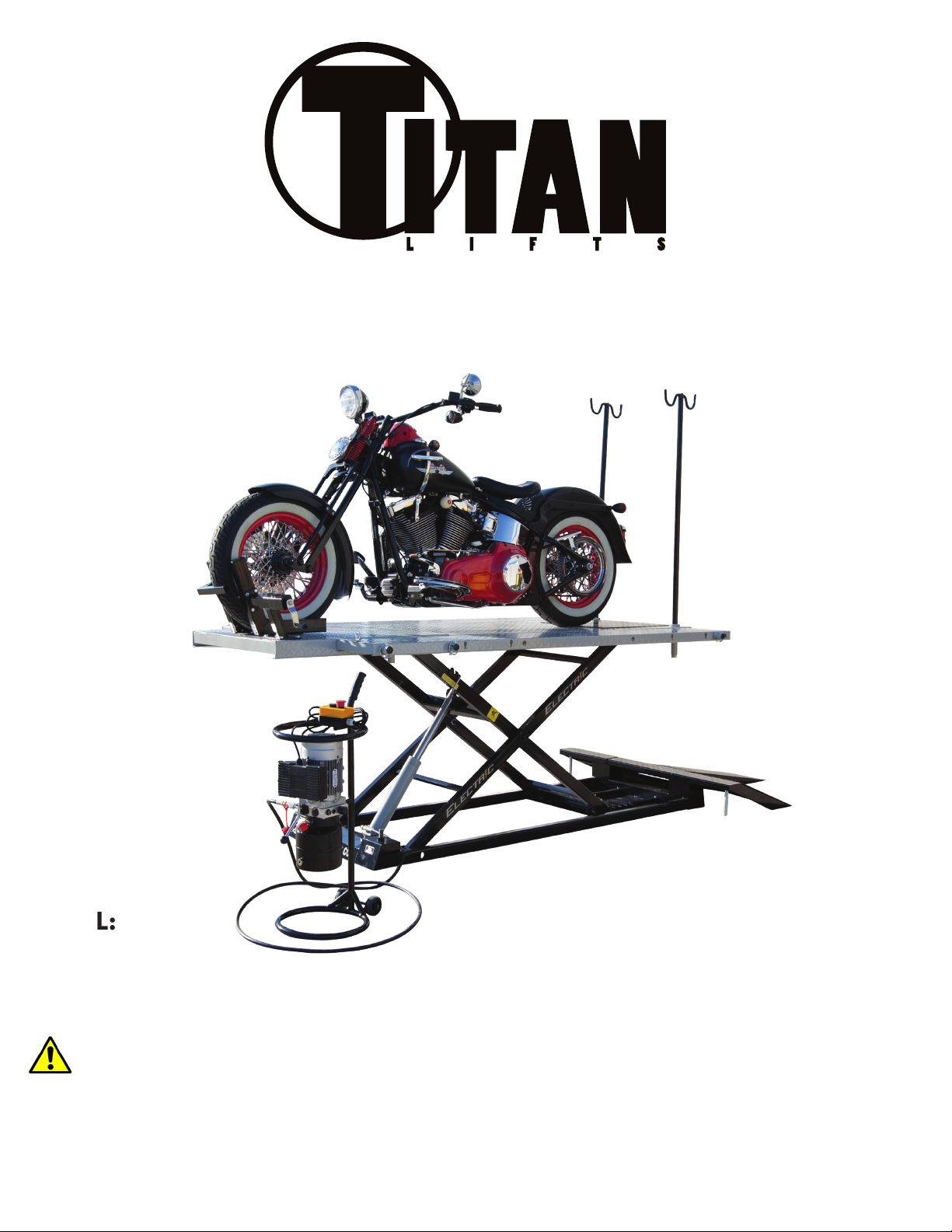

Titan Lifts HDML-1500XLT-E Instruction manual

INSTALLATION, OPERATION,

& MAINTENANCE MANUAL

MODEL:

HDML-1500XLT-E

1,500 LB CAPACITY ELECTRIC MOTORCYCLE/ATV LIFT

FOLLOW THIS MANUAL CAREFULLY TO ENSURE THE MACHINE WILL

FUNCTION CORRECTLY AND PROVIDE MANY YEARS OF DEPENDABLE SERVICE.

FAILURE TO FOLLOW THESE INSTRUCTIONS AND SAFETY WARNINGS MAY

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE. USE OF STRAPS IS

RECOMMENDED - SOLD SEPARATELY. KEEP THIS MANUAL IN A SAFE DRY PLACE

FOR FUTURE REFERENCE.

®

PO Box 7069 Greenwood, IN 46142

1.888.908-4826 FAX (317) 215.2770

www.titanlifts.com

TITAN MARKETING, LLC

®

To Our Valued Customers:

Thank you for purchasing a Titan Lifts®product. We hope this high quality equipment provides you with years of

dependable service.

It is unfortunate that rare situations may occur with the products you purchase from Titan Lifts®. We value your

business as well as the trust you have and need to maintain your relationship with us. Titan Lifts®carries liability

coverage that may protect our customers if a situation does occur. However, as in all accidents there must be

proof of liability for a claim to be made. Our insurance company requires the following procedures be observed in

order to consider a claim:

A. The claimant must contact the Titan Lifts®distributor immediately with the facts of the situation.

B. If any equipment is damaged, including vehicles or shop equipment, Titan Lifts®must be given the

opportunity to send an impartial representative to the site for proper assessment of the situation.

C. The Vehicle cannot be moved until either an impartial representative has reviewed the accident or clear

and precise pictures are taken that reect all the pertinent information for an impartial representative to be able

to access the information from a distance. Titan Lifts®or its representatives must approve the pictures before

anything can be moved.

D. If any potential liability is determined on behalf of Titan Lifts®, two estimates must be submitted for

damages to be reimbursed.

It is imperative that the claimant complies with these procedures, because without proper assessment of the

situation a claim will be denied.

ARBITRATION NOTICE

The installation or use of this equipment shall constitute an acknowledgement that the user agrees to resolve any

and all disputes or claims of any kind whatsoever, which relate in any way to the equipment, by way of binding

arbitration, not litigation. No suit or legal action may be led in any state or federal court. Any arbitration shall be

governed by the Federal Arbitration Act, and administered by the American Mediation Association, Indianapolis

Indiana. The maximum amount that an arbitrator may award and all damages shall not exceed the retail value of

this equipment.

WARRANTY NOTICE

This equipment must be assembled and used in the manner according to the documentation provided to be

covered by warranty.

Damaged or missing components must be reported within 72 hours of receipt to your freight carrier and to the

distributor. Claims must be led to cover cost.

If you have any questions or if we can be of any further assistance, please don’t hesitate to contact a Titan Lifts®

representative at 1-888-908-4826. Thank you for the opportunity to continue to serve your lift equipment needs.

CONTENTS

INSTRUCTIONS................................................................................................................. 1

OPERATION & MAINTENANCE ......................................................................................... 2

SAFETY PRECAUTIONS.................................................................................................... 3

PARTS LIST (FIG. 1) .......................................................................................................... 4

PARTS LIST (FIG. 1) - CONTINUED ................................................................................... 5

RAM PARTS DETAIL (FIG. 2)............................................................................................. 6

POWER UNIT (FIG. 3) ........................................................................................................ 7

ROLLER DROP-OUT PARTS DETAIL (FIG. 4)..................................................................... 8

CHECKING & FILLING HYDRAULIC FLUID ........................................................................ 9

BLEEDING.......................................................................................................................... 9

1

INSTRUCTIONS

WARNING: READ ENTIRE MANUAL AND COMPLY WITH ALL SAFETY AND SERVICE

PRECAUTIONS. DEATH, PERSONAL INJURY AND/OR PROPERTY DAMAGE MAY OCCUR IF

INSTRUCTIONS ARE NOT FOLLOWED CAREFULLY.

UNPACKING AND SET-UP *REFER TO PARTS LIST FIG. 1

1. Carefully unpack the lift making sure that all of the parts have been included.

2. Remove the lift and all parts from delivery pallet and place on a clean, solid at surface.

3. Take end of black Hydraulic Hose and attach to the Power Unit Assembly (67).

4. Remove the ll cap from the power unit and ll the oil tank reservoir between the minimum and

maximum range on the ll cap dipstick. To ll the oil tank reservoir, the lift must be completely

lowered. Fill the oil tank with a permium quality IS0-32 or AW-46 Hydraulic oil.

5. Plug the hydraulic power unit into a standard 110V - 120V 60Hz AC outlet. Unit must be

plugged into a dedicated circuit on a 15 amp circuit breaker. Raise the lift by pressing the green

button on the control panel to expose the top of Casters (22). Note: If the lift is not raising

level, check to make sure that the Wheels (42) are in their tracks.

6. Use the provided Allen wrench and place in top of Casters (22) and turn it clock-wise. Lower all

four casters until the lift rolls freely.

7. If using the Front Extension (9), slide the Front Extension over the front of the Deck Plate. Use

the second and third Connecting Bars (5) and secure to the Deck Plate with the Quick Pins (3)

or use Short Connecting Bar (68) without Side Extensions.

8. If using Side Extensions (7) then use the Connecting Bar (5) to assemble the Side Extensions

(7) to the Deck Plate (8) securing them with the Quick Pins (3). Slide the Side Extensions (7) to

the Deck Plate (8).

9. Take Ramp Stands (43) and screw into Bottom Ramps (44) and (46). Place the Extension

Ramp (47) over matching holes on the Center Ramp (45).

10. Take the Fixed Clamp (10) and bolt to location “B” on the Deck Plate (8) or Front Extension (9)

Using Bolts (11), Washers (12), Lock Washers (13), and Nuts (14) (Optional Equipment).

11. Take the Crank Assembly (69) and bolt to location “C” on the Deck Plate (8) or Front Extension

(9) using Bolts (11), Washers (12), Lock Washers (13) and Nuts (14). Bolt Moveable Clamp (16)

to Crank Assembly (69) using the provided Bolts (70) (Optional Equipment).

12. Insert the Tire Stop (15) onto the Fixed Clamp (10) using the Pin (60)(Optional Equipment).

13. Place Stands (1) on holes located on the end of the Deck Plate (8).

14. If necessary, raise or lower the Adjustment Legs (6) to make the lift Deck Plate (8) level with

the Ramps.

NOTE: The Stands (1) are for holding up a motorcycle with rear wheel removed. (Straps not

provided but should be used).

NOTE: Standard Dropout Plate (2) can be removed for easy rear wheel removal.

NOTE: Roller Dropout Plate (4) can be installed after motorcycle is loaded for easy rear

wheel cleaning or maintenance.

WARNING: Roller Dropout Plate (4) must be removed prior to unloading the

motorcycle from the lift & replaced with the Standard Dropout (2). Do NOT operate

motorcycle on Roller Dropout (4). Roller Dropout (4) is NOT to be used as a dyno device.

2

OPERATION & MAINTENANCE

*REFER TO PARTS LIST FIG. 1

* TEST THE LIFT SEVERAL TIMES FOR PROPER OPERATION BEFORE ATTEMPTING TO LIFT A LOAD.

1. Raise Casters (22) to lower lift off Casters (22) onto solid surface.

2. Roll motorcycle onto Deck Plate (8) until Wheel is inside the Clamp (10 & 16).

3. Tighten the Clamp to the tire by using the crank handle on the Moveable Clamp (16).

4. Load must be centered on the table at all times.

5. Load must be rmly positioned and secured on the table at all times.

6. WARNING: Do NOT raise the Deck Plate (8) higher than the highest locking position.

7. IMPORTANT: After reaching the desired working height, make sure the Handle (27) is

down in order to make the Safety Plate (61) set in the safety lock for your protection.

Press the Release Handle to set the Safety Plate (61) into the safety lock position.

8. When nished working, raise the lift to release pressure off the Safety Plate and pull the

Handle (27) up, and then press the Release Handle to lower the lift.

9. All moving parts have been lubricated at the factory and should be re-lubricated before

the rst use and at least once every six months to prevent damage.

10. Lightly oil cylinder rod at least once every six months or when it becomes dry.

11. Do NOT use this product if worn or damaged. Examine lift for structural cracks, bends,

or other signs of damage prior to each use. Check all hoses and connections before

each use to ensure proper working condition.

12. Keep lift clean, dry, and well maintained to extend longevity of the product.

If the lift does not appear to be working properly, follow bleeding instructions, pg 10.

WARNING: DO NOT LOAD THE MOTORCYCLE ONTO DECK PLATE (8) WITH

THE ROLLER DROPOUT (4) INSTALLED. USE THE STANDARD DROPOUT PLATE (2)

WHEN LOADING MOTORCYCLE.

WARNING: HANDLE (27) SHOULD BE MOVED DOWN ALL THE WAY WHEN

THE LIFT IS IN THE RAISED POSITION AND THE SAFETY SUPPORT PLATE (61)

LOCKED SO THE LIFT WILL NOT LOWER.

WARNING

The warnings, precautions and instructions in this manual cannot

cover all possible conditions and situations that may occur. The

operator must understand that the operator must supply common

sense and examine caution factors when using this product to

determine safety in all circumstances being used.

3

SAFETY PRECAUTIONS

1. Load should not exceed rated capacity for this lift - 1,500lb

2. Make sure the handle is in the down position and the safety plate is set in the safety

lock while the lift is in the raised position.

3. Move the lift only when it is lowered.

4. Do NOT ride vehicle onto lift.

5. Only trained people should operate the lift.

6. Power Unit pump should be at least 3 feet away when operating. Remain clear of the lift

when raising or lowering.

7. Indoor use recommended.

8. Do NOT move lift while loaded.

9. Keep hands, tools and other extremities from under carriage and moving parts.

10. Maintain a safe working environment. The work area should be clean, dry, clutter free

and sufciently lit.

11. Wear proper ANSI-approved safety attire. Do NOT wear loose tting clothing while

operating lift, long hair and sleeves should be secured.

12. Keep children and bystanders away from work area. Do NOT let children operate or play

on lift.

13. Do NOT use if under the inuence of drugs or alcohol. Operator must be alert at all

times when using heavy lift equipment.

14. Never operate the lift with someone on it.

Do NOT adjust safety valve.

15. Use this lift only for the work it is intended. Do NOT use this product for an application

for which it was not designed. Misuse can lead to personal injury and/or property

damage.

16. Industrial applications must follow OSHA requirements.

17. Do NOT use for aircraft purposes.

18. Have your lift serviced by a qualied technician using only identical Titan Lifts®

replacement parts and attachments. This will ensure that the safety of the lift is

maintained.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. THE MANUFACTURER OR DISTRIBUTOR

DOES NOT MAKE ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE PERFORMED BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Product’s Serial Number:____________________________________________________________________

Note: If product does not have a serial number, record the month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available individually as

replacement parts.

4

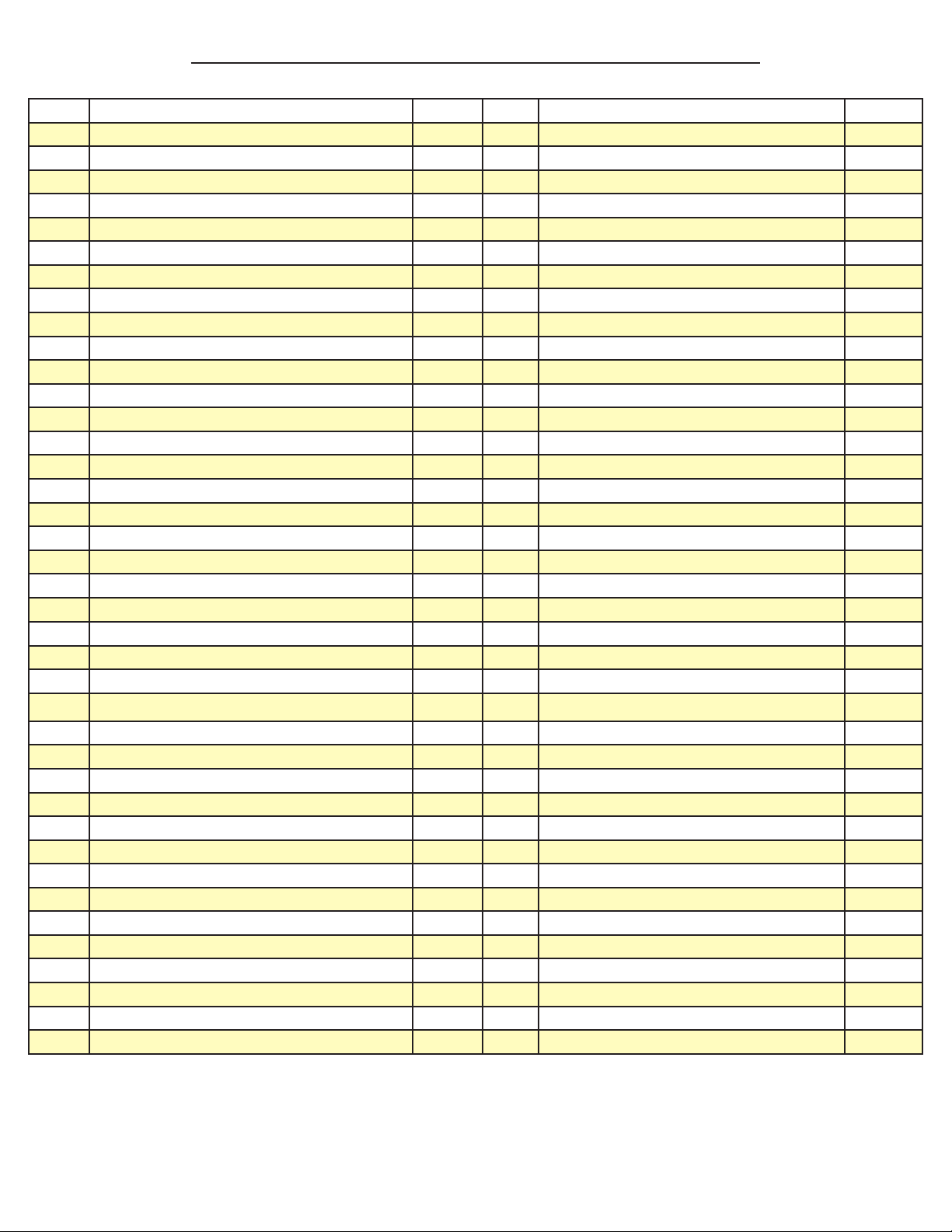

PARTS LIST (FIG. 1)

PLEASE MAKE SURE TO CONFIRM THAT ALL PARTS ARE INCLUDED.

5

PARTS LIST (FIG. 1) - CONTINUED

NO. DESCRIPTION QTY NO DESCRIPTION QTY

1 STAND POLE 2 40 RETAINING NUT M8 1

2 STANDARD DROPOUT PLATE 1 41 SAFETY CABLE LOCK BOLT 1

3 QUICK PIN 6 42 WHEEL 4

4 ROLLER DROP OUT PLATE (See Fig. 4) 1 43 RAMP STAND 2

5 CONNECTING BAR 3 44 RAMP-LEFT 1

6 ADJUST LEG 2 45 RAMP-CENTER 1

7 SIDE EXTENSIONS ( RIGHT & LEFT) 2 46 RAMP-RIGHT 1

8 DECK PLATE 1 47 EXTENSION RAMP 1

9 FRONT EXTENSION 1 48 PIN 1

10 FIXED CLAMP (COLOR) 1 49 WHEEL 2

11 BOLT M10*25 10 50 RETAINING RING Φ12 2

12 WASHER Φ10 12 51 PUMP BED-FRAME 1

13 EYE BOLT 4 52 COUPLING RING 1

14 NUT M10 14 53 ELECTRIC HYDRAULIC PUMP 1

15 TIRE STOP (COLOR) 1 54 BLOCK TERMINAL - GREEN 1

16 MOVABLE CLAMP (COLOR) 1 55 EMERGENCY BUTTON - RED 1

17 CYLINDER (See Fig. 2) 1 56 CONTROL BUTTON - GREEN 1

18 RETAINING NUT M16 5 57 HANDLE SLEEVE 1

19 BOLT M16*80 1 58 THREE-PIN PLUG WITH WIRE 1

20 INNER HEXAGON SCREW M16*90 2 59 TOOL BOX 1

21 RETAINING RING Φ20 6 60 WHEEL STOP PIN 1

22 CASTER 4 61 SAFETY SUPPORT PLATE 1

23 BOLT M16*90 2 62 RUBBER VISE PAD - RIGHT 2

24 LINK ROD 1 1 63 RUBBER VISE PAD - LEFT 2

25 INNER HEXAGON SCREW M20*120 2 64 PLASTIC VISE END CAP - BLK 4

26 RETAINING NUT M20 2 65 PLASTIC WHEEL STOP END CAP - BLK 2

27 HANDLE 1 66 VISE HANDLE - PLASTIC 1

28 SPRING 1 67 PUMP ASSEMBLY (See Fig. 3) 1

29 NUT M8 1 68 SHORT CONNECTING BAR 1

30 BUSHING 1 69 CRANK ASSEMBLY (COLOR) 1

31 BASE ASSEMBLY 1 70 BOLT M8*16 4

32 SAFETY LOCK CABLE 1 71 *COMPLETE VISE ASSEMBLY (COLOR) 1

33 SAFETY LATCH 2 72 SCREW M4*15 4

34 LINK ROD 2 1 73 BOLT M10*20 2

35 NUT M8 1 74 LOCK WASHER Φ10 2

36 WASHER Φ8 8 75 COUPLING BOLT 1

37 LOCK WASHER Φ8 8 76 O-RING 1

38 BOLT M8*20 6 77 DUST CAP 1

39 ADJUST SCREW 1

*OPTIONAL EQUIPMENT

6

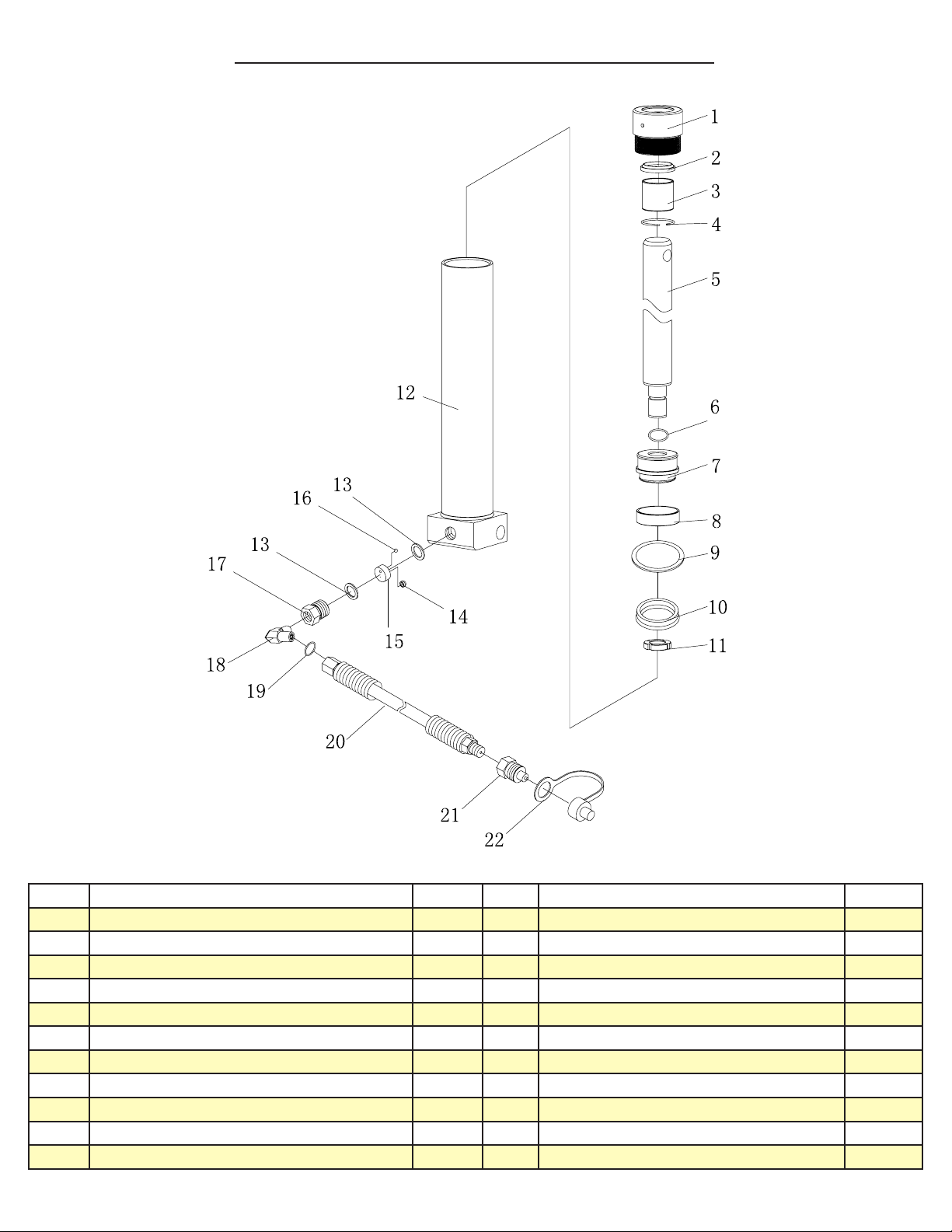

RAM PARTS DETAIL (FIG. 2)

NO. DESCRIPTION QTY NO DESCRIPTION QTY

1 RAM COVER 1 12 CYLINDER CASING (GREY) 1

2 DUST SEAL 1 13 WASHER 2

3 BACK-UP RING 1 14 FILLER NET 1

4 SPRING COLLAR 1 15 RELEASE VALVE 1

5 PISTON ROD 1 16 BALL 1

6 O-RING 1 17 ADAPTER FITTING 1

7 PISTON HEAD 1 18 90 DEGREE FITTING 1

8 PISTON RING 1 19 O-RING 1

9 SEAL GASKET 1 20 HYDRAULIC HOSE 1

10 OIL SEAL 1 21 HYDRAULIC HOSE FITTING 1

11 ROUND NUT 1 22 DUST CAP 1

7

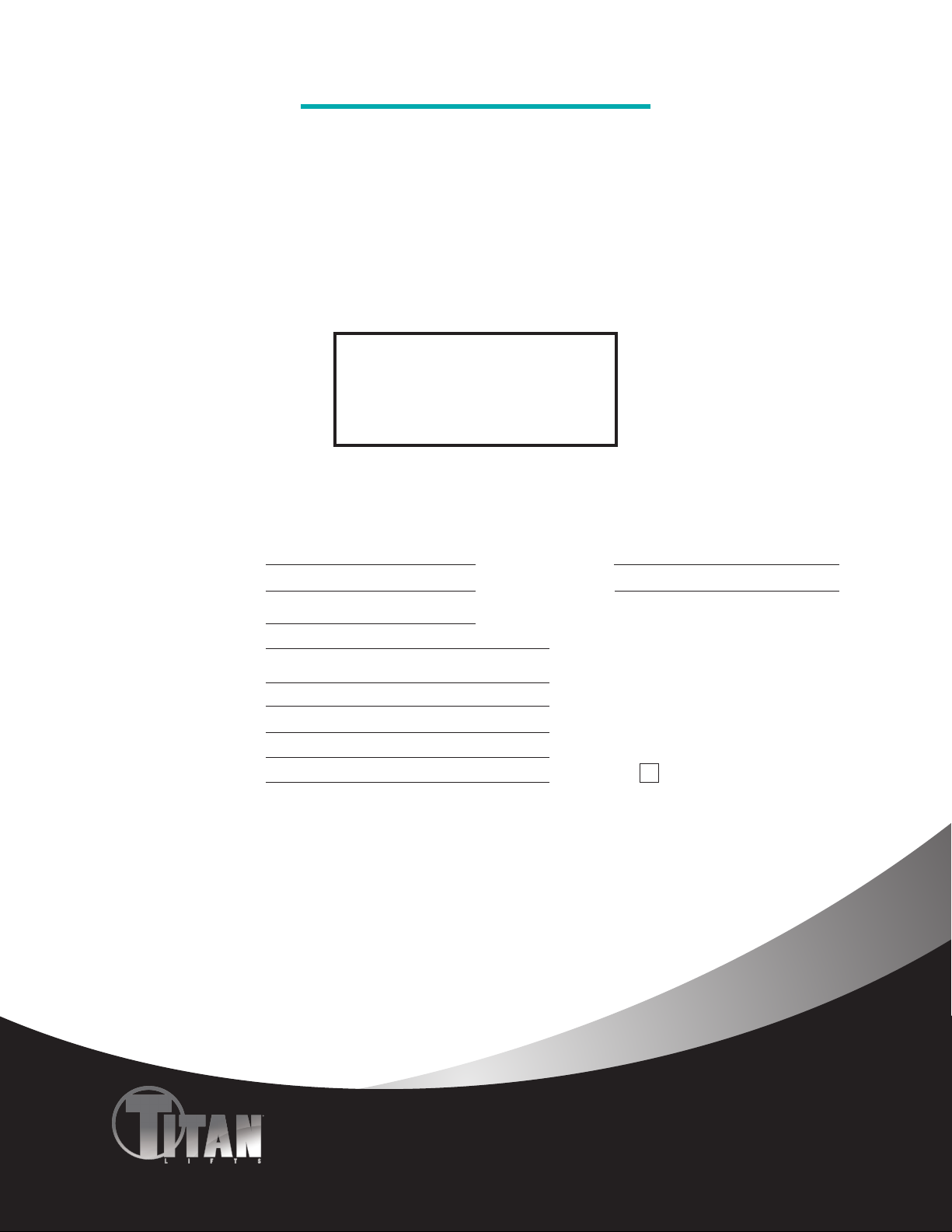

POWER UNIT (FIG. 3)

NO. DESCRIPTION QTY NO DESCRIPTION QTY

12 WASHER Φ10 1 57 HANDLE SLEEVE 1

49 WHEEL 2 58 THREE-PIN PLUG WITH WIRE 1

50 RETAINING RING Φ12 1 72 SCREW M4*15 4

51 PUMP BED-FRAME 1 73 BOLT M10*20 2

52 COUPLING RING 1 74 LOCK WASHER Φ10 2

53 ELECTRIC HYDRAULIC PUMP 1 75 COUPLING BOLT 1

54 BLOCK TERMINAL - GREEN 1 76 O-RING 1

55 EMERGENCY BUTTON - RED 1 77 DUST CAP 1

56 CONTROL BUTTON - GREEN 1

8

ROLLER DROP-OUT PARTS DETAIL (FIG. 4)

NO. DESCRIPTION QTY

01 DROPOUT PLATE (COLOR) 1

02 RETAINING NUT M8 4

03 BEARING 4

04 ROLLER 2

05 PIN 2

06 BUSHING 4

9

BLEEDING

CHECKING & FILLING HYDRAULIC FLUID

NOTE: If the lift appears not to be working properly, it may be necessary to bleed trapped

air from the hydraulic system.

1. Check uid level. Replace Fill Cap.

2. Depress and hold release handle.

3. Press the button to raise the lift while depressing the release handle.

4. Let up on release handle.

5. Raise the lift. If the lift does not elevate smoothly, repeat steps 2-5.

1. Lower the lift completely. Remove the ll cap.

2. The oil level should be even within the minimum and maximum range on the ll cap

dipstick.

3. If the uid level is low, add premium quality ISO-32, AW-46 hydraulic oil. DO NOT USE

ANY OTHER FLUID OR BRAKE FLUID.

EQUIPMENT MODEL:

TYPE OF POWER UNIT:

DATE OF PURCHASE:

PLACE PURCHASED:

NAME:

STREET:

CITY, STATE, ZIP:

PHONE:

EMAIL:

SERIAL NUMBER:

SERIAL NUMBER:

WARRANTY REGISTRATION

OPT OUT OF PROMOTIONS

In order to utilize the warranty on this Titan Lifts product, you must register your product with us. The

simplest way to do this is to visit TITANLIFTS.COM/WARRANTIES and submit your information online. If you

prefer to send your information through the mail, please ll out the form below and send this page to us at :

Titan Lifts

PO Box 7069

Greenwood, IN 46142

In order to receive your warranty, return this card

or visit TITANLIFTS.COM/WARRANTIES within 30 days.

P.O. Box 7069 • Greenwood, IN 46142 • Ph. 888-908-4826 • Fx. 317-215-2770 • www.titanlifts.com

LIMITED WARRANTY

The Titan 2 Post lifts, 4 Post lifts and Bridge Jacks are backed by a standard 1-year replacement parts warranty and a 5-year

structural warranty from the date of purchase, to the original purchaser only. The 1-year replacement parts warranty covers power

units, hydraulic cylinders, and all other assembly components such as, but not limited to: turn plates, slip plates, cables, chains,

valves, switches etc. This does not cover normal wear items such as, but not limited to: rubber lifting pads and nylon slide blocks.

Titan Elite model lifts have been discontinued but still qualify under the same terms as shown above.

Titan SL-6600 Scissor Lifts and PREMIER Series 2 Post Lifts are backed by a 2-year replacement parts warranty and a 5-year

structural warranty from the date of purchase, to the original purchaser only. The 2-year replacement parts warranty covers power

units, hydraulic cylinders, and all other assembly components such as, but not limited to: valves, switches, capacitors etc. This does

not cover normal wear items such as, but not limited to: rubber lifting pads, nylon slide blocks and rubber arm pads.

Titan MRL-6000 Scissor lifts are backed by a standard 1-year replacement parts warranty and a 5-year structural warranty from

the date of purchase, to the original purchaser only. The 1-year replacement parts warranty covers power units, hydraulic cylinders,

and all other assembly components such as, but not limited to: valves, switches, capacitors etc. This does not cover normal wear

items such as but not limited to rubber lifting pads.

Titan ROT-4500 Rotisseries are backed by a standard 1-year replacement parts warranty from the date of purchase, to the original

purchaser only. The 1-year replacement parts warranty covers components such as, but not limited to: hydraulic cylinders, caster

assemblies, bearings etc. This does not cover normal wear items such as, but not limited to, mounting adapters.

Titan Standard Duty and Heavy Duty motorcycle lifts are backed by a standard 1-year replacement parts warranty from the date of

purchase, to the original purchaser only. The 1-year replacement parts warranty covers power units, hydraulic cylinders, pneumatic

cylinders, and all other assembly components such as, but not limited to: cables, caster wheels, valves, switches, wheel vises etc.

This does not cover normal wear items such as, but not limited to: rubber wheel vise pads.

Titan Light Duty motorcycle lifts are warrantied for replacement parts only to the original purchaser for a period of 90 days from

the date of purchase. This 90 day replacement parts warranty covers items such as, but not limited to: hydraulic cylinder, casters,

pedal assemblies, wheel vises etc. This does not cover normal wear items such as, but not limited to: rubber wheel vise pads.

Titan Bulldog Moto Cradle Wheel Chock is warrantied for replacement parts, only to the original purchaser, for a period of 2-years

from the date of purchase.

XL Tool by Titan Wheel Service Machines and Helper Arm Assemblies are backed by a standard 1-year replacement parts

warranty from the date of purchase, to the original purchaser only. The 1-year replacement parts warranty covers internal boards,

motors, pneumatic cylinders, and all other assembly components such as, but not limited to: cabinet, switches, valves, ttings etc.

This does not cover normal wear items such as but not limited to: rubber pads, jaw protectors, air hoses, quick nut assemblies.

Titan shop equipment products and accessories are warrantied for replacement parts only to the original purchaser for a period of

90 days from the date of purchase. This 90 day replacement parts warranty covers products such as but not limited to: EZ -Mover

Jacks, Mini Jacks, tie down products, wheel service accessories, Bulldog Moto Cradle Wheel Chock accessories, dollies, stands,

Multi-purpose Jacks, etc.

Titan TJ1T, FJ2T, and FJ3T are warrantied for replacement parts only to the original purchaser for a period of 1 year from the date

of purchase.

For all warranty considerations, Titan Marketing, LLC will supply replacement parts only during the warranty period. The original

purchaser is responsible for all shipping, handling, and any labor charges incurred. Hydraulic/Pneumatic cylinders may qualify

for exchange under warranty if reported within the rst 30 days from date of sale. After the rst 30 days from date of sale, a seal

kit and installation instructions will be sent for cylinder repairs. All defective parts must be returned to Titan for inspection and

examination. Any parts that are found to be defective will be replaced or repaired to proper working order. Other items not listed

above may be considered general wear parts and therefore, will not be covered under warranty. These warranties do not extend to

defects caused by ordinary wear, abuse, misuse, shipping damage, improper installation, voltage or lack of required maintenance.

Titan Marketing, LLC is not to be held responsible for any failure that results from an accident, purchaser/operator abuse, neglect,

or failure to operate products in accordance with instructions provided in the owner’s manual(s) supplied. Damage caused by rain,

excessive humidity, corrosive environments or other contaminants are not covered under warranty. THESE WARRANTIES DO NOT

EXTEND TO ANY COSMETIC DEFECT NOT INTERFERING WITH EQUIPMENT FUNCTIONALITY OR ANY INCIDENTAL, INDIRECT, OR

CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF A TITAN

MARKETING LLC PRODUCT OR THE BREACH OR DELAY IN PERFORMANCE OF THE WARRANTY.

WARNING

The warnings, precautions and instructions in this manual cannot

cover all possible conditions and situations that may occur. The

operator must understand that the operator must supply common

sense and examine caution factors when using this product to

determine safety in all circumstances being used.

®

PO Box 7069 Greenwood, IN 46142

1.888.908-4826 FAX (317) 215.2770

www.titanlifts.com

TITAN MARKETING, LLC

Copyright © 2018 by Titan Marketing, LLC. All rights reserved. No portion of this manual or any artwork contained herein may be

reproduced in any shape or form without the express consent of Titan Marketing, LLC. Diagrams within this manual may not be

drawn proportionally. Due to continuing improvements, actual product may dier slightly from the product described herein. Tools

required for assembly and service may not be included.

Patent No.: US 8,104,588 B2

CA 2,729,670 5/7/18

Table of contents

Other Titan Lifts Lifting System manuals

Titan Lifts

Titan Lifts MD-1250-XL Instruction manual

Titan Lifts

Titan Lifts HD2P-15000C Instruction manual

Titan Lifts

Titan Lifts XML-300 Instruction manual

Titan Lifts

Titan Lifts HD2P-12000F Instruction manual

Titan Lifts

Titan Lifts PREMIER Series Instruction manual

Titan Lifts

Titan Lifts HD2P-9000AC Instruction manual

Titan Lifts

Titan Lifts RJ-6K-HP Instruction manual

Titan Lifts

Titan Lifts HD2P-10000AC-D Instruction manual

Titan Lifts

Titan Lifts Master Series Instruction manual

Titan Lifts

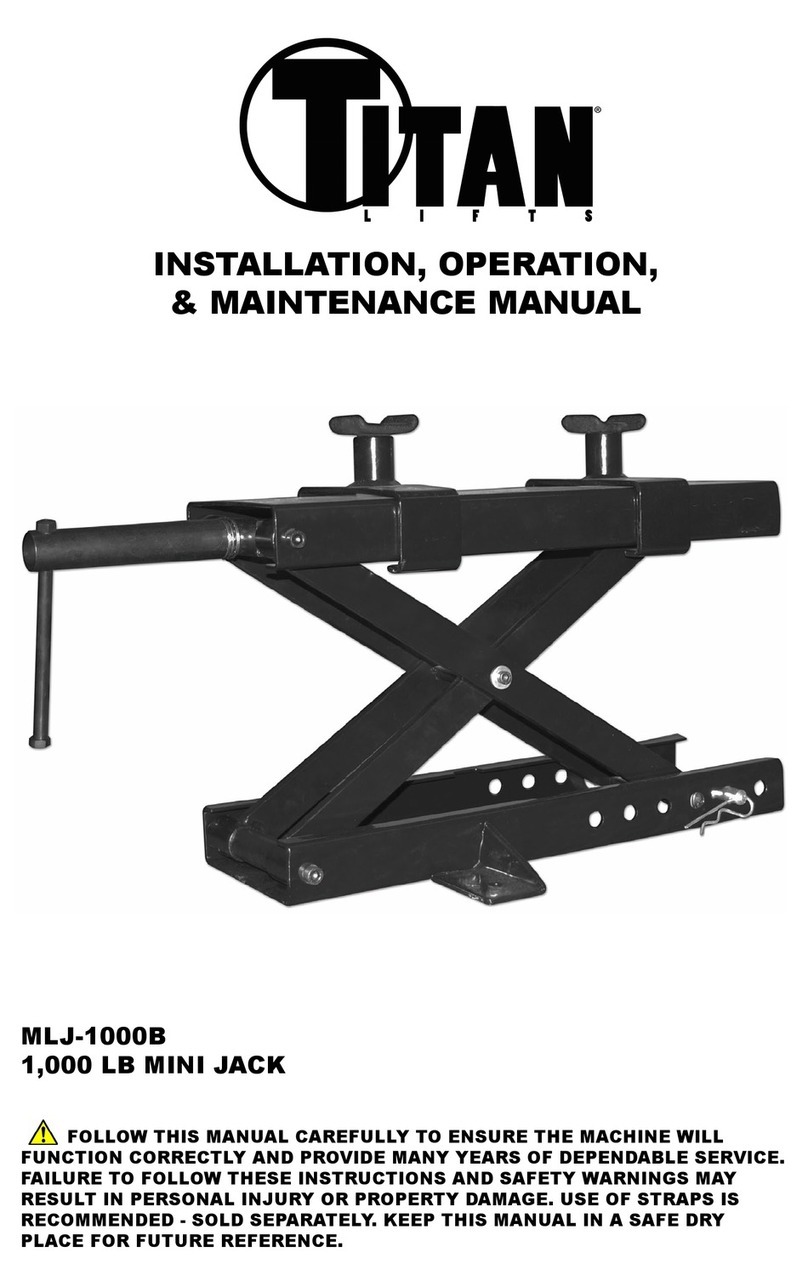

Titan Lifts MLJ-1000B Instruction manual