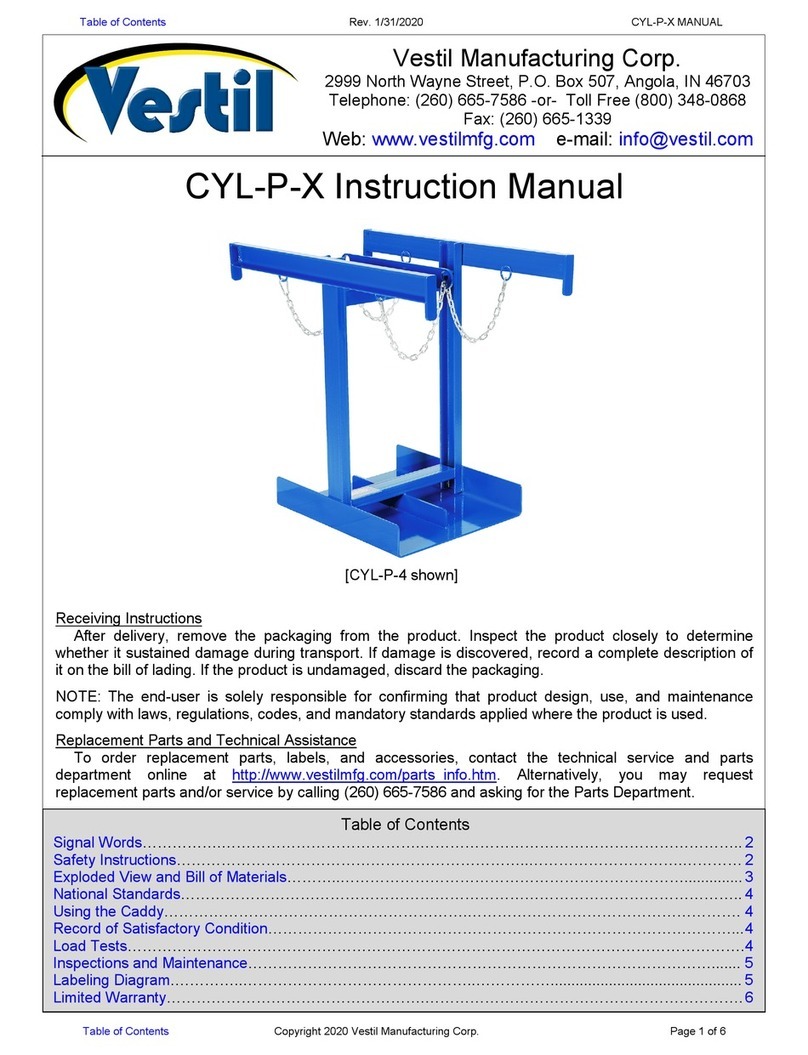

CONTENTS

1-SAFETY .....................................................................................................................1

1.1 INTRODUCTION........................................................................................................................ 1

1.2 SAFETY INSTRUCTIONS FOR COMMISSIONING...................................................................... 1

1.3 SAFETY INSTRUCTIONS FOR OPERATION............................................................................... 1

1.4 SAFETY INSTRUCTIONS FOR MAINTENANCE ......................................................................... 3

1.5 RISKS....................................................................................................................................... 3

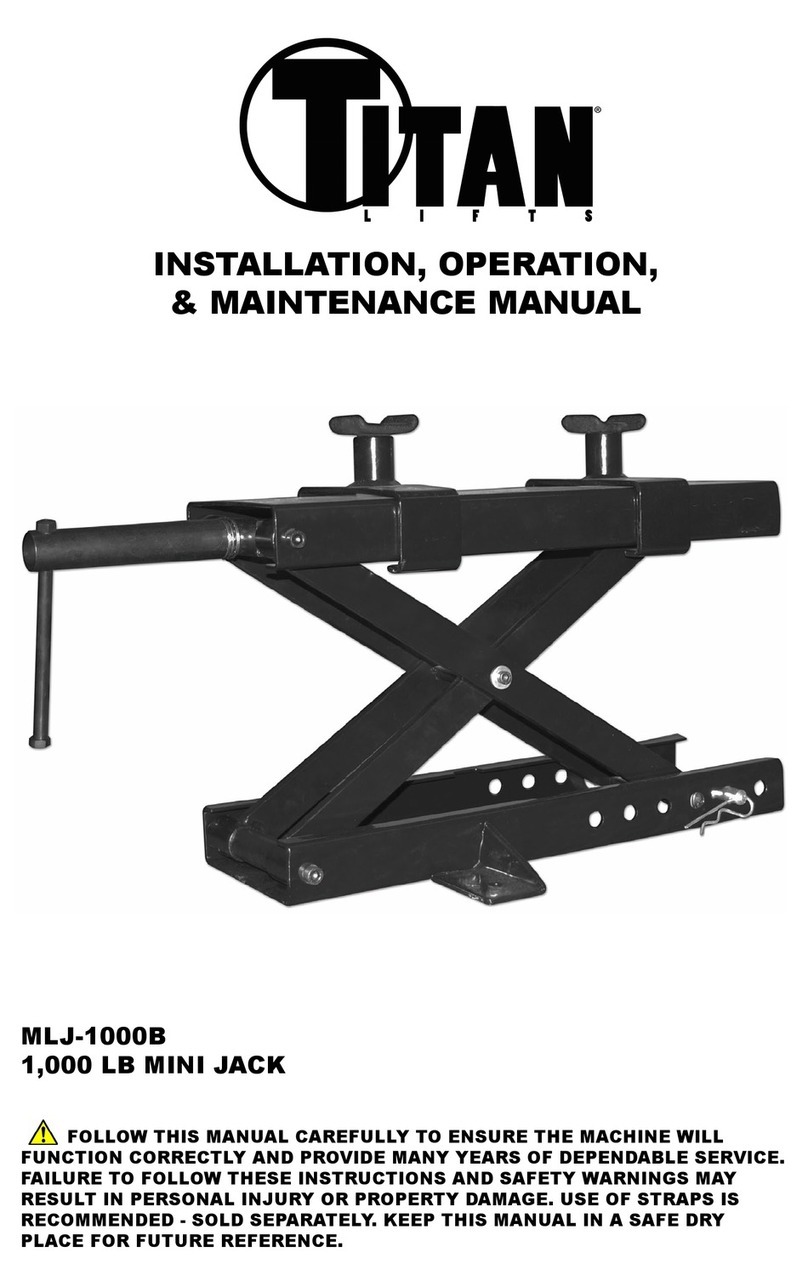

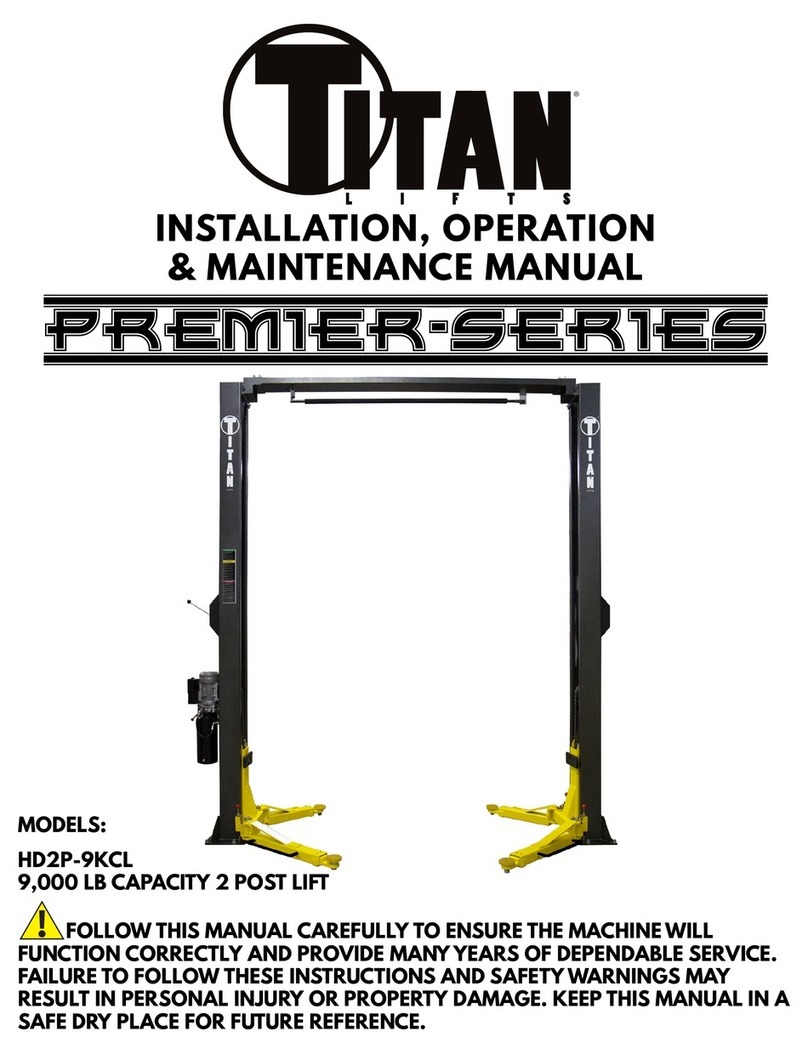

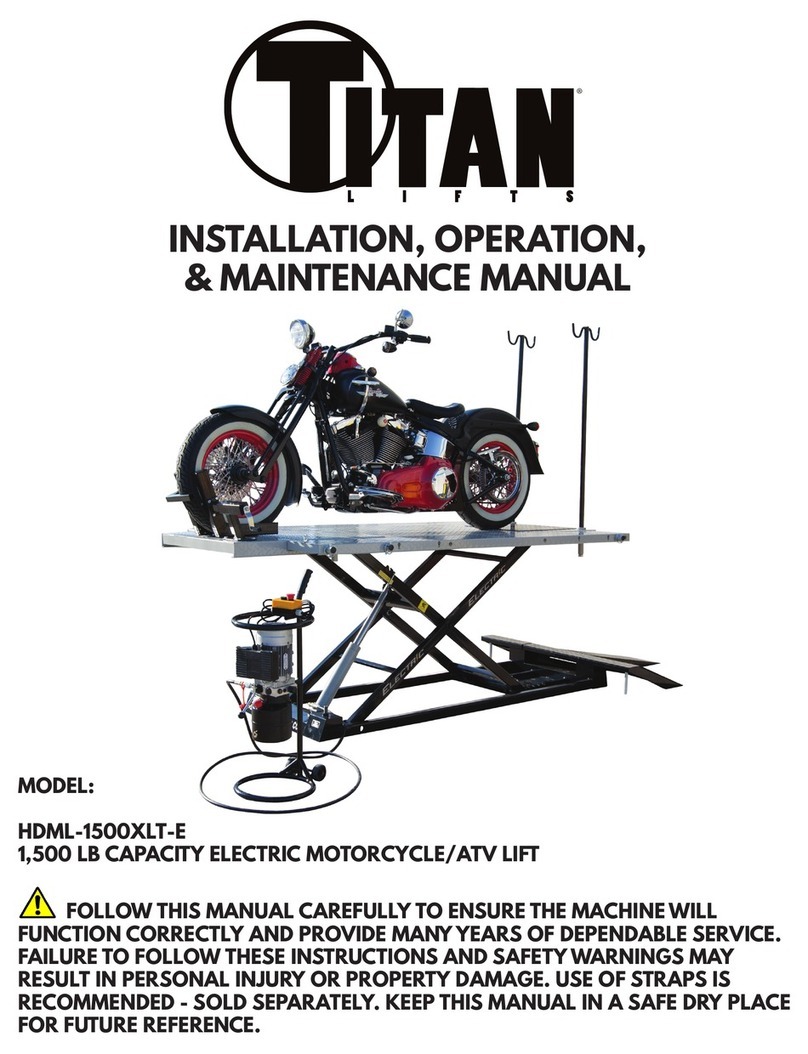

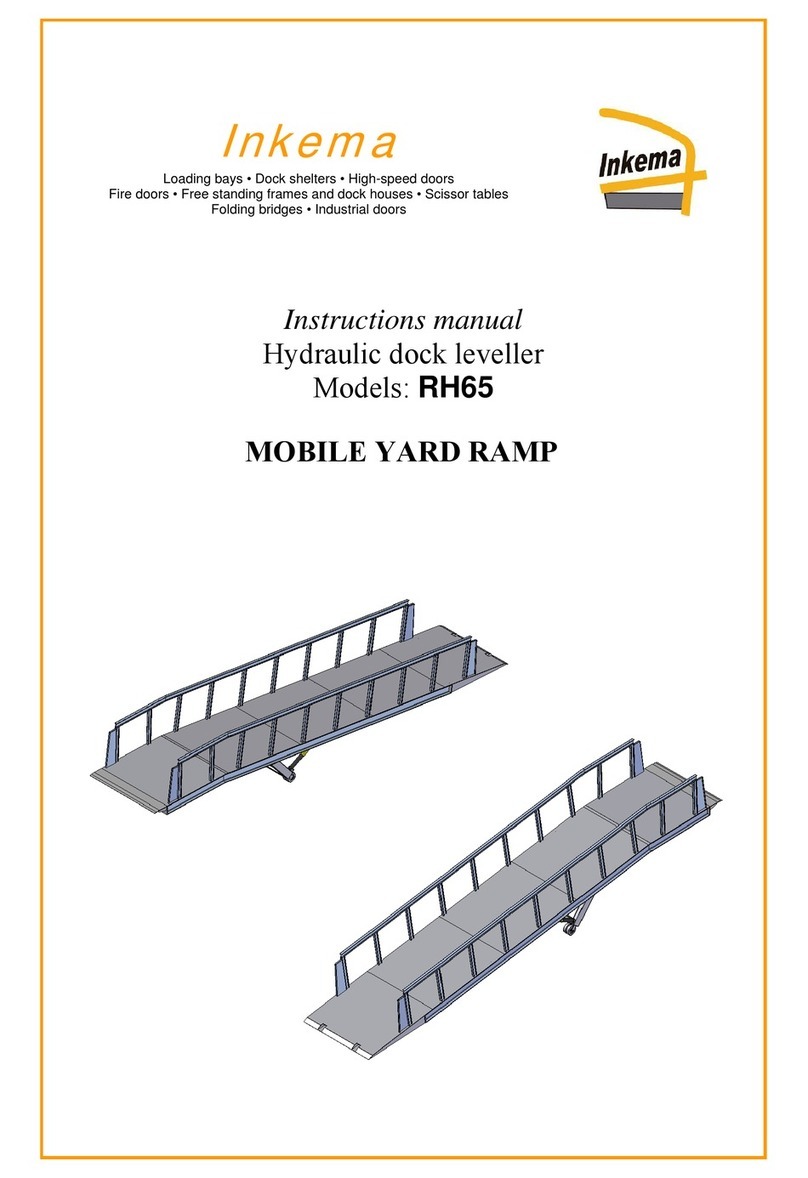

2-DESCRIPTION............................................................................................................4

3-UNPACKING & SETUP................................................................................................5

3.1 DELIVERY AND CHECK OF PACKAGES ..................................................................................... 5

3.2 LIFTING AND HANDLING.......................................................................................................... 5

3.3 PREPARATION ......................................................................................................................... 5

4 SPECIFICATIONS .......................................................................................................6

5-FLOOR REQUIREMENTS ............................................................................................6

5.1 SELECTING THE SITE AREA ..................................................................................................... 6

5.2 FLOOR REQUIREMENTS ........................................................................................................... 6

5.3 IMPORTANT CONCRETE AND ANCHORING INFORMATION ..................................................... 7

5.4 ANCHORING TIP SHEET........................................................................................................... 7

6-INSTALLATION INSTRUCTIONS................................................................................8

7-OPERATION INSTRUCTIONS...................................................................................15

7.1 DEFECTS / MALFUNCTIONS....................................................................................................15

7.2 CONTROLS..............................................................................................................................15

7.3 OPERATION.............................................................................................................................16

8-MAINTENANCE........................................................................................................18

8.1 MAINTENANCE SCHEDULE .....................................................................................................18

8.1.1 DAILY ....................................................................................................................................................................................... 18

8.1.2 WEEKLY ................................................................................................................................................................................... 18

8.1.3 MONTHLY................................................................................................................................................................................ 19

8.1.4 BIMONTHLY............................................................................................................................................................................ 19

8.1.5 YEARLY .................................................................................................................................................................................... 19

8.1.6 EVERY OTHER YEAR.............................................................................................................................................................. 19

8.2 MAINTENANCE BY OPERATOR ...............................................................................................20

8.2.1 HYDRAULIC SYSTEM ............................................................................................................................................................ 20

8.2.2 GREASING POINTS................................................................................................................................................................ 20

8.2.3 OPERATION AND WEAR CHECKS ....................................................................................................................................... 21

8.2.4 LIFT STABILITY...................................................................................................................................................................... 21

8.3 CLEANING ...............................................................................................................................21

9-TROUBLESHOOTING ...............................................................................................22

10-OWNER/EMPLOYER RESPONSIBILITIES................................................................23

11-DIAGRAMS (FIG. 1-11)...........................................................................................24

FIG. 1 - EXPLODED PARTS VIEW ...................................................................................................24

FIG. 2 - ADAPTERS .......................................................................................................................26

FIG. 3 - CARRIAGE ........................................................................................................................27

FIG. 4-1 - CABLE ...........................................................................................................................28

FIG. 4-2 - CROSSBEAM.................................................................................................................28

FIG. 5 - SAFETY LOCKS.................................................................................................................29

FIG. 6 - HOSES/POWER UNIT ........................................................................................................30

FIG. 7 - CABLES / PULLEYS...........................................................................................................31

FIG. 8 - POWER UNIT.....................................................................................................................32

FIG. 9 - HYDRAULICS ....................................................................................................................33

FIG. 10 - ELECTRICAL ...................................................................................................................34

FIG. 11 - DIMENSIONS ..................................................................................................................35