2.7 Specifications

Model

TS800L / TS820L

TS800R / TS820R

Input signal

4~20mA DC

Impedance

500Ω(20mA DC)

Supply pressure

0.14~0.7MPa

Stroke

10~150mm

0~900

Air connection

PT1/4, NPT1/4

Gauge connection

PT1/8, NPT1/8

Conduit

G(PF)1/2, NPT1/2, M20

Explosion proof type

II 2G Ex ia IIC T5/T6 Gb

II 2D Ex ia IIIC T100℃/85℃Db IP6X

Enclosure

IP66 (EN60529)

Ambient

Temp.

Acting Temp.

-30℃∼85℃(Standard type),

-40℃∼85℃(Low temp type)

Explosion proof

Temp.

-40℃~60℃(T5) / -40℃~40℃(T6)

Linearity

±0.5% F.S.

Sensitivity

±0.2% F.S

Hysteresis

±0.5% F.S

Repeatability

±0.3% F.S

Air consumption

Below 2.3LPM (Sup.=0.14MPa)

Required air quality

Class 3 (ISO8573-1)

Flow capacity

Over 100LPM (Sup.=0.14MPa)

Material

Aluminum die cast

Weight

2.2kg

Option specifications

Option

Item

Specification

HART

HART version

HART 7

Position transmitter

Wire connection type

2 Wires

Supply voltage

10~30V DC

Limit switch

Mechanical type

AC125V, 3A, DC30V, 2A

Proximity type

DC8.2V 8.2A

Note: Please contact our sales department for other specifications.

11

Smart valve positioner

TS800 Series

tissin

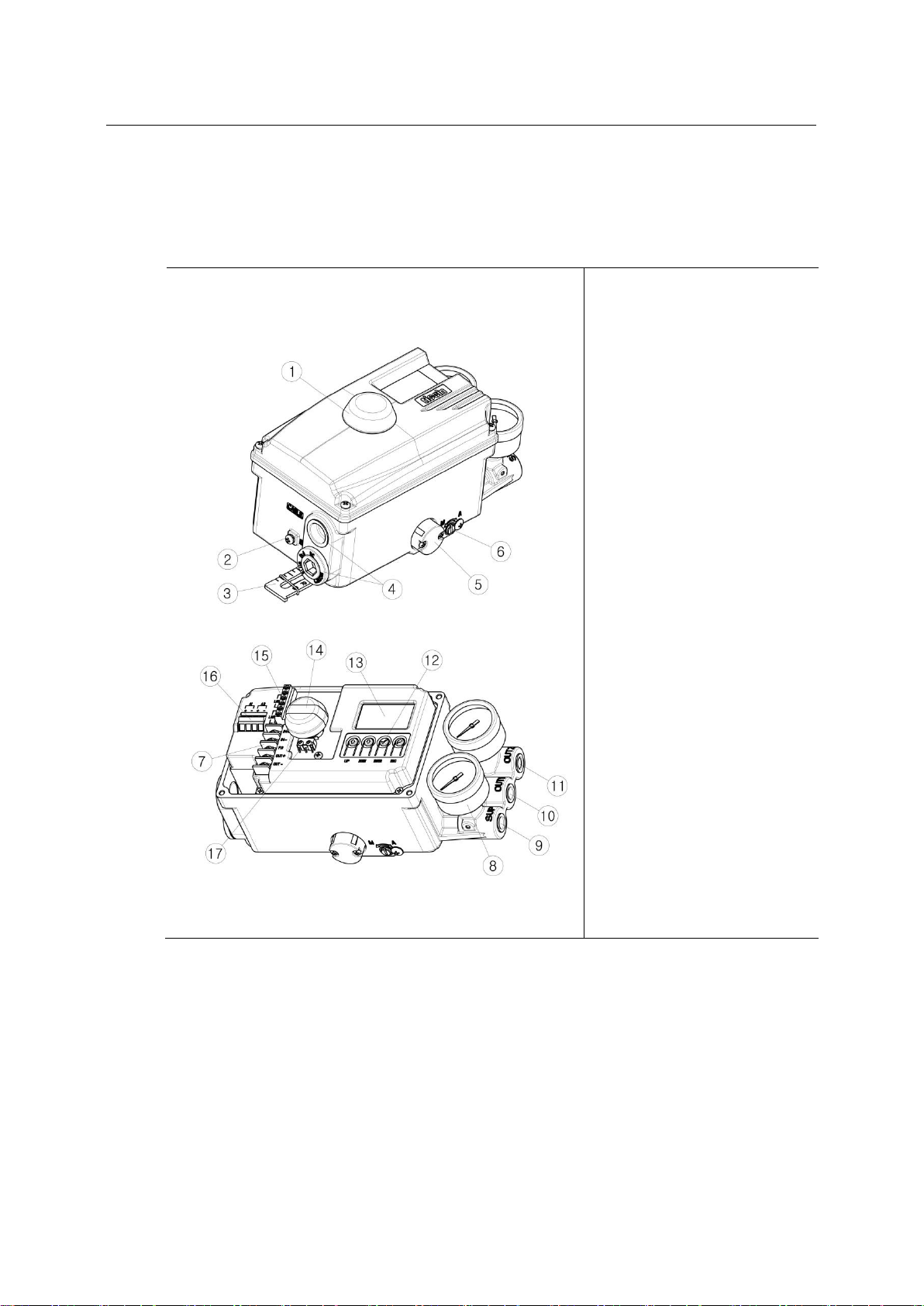

2.8 Structure

2.8.1 External structure

①Dome cover

②External ground

③Feedback lever

④Conduit

⑤Air vent hole cover

⑥Auto/Manual switch

⑦Terminal block

⑧Pressure gauge

⑨Air supply port

⑩OUT1 port

⑪OUT2 port

⑫Button

⑬LCD

⑭Dome indicator

⑮Limit switch

connection terminal

○

16 Alarm connection

terminal

○

17 Limit switch

Note: Only Limit switch type product is equipped with Dome indicator.

12

Smart valve positioner

TS800 Series

tissin

2.8.2 Internal structure

①Pilot valve

②Potentiometer

③Pressure sensor (Option)

④Torque motor

⑤Main PCB

⑥Terminal block

⑦HART communication module (Option)

⑧Position transmitter module(Option)

⑨Buttons

⑩Alarm signal connection terminal

⑪PCB cover

⑫Limit switch connection terminal

⑬Limit switch (Option)

13

Smart valve positioner

TS800 Series

tissin

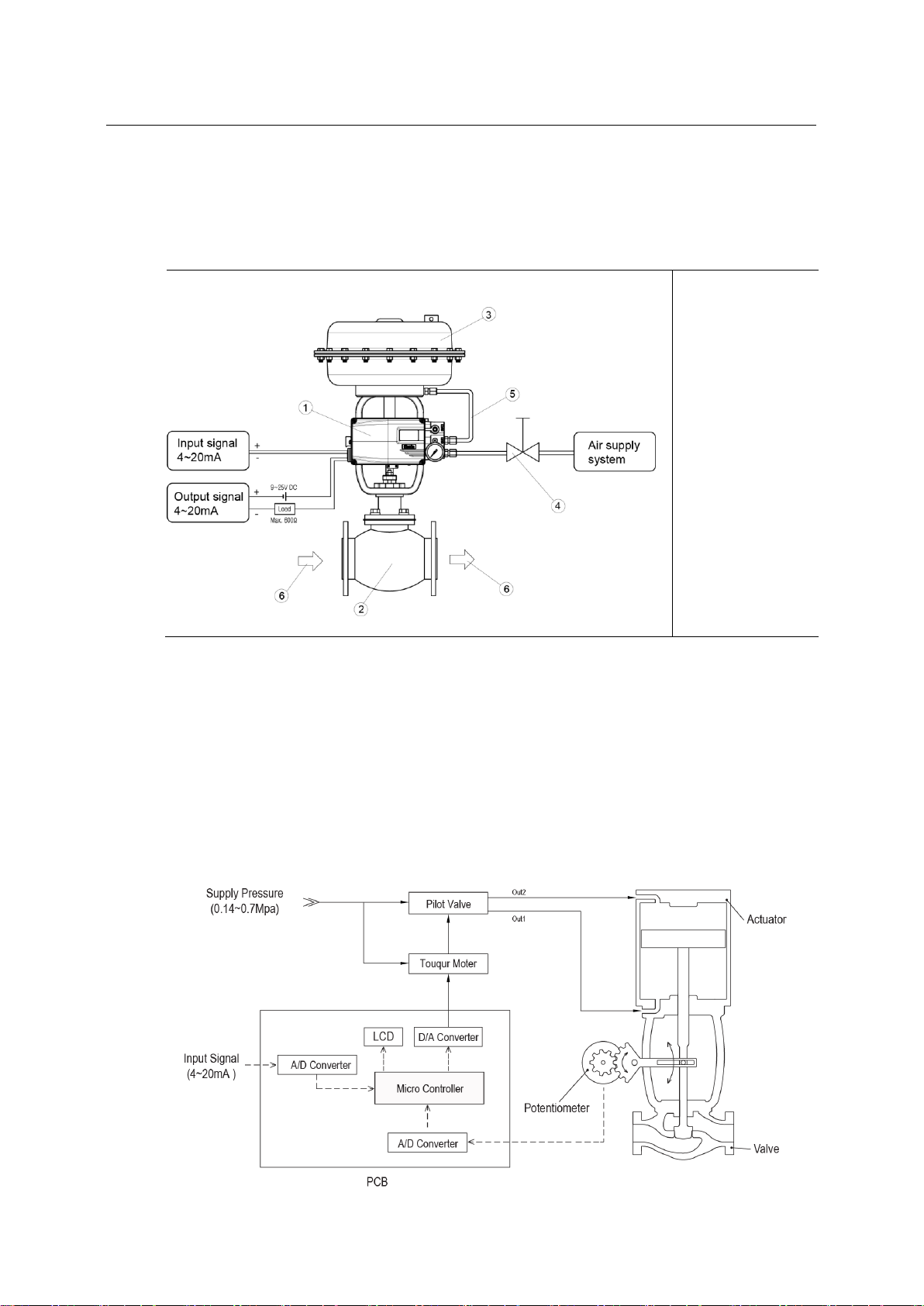

2.9 System configuration

Basically, the control valve system consists of a positioner for controlling the pneumatic

pressure of the actuator, an actuator for controlling the opening of the valve, and a valve for

controlling the flow of the fluid.

①Positioner

(TS800)

②Valve

③Actuator

④Regulator

⑤OUT1 vent line

⑥Fluid

2.10 Operation Principle

TS800 receives 4-20mA input signal of the control room, micro-processor (CPU) compares

input signal with position feedback through potentiometer and sends control signal to I/P

conversion module torque motor, torque motor converts it to a pneumatic signal to controls

pilot valve to controls the opening of the control valve by converting output pressure of OUT1

and OUT2.

14

Smart valve positioner

TS800 Series

tissin

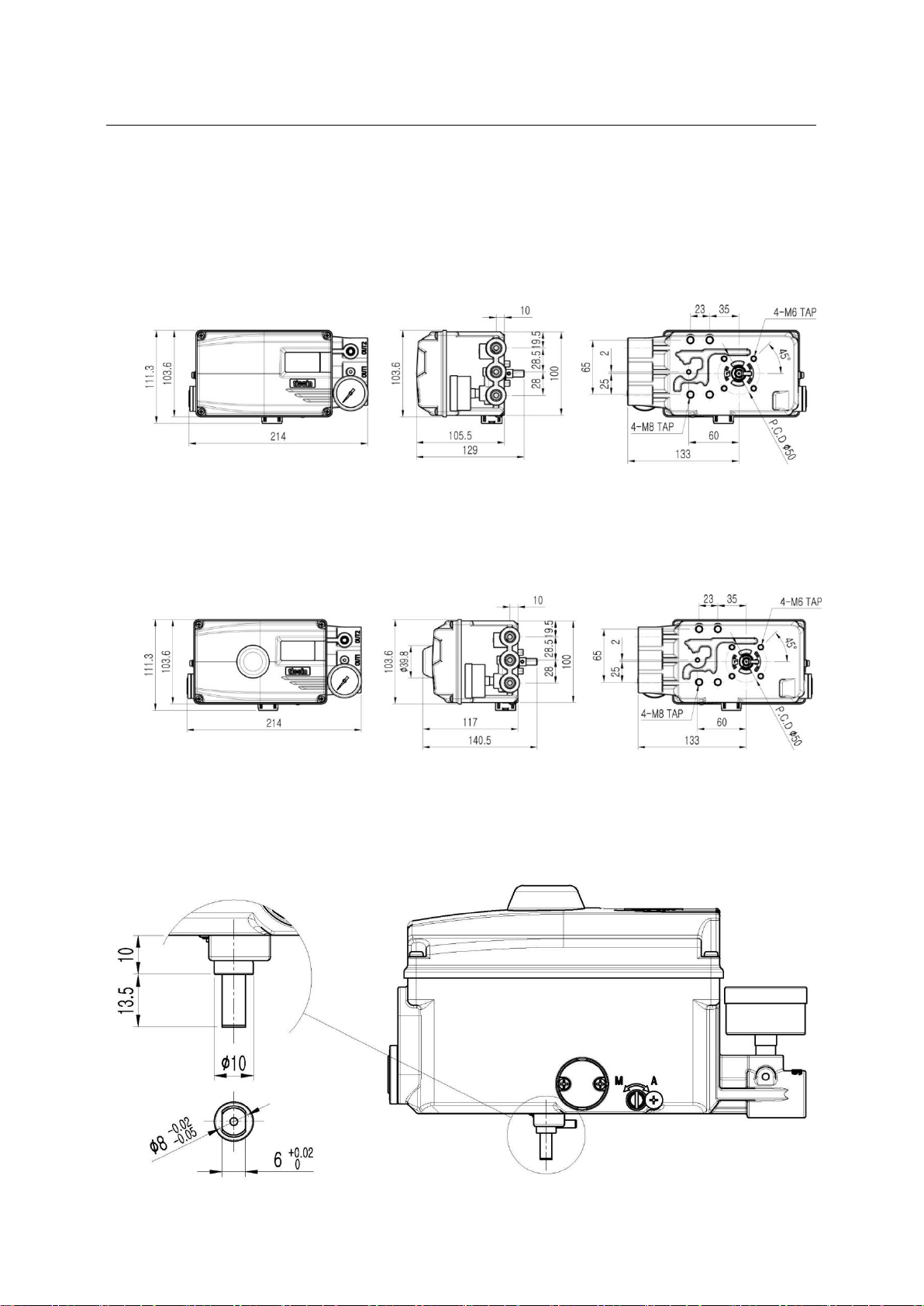

2.11 Approval drawings

2.11.1 TS800 standard type

2.11.2 TS800 with limit switch type

2.11.3 TS800 feedback shaft connection

15

Smart valve positioner

TS800 Series

tissin

3 Installation

3.1 Before installation

WARING

Make sure if TS800 is appropriate to the valve and actuator installation conditions and

the site requirements specifications before installation.

If the installation state is not correct, TS800 control characteristics may be degraded.

3.2 TS800L installation

3.2.1 Notes on installation

When make the mounting bracket and connecting the lever to the stem connection pin, be

sure to observe the following two points.

If failure to observe the followings, it will affect the product performance such as linearity.

NOTICE

①When the valve stroke is 50%, the feedback lever should be horizontal.

②When the valve stroke is 50%, the stem connection pin must be located at the numeric

position marked on the feedback lever that is corresponding to the valve stroke.

①Feedback lever

②Stem connection pin

③Pin fixing spring

④Actuator stem

⑤Valve opening indicator

16

Smart valve positioner

TS800 Series

tissin

3.2.2 Effective rotation angle range of feedback lever

The effective rotation angle of TS800L lever is respectively 30oupward and downward that is

based on horizon.

Follow 3.2.1 notes, effective rotation angle can be maintained to achieve the best

performance.

3.2.3 Lever type and dimension

The numeric positions marked on the feedback lever correspond to the valve stroke, and the

stem connection pin must be connected to the corresponding marked location.

Lever No.

Valve stroke

Dimensions

No.1

10~80mm

No.2

70~150mm

No.3

10~70mm

For the tube less

type actuator

NOTICE

If the rotation angle range is too small during operation, the performance of products

such as linearity may be degradation.

If the rotation angle range is too big during operation, may damage the product or cause

malfunctions.

17

Smart valve positioner

TS800 Series

tissin

3.2.4 Bracket Installation

Refer to the TS800L drawing (refer to 2.11.1) and actuator drawing, please make appropriate

bracket and install the positioner on the actuator.

①Bracket

②Bolt (M8)

③Washer

④Feedback lever

⑤Lever fixing bolt

⑥Main shaft

⑦Shaft fixing pin

3.2.5 Dimension after installation

<Lever No.1 or 2 > <Lever No.3>

①Stem connection pin

②Feedback lever

③Bracket

④Actuator york

⑤Lever adapter

18

Smart valve positioner

TS800 Series

tissin

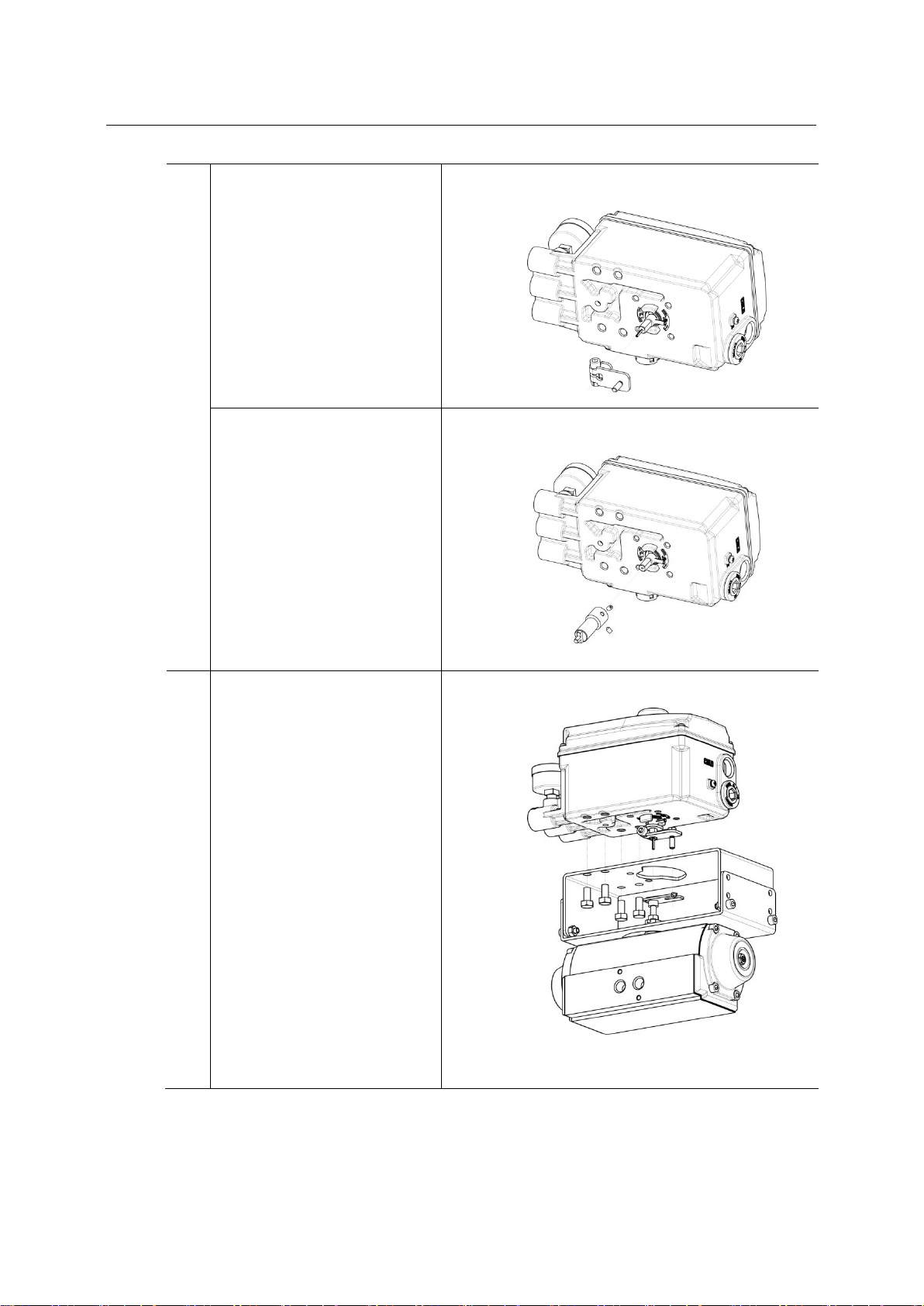

3.3 TS800R installation

3.3.1 TS800R installation examples

<Fork lever type> <NAMUR type>

3.3.2 TS800R bracket installation components

When shipped from the factory, components No.1~8 are provided as standard.

The brackets support the NAMUR mounting standard (VDI/VDE3835, IEC60534-6-2).

<Fork lever type> <NAMUR type>

①Lower bracket(1)

②Upper bracket(1)

③Nuts(4)

④Screws (M6x4)

⑤Screws (M8x4)

⑥Fork lever(1)

⑦NAMUR adapter (1)

⑧Adapter fixing pin(2)

19

Smart valve positioner

TS800 Series

tissin

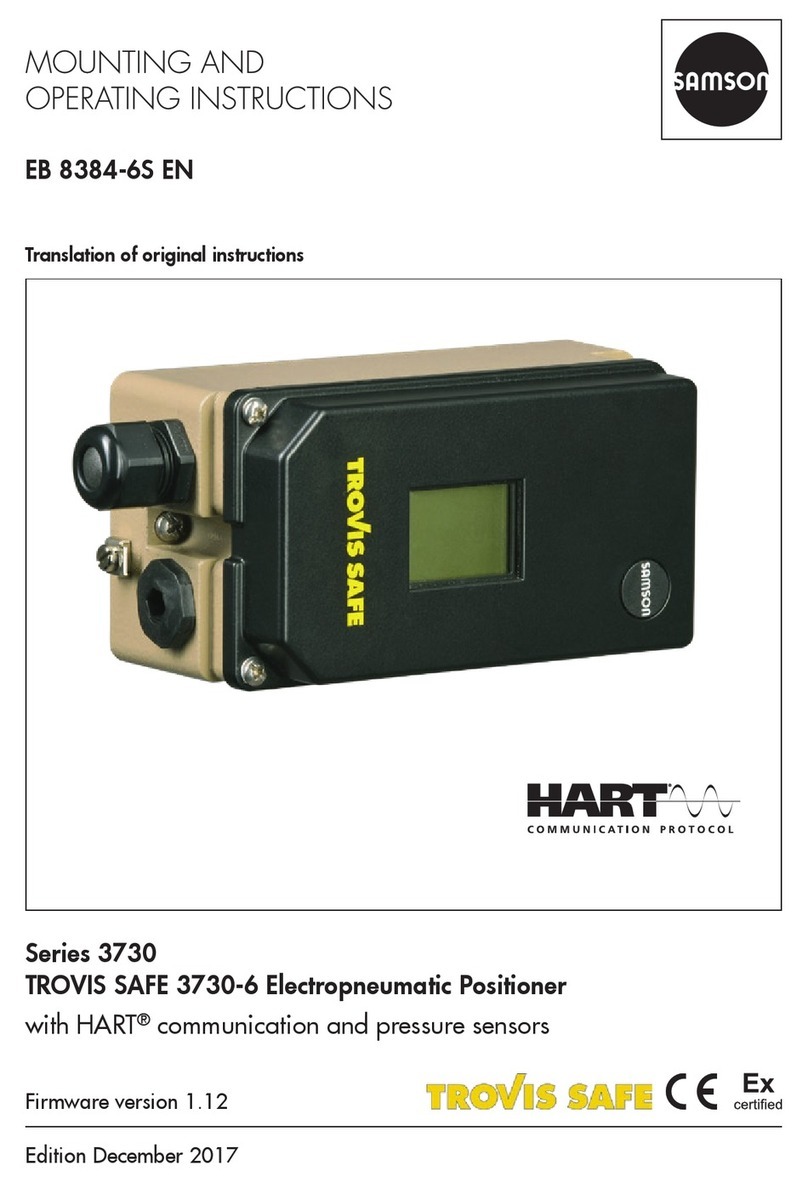

3.3.3 TS800R installation steps

1

Lower bracket installation

Attach the lower bracket to the

actuator and secure it with the

screw.

2

Fork lever installation

Insert the fork lever into

actuator stem and tighten with

the fixing bolt.

Position the start point of the

fork lever according to actuator

stem’s rotation direction.

3

Tighten upper and lower

brackets

Connect the upper bracket to

the lower bracket attached to

the actuator and fasten with

the screw.

Tighten the bolts to the

corresponding holes of 20, 30

and 50 depending on the

actuator stem height.

20

Smart valve positioner

TS800 Series

tissin

4

Shaft lever installation

Fork lever type

Insert the shaft lever into the

main shaft and tighten with the

fixing bolt.

NAMUR type

Insert NAMUR shaft adapter

into the main shaft and fix it

with two fixing pins.

5

Attach the positioner to the

upper bracket and fix it with

screw.

At this time, insert the lever pin

at the bottom of the fork lever

into the hole of the fork lever

attached to the actuator and

then align the center.

Other manuals for TS800 Series

2

This manual suits for next models

4

Table of contents

Other tissin Valve Positioner manuals

Popular Valve Positioner manuals by other brands

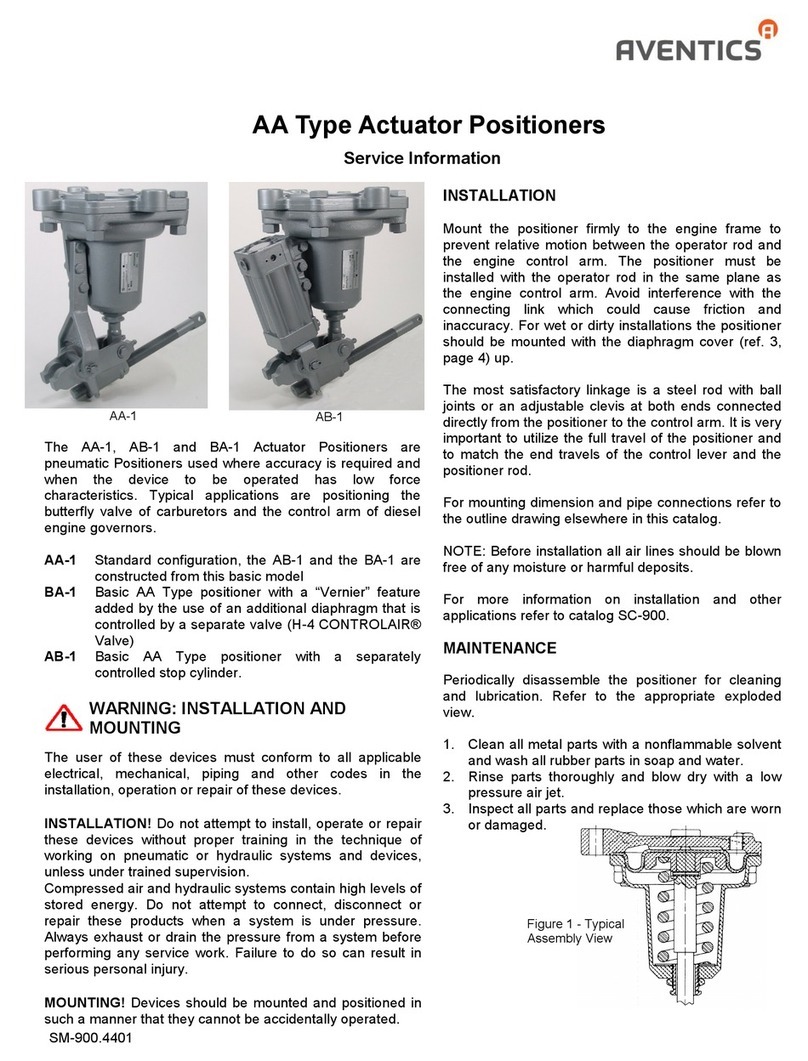

Samson

Samson TROVIS SAFE 3730-6 Mounting and operating instructions

Aventics

Aventics AB-1 Service information

Aventics

Aventics R431004026 Service information

Swegon

Swegon SILVER C quick start guide

Avid Technology

Avid Technology EaziCal II operating manual

halstrup-walcher

halstrup-walcher PSD4 Series instruction manual