5/18

9

4. After making sure the conveyor is cleared off and the drive pulley is moving the belt in the correct direction,

run the conveyor. Take up slack belt with the take-up provided until there is no slippage between the drive

pulley and the belt.

A GENERAL RULE FOR CORRECT BELT TENSION IS THAT THE BELT MUST BE

TIGHT ENOUGH TO MOVE YOUR PRODUCT AT FULL LOAD. OVERTIGHTENING

OF THE BELT WILL CAUSE THE BELT, PULLEYS, BEARINGS, AND DRIVE

COMPONENTS TO WEAR OUT PREMATURELY.

III. MAINTENANCE

BELT TRACKING

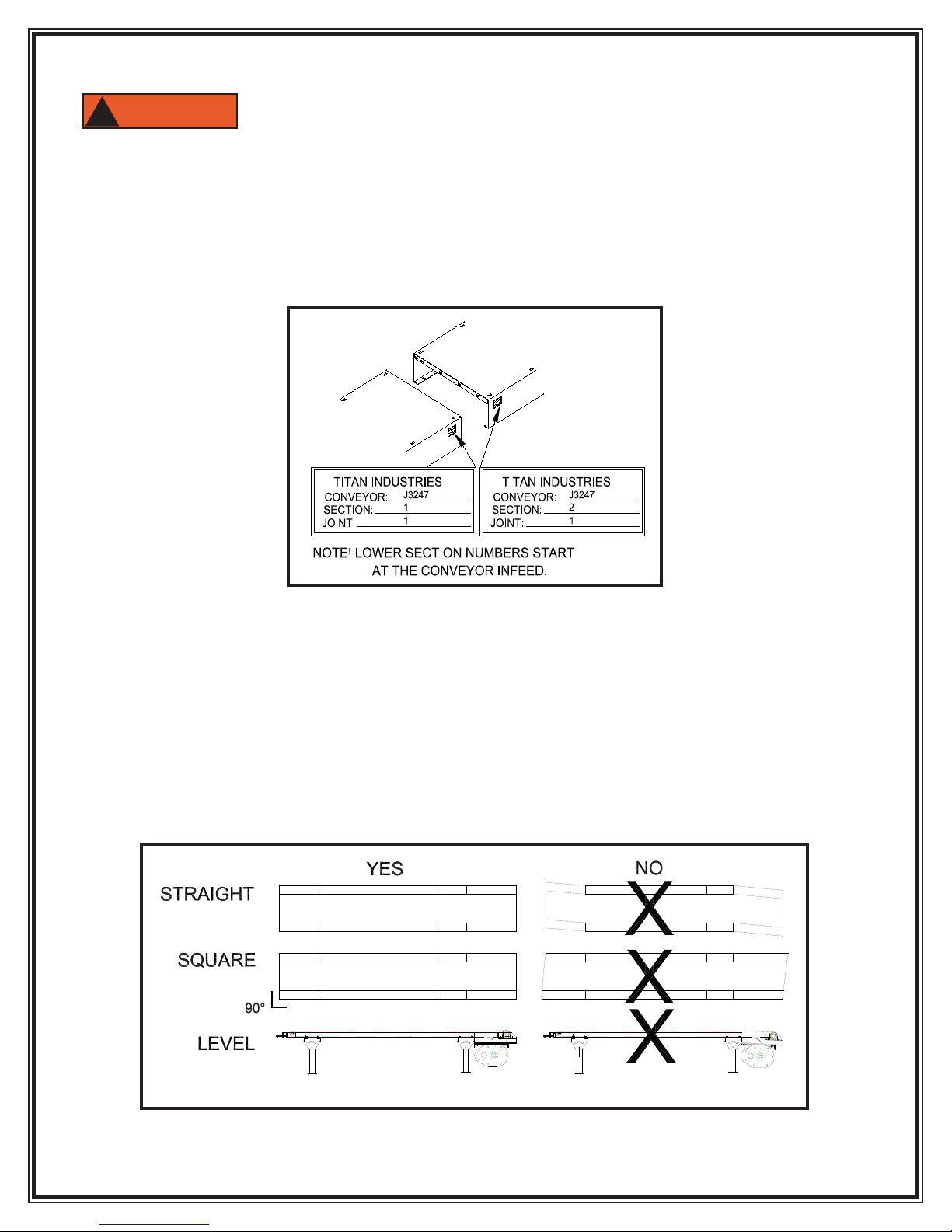

1. Level all frames crosswise.

2. Square the tail pulley.

3. Square all troughing and return idlers.

4. Make sure the belt splice is square.

5. Adjust individual troughing or return idlers as needed.

After completing the above steps, test the belt at a slow running speed. Then load the belt with material and continue

testing until normal operating speed and conditions cause no deviation from central running. Start with a light load

and gradually work up to the load that the conveyor was designed to handle. Adjustments to the loading chute may

be required to ensure that the load is being centered on the belt.

IDLER MAINTENANCE

All regreasable idler series use the same principle: One shot-grease through, with a standard alemite 1627-B on

one end and a bushing-pressure relief tting combination on the other end. If a change in the greasing side of the

idler is needed after the idler is installed, the ttings are interchangeable.

• The idler rolls are lled with grease from at the factory. Idlers that have been stored for longer periods of time

need to be purged and re-lled with grease.

• Idlers should be re-lubricated every 800 – 1000 hours unless running in extremely dirty or wet conditions where

more frequent greasing would be required.

• Do not over-grease! More idlers fail from over-greasing than from lack of grease. Make sure all ttings are

cleaned before and after greasing.

• Re-lubrication should not be done when outside temperature is below freezing. Grease is sluggish and stiff at

these temperatures and may cause internal damage.

• Roller grease seals are designed to hold in grease while there is pressure in the idler lubrication system. When

grease passes through all three rolls, the pressure relief t restricts the ow, causing internal pressure that results

in greasing being purged through the bearings. At a maximum pressure of 25 lbs. the relief tting releases; thus

protecting seals from excessive pressure. Leakage may occur around the outside ring of the seals. This is known

as star burst or starring. This will ush the contaminants away from the bearing