Titon CME3 Q Plus A User manual

Other Titon Fan manuals

Titon

Titon solitude User manual

Titon

Titon TP221T User manual

Titon

Titon CME1 User manual

Titon

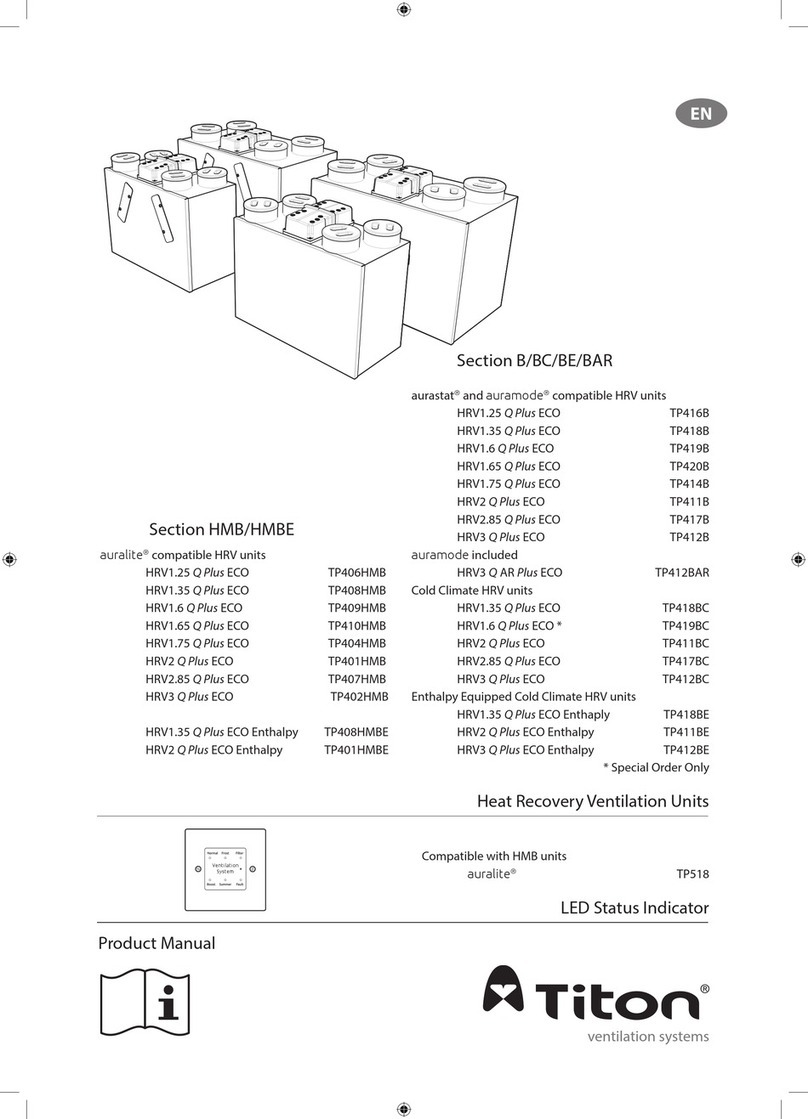

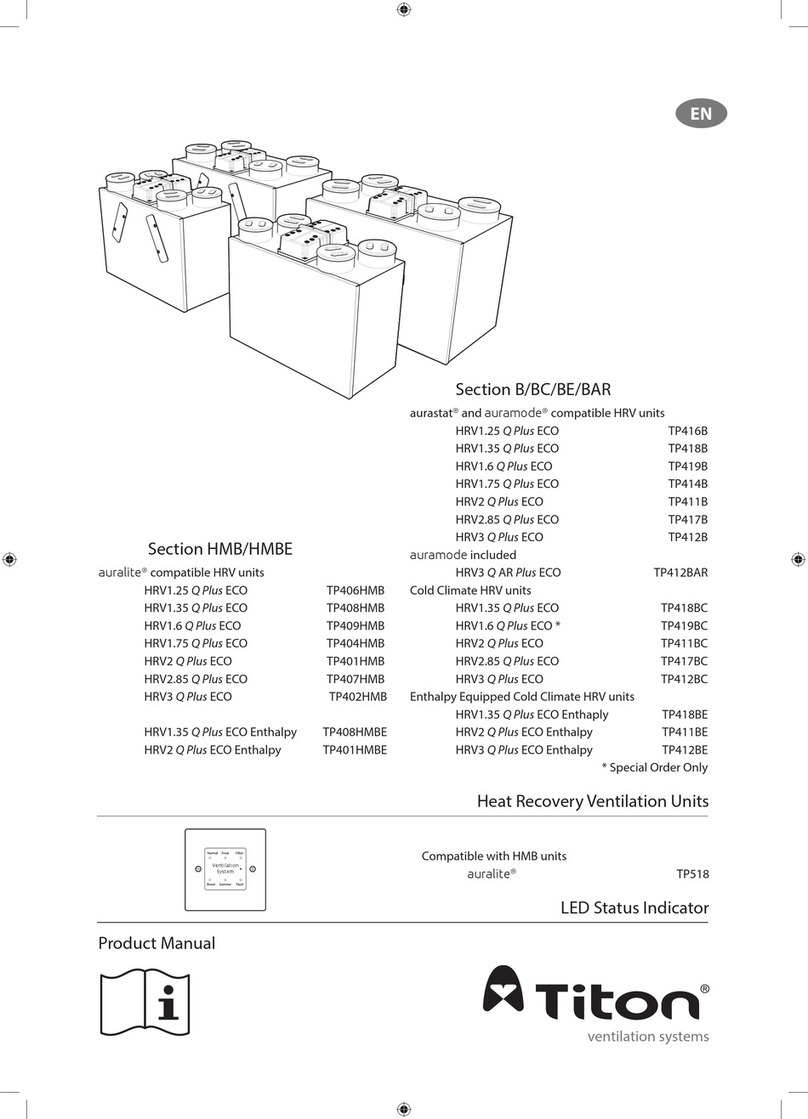

Titon HRV1.25 Q Plus ECO Installation instructions

Titon

Titon TP408HMBE User manual

Titon

Titon HRV1.35 Q Plus ECO Assembly instructions

Titon

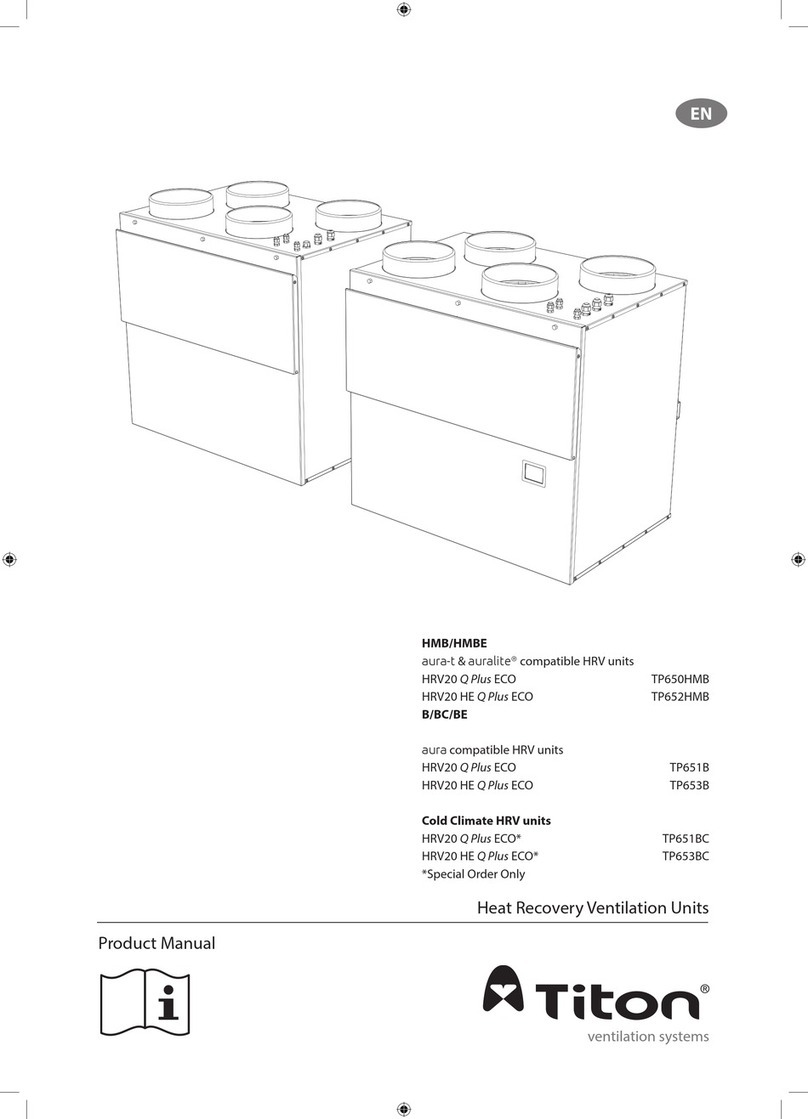

Titon HRV20 Q Plus ECO User manual

Titon

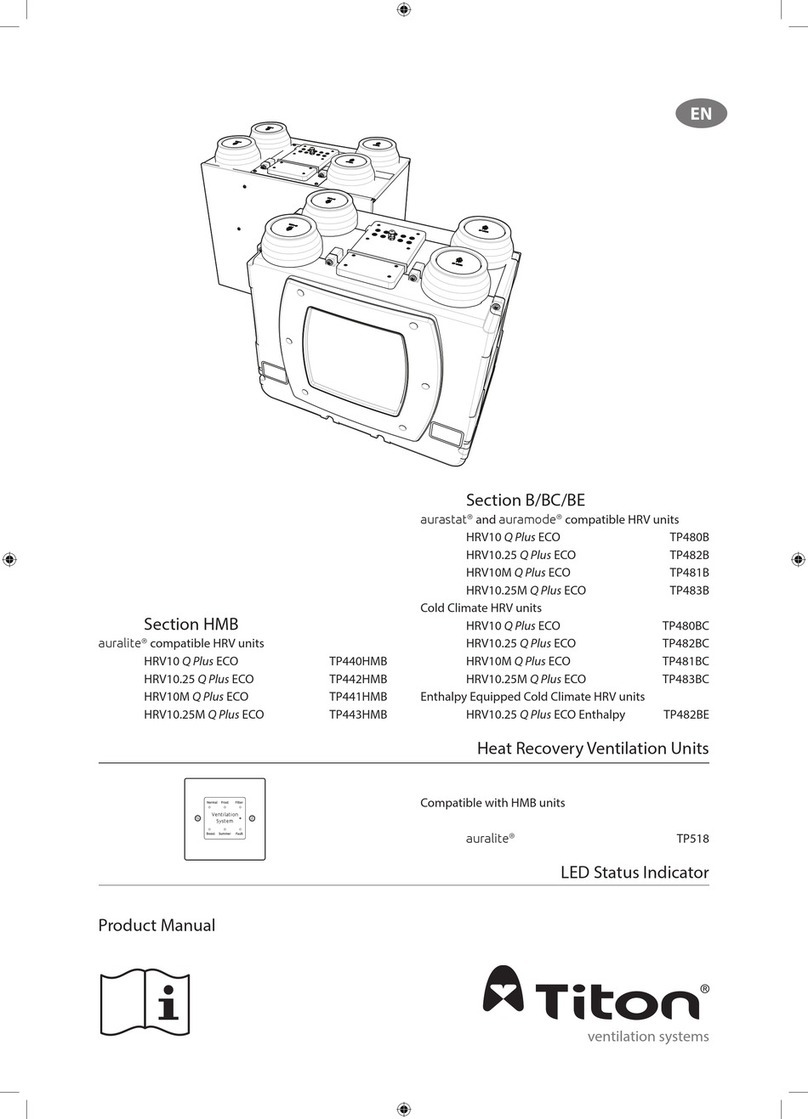

Titon HRV10.25 Q Plus ECO User manual

Titon

Titon WCME100 User manual

Titon

Titon CME3Q+ Owner's manual

Titon

Titon CME3.1Q+ User manual

Titon

Titon CME MEV User manual

Titon

Titon MVHR User manual

Titon

Titon PIV L3 User manual

Titon

Titon HRV1.25 QPtus ECO User manual

Titon

Titon TP440MB User manual

Titon

Titon TP302A User manual

Titon

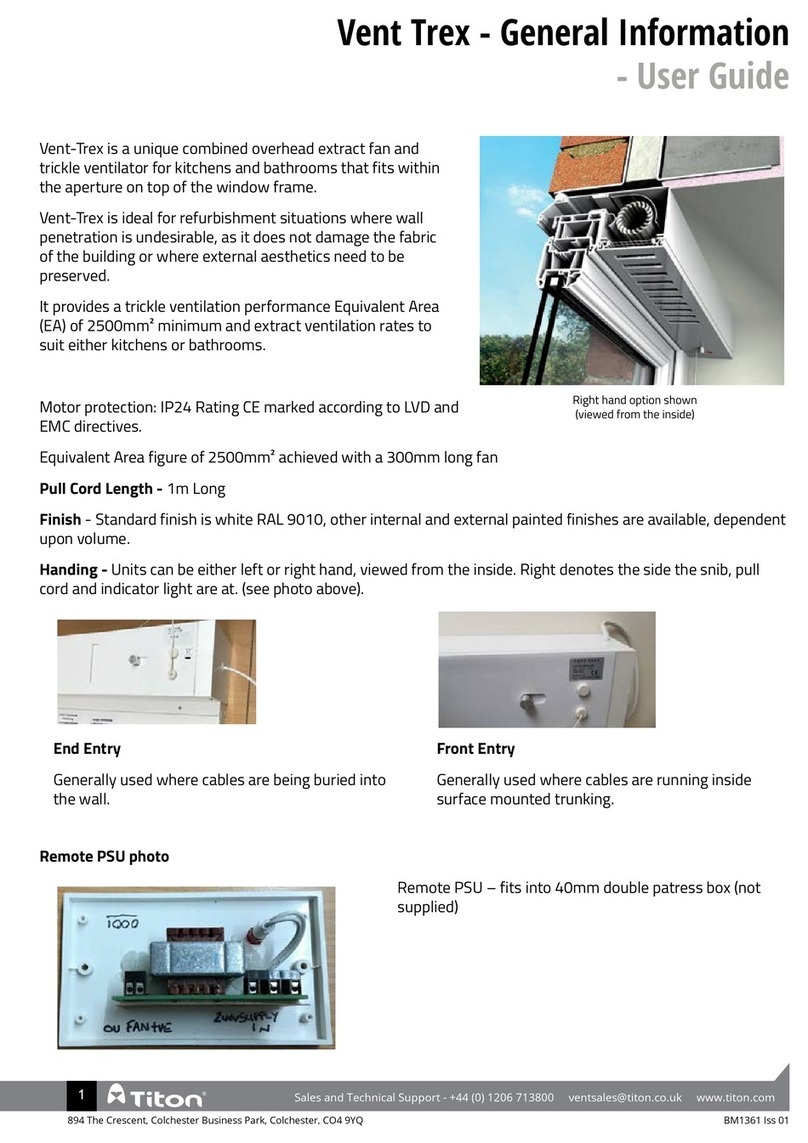

Titon Vent Trex User manual

Titon

Titon CME2Q+ Owner's manual

Titon

Titon Titon Ultimate dMEV User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions