TLV DR8-3P User manual

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

Clean Steam Direct-acting Pressure Reducing Valve

DR8-3P / DR8-3EP

DR8-6P / DR8-6EP

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

1

Contents

Introduction .......................................................................1

Safety Considerations.......................................................2

Specifications....................................................................4

Acceptable Operating Range............................................4

Correct Usage of the DR8 Direct-acting Pressure

Reducing Valve.................................................................5

Configuration.....................................................................8

Installation.........................................................................9

Adjustment ......................................................................12

Maintenance....................................................................13

Disassembly....................................................................14

Reassembly ....................................................................19

Troubleshooting ..............................................................20

Product Warranty ............................................................22

Introduction

Thank you for purchasing the TLV DR8 clean steam direct-acting pressure

reducing valve.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check

the specifications and external appearance to make sure nothing is out of

the ordinary. Also be sure to read this manual carefully before use and

follow the instructions to be sure of using the product properly.

The TLV DR8 clean steam direct-acting pressure reducing valve has been

developed especially for the food, beverage and pharmaceutical

industries. This product has an angle type structure with special polishing

applied to internal parts to minimize areas for condensate to accumulate,

and prevent contamination inside the product. Additionally this product has

a structure that is easily disassembled to make internal cleaning

convenient.

For products with special order specifications or options, if detailed

instructions for the special order specifications or options are not

contained in this manual, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the

front cover. It is necessary not only for installation but for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it

in a safe place for future reference.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the

instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve opening/closing should be carried out only by trained

maintenance personnel.

The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of

cautionary items are used to indicate the degree of urgency and the

scale of potential damage and danger: DANGER, WARNING and

CAUTION.

The three types of cautionary items above are very important for safety:

be sure to observe all of them as they relate to installation, use,

maintenance, and repair. Furthermore, TLV accepts no responsibility

for any accidents or damage occurring as a result of failure to observe

these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious

injury

CAUTION

Indicates that there is a possibility of injury or

equipment/product damage

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents.

Local regulations may restrict the use of this product to below

the conditions quoted.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until

the internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Continued on the next page

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

3

CAUTION

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to

the product and burns or other injury due to malfunction or the

discharge of fluids.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading

to fluid discharge, which may cause burns or other injury.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

4

Specifications

Install properly and DO NOT use this product outside the recom mended

operating pressure, temperature and other specification ranges.

Im proper use may result in such hazards as dam age to the product or

malfunctions which m ay lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may dam age the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the indications on the spring housing for detailed specifications.

Connection Standard No.

CNo.**

Production

Lot No.

Inner Diameter

Primary Pressure Range

Secondary Pressure Adjustable Range

Connection Standard

Nominal Diameter

Maximum Allowable

Pressure/Temperature*

Maximum Operating

Pressure/Temperature

Model

*Maximum allowable pressure (PMA) and maximum

allowable temperature (TMA) are PRESSURE SHELL

DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

**CNo. (Charge/Mill No.) is displayed for products with

options. This item is omitted when there are no options.

Acceptable Operating Range

Model

DR8-3P/DR8-3EP

DR8-6P/DR8-6EP

Primary Pressure Range

0.2 to 0.4 MPaG

(30 to 60 psig)

0.4 to 0.8 MPaG

(60 to 115 psig)

Adjustable Pressure Range

0.018 to 0.3 MPaG

(2.5 to 45 psig)

0.27 to 0.6 MPaG

(40 to 85 psig)

No more than a maximum of 75% of the primary pressure

Minimum Adjustable Flow Rate

Steam: 20 kg/h (44 lb/h) or more

(1 MPa = 10.197 kg/cm2)

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

5

Correct Usage of the DR8 Direct-acting Pressure

Reducing Valve

Install properly and DO NOT use this product outside the recom mended

operating pressure, temperature and other specification ranges.

Im proper use may result in such hazards as dam age to the product or

malfunctions which m ay lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

1. The DR8 should be operated only within its specifications.

2. Installing an ON/OFF valve (solenoid valve or motorized valve)

Motorized

Valve

DR8

Inlet Side

Steam Trap

Motorized

Valve

DR8

Outlet Side

Steam Trap

If an on-off valve, such as a motorized valve, is required to stop supply of

steam to the steam-using equipment, install it at the inlet side of the DR8. If a

solenoid valve is installed at the outlet of the DR8, it will cause heavy

chattering and may lead to damage of the DR8. (When the on-off valve opens,

the secondary pressure of the DR8 changes from zero to the set pressure,

passing through an area of the reducing ratio of less than 30:1, where

adjustment is impossible, chattering occurs momentarily.) To save energy, it is

recommended to install the on-off valve as near to the boiler, as possible.

NOTE: To prevent water hammer, it is recommended that aslow-acting motorized

on-off valve be used. In particular, if a fast-acting on-off solenoid valve is

used for frequent temperaturecontrol, the potential water hammer effect

can damage the steam-using equipment and the DR8.

3. Installing a control and/or safety valve

Inlet

Valve

Steam

Trap

Pressure

Gauge

Outlet

Valve

Safety

(Relief)

Valve

Steam-using

Equipment

Steam

Trap

Steam-using

Equipment

Inlet

Valve

Steam

Trap

Pressure

Gauge

Outlet

Valve

Safety (Relief)

Valve

Steam

Trap

A control valve (i.e. for temperature control) installed between the DR8 and

the steam-using equipment (downstream of the DR8) may raise the pressure

between the DR8 and the control valve when the control valve is closed,

depending on the spatial relationship. Therefore, a safety valve should be

installed downstream of the control valve.

NOTE: When installing a safety valve to protect steam-using equipment, be sure to

install it on, or directly before, the inlet of the steam-using equipment. If the

safety valve is installed between the DR8 and a control valve, an eventual

pressure rise could activate the safety valve.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

6

4. Precautions for the installation of additional fittings before or after the DR8

In order to ensure a stable steam flow, the piping upstream and downstream

of the DR8must be in straight runs. If the DR8 is installed either directly

before or after an elbow or control valve, unevenness in steam flow may result

in chattering and unstable pressure.

To ensure a stable steam flow, it is recommended that the DR8be installed on

straight runs of piping, as illustrated below.

①Inlet (primary side) of the pressure reducing valve (NOTE: d = pipe diameter)

Maintain a straight

piping run of 10 d or

more when a manual

valve, a strainer or an

elbow, etc. is installed.

(Example: if nominal

size is 25 mm (1 in),

have 250 mm (10 in)

or more)

Inlet

Valve

Steam

Trap

Control

Valve

DR8

Steam

Trap

Steam

Trap

Steam

Trap

Steam

Trap

Steam

Trap

DR8

DR8 DR8

DR8 DR8

Control

Valve

Inlet

Valve

10 dor more Lessthan

10 d

30 dor more Lessthan

30d

10 d or more

Lessthan

10 d

Maintain a straight

piping run of 30 d or

more when an

automatic valve (on-off

valve) is installed.

(Example: if nominal

size is 25 mm (1 in),

have 750 mm (30 in)

or more)

Maintain a straight

piping run of 10 d or

more when a manual

valve, a strainer or an

elbow, etc. is installed.

(Example: if nominal

size is 25 mm (1 in),

have 250 mm (10 in)

or more)

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

7

②Outlet (secondary side) of the pressure reducing valve

Maintain a straight piping

run of 15 d or more when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size

is 25 mm (1 in), have 375

mm (15 in) or more)

Steam

Trap

Second

Pressure

Reducing

Valve

DR8

Steam

Trap

Steam

Trap

Steam

Trap

Steam

Trap

Steam

Trap

DR8

DR8 DR8

DR8 DR8

Safety (Relief)

Valve

Outlet

Valve

15 dor more Lessthan

15d

30 dor more Lessthan

30d

Outlet

Valve

Safety (Relief)

Valve

Second

Pressure

Reducing

Valve

30 dor more

Lessthan

10d

Lessthan

10d

Lessthan

30d

Maintain a straight piping

run of 30 d or more when a

safety valve is installed.

(Example: if nominal size is

25 mm (1 in), have 750 mm

(30 in) or more)

Maintain a straight piping

run of 30 d or more when

another pressure reducing

valve is installed. (Two-

stage pressure reduction)

(Example: if nominal size

is 25 mm (1 in), have 750

mm (30 in) or more)

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

8

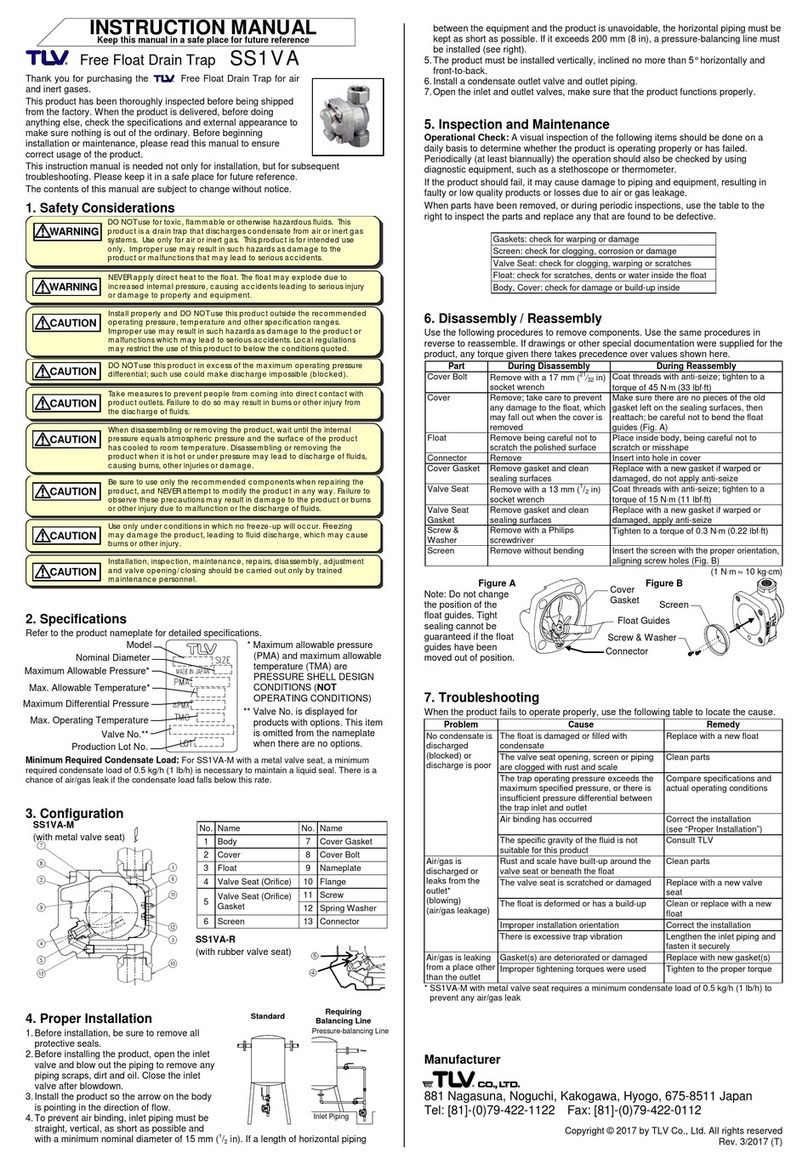

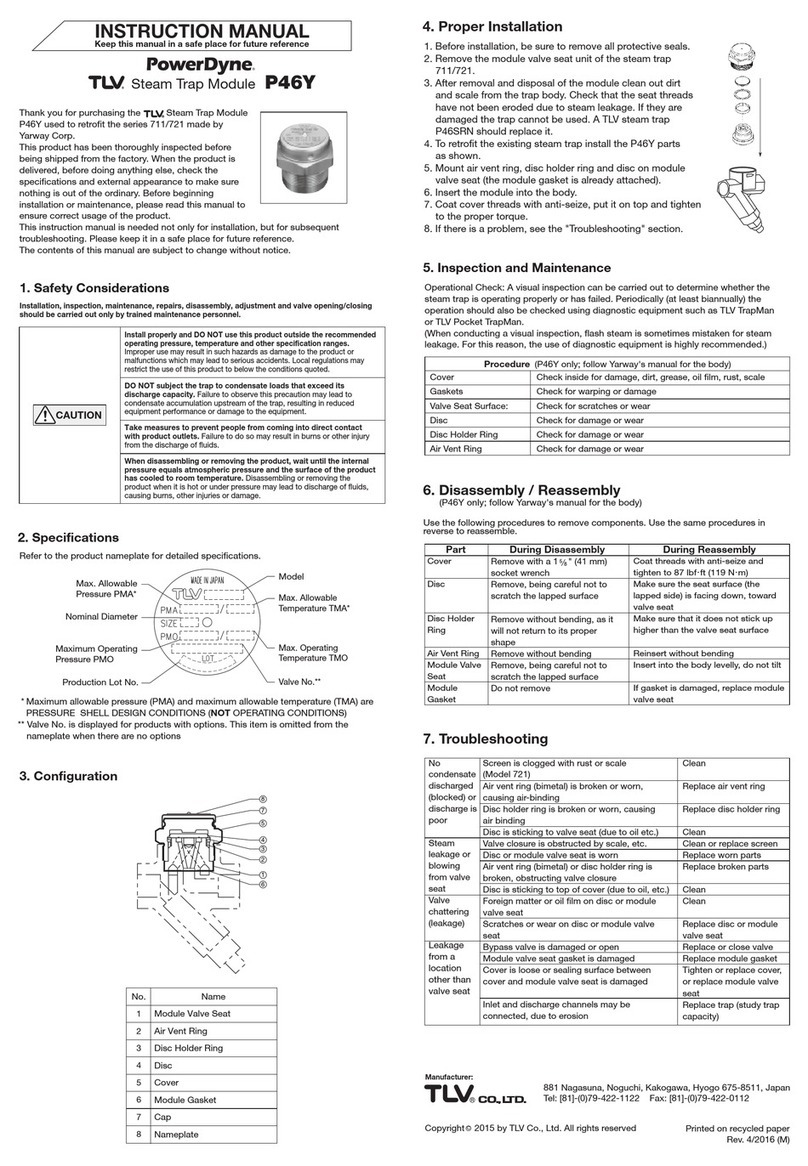

Configuration

A

A

Fig. A

Size 40 mm (1 1/2 in) (1,1 1/2,1 1/2 in)

Size 25,38,40 mm

Size 25 mm (1 in) (1/2 to 3/4 in)

Size 15 to 20 mm

(1/2 to 3/4 in)

Size 15 to 20 mm

No.

Name

A*1

B*1

C*1

D*1

1

Body

2

Valve

3

Diaphragm

4

Protective Sheet

5

Spring Housing

6

Upper Diaphragm

Retainer

7

Coil Spring

8

Cap

9

Lower Diaphragm

Retainer

10

Spacer

11

Spring Washer

12

Locknut

13

Plain Washer

14

Retainer Gasket

15

Spring Retainer

16

Locknut

17

Adjustment Screw

18

Valve Guide

19

Inlet Clamp Gasket*2

20

Snap Ring

21

Slide Bearing

22

Body Clamp

23

Body Clamp Bolt*3

24

Body Clamp Nut*3

25

Spring Washer*3

26

Inlet Clamp*3

27

Inlet Clamp Bolt*4

28

Inlet Clamp Nut*4

29

Spring Washer*4

30

Adapter*5

*1 Replacement parts are available

only in the following kits:

A: Maintenance Kit

B: Repair Kit for Diaphragm

C: Repair Kit for Valve

D: Repair Kit for Valve Guide

*2 Number of parts for sizes 15 to 20

mm (1/2to 3/4in): 2 pieces, 25 mm

(1 in): 1 piece

*3 Number of parts: 2 pieces

*4 Number of parts for sizes 15 to 20

mm (1/2to 3/4in): 4 pieces, 25 mm

(1 in): 2 pieces

*5 For sizes 15 to 20 mm (1/2to 3/4in)

only

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

9

Installation

Install properly and DO NOT use this product outside the recom mended

operating pressure, temperature and other specification ranges.

Im proper use may result in such hazards as dam age to the product or

malfunctions which m ay lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from com ing into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

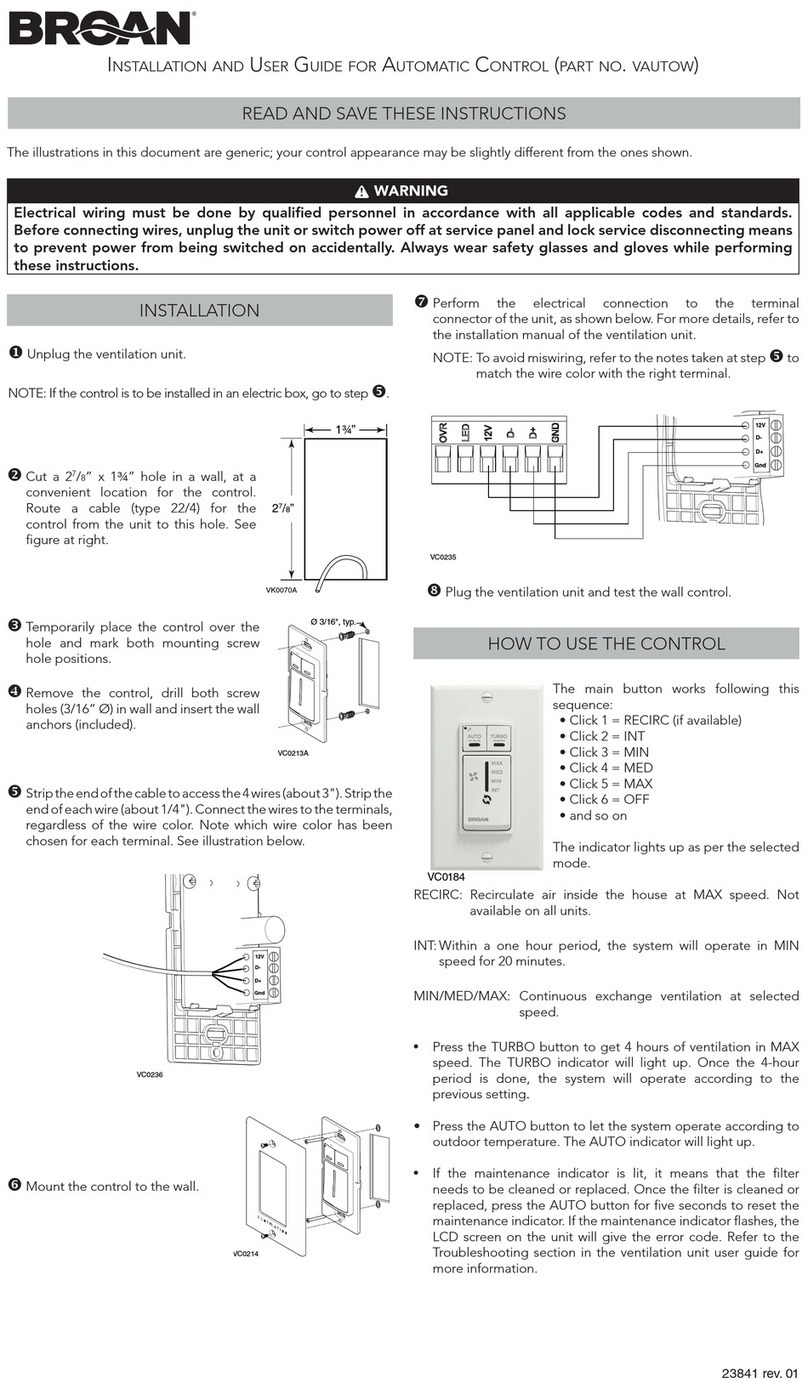

1. Removing the Protective Caps

Before installation, be sure to remove all protective seals and caps

covering the product inlet and outlets. (Found in 2 locations)

2. Tolerance Angle for Installation

Make sure the DR8 is installed vertically so that the arrow mark on

the body matches the direction of steam flow, the outlet is

horizontal, and the adjustment screw section faces up.

Allowable inclination is 10 degrees in the fore-aft direction

and 15 degrees side to side in the plane perpendicular to

the steam flow line.

3. Piping Support

Install the DR8, paying attention to avoid excessive load, bending and

vibration. It is recommended that the inlet and

outlet pipes be supported securely.

4. Maintenance Space

Leave sufficient space for maintenance,

inspection and repair.

A: 260 mm (101/4in)

B: 110 mm (41/2in)

A

BB

DR-8

Piping

Support

Piping

Support

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

10

5. Piping Size

If the secondary steam flow velocity is expected to be more than 30 m/s (100

ft/s), install a diffuser in order to keep the flow velocity below 30 m/s (100 ft/s).

If the distance between the DR8 and the steam-using equipment is great, a

possible drop in pressure should be taken into consideration when selecting

the piping size.

Bypass Valve

DR8

Pressure

Gauge

Inlet Side Inlet

Valve

Outlet

Valve

Pressure

Gauge

Secondary

Side

Safety Valve

(Relief Valve)

Steam Trap

Bypass Valve

Safety Valve

(Relief Valve)

DR8 Outlet

Valve

Pressure

Gauge

Pressure

Gauge

Inlet Side Inlet

Valve

Secondary

Side

Steam Trap

Outlet Pressure Valve Gauge

Straight piping: 10d or longer for primaryside,15d

or longer for secondary side (d=pipe diameter)

6. Two-stage Pressure Reduction

Employ 2-stage pressure reduction if the required reduction is not possible due

to DR8 operating range limitations (when it is not possible to reduce to the

desired pressure using a single pressure reducing valve).

Steam

Trap

Steam Trap

Primary

Side

Inlet

Valve

Inlet

Valve Steam

Trap

Secondary

Side

Outlet

Valve

Outlet

Valve

Bypass Valve

Bypass Valve DR8

DR8 Pressure

Gauge

Pressure

Gauge

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

11

7. Accessories

Always install a bypass line. At the inlet and outlet, install a pressure gauge

and a shut-off valve. Ball valves, which will not retain condensate, are

recommended for inlet/outlet shut-off valves. The nominal pipe size for the

bypass line should be 1/2or greater of the primary pipe size.

Ball Valve

Steam Trap

Primary

Side

Pressure

Gauge Inlet

Valve

Outlet

Valve

Ball Valve Pressure

Gauge

Bypass Valve Safety Valve

(Relief Valve)

Secondary

Side

8. Blowdown (Installing the bypass valve)

Before installing the DR8 or supplying steam to the DR8, be sure to blow down

all piping thoroughly. Installing the bypass valve makes blowdown easier.

Blowdown is especially important for newly installed piping or after the system

has been shut down for a long period of time. This will reduce operation failure

caused by condensate or foreign matter. The bypass valve should not be

opened too quickly. If a safety valve (or relief valve) is installed, perform

blowdown staying clear of pressurized blow-out.

If condensate accumulates while the inlet valve is closed, install a steam trap

that has a sufficient discharge capacity considering the initial condensate

discharge amount.

To perform blowdown, close the inlet valve (A) first, then the outlet valve (B), and

open the bypass valve (C). Do not open valves too quickly.

Steam Trap

Primary

Side

Pressure

Gauge Inlet

Valve

(A)

Outlet

Valve

(B)

Pressure

Gauge

Bypass Valve

(C) Safety Valve

(Relief Valve)

Secondary

Side

DR8

Steam Trap

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

12

Adjustment

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which m ay cause burns or other injury.

CAUTION

To avoid problems such as water hammer and to protect steam-using equipment,

the DR8 should be correctly adjusted.

1. It is necessary to blow down all pipe lines thoroughly. The blowdown is

especially important if the line is new or has been shut down for a long period

of time. Take particular care to ensure that matter such as condensate and dirt

does not remain inside the steam-using equipment.

(Stay clear of any pressurized blow-out from the safety valve.)

2. Make sure that the shut-off and bypass valves located upstream and

downstream of the DR8 are completely closed.

3. Remove the cap and loosen the locknut, then turn the adjustment screw

counterclockwise to free the coil spring.

4. Slowly, fully open the shut-off valve at the inlet of the DR8.

5. Slightly open the shut-off valve at the outlet of the DR8.

6. Turn the adjustment screw clockwise until the desired outlet pressure is

obtained. Wait several minutes.

Clockwise Counter-

clockwise

Increase Pressure Decrease Pressure

7. Slowly, fully open the shut-off valve at the outlet of the DR8.

8. After setting, hold the adjustment screw and retighten the locknut.

9. When shutting down the system, always close the outlet shut-off valve first and

then the inlet valve. (If the inlet shut-off valve is closed first, the safety valve

may be tripped.)

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

13

Maintenance

Take measures to prevent people from com ing into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended com ponents when repairing the

product, and NEVER attem pt to modify the product in any way. Failure to

observe these precautions may result in dam age to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Parts Inspection

When parts have been removed, or during periodic inspections, use the following

table to inspect the parts and replace any that are found to be defective.

Part

Inspection and Maintenance Frequency

Diaphragm

If hunting or chattering takes place, cracks or fatigue may develop in

a short period of time.

Protective Sheet

Check for cracks

Body

(Seat section)

If there is chattering or dirt, premature wear may result.

Valve

(Seat section)

If there is chattering or dirt, premature wear may result.

Valve Guide,

(Slide Bearing)

If hunting or chattering takes place, premature wear may result.

Gaskets

Check for deformation or scratches

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

14

Disassembly

When disassembling or removing the product, wait until the internal

pressure equals atm ospheric pressure and the surface of the product

has cooled to room temperature. Disassem bling or removing the

product when it is hot or under pressure m ay lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

It is a recommended practice to dismantle and inspect the DR8 once a year for

preventive maintenance purposes. It is especially important to perform an

inspection immediately after the initial run of a new line or before or after

equipment such as a heater is out of service for a long period of time.

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

Remove all steam from the piping (both upstream and downstream).

Wait for the body to cool before attempting to remove the DR8 from the line.

Then remove the DR8 from the piping, and secure it in a vise to perform the

inspection.

Disassembling the Adjustment Section

Loosen the cap and the locknut first. Loosen the adjustment screw completely

and remove the body clamp.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

15

After removing the spring housing, remove the adjustment screw, spring retainer,

and coil spring.

Check for seizure or any damaged screw threads.

Adjustment Screw

(Reverse thread)

Spring Retainer

(Reverse thread)

Coil Spring

Disassembling the Diaphragm Section

Hold the valve in place with an adjustable wrench across the flats on the upper

part of the valve and use another wrench to remove the locknut. After removing

the locknut, remove the plain washer, the upper diaphragm retainer and the

diaphragm.

The upper diaphragm retainer,

diaphragm, protective sheet,

lower diaphragm retainer and

retainer gasket can be removed

after removing the locknut.

UpperDiaphragm

Retainer

Diaphragm

Lower Diaphragm

Retainer

Retainer Gasket

Locknut

Spring Washer

Plain Washer

Spacer

Protective Sheet

Locknut

Valve

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

16

Disassembling the Valve Section

Remove the inlet clamp(s) holding the body, valve guide and adapter (for sizes

15 to 20 mm (1/2to 3/4in) only).

Remove the adapter and the inlet clamp gasket.

(for sizes 15 to 20 mm (1/2to 3/4in) only)

Separate the valve guide from the body. The valve comes off with the valve guide.

Valve

Inlet Clamp Gasket

Valve Guide

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

17

Disassembling the Valve Guide Section

Snap Ring*

Slide Bearing*

Valve Guide

*The slide bearing and snap ring cannot be

removed individually as they are

incorporated with the valve guide and

must be replaced as a set with the valve

guide.

Cleaning

After inspecting for scratches, erosion, etc. on the seating surface of the body

and valve, cracks or deterioration of the diaphragm and protective sheet, wear on

the valve guide, cracks or deterioration of the retainer gasket, and if there are no

abnormalities, clean and reassemble the parts.

The following parts will require cleaning before reassembly:

Diaphragm, protective sheet, valve, valve guide, retainer gasket, body,

lower diaphragm retainer, adapter (for sizes 15 to 20 mm (1/2to 3/4in) only)

NOTE: Avoid using solvent to clean these parts as it may accelerate deterioration

of the diaphragm, protective sheet, and resin part of the valve guide and

retainer gasket.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

18

Exploded View

Adjustment Srew

Spring Retainer

Coil Spring

Cap

Locknut

Spring Housing

Locknut

Plain Washer

Spring Washer

Upper Diaphragm

Retainer

Spacer

Protective Sheet

Lower Diaphragm

Retainer

Retainer

Gasket

Valve

Inlet Clamp Nut

Spring Washer

Inlet Clamp

Inlet Clamp Gasket

Inlet Clamp Gasket

Snap

Ring*

Slide Bearing*

Valve Guide

Inlet Clamp Nut

Spring Washer

Inlet Clamp Bolt

Inlet Clamp Bolt

Inlet Clamp

Adapter

(For sizes 15 to 20 mm (1/2to 3/4in) only)

Body Clamp Nut

Spring Washer

Body Clamp

Body Clamp Bolt

Body

For sizes 15 to 20 mm

(1/2to 3/4in)

* The slide bearing and snap ring cannot be removed individually as they are incorporated

with the valve guide and must be replaced as a set with the valve guide.

172-65613MA-04 (DR8-3P/DR8-3EP/DR8-6P/DR8-6EP) 18 May 2021

19

Reassembly

Reassemble the unit using the same procedure as used for disassembly; but in

reverse order. In addition, observe the following precautions:

1. The diaphragm and the protective sheet also perform the role of gaskets and

may be re-used if free from cracks, deterioration or deformation. If any

abnormalities are found, these parts need to be replaced. The protective

sheet must fit to the groove of the body. Make sure that the convex portion

of the diaphragm faces up.

Protective Sheet

Diaphragm

2. Make sure there are no scratches or erosion on the surface of the valve seat

section of the body and seating surface of the valve, as this will lead to leakage.

If no abnormalities are found, these parts can be reused. When there are

scratches or erosion on these parts, the body and/or valve need to be replaced.

Viewing the valve seat section

of the body from the inlet side Valve

Seating

surface

3. The retainer gasket may be re-used if it has no cracks or deterioration. If any

abnormalities are found, it needs to be replaced.

4. Applying anti-seize to all non-wetted threaded parts is recommended.

Threaded portion of

the valve

5. Standard torques for fastening the respective screws and the width across

flats of the tools to be used are as follows:

Part

Torque

Distance Across Flats

Nm

(lbfft)

mm

(in)

Locknut

3

(2.2)

17

(21/32)

Body Clamp Nut,

Inlet Clamp Nut

3

(2.2)

17

(21/32)

(1 Nm 10 kgcm)

NOTE: If drawings or other special documentation were supplied for the product, any

torque given there takes precedence over values shown here.

Other manuals for DR8-3P

2

This manual suits for next models

3

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

LSIS

LSIS XGT Series user manual

Grohe

Grohe GROHSAFE 3.0 35 11 Series owner's manual

Emerson

Emerson ANDERSON GREENWOOD MARVAC 121 Series Installation and maintenance instructions

Vortice

Vortice SCNRL5 Instruction booklet

V Expressions

V Expressions Roland TD-27 quick start guide

Sices

Sices REWIND user manual

Baker Hughes

Baker Hughes Masoneilan MiniTork II 37002 Series instruction manual

ADEMCO

ADEMCO LYNX-AVM Installation and setup guide

jbc

jbc ALE-908UVA instruction manual

american flame

american flame AF-LMF-RV Installation and operation instructions

VXI

VXI VT1419A Multifunction Plus user manual

Bürkert

Bürkert Type 2000 Service manual