TLV A-COS-10 User manual

172-65254MA-04 (A-COS-10) 22 April 2020

Pressure Reducing Valve for Air

A-COS-10

Copyright © 2020 by TLV CO., LTD.

All rights reserved

172-65254MA-04 (A-COS-10) 22 Apr 2020

1

Contents

Introduction......................................................................... 1

Safety Considerations ........................................................ 2

Specifications ..................................................................... 4

Acceptable Operating Range.............................................. 4

Correct Usage of the A-COS Pressure Reducing Valve..... 5

Configuration...................................................................... 7

Installation .......................................................................... 8

Adjustment ....................................................................... 12

Maintenance..................................................................... 13

Disassembly..................................................................... 14

Reassembly...................................................................... 18

Troubleshooting................................................................ 19

Product Warranty.............................................................. 22

Introduction

Thank you for purchasing the TLV pressure reducing valve for air, A-COS.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

Using air in which matter such as condensate, scale or types of oil is

entrained can not only result in problems with the air-using equipment and in

lowered productivity, but can also lead to shortened service life for and

malfunction of the reducing valves.

The TLV pressure reducing valve for air, model A-COS, is a new reducing

valve that eliminates these problems and makes possible the supply of high-

quality air at a constant pressure.

If detailed instructions for special order specifications or options not

contained in this manual are required, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the

front cover. It is needed not only for installation, but also for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

172-65254MA-04 (A-COS-10) 22 Apr 2020

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

DO NOT use the product in excess of the maximum operating

pressure differential.

Such use could make discharge through the air trap impossible

(blocked).

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the object

should fall.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

Continued on the next page

172-65254MA-04 (A-COS-10) 22 Apr 2020

3

CAUTION

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface

of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes to

the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

172-65254MA-04 (A-COS-10) 22 Apr 2020

4

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

DO NOT use the product in excess of the maximum operating pressure

differential; such use could make discharge impossible (blocked).

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the product nameplate for detailed specifications.

Model

Nominal Diameter

Maximum Operating

Temperature

Valve No.*

Secondary Pressure

Adjustable Range

Primary Pressure

Range

Production Lot No.

* Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

Acceptable Operating Range

Model

A-COS-10

Applicable Fluid

Air

Primary Pressure Range

0.1 to 0.9 MPaG (15 to 130 psig)

Secondary Pressure Adjustable Range

0.05 to 0.7 MPaG (7 to 100 psig)

Minimum Differencial Pressure

0.05 MPa (7 psi) and larger

Maximum Operating Temperature

100 °C (212 °F)

Minimum Adjustable Flow Rate

10% of rated flow rate and larger

(1 MPa = 10.197 kg/cm2)

172-65254MA-04 (A-COS-10) 22 Apr 2020

5

Correct Usage of the A-COS Pressure Reducing Valve

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

1. The product should be operated only within its specifications.

2. Installing an ON-OFF Valve (Solenoid Valve or Motorized Valve)

If an on-off valve, such as a motorized valve, is required, install it at the inlet side

of the product. If a solenoid valve is installed at the outlet of the product, its

opening and closing will cause heavy chattering and may lead to damage of the

piston and main valve. (When the on-off valve opens, the secondary pressure of

the product changes from zero to the set pressure. Passing through an area of

the reducing ratio of less than 10:1, where adjustment is impossible, chattering

occurs momentarily.)

NOTE: To prevent water hammer, it is recommended that a slow-acting

motorized on-off valve be used. In particular, if a fast-acting on-off

solenoid valve is used for frequent temperature control, the potential

water hammer effect can damage the air-using equipment and the

product.

Inlet Side

Motorized

Valve A-COS

Outlet Side

A-COS Solenoid

Valve

3. Installing a Safety Valve and a Control Valve

Safety

Valve

A-COS

Control

Valve

Air-using

Equipment

A-COS

Control

Valve

Safety

Valve

Air-using

Equipment

When installing a safety valve to protect the air-using equipment, be sure to

install it on the air-using equipment or directly before the inlet of the air-using

equipment. If the safety valve is installed on the outlet side of the product

between the product and a control valve, an eventual pressure rise could

activate the safety valve.

172-65254MA-04 (A-COS-10) 22 Apr 2020

6

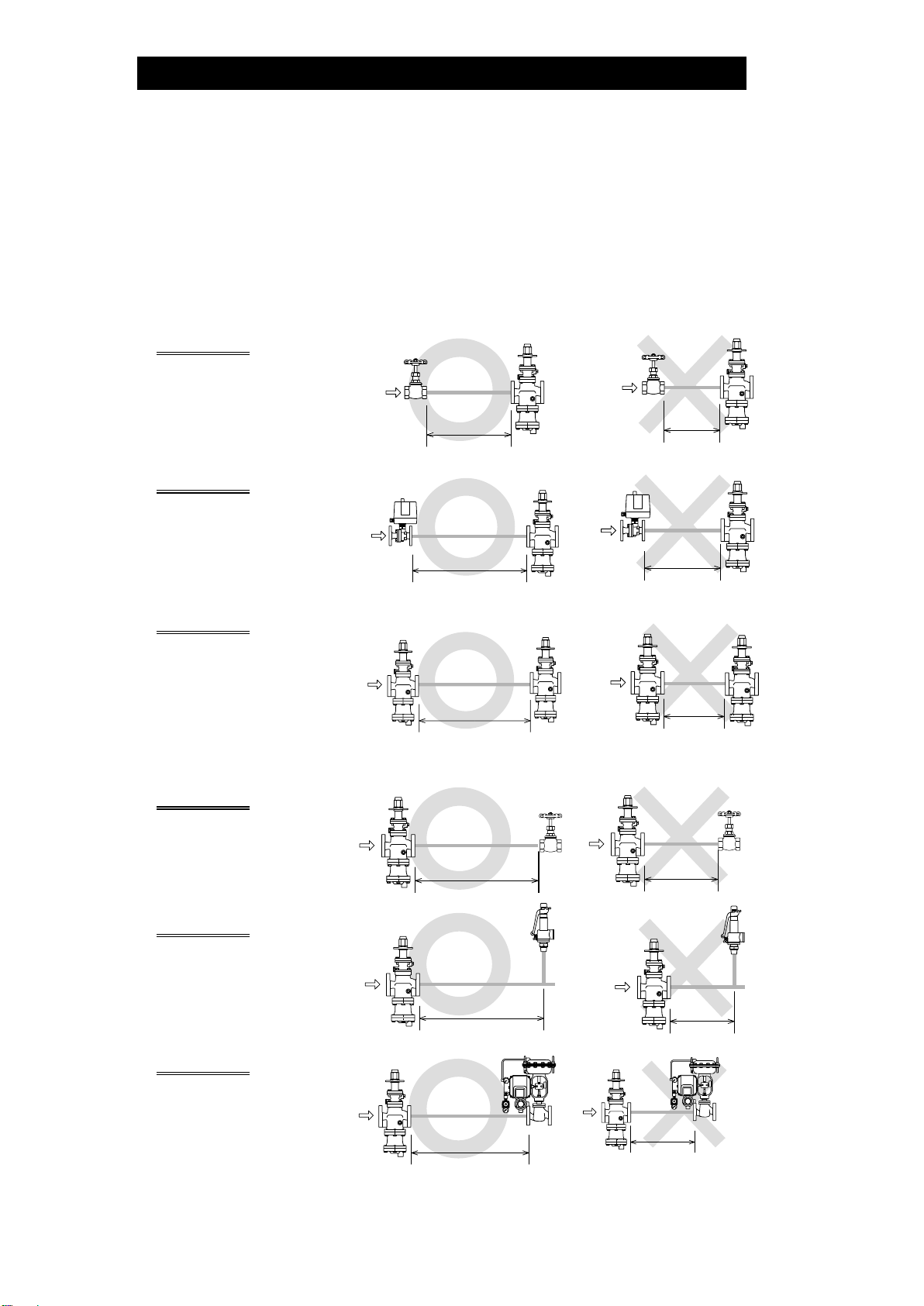

4. Precautions for the Installation of Additional Fittings Before or After the product

In order to ensure stable air flow, the piping upstream and downstream of the

product must be straight runs. If the product is installed either directly before or

after an elbow or control valve, unevenness in air flow may result in chattering

and unstable pressure.

To ensure stable air flow, it is recommended that the product be installed on

straight runs of piping, as illustrated below.

①Inlet (primary side) of the product NOTE: d = pipe diameter

Maintain a straight piping run

of 10 d or more when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size is

25 mm (1 in), have 250 mm

(10 in) or more)

Valve, Strainer,

Elbow, etc. A-COS

10 d or more

Valve, Strainer,

Elbow, etc. A-COS

Less

than

10 d

Maintain a straight piping run

of 30 d or more when an

automated valve (on-off

valve) is installed.

(Example: if nominal size is

25 mm (1 in), have 750 mm

(30 in) or more)

Automated

Valve A-COS

30 d or more

Automated

Valve A-COS

Less than

30 d

Maintain a straight piping run

of 30 d or more when

another pressure reducing

valve is installed. (Two-stage

pressure reduction)

(Example: if nominal size is

25 mm (1 in), have 750 mm

(30 in) or more)

30 d or more

A-COS

Second

Reducing

Valve

Less

than

30 d

A-COS

Second

Reducing

Valve

②Outlet (secondary side) of the product

Maintain a straight piping run

of 15 d or more when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size is

25 mm (1 in), have 375 mm

(15 in) or more)

A-COS

15 d or more

Valve, Strainer,

Elbow, etc.

A-COS

Less than

15 d

Valve, Strainer,

Elbow, etc.

Maintain a straight piping run

of 30 d or more when a

safety valve is installed.

(Example: if nominal size is

25 mm (1 in), have 750 mm

(30 in) or more)

30 d or more

A-COS Safety

Valve

Less than

30 d

A-COS Safety

Valve

Maintain a straight piping run

of 30 d or more when a

control valve or an

automated valve (on-off

valve) is installed.

(Example: if nominal size is

25 mm (1 in), have 750 mm

(30 in) or more)

30 d or more

A-COS Control or

Automated

Valve

Less than

30 d

A-COS Control or

Automated

Valve

172-65254MA-04 (A-COS-10) 22 Apr 2020

7

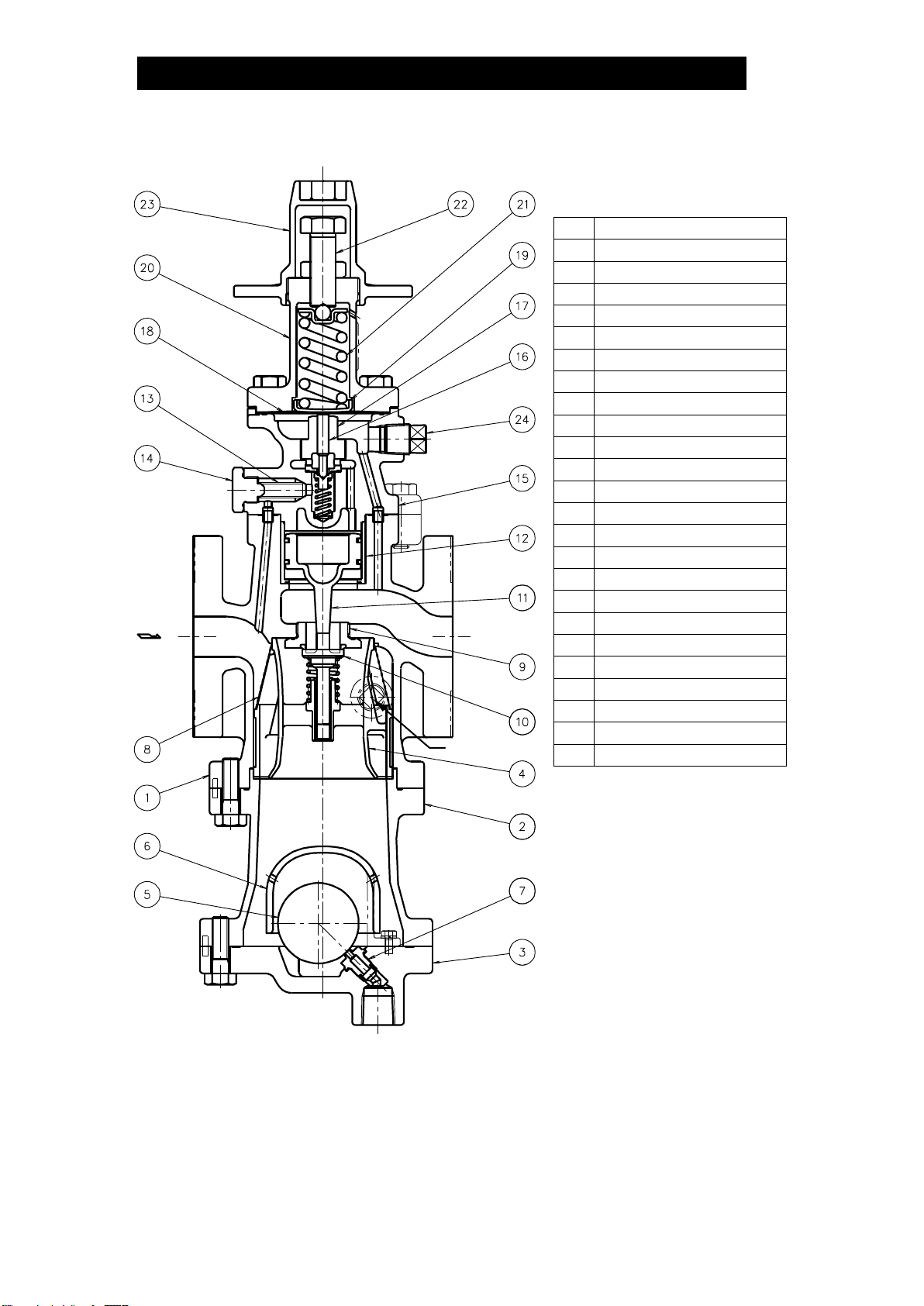

Configuration

Plug (option)

No.

Name

1

Main Body

2

Separator Body

3

Trap Cover

4

Separator

5

Float

6

Float Cover

7

Trap Valve Seat

8

Separator Screen

9

Main Valve Seat

10

Main Valve

11

Piston

12

Cylinder

13

Pilot Screen

14

Pilot Screen Holder

15

Pilot Body

16

Pilot Valve

17

Pilot Valve Seat

18

Diaphragm

19

Diaphragm Support

20

Spring Housing

21

Coil Spring

22

Adjustment Screw

23

Spanner Cap

24

Plug –Sensing Line Port

172-65254MA-04 (A-COS-10) 22 Apr 2020

8

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Blowdown

Before installing the product,

be sure to blow down all

piping thoroughly. If this is

not possible, perform a

blowdown using the bypass

valve.

Blowdown is especially

important for newly installed

piping or after the system

has been shut down for a

long period of time.

2. Removing Seal and Cap

Before installation, be sure to remove all protective seals and caps.

(Found in 3 locations, on the product inlet and outlets.)

3. Installation Angle

Make sure the product is installed on horizontal piping,

so that the arrow mark on the body matches the direction

of air flow and the adjustment section faces up.

Allowable inclination is 10 degrees in the fore-aft

direction and 15 degrees in the plane perpendicular to

the air flow line.

Open Close

A-COS

Open

172-65254MA-04 (A-COS-10) 22 Apr 2020

9

Small Hole

4. Spacer Installation

If spacing adjustment is necessary to

accommodate installation, install a spacer on the

outlet flange. The spacer should consist of a

spacer, gaskets, bolts and nuts. Fit gaskets to

both sides of the spacer between the product

outlet and the pipe flange. Fasten with bolts and

nuts.

5. Piping Support

Install the product, paying

attention to avoid excessive

load, bending and vibration.

Support the inlet and outlet

pipes securely.

6. Maintenance Space

Leave sufficient space for maintenance, inspection

and repair.

(Unit: mm (in))

7. Trap Outlet Pipe

For ease of maintenance, installation of a union

connection is recommended for the trap outlet pipe.

Connect the outlet pipe to a condensate return line, or

extend it to a trench. In the case of the latter, make

sure the end of the pipe is above the waterline.

8. Blowdown Valve (requires optional plug)

In an environment of heavy dirt or scale, or when the

air equipment is used only periodically, be sure to

install a strainer at the inlet of the product and a

blowdown valve on the main body.

1) Remove the plug from the main body and install a

blowdown valve.

2) Open the 10 mm (3/8 in) blowdown valve and blow

any residual dirt and scale off of the screen.

3) Periodically activate the blowdown valve to keep

the system free of dirt and scale.

100 (4)

100

(4) 100

(4)

100 (4)

400

(16) 400

(16)

Apx.

300

(12)

Remove the 3/8 in

plug (optional)

and install the

blowdown valve.

Correct

spacer location

Incorrect

spacer location

172-65254MA-04 (A-COS-10) 22 Apr 2020

10

9. Piping Size/Diffuser

If it is expected that the secondary air flow velocity will be more than 30 m/s (100

ft/s), install a diffuser in order to keep the flow velocity below 30 m/s (100 ft/s).

If the distance between the product and the air-using equipment is great, a possible

drop in pressure should be taken into consideration when selecting the piping size. In

addition, when installing the strainer, the strainer screen should be either at the3

o’clock or 9 o’clock position to prevent condensate accumulation.

Bypass Valve

Pressure Gauge

Pressure Gauge A-COS

Ball Valve Ball Valve

Bypass Valve

Straight-run Piping Lengths: (d = pipe diameter)

Upstream: 10 d or more / Downstream: 15 d or more

Ball Valve

A-COS Bypass Valve Bypass Valve

Pressure Gauge

Pressure Gauge

Ball Valve

Diffuser

10. Two-stage Pressure Reduction

Two-stage pressure reduction should be performed whenever the pressure

cannot be reduced to the desired level with the product due to operating range

limitations, such as when the reduction ratio is greater than 10:1.

A-COS

Pressure

Reducing

Valve

Bypass valve

Pressure Gauge

Inlet Inlet Side Outlet Side

Pressure Gauge

Bypass valve Safety Valve

(Relief Valve)

Pressure Gauge

Outlet

Outlet SideInlet Side

A-COS

Bypass valve

Pressure Gauge

Safety Valve

(Relief Valve)

Pressure Gauge

OutletInlet Inlet Side Outlet Side

172-65254MA-04 (A-COS-10) 22 Apr 2020

11

11. Accessories

Always install a shut-off valve, pressure gauge and bypass lines at both inlet and

outlet.

Ball valves, which will not retain condensate, are recommended for inlet and

outlet shut-off valves. The bypass pipe should be at least 1/2of the size of the

inlet (primary side) pipe.

Bypass Valve

Ball Valve Ball Valve

A-COS

Safety Valve

(Relief Valve)

Pressure Gauge

Pressure Gauge

A-COS

Pressure

Gauge

172-65254MA-04 (A-COS-10) 22 Apr 2020

12

Adjustment

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

The product should be properly adjusted for protection of the air-using equipment

against water hammer.

1. It is necessary to blow down all pipe lines thoroughly. The blowdown is especially

important if the line is new or has been shut down for a long period of time.

Take particular care to ensure that matter such as condensate and dirt does not

remain inside the air-using equipment.

(Stay clear of any pressurized blow-out from the safety valve.)

2. Make sure that the shut-off valve and the bypass valve located upstream and

downstream of the product are completely closed.

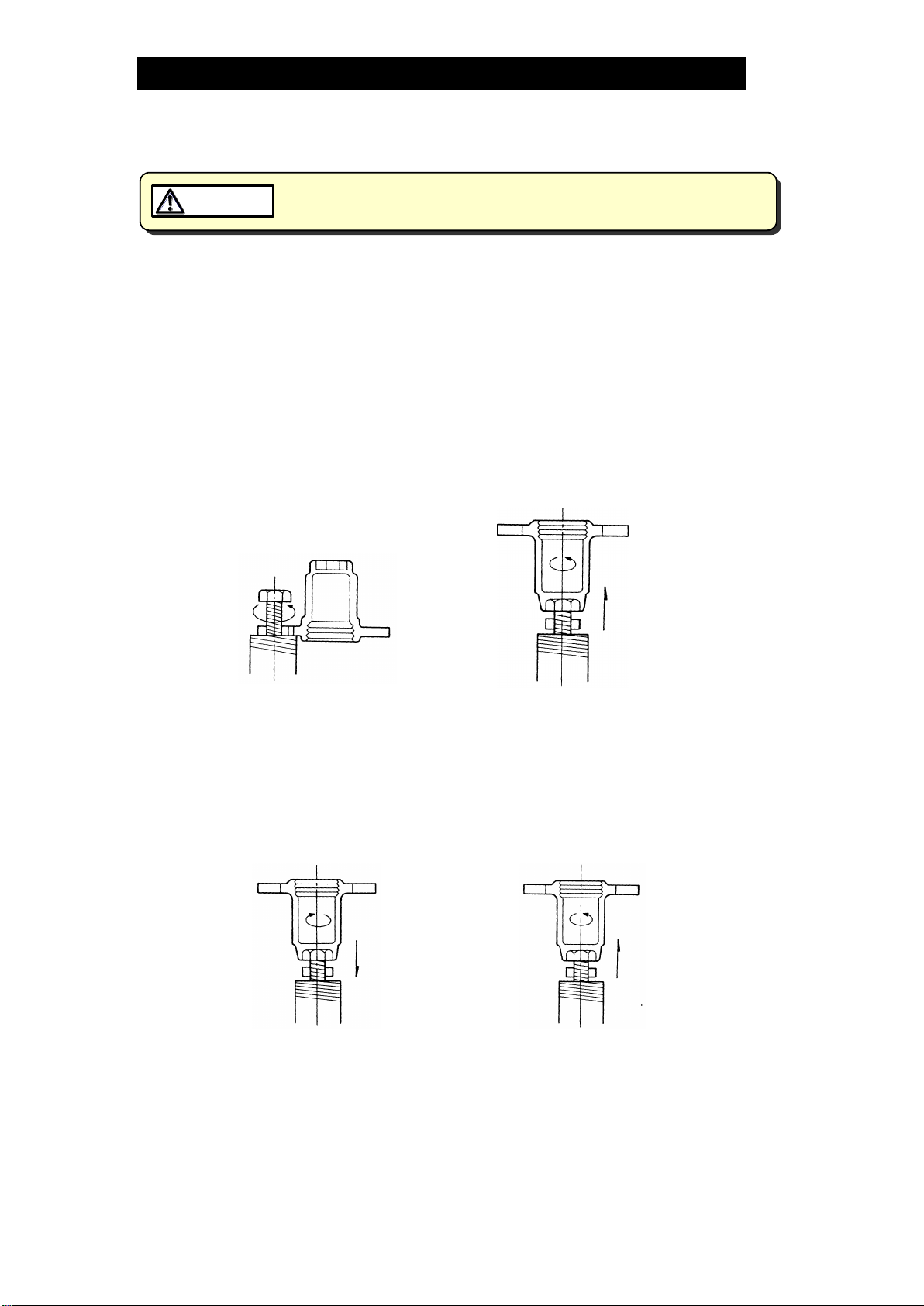

3. Remove the spanner cap, loosen the locknut and turn the adjustment screw

counterclockwise to reduce tension on the coil spring.

Loosen the locknut Loosen the

adjustment screw

Counterclockwise

4. Slowly, fully open the shut-off valve at the inlet of the product. Allow sufficient

time for condensate remaining at the inlet of the product to be discharged.

5. Slightly open the shut-off valve at the outlet of the product.

6. Turn the adjustment screw until the desired outlet pressure is obtained. Wait

several minutes.

Loosen the Adjustment Screw

Decrease Pressure

Tighten the Adjustment Screw

Increase Pressure

Counterclockwise

Clockwise

7. Slowly, fully open the shut-off valve at the outlet of the product.

8. After setup, retighten the locknut and replace the spanner cap.

9. When shutting down the system, always close the outlet shut-off valve first and

then the inlet valve.

172-65254MA-04 (A-COS-10) 22 Apr 2020

13

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

To ensure long service life of the product, the following inspection and maintenance

is recommended to be performed regularly.

Part

Inspection and Maintenance Frequency

Screens

(Separator and Pilot)

Disassemble and clean annually.

If there is substantial blockage, install a strainer

(approximately 60 mesh) ahead of the product.

Main Valve,

Main Valve Seat,

Pilot Valve,

Pilot Valve Seat

Replace after approximately 15,000 hours.

If there is chattering or dirt, premature wear may result.

Piston Ring

Replace after approximately 8,000 hours.

If there is chattering or if scale build-up is severe,

premature wear may result.

Piston

Replace after approximately 30,000 hours.

If hunting or chattering takes place, premature wear may

result.

Trap Valve Seat

Replace after approximately 40,000 hours.

If scale build-up is severe, blockage may occur in a short

period of time.

Diaphragm

Replace after approximately 30,000 hours.

If hunting or chattering takes place, cracks or fatigue may

develop in a short period of time.

172-65254MA-04 (A-COS-10) 22 Apr 2020

14

Disassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

It is a recommended practice to dismantle and inspect the product once a year for

preventive maintenance purposes. It is especially important to perform an inspection

immediately after the initial run of a new line or before or after equipment that is out

of service for a long period of time. (Installation, inspection, maintenance, repairs,

disassembly, adjustment and valve opening/closing should be carried out only by

trained maintenance personnel.)

Remove all pressure from the piping (both upstream and downstream). Then remove

inlet and outlet flange retaining bolts and nuts to permit removal of the product.

Secure the product in a vise to perform the inspection.

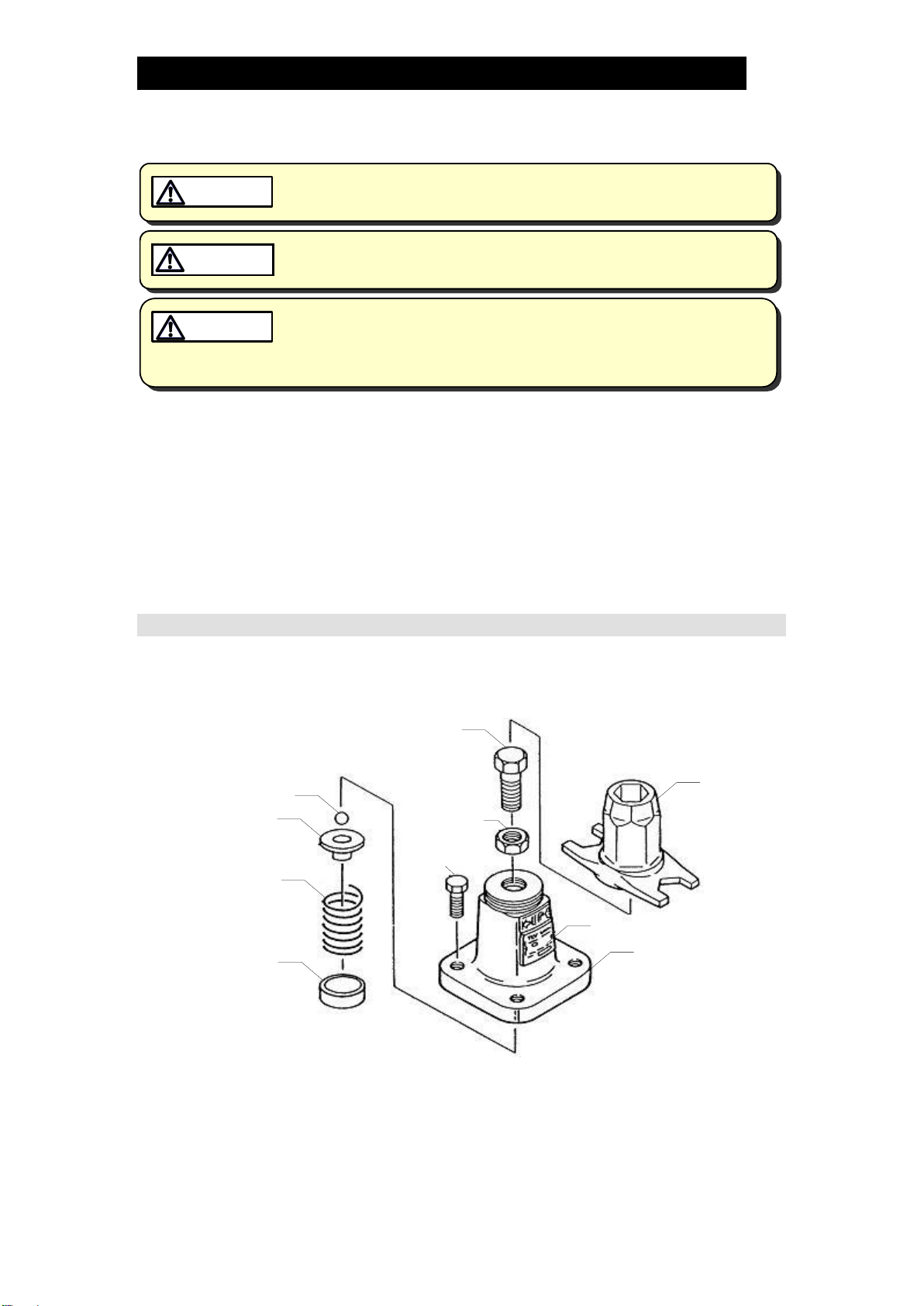

Disassembling the Adjustment Section

Loosen the adjustment screw completely and remove the hex bolts. Having removed

the spring housing, you will see the diaphragm support, coil spring and spring housing.

Check for seizure or any damaged screw threads.

Spanner Cap

Nameplate

Spring Housing

Diaphragm Support

Coil Spring

Spring Retainer

Ball

Adjustment Screw

Locknut

Hex Bolt

172-65254MA-04 (A-COS-10) 22 Apr 2020

15

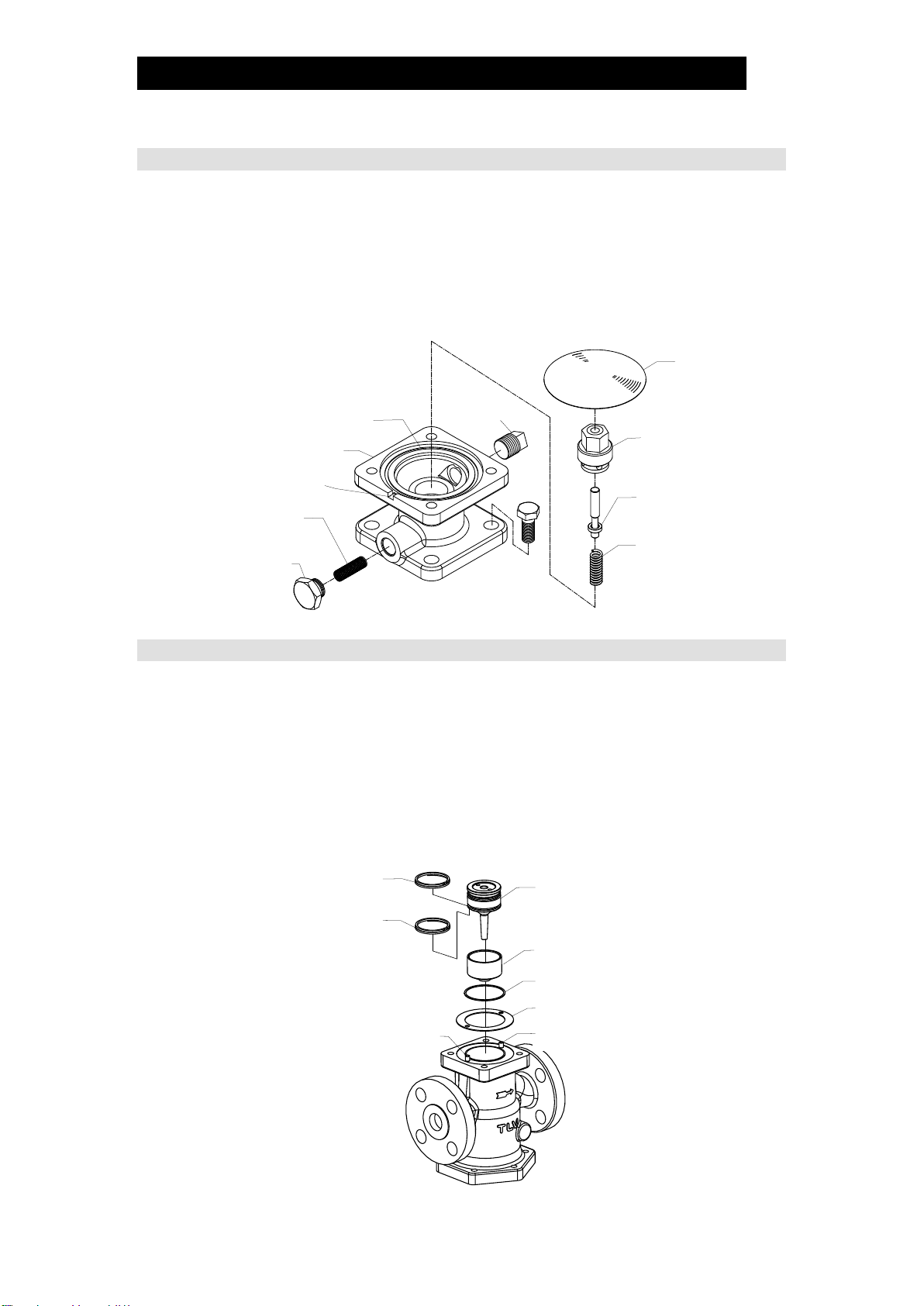

Disassembling the Pilot Section

The diaphragm is removed by utilizing the notch in the pilot body. Loosen the pilot

valve seat with a box wrench and remove it. Lift the pilot valve spring up and out with

a pair of tweezers. Then loosen and remove the screen holder to remove the screen.

Check for any fault on the pilot valve seat, the seat of the pilot valve, flaws on the

gaskets, and clogging of the screen. Check for deformation, corrosion or faults on

the diaphragm. The diaphragm should be convex (open downward), with the printed

UP mark on the top.

Diaphragm

Pilot Valve Seat

& Gasket

Pilot Valve

Pilot Valve Spring

Gasket

Pilot Body

Notch

Pilot Screen

Pilot Screen Holder

& Gasket

Plug

Hex Bolt

Disassembling the Piston Section

Remove the pilot body after loosening and removing the hex bolts (stud bolts).

During this process, pay attention not to lose the connecting tubes (2).

Remove the piston and the cylinder from the body. Then remove the piston rings and

the tension rings from the piston. Do not apply too much force when removing the

piston rings and tension rings.

Check for the interior of the cylinder, the exterior of the piston rings, the small hole

on the piston and the cylinder gasket for any fault or abnormality.

Piston Ring

Tension Ring

Piston Ring

Tension Ring

Piston

Cylinder

Cylinder Gasket

Gasket

Connecting TubeConnecting Tube

172-65254MA-04 (A-COS-10) 22 Apr 2020

16

Disassembling the Separator and Main Valve Section

Turn the product upside down for easy dismantling of the separator and main valve.

Loosen the hex bolts and remove the separator body. Be careful, as the separator

may drop off when the product is returned to the normal attitude.

Removal of the separator and pressed-in sleeve permits removal of the main valve

spring, the main valve and screen. Loosen the valve seat with a box wrench and

remove it from the body.

Check for damage on the seating and sliding surfaces of the main valve, the

seating surface of the valve seat, the gaskets, and for clogging of the screen.

At start-up following shutdown for a long period, always blow down the piston

section of the body through the plug (option).

Disassembling the Air Trap Section

Loosen the trap cover bolts and remove the trap cover. Be careful, as hot

condensate may splash out.

Remove the float cover

bolts from the float cover to

reveal the float. Remove

the float, remove the trap

valve seat with a box

wrench.

Check to make sure that

there is no deformation of

the float, abnormality in

the trap valve seat or dirt

accumulation in the trap

cover.

Float Cover Bolt

Spring Washer

Gasket

Trap Cover

Guide Pin

Trap Cover Bolt

Trap Valve Seat

& Gasket

Protective Bushing

Float

Float Cover

Body

Gasket

Valve Seat

Main Valve

Hex Bolt

Gasket

Screen

Sleave

Corrugated Spring Washer

Separator

Separator Body

Spring Retainer

Main Valve Spring

172-65254MA-04 (A-COS-10) 22 Apr 2020

17

Cleaning

After inspection and removal of any abnormality, clean and reassemble the parts.

The following parts will require cleaning before reassembly:

Trap Cover

Piston

Float

Piston Ring

Trap Valve Seat

Cylinder

Pilot Screen

Separator Screen

Main Valve Seat

Pilot Valve

Main Valve

Pilot Valve Seat

Main Valve Holder

Adjustment Screw

It is permissible to clean using water, however cleaning with a mild detergent is

recommended for more effective cleaning.

(Coat threaded position with anti-seize after cleaning.)

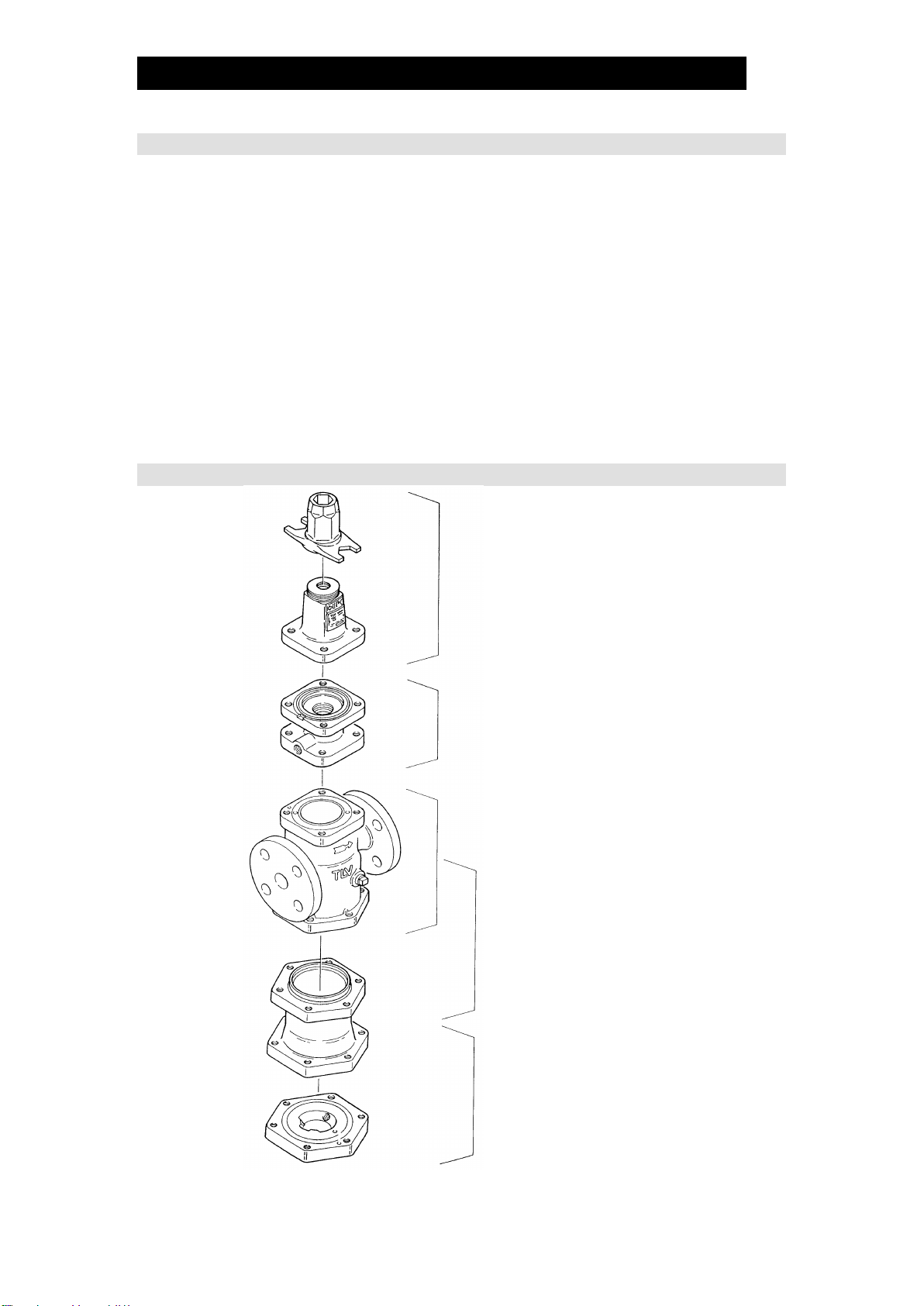

Exploded View

Adjustment

Section

Pilot

Section

Piston

Section

Separator / Main

Valve Section

Air Trap

Section

172-65254MA-04 (A-COS-10) 22 Apr 2020

18

Reassembly

Assemble the unit using the same procedure as used for disassebling it; but in

reverse order. Observe the following precautions:

1. The PTFE gaskets may be re-used if free from fault, crushing or deformation.

2. Apply anti-seize to the threaded portion of screws and bolts, the spring housing,

ball and adjustment screw. Apply a small amount of anti-seize to the threads of

the valve seat, pilot valve seat and screen holder. Apply anti-seize carefully to

ensure it does not come into contact with other parts.

3. Fasten the bolts one at a time in an alternating

diagonal pattern to provide uniform seating.

4. After assembly, make sure that the piston and the

pilot guide operate smoothly without binding.

1) Fit the piston ring to the outside of the tension

ring.

2) The ring gaps should be opposite each other.

5. Standard fastening torque and the width across

flats for the tools to be used are as follows:

Part

A-COS

Connection Size

Width Across Flats

Tightening Torque

mm

(in)

mm

(in)

Nm

(lbf·ft)

Spring Housing Bolt

All

17

(21/32)

40

(29)

Pilot Valve Seat

All

19

(3/4)

70

(51)

Screen Holder

All

24

(15/16)

40

(29)

Pilot Body Bolt

15 –40

(1/2–11/2)

17

(21/32)

60

(44)

50

(2)

19

(3/4)

70

(51)

Trap Cover Bolt

15 –40

(1/2–11/2)

17

(21/32)

60

(44)

50

(2)

19

(3/4)

70

(51)

Valve Seat

15, 20

(1/2, 3/4)

36

(17/16)

100

(73)

25

(1)

41

(15/8)

125

(92)

32, 40

(11/4, 11/2)

60

(23/8)

250

(185)

50

(2)

70

(23/4)

300

(220)

Float Cover Bolt

15, 20

(1/2, 3/4)

8

(5/16)

7

(5)

25 –40

(1 –11/2)

10

(3/8)

10

(7)

50

(2)

13

(1/2)

20

(15)

Trap Valve Seat

15, 20

(1/2, 3/4)

11

(7/16)

10

(7)

25 –40

(1 –11/2)

13

(1/2)

15

(11)

50

(2)

17

(21/32)

40

(29)

(1 Nm 10 kgcm)

NOTE: -If a torque greater than that recommended is applied, the body or its

components may be damaged.

-Coat all threaded portions with anti-seize.

-If drawings or any other special documentation were supplied for the product,

any torque given there takes precedence over the values shown here.

Piston Ring

Tension Ring

Ring Gaps

Assembling the Piston Ring

172-65254MA-04 (A-COS-10) 22 Apr 2020

19

Troubleshooting

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

This product is shipped after stringent checks and inspection and should perform

its intended function for a long period of time without failure. However, should there

be any problem encountered in the operation of the product, consult the

troubleshooting guide below.

Problems are classified as follows:

1. The secondary pressure does not increase.

2. The secondary pressure cannot be adjusted or increases abnormally.

3. Hunting (fluctuation of the secondary pressure) occurs.

4. Chattering (a heavy mechanical noise) occurs.

5. Air leaks from the air trap or condensate is not discharged.

6. Abnormal noises.

Major causes for the above problems are usage under non-specified conditions

(out of specification), insufficient pressure or flow rate, and clogs by dirt and scale.

To ensure performance for a long period of time, it is recommended that the

“Acceptable Operating Range”, “Correct Usage of the A-COS Pressure Reducing

Valve” and “Adjustment” sections be reviewed.

It is a recommended practice to dismantle and inspect the product once a year for

preventive maintenance purposes. It is especially important to perform an

inspection immediately after the initial run of a new line or before or after equipment

such as a heater is out of service for a long period of time. (Installation, inspection,

maintenance, repairs, disassembly, adjustment and valve opening/closing should

be carried out only by trained maintenance personnel.)

Problem

Symptom

Cause

Remedy

The secondary

pressure does

not rise

The pressure does

not increase

No air is being supplied or

the inlet valve is closed

Check the valves and

piping at the primary side

The entrance to the

screens or strainer is

clogged

Clean or blow down

The secondary

pressure

cannot be

adjusted or

increases

abnormally

Adjustment is

difficult, and set

pressure varies

The pilot screen is clogged

Clean

There is insufficient air

flow

Check the flow, replace

the product if necessary

The piston is clogged

with dirt

Clean

Check the piston ring

The piston ring is worn

Replace with a new piston

ring

Continued on the next page

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

Emax

Emax Aeris Link TX 2.4G/915M quick start guide

SPX FLOW

SPX FLOW APV DELTA SD4 Series instruction manual

Ublox

Ublox MAX-8 Series Hardware Integration Manual

caenrfid

caenrfid easy2read Lepton3x1 Technical information manual

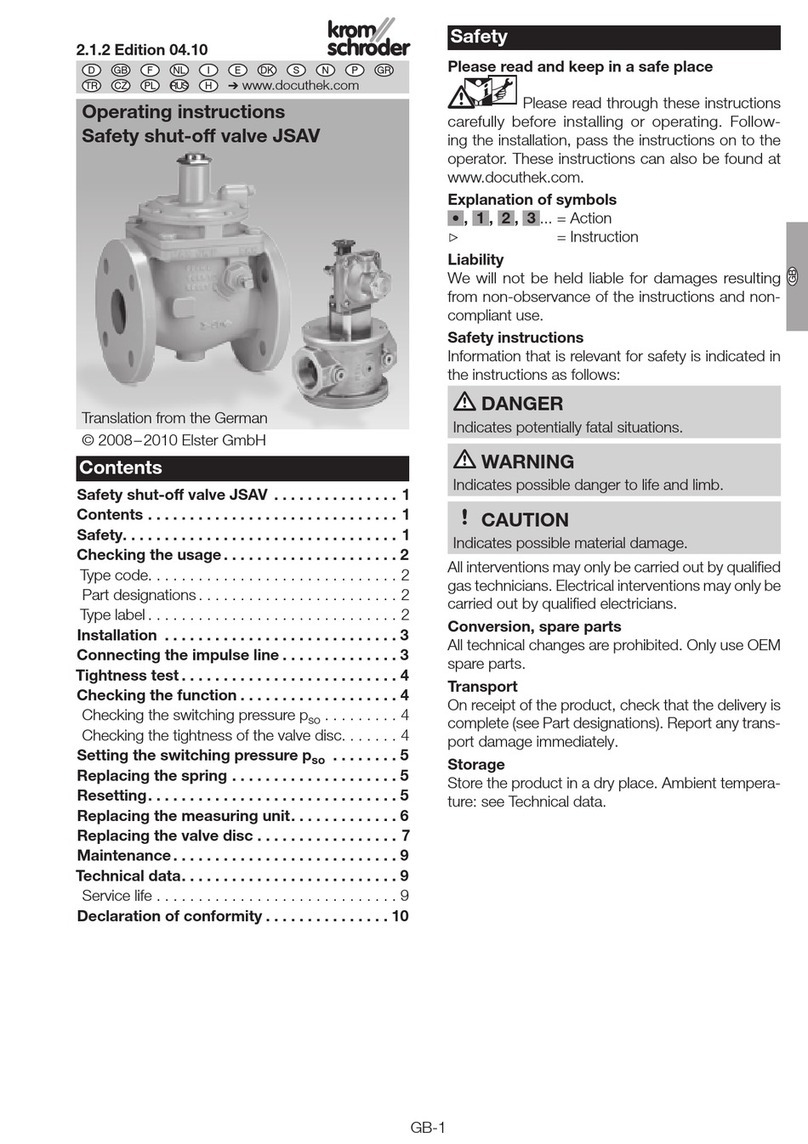

Krom Schroder

Krom Schroder JSAV operating instructions

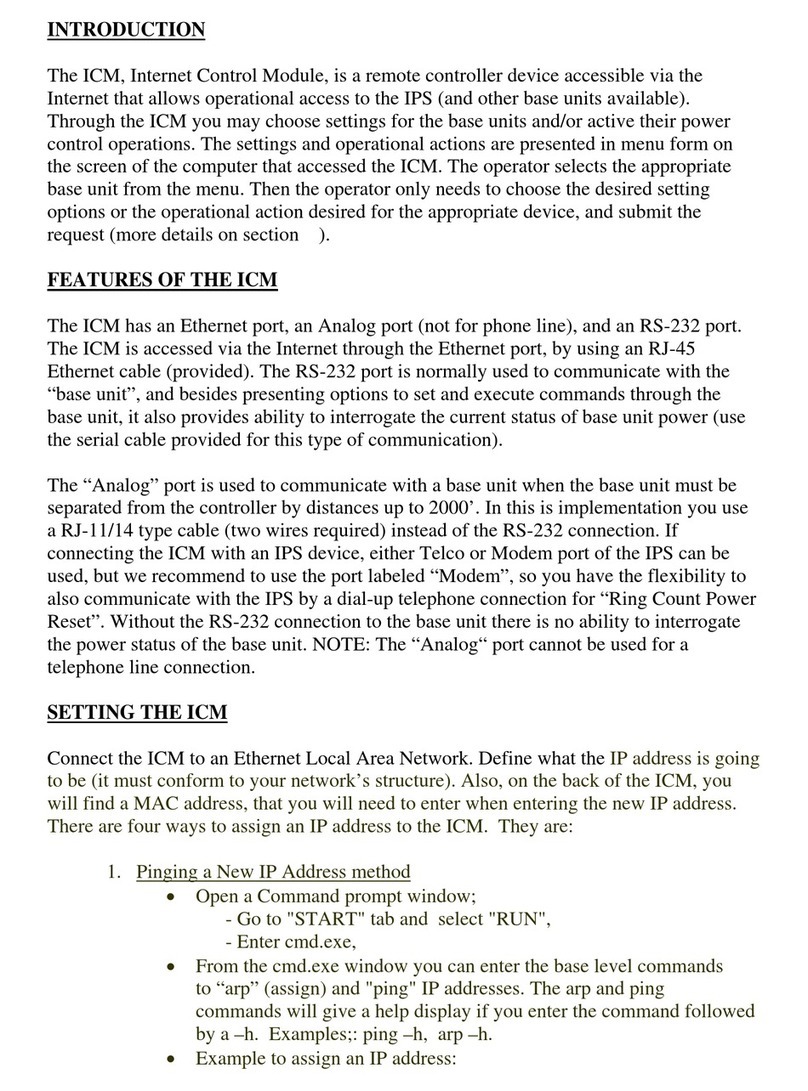

Multilink

Multilink ICM user guide