TLV A-DR20-2 User manual

172-65634MAJ-03 (A-DR20) 6 October 2021

Direct-acting Pressure Reducing Valve for Air

A-DR20-2/A-DR20-6/A-DR20-10

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-65634MAJ-03 (A-DR20) 6 Oct 2021

1

Contents

Introduction .......................................................................1

Safety Considerations.......................................................2

Specifications....................................................................4

Acceptable Operating Range............................................4

Configuration.....................................................................5

Correct Usage of the A-DR20 Direct-acting Pressure

Reducing Valve.................................................................6

Installation.........................................................................8

Adjustment ......................................................................10

Maintenance....................................................................10

Disassembly....................................................................11

Reassembly ....................................................................14

Troubleshooting ..............................................................15

TLV EXPRESS LIMITED WARRANTY...........................17

Service............................................................................19

Introduction

Thank you for purchasing the TLV A-DR20 direct-acting pressure reducing

valve for air.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

The TLV A-DR20 is a direct-acting pressure reducing valve for air which

adopts a soft seat design on the main valve and minimizes the lockup

pressure*. It also provides a more stable secondary pressure than

conventional direct-acting reducing valves. The A-DR20 is designed for a long

service life, and is made of stainless steel for superior durability.

For products with special order specifications or options, if detailed

instructions for the special order specifications or options are not contained in

this manual, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the front

cover. It is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place

for future reference.

*Lockup pressure: The increase in set pressure that occurs after air-using equipment is shut

down by closing the inlet valve to the equipment

172-65634MAJ-03 (A-DR20) 6 Oct 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the

instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve opening/closing should be carried out only by trained

maintenance personnel.

The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance,

and repair. Furthermore, TLV accepts no responsibility for any accidents or

damage occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates an urgent situation which poses a threat of death or

serious injury

Indicates that there is a potential threat of death or serious injury

Indicates that there is a possibility of injury or equipment / product

damage

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Continued on the next page

DANGER

WARNING

CAUTION

CAUTION

172-65634MAJ-03 (A-DR20) 6 Oct 2021

3

Do not use excessive force when connecting threaded pipes to

the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

CAUTION

172-65634MAJ-03 (A-DR20) 6 Oct 2021

4

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

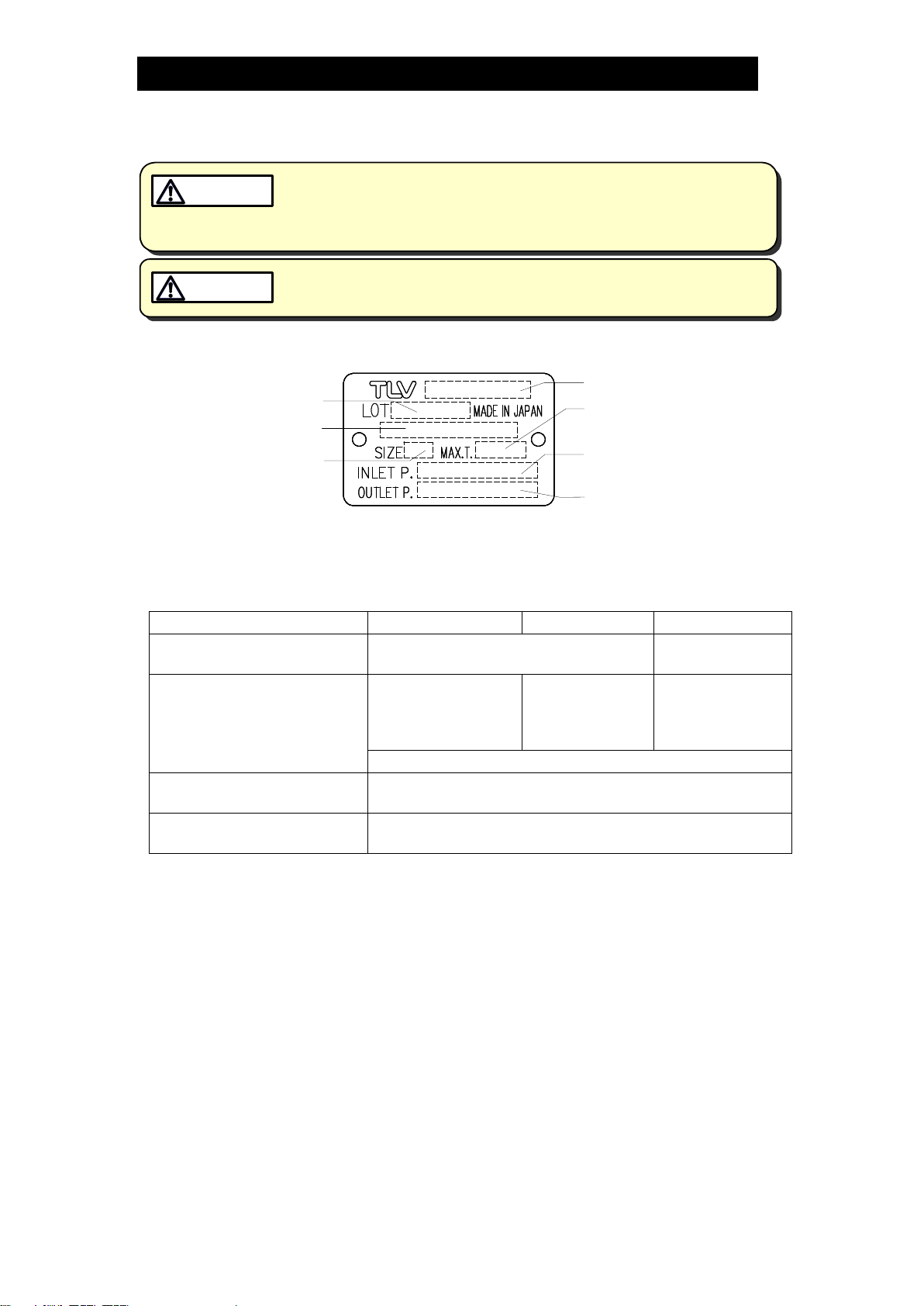

Refer to the product nameplate for detailed specifications.

* Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

Acceptable Operating Range

Model

A-DR20-2

A-DR20-6

A-DR20-10

Primary Pressure Range

0.2 –1.0 MPaG

(30 –150 psig)

0.6 –1.0 MPaG

(85 –150 psig)

Pressure Adjustable Range

0.014 –0.2 MPaG

(2 –30 psig)

(but limited to 1/30 of

primary pressure)

0.18 - 0.6 MPaG

(27 –85 psig)

0.54 –0.9 MPaG

(76 –125 psig)

No more than a maximum of 90% of the primary pressure

Maximum Operating

Temperature

100 °C (212 F)

Minimum Adjustable Flow

Rate

5% of the rated flow rate

(1 MPa = 10.197 kg/cm2)

Model

Nominal Diameter

Maximum Operating

Temperature

Valve No.*

Secondary Pressure

Adjustable Range

Primary Pressure

Range

Production Lot No.

172-65634MAJ-03 (A-DR20) 6 Oct 2021

5

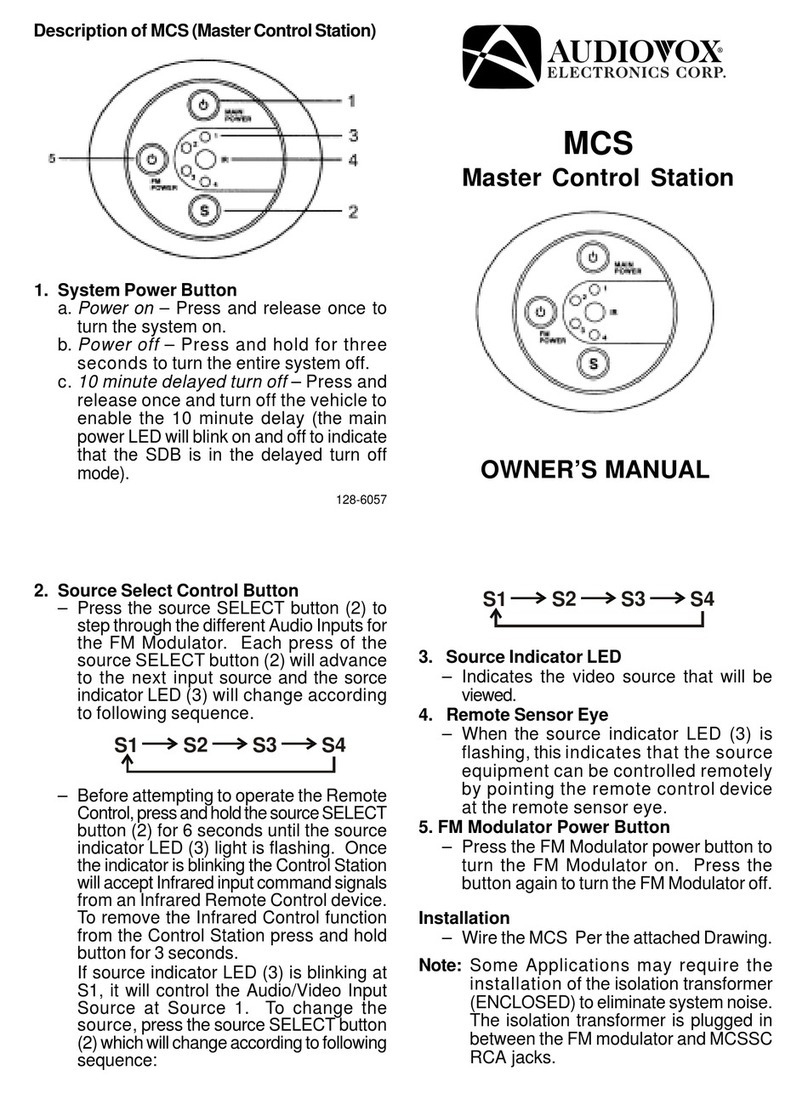

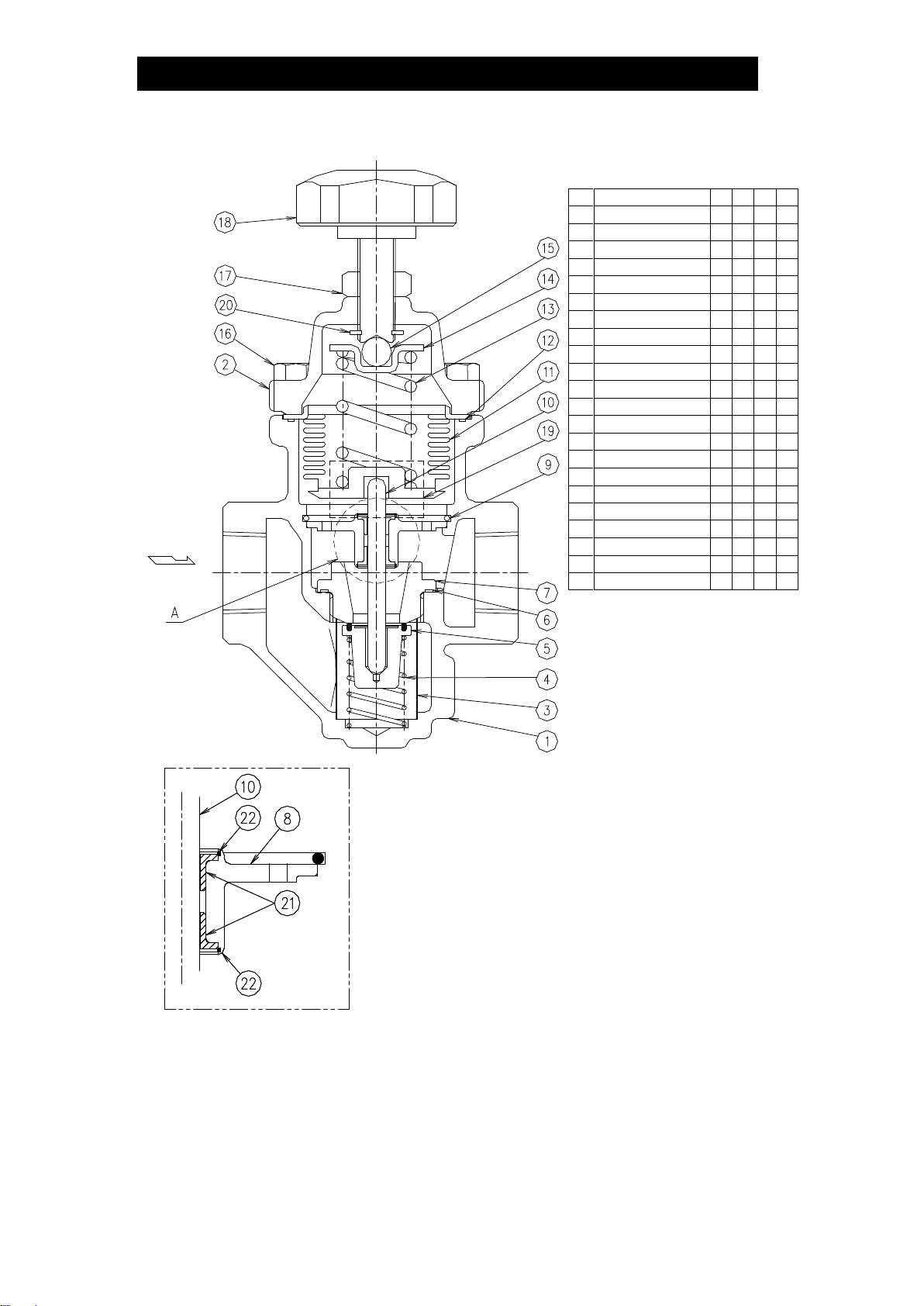

Configuration

No.

Name

A*1

B*1

C*1

D*1

1

Body

2

Cover

3

Screen

4

Coil Spring

5

Main Valve*2

6

Valve Seat Gasket

7

Valve Seat

8

Spacer*4

9

Snap Ring

10

Valve Stem

11

Bellows

12

Cover Gasket

13

Coil Spring

14

Spring Guide

15

Steel Ball

16

Cover Bolt

17

Locknut

18

AdjustmentHandle

19

Nameplate

20

Retaining Ring

21

Slide Bearing*3*4

22

Snap Ring*3*4

*1Replacement parts are

available only in the

following kits:

A: Maintenance Kit

B: Repair Kit for Spacer

C: Repair Kit for Main Valve

D: Repair Kit for Bellows

*2Rubber (standard: fluorine

rubber) is used in the

seating area. The rubber is

inlaid in the main valve.

*3Number of parts: 2 pieces

*4Shipped as a unit

Enlarged View of A

172-65634MAJ-03 (A-DR20) 6 Oct 2021

6

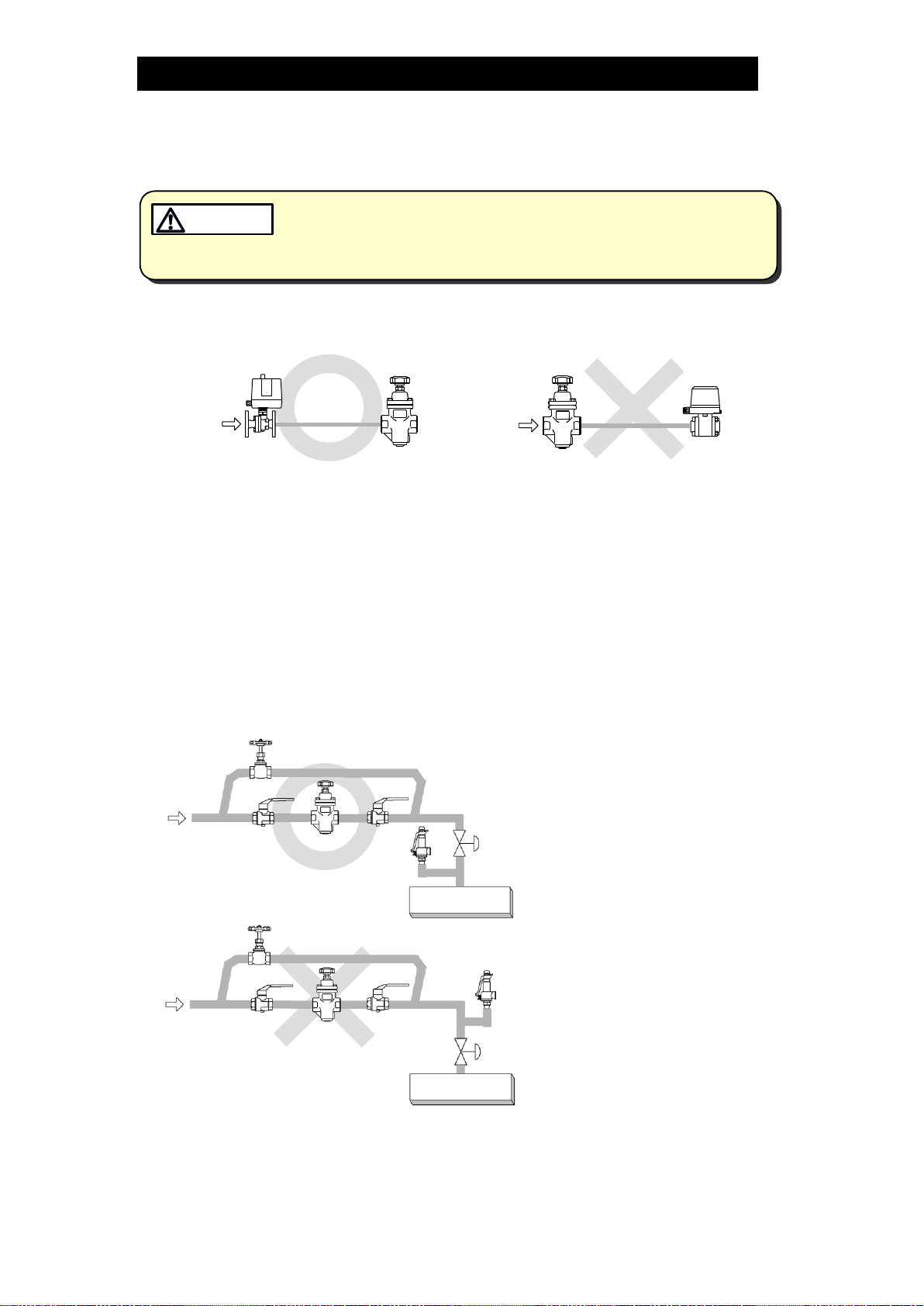

Correct Usage of the A-DR20 Direct-acting Pressure

Reducing Valve

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

1. The A-DR20 should be operated only within its specifications.

2. Installing an ON/OFF Valve (Solenoid Valve or Motorized Valve)

If an on-off valve is required to stop supply of air to the air-using equipment, install

it at the inlet side of the A-DR20.

If a solenoid valve is installed at the outlet of the A-DR20, it will cause heavy

chattering and may lead to damage of the A-DR20. (When the on-off valve opens,

the secondary pressure of the A-DR20 changes from zero to the set pressure.

Passing through an area of the reducing ratio of less than 30:1 where adjustment

is impossible, chattering occurs momentarily.) To save energy, install the on-off

valve as near to the boiler, or compressor, as possible.

NOTE: To prevent water hammer, it is recommended that a slow-acting motorized

on-off valve be used. If a fast-acting solenoid valve is used, the potential

water hammer effect can damage the air-using equipment and the

pressure reducing valve.

3. Installing a Control and/or Safety Valve

A control valve (i.e. for temperature

control) installed between the

A-DR20 and the air-using equipment

(downstream of the

A-DR20) may raise the pressure

between the A-DR20 and the control

valve when the control valve is

closed, depending on their proximity.

Therefore, this valve should be

installed close to the

air-using equipment, as illustrated.

Also, a safety valve should be

installed downstream of the control

valve.

NOTE: When installing a safety valve to protect the air-using equipment, be sure to

install it on, or directly before the inlet, of the air-using equipment. If the

safety valve is installed between the A-DR20 and a control valve, an

eventual pressure rise could activate the safety valve.

Inlet Side

A-DR20

Motorized Valve

Outlet Side

A-DR20 Solenoid Valve

A-DR20 Safety

Valve

Control

Valve

Air-using

Equipment

A-DR20

Safety

Valve

Control

Valve

Air-using

Equipment

172-65634MAJ-03 (A-DR20) 6 Oct 2021

7

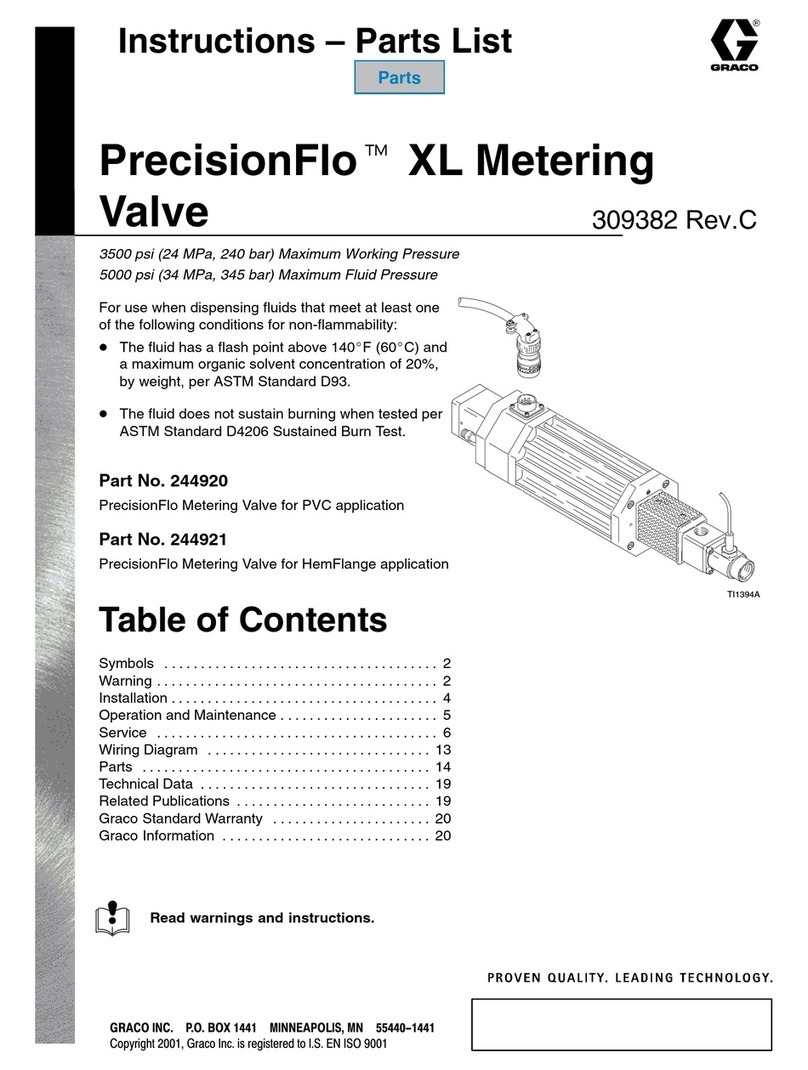

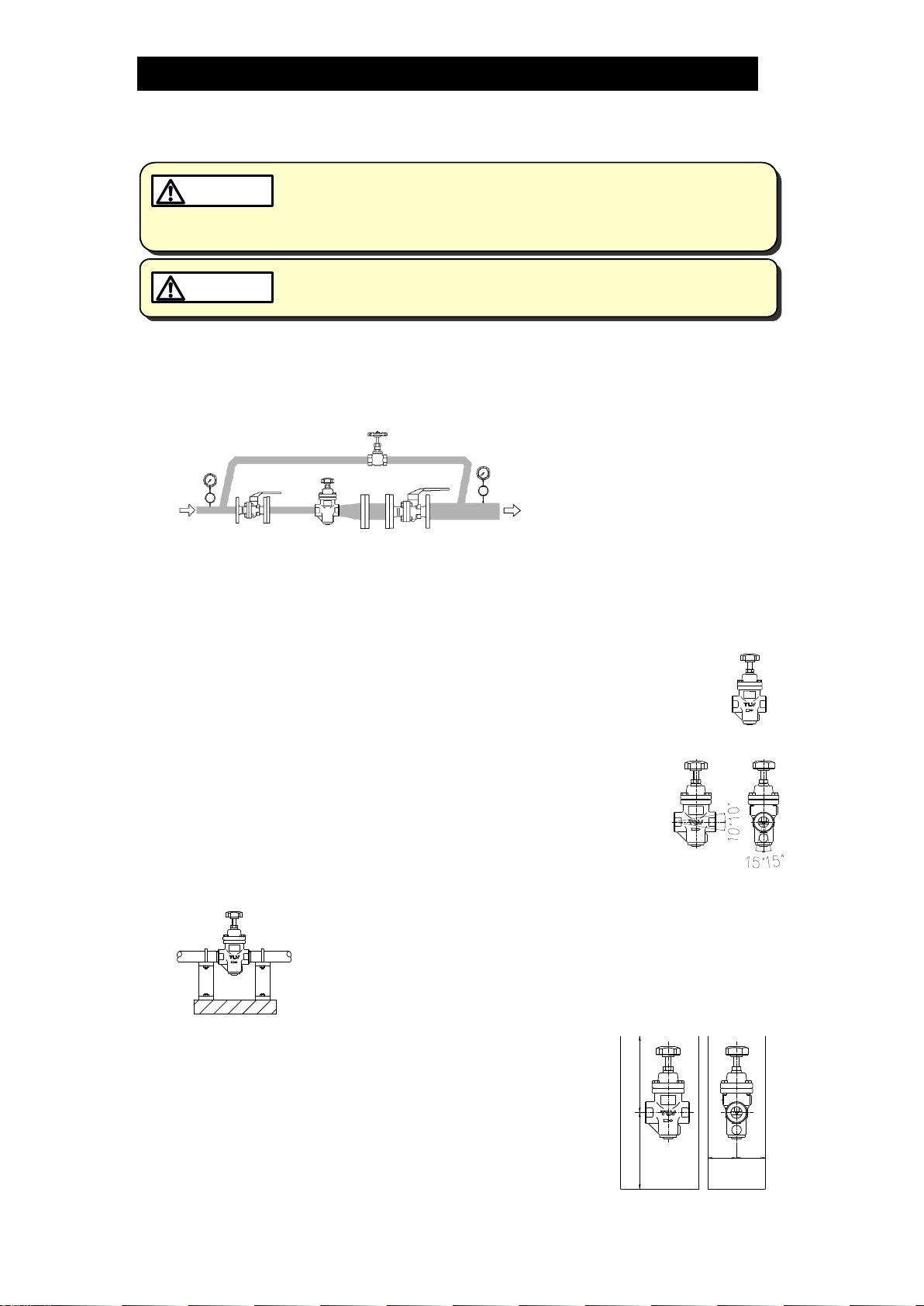

4. Recommended Straight Pipe Runs

In order to ensure a stable flow of air, the piping upstream and downstream of the

A-DR20 must be straight runs. If the A-DR20 is installed either directly before or

after an elbow or control valve, unevenness in flow may result in chattering and

unstable pressure.

To ensure a stable air flow, it is recommended that the A-DR20 be installed on

straight runs of piping, as illustrated below.

(1) Inlet (primary side) of the A-DR20 NOTE: d = pipe diameter

Maintain a straight piping

run of 10 d or more

when a manual valve, a

strainer or an elbow, etc.

is installed.

(Example: if nominal size

is 25 mm (1 in), have

250 mm (10 in) or more)

Maintain a straight piping

run of 30 d or more

when an automated

valve (on-off valve) is

installed.

(Example: if nominal size

is 25 mm (1 in), have

750 mm (30 in) or more)

Maintain a straight piping

run of 30 d or more

when another pressure

reducing valve is

installed. (Two-stage

pressure reduction)

(Example: if nominal size

is 25 mm (1 in), have

750 mm (30 in) or more)

(2) Outlet (secondary side) of the A-DR20

Maintain a straight piping

run of 15 d or more

when a manual valve, a

strainer or an elbow, etc.

is installed.

(Example: if nominal size

is 25 mm (1 in), have 375

mm (15 in) or more)

Maintain a straight

piping run of 30 d or

more when a safety

valve is installed.

(Example: if nominal size

is 25 mm (1 in), have 750

mm (30 in) or more)

10d or more

A-DR20

Valve, elbow,

strainer, etc.

A-DR20

Valve, elbow,

strainer, etc.

Less than

10d

Automated

Valve

A-DR20

30dor more

A-DR20

Automated

Valve

Less than

30d

30dor more

A-DR20

Pressure

Reducing

Valve

A-DR20

Pressure

Reducing

Valve

Less than

30d

A-DR20

15dor more

Valve, elbow,

strainer, etc.

A-DR20

Less than

15d

Valve, elbow,

strainer, etc.

A-DR20

30dor more

Safety Valve

Safety Valve

A-DR20

Less than

30d

172-65634MAJ-03 (A-DR20) 6 Oct 2021

8

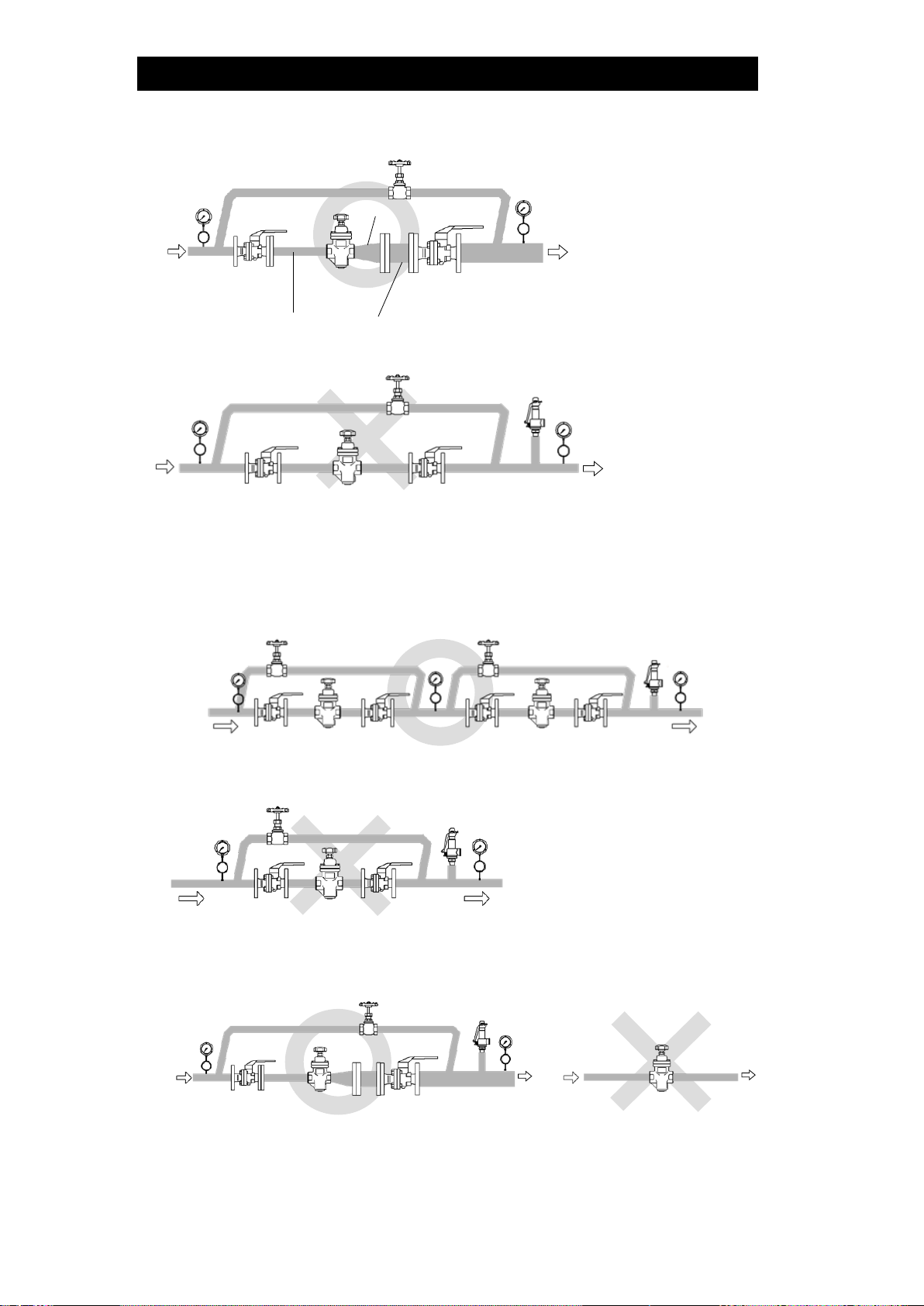

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Blowdown

Blowdown Using a Bypass Line

Before installing the A-DR20

unit, be sure to blow down all

piping thoroughly. If this is not

possible, perform a blowdown

using the bypass valve.

Blowdown is especially

important for newly installed

piping or after the system has

been shut down for a long

period of time.

2. Removing the Protective Caps

Before installation, be sure to remove all protective seals and caps

covering the product inlet and outlet.

(Found in 2 locations; on the product inlet and outlet.)

3. Installation Angle

4. Piping Support

Install the A-DR20, paying attention to avoid excessive load,

bending and vibration. Supporting the inlet and outlet pipes

securely.

5. Maintenance Space

Leave sufficient space for maintenance, inspection and

repair. (Unit: mm (in))

A-DR20

Open

Closed

Closed

Primary

Side Secondary

Side

Install the A-DR20 horizontally, so that the arrow mark on the

body is in the direction of flow. Allowable inclination is 10

degrees in the fore-aft direction and 15 degrees side to side in

the plane perpendicular to the air flow line.

150 (6)

150 (6)

150

(6) 150

(6)

172-65634MAJ-03 (A-DR20) 6 Oct 2021

9

6. Piping Size/Diffuser

If the secondary air flow

velocity is expected to be

more than 30m/s (100

ft/s), install a diffuser in

order to keep the flow

velocity below 30m/s

(100 ft/s). If the distance

between the A-DR20 and

the air-using equipment

is great, a possible drop

in pressure should be

taken into consideration

when selecting the piping

size.

In addition, when

installing the strainer, the

strainer screen should

be either at the 3 o’clock

or 9 o’clock position to

prevent condensate

accumulation..

7. Two-stage Pressure Reduction

Install a pressure reducing

valve at the inlet side of the

A-DR20 wherever the

pressure cannot be reduced

to the desired level with a

single A-DR20 due to

operating range limitations,

such as when the reduction

ratio is greater than 30:1.

8. Accessories

Always install a shut-off valve, pressure gauge and bypass lines at both inlet and outlet.

Ball valves, which will not retain condensate, are recommended for inlet and outlet shut-

off valves. The bypass pipe should be at least ½ of the size of the inlet (primary) pipe.

A-DR20

Open

Closed

Closed

Primary

Side Secondary

Side

Diffuser

Straight piping: 10d or longer upstream,

15d or longer downstream

(d: nominal diameter)

A-DR20

Primary

Side Secondary

Side

A-DR20

Primary

Side Secondary

Side

Pressure

Gauge

Bypass Valve

Inlet

Valve Outlet

Valve

Safety Valve

(Relief Valve)

Pressure

Reducing

Valve

Bypass Valve

Inlet

Valve Outlet

Valve

Pressure

Gauge

Primary

Side Secondary

Side

A-DR20

Pressure

Gauge

Inlet

Valve Outlet

Valve

Safety Valve

(Relief Valve)

Bypass Valve

Pressure

Gauge

A-DR20

Primary

Side Primary

Side

A-DR20

Secondary

Side Secondary

Side

172-65634MAJ-03 (A-DR20) 6 Oct 2021

10

Adjustment

To avoid problems such as water hammer and to protect air-using equipment, the

A-DR20 should be properly adjusted.

1. It is necessary to blow down all pipe lines thoroughly.

The blowdown is especially important if the line is new or has been shut down for a

long period of time. Take particular care to ensure that matter such as condensate

and dirt does not remain inside the air-using equipment.

(Stay clear of any pressurized blow-out from the safety valve.)

2. Make sure that the shut-off and bypass valves

located upstream and downstream of the

A-DR20 are completely closed.

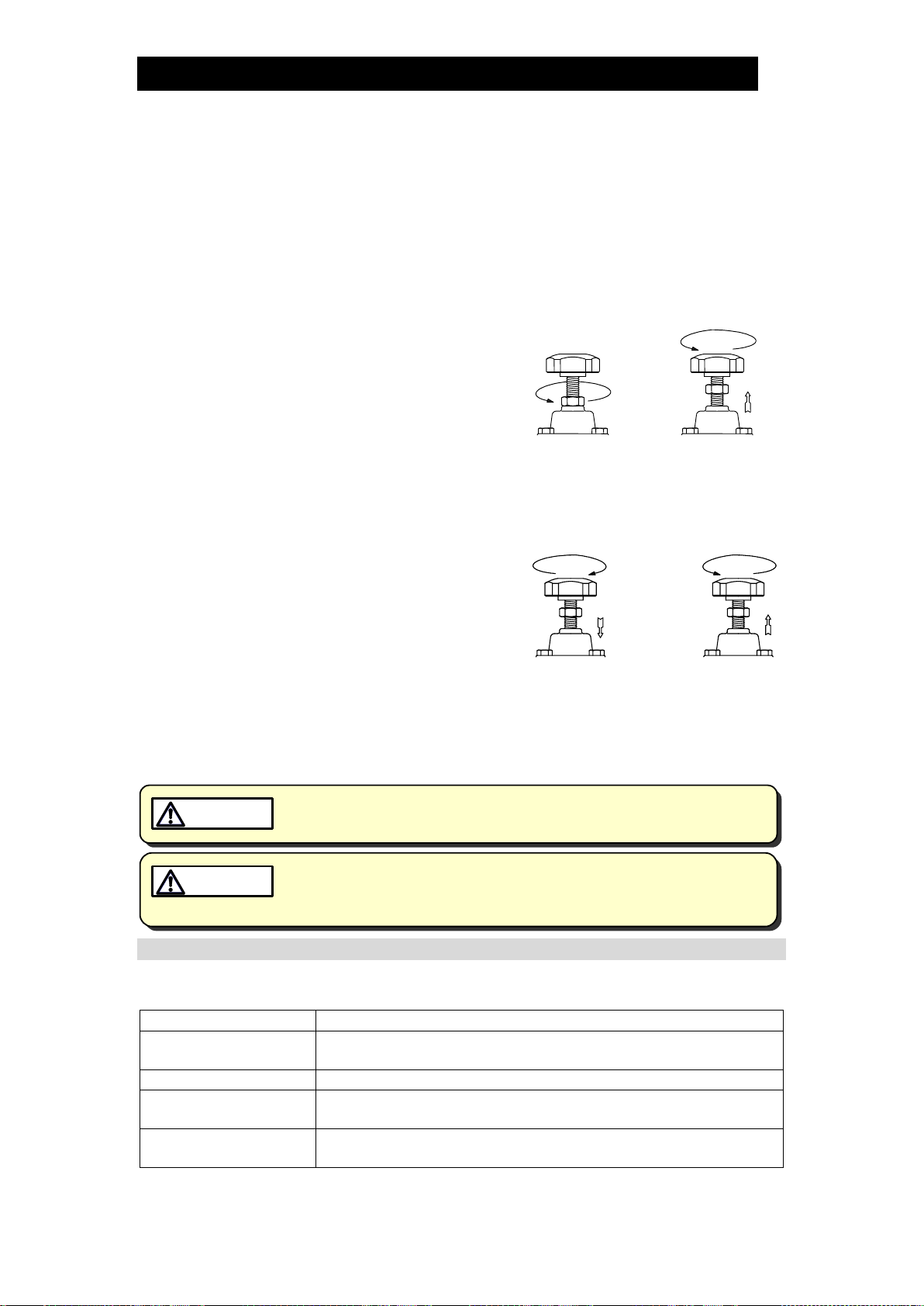

3. Loosen the locknut, then turn the adjustment

handle counter-clockwise to free the coil spring.

4. Slowly, fully open the shut-off valve at the inlet of

the A-DR20.

5. Slightly open the shut-off valve at the outlet of the A-DR20.

6. Turn the adjustment handle clockwise until the

desired outlet pressure is obtained. Wait

several minutes.

7. Slowly, fully open the shut-off valve at the

outlet of the A-DR20.

8. After setting, retighten the locknut.

9. When shutting down the system, always

close the outlet shut-off valve first and then

the inlet valve.

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

To ensure a long service life for the A-DR20, the following inspection and

maintenance should be performed regularly.

Part

Inspection and Maintenance Frequency

Screen

Disassemble and clean annually. If there is substantial blockage,

install a strainer (approximately 60 mesh) ahead of the A-DR20.

Main Valve, Valve Seat

If there is chattering or dirt, premature wear may result.

Valve Stem,

Spacer (Slide Bearing)

If hunting or chattering takes place, premature wear may result.

Bellows

If hunting or chattering takes place, cracks or fatigue may develop

in a short period of time.

Loosen the

Locknut

Fully Raise the

Adjustment Handle

Increase

Pressure

Clockwise

Counter-clockwise

Decrease

Pressure

172-65634MAJ-03 (A-DR20) 6 Oct 2021

11

Disassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

It is a recommended practice to dismantle and inspect the A-DR20 once a year for

preventive maintenance purposes. It is especially important to perform an inspection

immediately after the initial run of a new line or before or after equipment is taken out

of service for a long period of time.

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

Remove all pressurized air from the piping (both upstream and downstream).

Remove the A-DR20 from the piping, and secure it in a vise to perform disassembly

and inspection.

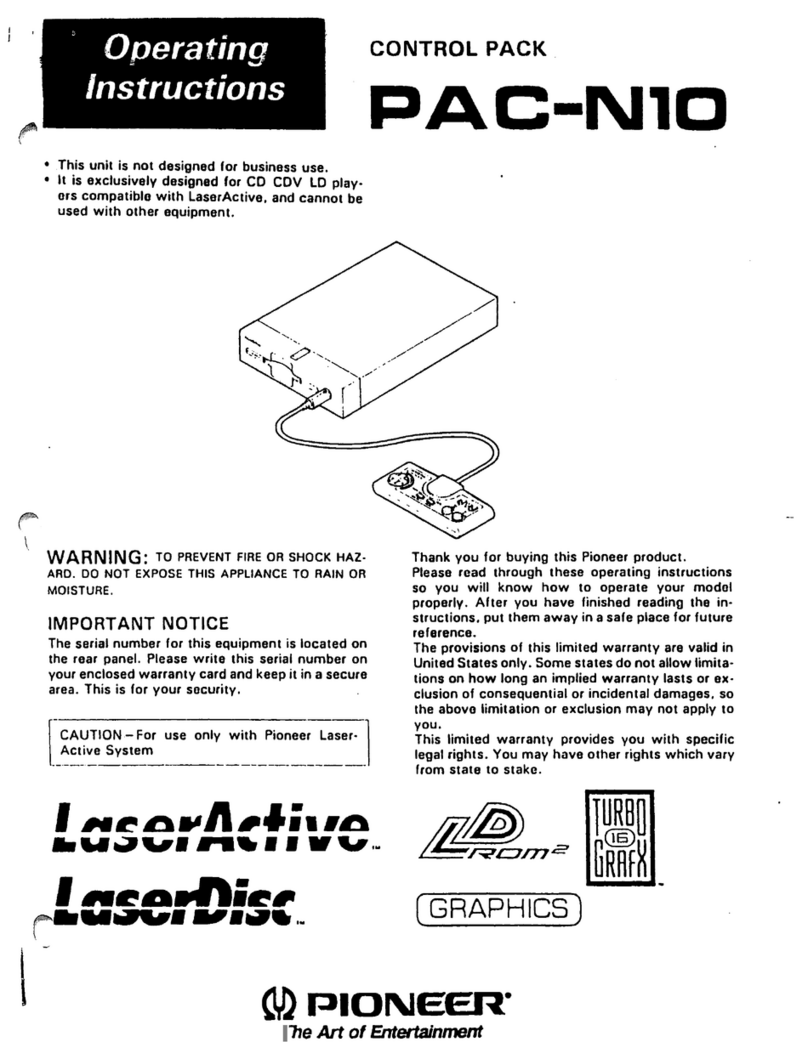

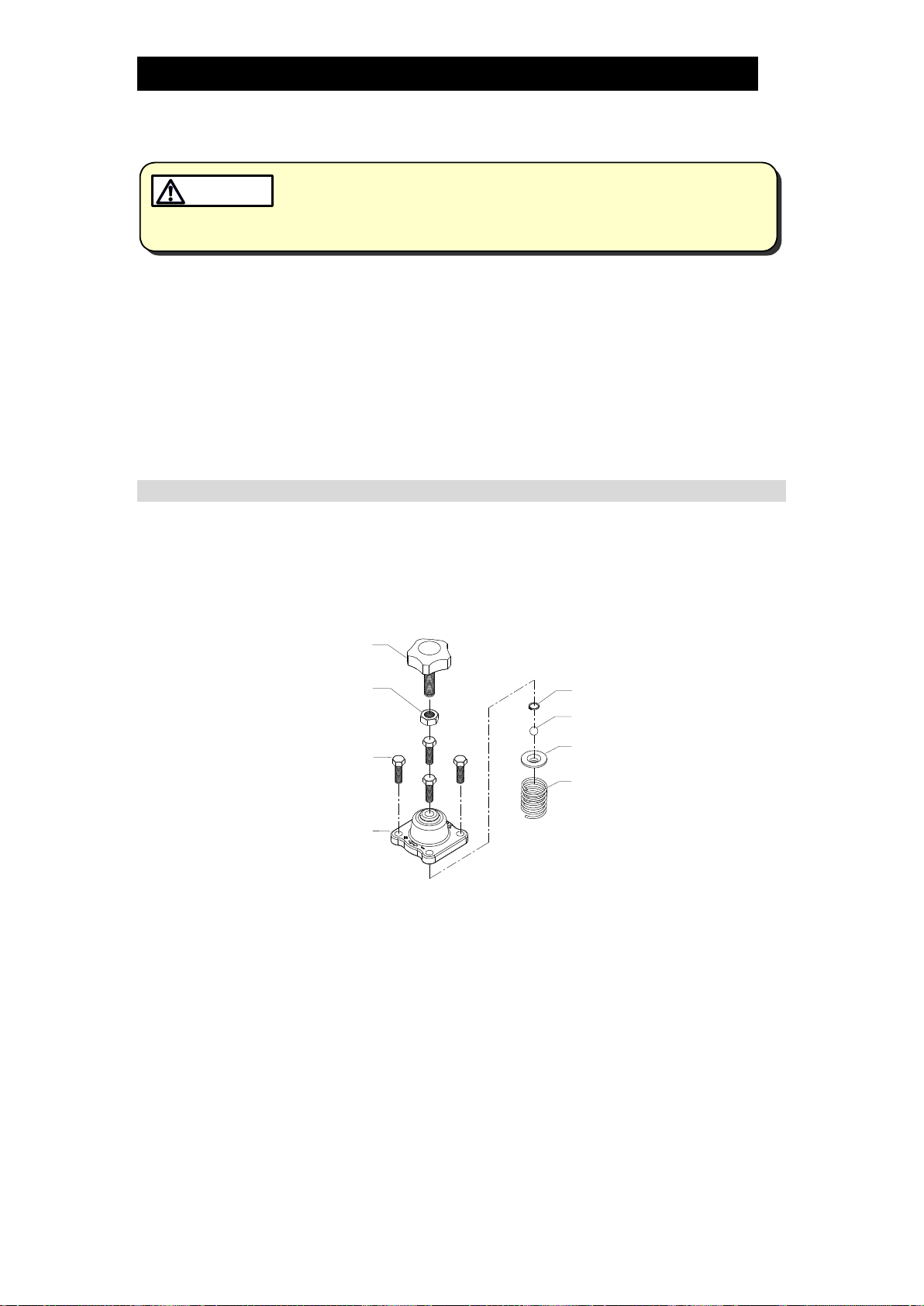

Disassembling the Adjusting Section

Loosen the adjustment handle completely and remove the cover bolts. After

removing the cover, you will see the steel ball, the spring retainer and the coil spring.

Check for seizure or any damaged screw threads.

Retaining Ring

Steel Ball

Spring Guide

Coil Spring

Adjustable Handle

Locknut

Cover Bolt

Cover

172-65634MAJ-03 (A-DR20) 6 Oct 2021

12

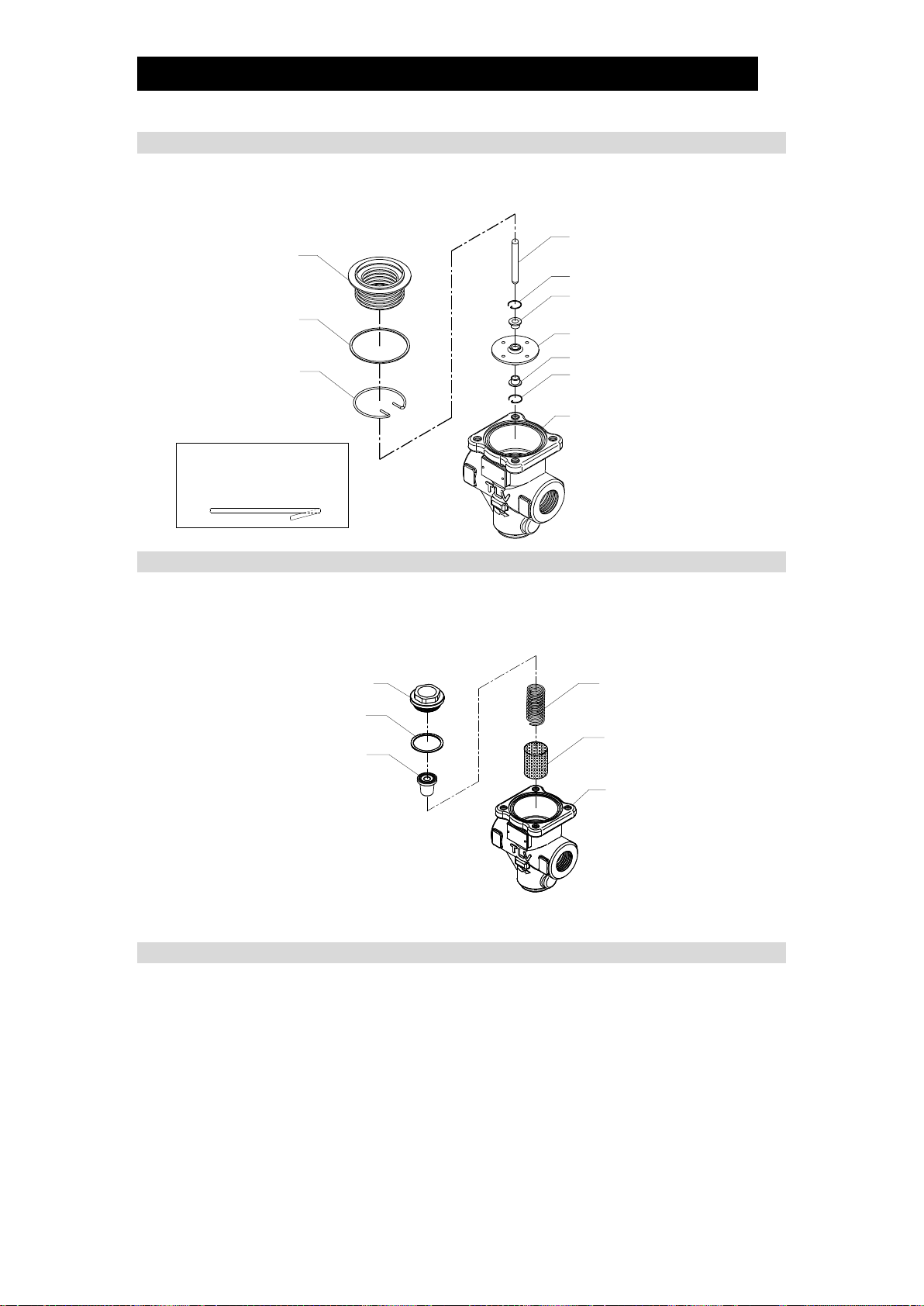

Disassembling the Bellows Section

Remove the bellows from the body, then the valve stem. Pinch the straight sections

of the snap ring that is holding the spacer together using a tool such as needle-nose

pliers and remove the snap ring. Remove the spacer.

Disassembling the Valve Section

Loosen the valve seat with a wrench and remove it from the body. The coil spring is

exerting an upward pressure on the bottom of the valve seat, so be careful that the

valve seat is not thrown out. After removing the valve seat, remove the main valve,

the coil spring and the screen.

*The rubber is inlaid in the main valve and cannot be removed. The

main valve itself must be replaced.

Cleaning

After inspection and removal of any abnormality, clean and reassemble the parts.

The following parts will require cleaning before reassembly:

Threads of the adjustment handle, threads of the cover, bellows, valve stem,

main valve, valve seat, spacer (including slide bearing), screen.

It is permissible to clean using water. However, cleaning with a mild detergent is

recommended for more effective cleaning.

Valve Stem

Snap Ring*1

Slide Bearing*1

Spacer

Slide Bearing*1

Snap Ring*1

Body

Bellows

Cover Gasket

Snap Ring*2

*1Cannot be removed

individually as it is

incorporated with the

spacer

*2Insert the snap ring so

that both ends are

facing down.

Body

Screen

Coil Spring

Valve Seat

Valve Seat Gasket

Main Valve*

172-65634MAJ-03 (A-DR20) 6 Oct 2021

13

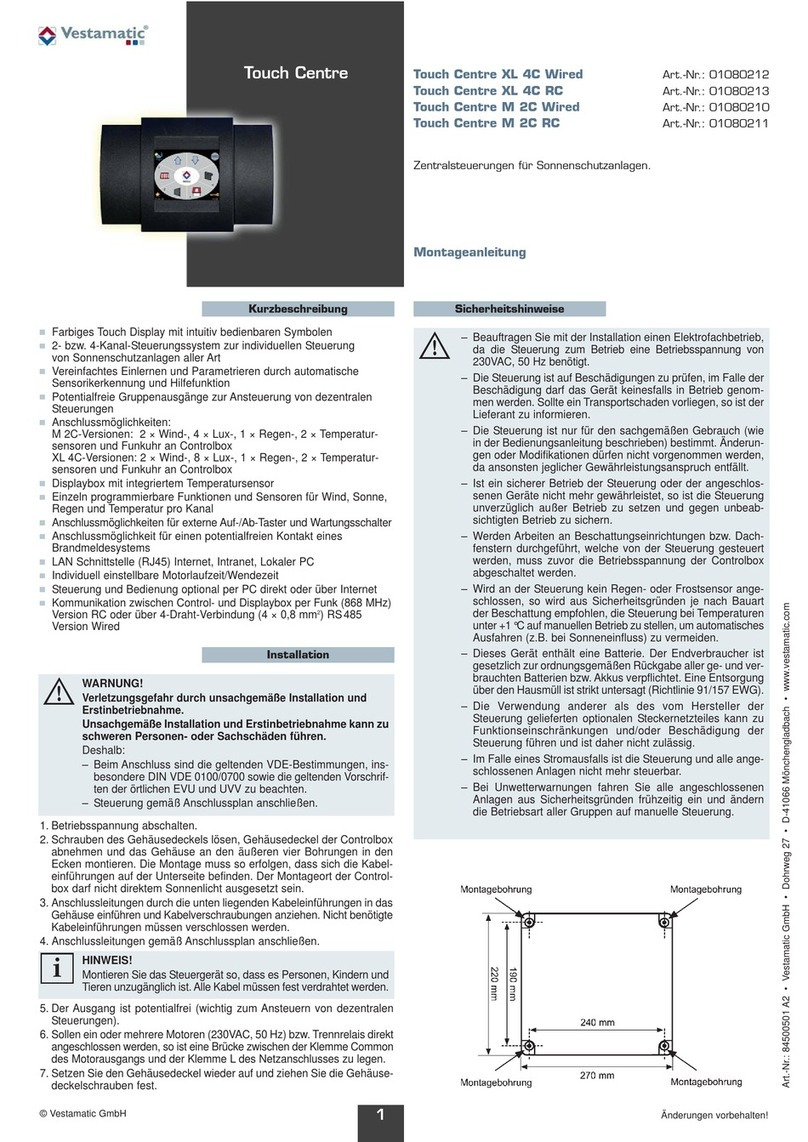

Exploded View

*1Cannot be removed individually as it is incorporated with the spacer and must be replaced

as a set with the spacer.

*3The rubber is inlaid in the main valve and cannot be removed. The main valve itself must be

replaced.

Valve Seat

Valve Seat

Gasket

Main Valve*3

Coil Spring

Screen

Body

Adjustment

Handle

Locknut

Cover Bolt

Cover

Retaining

Ring

Steel Ball

Spring

Guide

Spacer

Slide Bearing*1

Slide Bearing*1

Snap Ring*1

Snap Ring*1

Bellows

Cover

Gasket

Snap

Ring*2

Valve Stem

Coil

Spring

*2Insert the snap ring

so that both ends

are facing down.

172-65634MAJ-03 (A-DR20) 6 Oct 2021

14

Reassembly

Assemble the unit using the same procedure as used for disassembling it; but in

reverse order. Observe the following precautions:

1. The PTFE gaskets may be re-used if free from fault, crushing or deformation.

2. Apply anti-seize to the steel ball and threaded portions of screws, bolts and the

adjustment handle. Apply a small amount of anti-seize agent to the threads of

the valve seat carefully to ensure it does not come into contact with other parts.

3. Fasten the bolts one at a time in a diagonal pattern alternately to provide

uniform seating.

4. After assembly, make sure that the valve stem operates smoothly without binding.

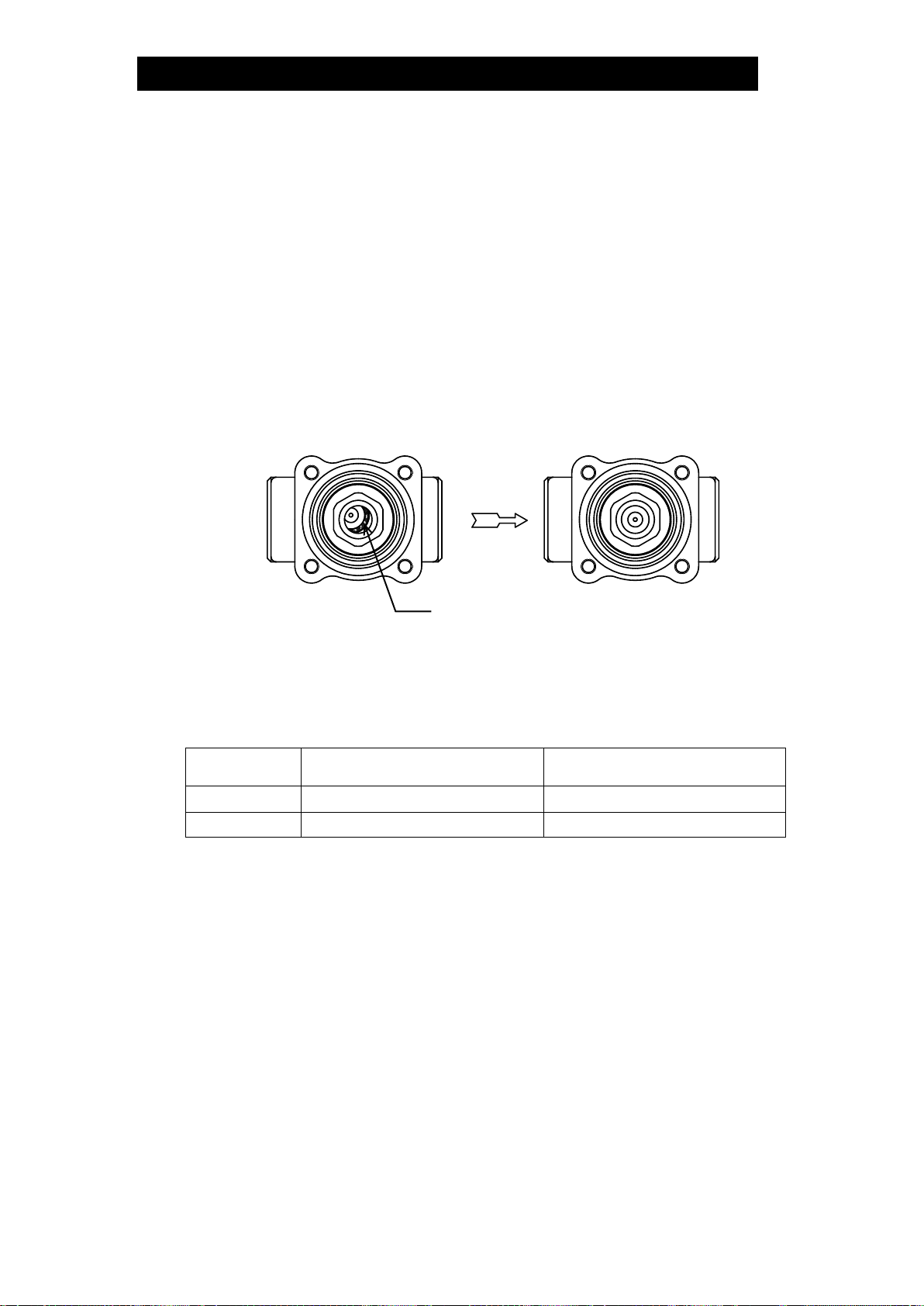

As shown in the figures above, when the main valve is tightened it may become

off-centered on the valve seat. If this occurs, move the main valve back to center.

5. Standard torque for fastening the respective screws and the width across flats of

the tools to be used are as follows:

Part

Torque

Distance Across Flats

Nm

(lbfft)

mm

(in)

Cover Bolt

25

(19)

13

(1/2)

Valve Seat

120

(88)

27

(11/16)

(1 Nm 10 kgcm)

NOTE: -If drawings or other special documentation were supplied for the product, any

torque given there takes precedence over values shown here.

Valve Seating Surface

172-65634MAJ-03 (A-DR20) 6 Oct 2021

15

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

This product is shipped after stringent checks and inspection, and should perform its

intended function for a long period of time without failure. However, should there be

any problem encountered in the operation of the A-DR20, consult the troubleshooting

guide below. Problems are classified as follows:

1. The secondary pressure does not increase

2. The secondary pressure cannot be adjusted or increases abnormally

The secondary pressure increases abnormally

3. Hunting (fluctuation of the secondary pressure) occurs

4. Chattering (a heavy mechanical noise) occurs

5. Abnormal noises

Major causes for the above problems are usage under non-specified conditions (out

of specification), insufficient pressure or flow rate, and clogs by dirt and scale.

To ensure performance for a long period of time, it is recommended that the

“Acceptable Operating Range”, “Correct Usage of the A-DR20 Direct-acting Pressure

Reducing Valve” and “Adjustment” sections be reviewed.

Problem

Symptom

Cause

Remedy

The

secondary

pressure

does not

rise

Pressure does not

increase

No air is being supplied

Check the

primary/secondary piping

and valves of the unit

The valve at the primary

side is closed

The entrance to the screens

or strainer is clogged

Clean or blow down

Flow rate exceeds

specifications

Check the flow rate; check

the model selection, replace

with a more suitable unit if

necessary

It exceeds the adjustable

pressure range

Check the model selection,

replace with a more suitable

unit if necessary

The

secondary

pressure

cannot be

adjusted or

increases

abnormally

Adjustment is

difficult and set

pressure varies

The flow rate is too low

Check the flow rate; check

the model selection, replace

with a unit that has a

smaller nominal diameter or

a more suitable unit if

necessary

Pressure fluctuation at the

primary side is large

Check the primary

pressure; check the model

selection, replace with a

more suitable unit if

necessary

Buildup on the valve stem

prevents smooth movement

through the spacer

Clean and inspect the valve

stem and spacer

Flow rate fluctuation is too

large

Check the flow rate, re-set

the pressure; check the

model selection, replace

with a more suitable unit if

necessary

Continued on the next page

172-65634MAJ-03 (A-DR20) 6 Oct 2021

16

Problem

Symptom

Cause

Remedy

The

secondary

pressure

cannot be

adjusted or

increases

abnormally

Adjustment is

difficult and set

pressure varies

The adjustment handle has

seized

Replace with a new

adjustment handle

The holes in the spacer are

clogged

Clean

The slide bearing is

distorted or damaged

Replace with a new spacer

(when replacing the slide

bearing or snap ring, these

parts need to be replaced

as a set with the spacer)

The bellows is distorted or

damaged

Replace with a new bellows

The selected model is

inappropriate for the service

conditions (specifications)

Check the model selection,

replace with a more suitable

unit if necessary

Upon closing the

valves at the

secondary side, the

secondary pressure

abruptly rises as

high as the primary

pressure

The bypass valve is leaking

Check, clean, and replace

with a new valve if

necessary

There is a build-up of dirt on

or damage to the main

valve or the valve seat

Clean and align

Hunting or

chattering

occurs

Occurs at low air

demand

The flow rate is too low

Check the flow rate; check

the model selection, replace

with a unit that has smaller

nominal diameter or a more

suitable unit if necessary

Hunting never

stops

There is too high a reduction

ratio

Use two-stage reduction

The selected model is

inappropriate for the service

conditions (specifications)

Check the model selection,

replace with a more suitable

unit if necessary

Chattering never

stops

Condensate is entrained

Install a steam trap; check

the piping

The selected model is

inappropriate for the service

conditions (specifications)

Check the model selection,

replace with a more suitable

unit if necessary

Abnormal

noises

Makes a high-

pitched noise

The required pressure

reduction exceeds

specifications

Use two-stage reduction

Flow rate exceeds

specifications

Check the flow rate; check

the model selection, replace

with a unit that has a larger

nominal diameter or a more

suitable unit if necessary

A valve installed close to

the reducing valve

opens/closes too quickly

Install the valve at as great

a distance away as possible

NOTE: When replacing parts with new, use the parts list for reference and replace with parts

from the Maintenance Kit, Repair Kit, etc. (Please note that replacement parts are only

available in pre-packaged kits.)

172-65634MAJ-03 (A-DR20) 6 Oct 2021

17

TLV EXPRESS LIMITED WARRANTY

Subject to the limitations set forth below, TLV CO., LTD., a Japanese corporation

(“TLV”), warrants that products which are sold by it, TLV International Inc. (“TII”) or

one of its group companies excluding TLV Corporation (a corporation of the United

States of America), (hereinafter the “Products”) are designed and manufactured by

TLV, conform to the specifications published by TLV for the corresponding part

numbers (the “Specifications”) and are free from defective workmanship and

materials. The party from whom the Products were purchased shall be known

hereinafter as the “Seller”. With regard to products or components manufactured by

unrelated third parties (the “Components”), TLV provides no warranty other than the

warranty from the third party manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by persons other than TLV, TII

or TLV group company personnel, or service representatives authorized by TLV;

or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and

maintenance by persons other than TLV or TLV group company personnel, or

service representatives authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV,

TII or TLV group companies; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the

Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water,

nitrogen, carbon dioxide and inert gases (helium, neon, argon, krypton, xenon

and radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the

Product.

Duration of Warranty

This warranty is effective for a period of one (1) year after delivery of Products to the

first end user. Notwithstanding the foregoing, asserting a claim under this warranty

must be brought within three (3) years after the date of delivery to the initial buyer if

not sold initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY

OPERATION OF LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT

NEGATED HEREBY, ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN

DURATION TO ONE (1) YEAR FROM THE DATE OF SHIPMENT BY THE SELLER.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS

WARRANTY OR UNDER ANY IMPLIED WARRANTIES NOT NEGATED HEREBY

(INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE), IS REPLACEMENT; PROVIDED: (a) THE CLAIMED DEFECT IS

172-65634MAJ-03 (A-DR20) 6 Oct 2021

18

REPORTED TO THE SELLER IN WRITING WITHIN THE WARRANTY PERIOD,

INCLUDING A DETAILED WRITTEN DESCRIPTION OF THE CLAIMED DEFECT AND

HOW AND WHEN THE CLAIMED DEFECTIVE PRODUCT WAS USED; AND (b) THE

CLAIMED DEFECTIVE PRODUCT AND A COPY OF THE PURCHASE INVOICE IS

RETURNED TO THE SELLER, FREIGHT AND TRANSPORTATION COSTS PREPAID,

UNDER A RETURN MATERIAL AUTHORIZATION AND TRACKING NUMBER ISSUED BY

THE SELLER. ALL LABOR COSTS, SHIPPING COSTS, AND TRANSPORTATION COSTS

ASSOCIATED WITH THE RETURN OR REPLACEMENT OF THE CLAIMED DEFECTIVE

PRODUCT ARE SOLELY THE RESPONSIBILITY OF BUYER OR THE FIRST END USER.

THE SELLER RESERVES THE RIGHT TO INSPECT ON THE FIRST END USER’S SITE

ANY PRODUCTS CLAIMED TO BE DEFECTIVE BEFORE ISSUING A RETURN MATERIAL

AUTHORIZATION. SHOULD SUCH INSPECTION REVEAL, IN THE SELLER’S

REASONABLE DISCRETION, THAT THE CLAIMED DEFECT IS NOT COVERED BY THIS

WARRANTY, THE PARTY ASSERTING THIS WARRANTY SHALL PAY THE SELLER FOR

THE TIME AND EXPENSES RELATED TO SUCH ON-SITE INSPECTION.

Exclusion of Consequential and Incidental Damages

IT IS SPECIFICALLY ACKNOWLEDGED THAT THIS WARRANTY, ANY OTHER EXPRESS

WARRANTY NOT NEGATED HEREBY, AND ANY IMPLIED WARRANTY NOT NEGATED

HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR

ITS TLV GROUP COMPANIES WILL IN ANY EVENT BE LIABLE FOR, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO LOST PROFITS, THE

COST OF DISASSEMBLY AND SHIPMENT OF THE DEFECTIVE PRODUCT, INJURY TO

OTHER PROPERTY, DAMAGE TO BUYER’S OR THE FIRST END USER’S PRODUCT,

DAMAGE TO BUYER’S OR THE FIRST END USER’S PROCESSES, LOSS OF USE, OR

OTHER COMMERCIAL LOSSES. WHERE, DUE TO OPERATION OF LAW,

CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER THIS WARRANTY, UNDER ANY

OTHER EXPRESS WARRANTY NOT NEGATED HEREBY OR UNDER ANY IMPLIED

WARRANTY NOT NEGATED HEREBY (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE) CANNOT BE

EXCLUDED, SUCH DAMAGES ARE EXPRESSLY LIMITED IN AMOUNT TO THE

PURCHASE PRICE OF THE DEFECTIVE PRODUCT. THIS EXCLUSION OF

CONSEQUENTIAL AND INCIDENTAL DAMAGES, AND THE PROVISION OF THIS

WARRANTY LIMITING REMEDIES HEREUNDER TO REPLACEMENT, ARE

INDEPENDENT PROVISIONS, AND ANY DETERMINATION THAT THE LIMITATION OF

REMEDIES FAILS OF ITS ESSENTIAL PURPOSE OR ANY OTHER DETERMINATION

THAT EITHER OF THE ABOVE REMEDIES IS UNENFORCEABLE, SHALL NOT BE

CONSTRUED TO MAKE THE OTHER PROVISIONS UNENFORCEABLE.

Exclusion of Other Warranties

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

AND ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE EXPRESSLY DISCLAIMED.

Severability

Any provision of this warranty which is invalid, prohibited or unenforceable in any

jurisdiction shall, as to such jurisdiction, be ineffective to the extent of such invalidity,

prohibition or unenforceability without invalidating the remaining provisions hereof,

and any such invalidity, prohibition or unenforceability in any such jurisdiction shall

not invalidate or render unenforceable such provision in any other jurisdiction.

172-65634MAJ-03 (A-DR20) 6 Oct 2021

19

Service

For Service or Technical Assistance: Contact your TLV representative or your regional TLV

office.

In Europe:

Daimler-Benz-Straße 16-18, 74915 Waibstadt, Germany

Tel:

Fax:

[49]-(0)7263-9150-0

[49]-(0)7263-9150-50

Units 7 & 8, Furlong Business Park, Bishops Cleeve, Gloucestershire GL52

8TW, U.K.

Tel:

Fax:

[44]-(0)1242-227223

[44]-(0)1242-223077

Parc d’Ariane 2, bât. C, 290 rue Ferdinand Perrier, 69800 Saint Priest,

France

Tel:

Fax:

[33]–(0)4-72482222

[33]-(0)4-72482220

In North America:

13901 South Lakes Drive, Charlotte, NC 28273-6790, U.S.A.

Tel:

Fax:

[1]-704-597-9070

[1]-704-583-1610

In Mexico and Latin America:

Av. Jesús del Monte 39-B-1001, Col. Hda. de las Palmas, Huixquilucan,

Edo. de México, 52763, Mexico

Tel:

Fax:

[52]-55-5359-7949

[52]-55-5359-7585

In Oceania:

Unit 8, 137-145 Rooks Road, Nunawading, Victoria 3131, Australia

Tel:

Fax:

[61]-(0)3-9873 5610

[61]-(0)3-9873 5010

In East Asia:

36 Kaki Bukit Place, #02-01/02, Singapore 416214

Tel:

Fax:

[65]-6747 4600

[65]-6742 0345

Room 5406, No. 103 Cao Bao Road, Shanghai, China 200233

Tel:

Fax:

[86]-(0)21-6482-8622

[86]-(0)21-6482-8623

No.16, Jalan MJ14, Taman Industri Meranti Jaya, 47120 Puchong,

Selangor, Malaysia

Tel:

Fax:

[60]-3-8065-2928

[60]-3-8065-2923

252/94 (K-L) 17th Floor, Muang Thai-Phatra Complex Tower B,

Rachadaphisek Road, Huaykwang, Bangkok 10310, Thailand

Tel:

Fax:

[66]-2-693-3799

[66]-2-693-3979

#302-1 Bundang Technopark B, 723 Pangyo-ro, Bundang, Seongnam,

Gyeonggi, 13511, Korea

Tel:

Fax:

[82]-(0)31-726-2105

[82]-(0)31-726-2195

In the Middle East:

Building 2W, No. M002, PO Box 371684, Dubai Airport Free Zone, Dubai,

UAE

Email:

In Other Countries:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-427-1818

[81]-(0)79-425-1167

Manufacturer:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-422-1122

[81]-(0)79-422-0112

This manual suits for next models

2

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

SMC Networks

SMC Networks SJ3A6 Series Operation manual

EL.MO. Spa

EL.MO. Spa SCMAS5 Technical manual

Metso

Metso Jamesbury 7000 Series Installation maintenance and operating instructions

Orbinox

Orbinox EX Installation, operation & maintenance manual

Clack

Clack WS2CI/QC manual

Procentec

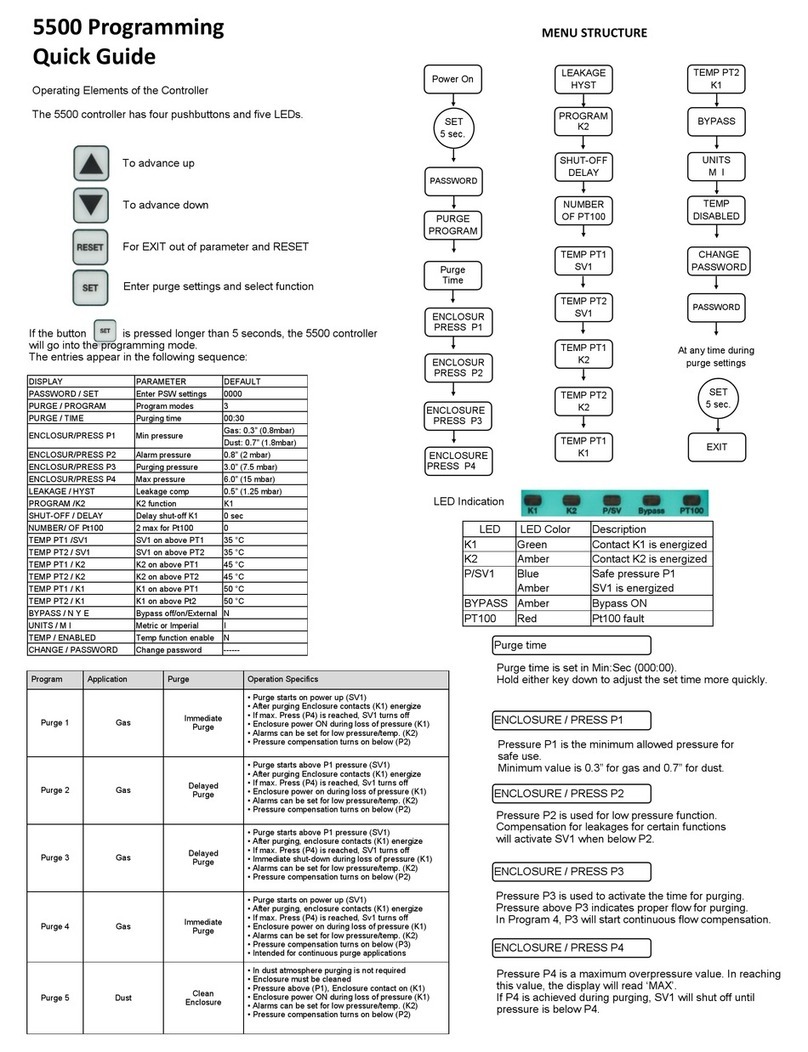

Procentec ProfiHub F1 user manual