CONTENTS

1-SAFETY........................................................................................................................... 1

1.1 INTRODUCTION .............................................................................................................................. 1

1.2 SAFETY INSTRUCTIONS FOR COMMISSIONING ............................................................................. 1

1.3 SAFETY INSTRUCTIONS FOR OPERATION...................................................................................... 1

1.4 SAFETY INSTRUCTIONS FOR MAINTENANCE................................................................................. 3

1.5 RISKS............................................................................................................................................. 3

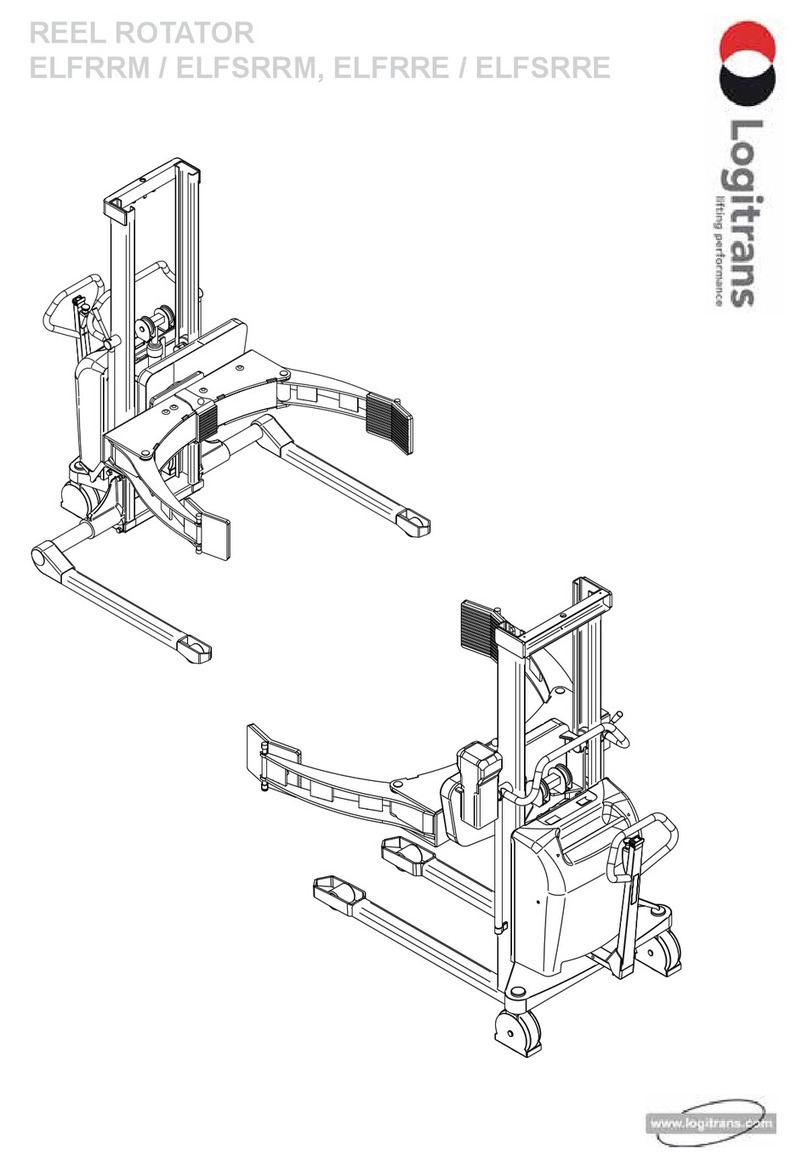

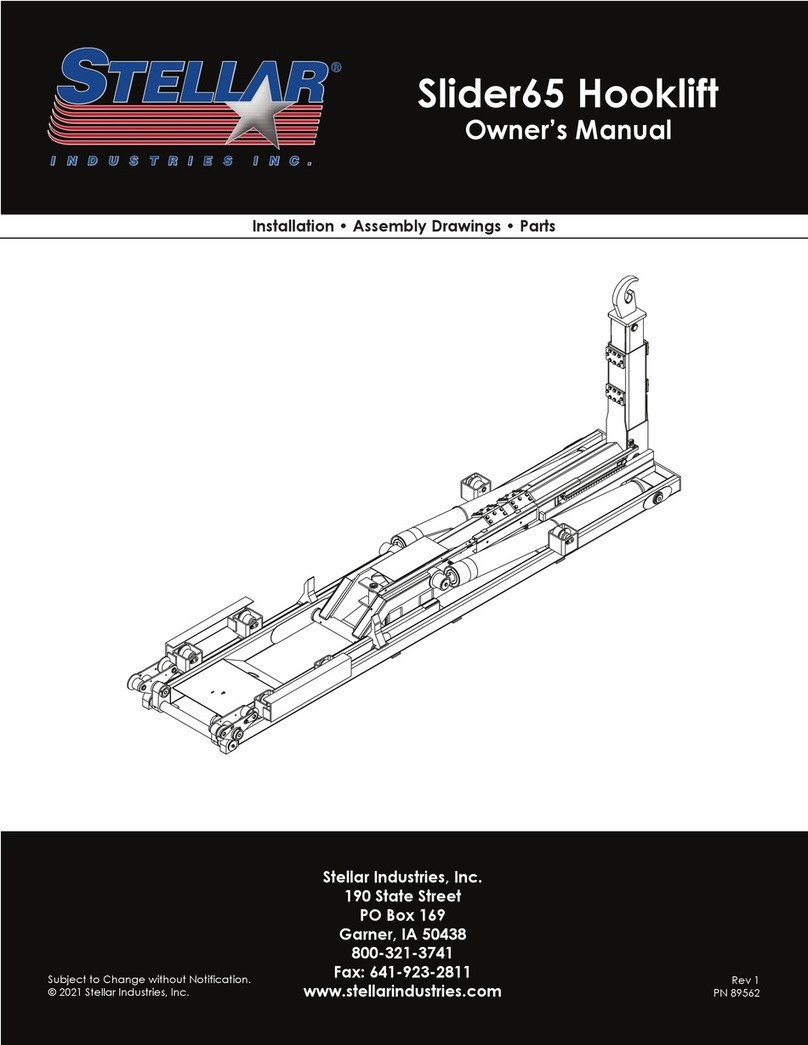

2-DESCRIPTION .................................................................................................................4

3-UNPACKING & SETUP ..................................................................................................... 5

3.1 DELIVERY AND CHECK OF PACKAGES ............................................................................................ 5

3.2 LIFTING AND HANDLING ................................................................................................................ 5

3.3 PREPARATION................................................................................................................................ 5

4 SPECIFICATIONS.............................................................................................................6

5-FLOOR REQUIREMENTS..................................................................................................6

5.1 SELECTING THE SITE AREA ............................................................................................................ 6

5.2 FLOOR REQUIREMENTS ................................................................................................................. 6

5.3 IMPORTANT CONCRETE AND ANCHORING INFORMATION ............................................................. 7

5.4 ANCHORING TIP SHEET ................................................................................................................. 7

6-INSTALLATION INSTRUCTIONS.......................................................................................8

7-OPERATION INSTRUCTIONS ......................................................................................... 11

7.1 DEFECTS / MALFUNCTIONS ..........................................................................................................11

7.2 CONTROLS ....................................................................................................................................11

7.2.1 UP CONTROL.........................................................................................................................................................................11

7.2.2 SAFETY LOCK CONTROL......................................................................................................................................................11

7.2.3 LOWERING CONTROL...........................................................................................................................................................12

7.3 OPERATION...................................................................................................................................12

8-MAINTENANCE ............................................................................................................. 14

8.1 MAINTENANCE SCHEDULE............................................................................................................14

8.1.1 DAILY......................................................................................................................................................................................14

8.1.2 WEEKLY .................................................................................................................................................................................14

8.1.3 MONTHLY ..............................................................................................................................................................................15

8.1.4 BIMONTHLY...........................................................................................................................................................................15

8.1.5 YEARLY ..................................................................................................................................................................................15

8.1.6 EVERY OTHER YEAR.............................................................................................................................................................15

8.2 MAINTENANCE BY OPERATOR ......................................................................................................16

8.2.1 HYDRAULIC SYSTEM ...........................................................................................................................................................16

8.2.2 GREASING POINTS...............................................................................................................................................................16

8.2.3 OPERATION AND WEAR CHECKS........................................................................................................................................17

8.2.4 LIFT STABILITY .....................................................................................................................................................................17

8.3 CLEANING .....................................................................................................................................17

9-TROUBLESHOOTING ..................................................................................................... 18

10-OWNER/EMPLOYER RESPONSIBILITIES ..................................................................... 19

11-DIAGRAMS (FIG. 1-5) .................................................................................................. 20

FIG. 1 - DIMENSIONS ..........................................................................................................................20

FIG. 2 - CABLES...................................................................................................................................21

FIG. 3 - EXPLODED VIEW 1 ..................................................................................................................22

FIG. 4 - EXPLODED VIEW 2 ..................................................................................................................23

FIG. 5 - POWER UNIT...........................................................................................................................26