TLV CV-COSR User manual

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 June 2019

Pneumatic Control Valve

CV-COSR

Copyright © 2019 by TLV CO., LTD.

All rights reserved

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

1

Contents

Introduction ........................................................................ 2

Safety Considerations........................................................ 3

Specifications..................................................................... 5

Configuration...................................................................... 7

Installation.......................................................................... 8

Electrical Wiring ................................................................11

Operational Check ........................................................... 12

Maintenance..................................................................... 14

Disassembly/Reassembly................................................ 15

Troubleshooting................................................................ 19

Product Warranty ............................................................. 21

Options............................................................................. 22

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

2

Introduction

Thank you for purchasing the TLV pneumatic control valve.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

This product employs an integrated positioner/diaphragm-type actuator with

no lever, making it very compact. In addition, a threaded condensate drainage

port is provided at the bottom of the body to allow installation of a blow valve

or steam/air trap in order to eliminate condensate flowing in the piping,

contributing to prevention of valve seat erosion and rapid start-up of the

equipment.

This instruction manual is intended for use with the model(s) listed on the front

cover. It is needed not only for installation, but also for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

3

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the

object should fall.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Continued on next page

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

4

CAUTION

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

Make sure the power supply is OFF before carrying out work

on the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger

that equipment may malfunction or electric shock may occur,

leading to injury or other accidents.

Make sure that wiring work requiring a special license is

carried out by qualified personnel.

If carried out by unqualified personnel, overheating or short

circuits leading to injury, fires, damage or other accidents may

occur.

When using this product, NEVER stand close to, or leave

tools anywhere near, moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving

parts could lead to injury or damage or other accidents.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

5

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the product nameplate*** for detailed specifications.

Model

Nominal Diameter

Maximum Allowable*

Pressure*

Maximum Operating

Pressure

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Valve No.**

Production Lot No.

Cv(US) or Kvs(DIN) & Valve Characteristic

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

*** Nameplate layout depends on product specifications.

Actuator/Pneumatic Positioner

Actuator Area

120 cm2(18.6 in2)

Operation

Air-to-Open (Reverse Action)

Air Supply Connection Port

Pneumatic positioner body G1/4(with adapter for

G1/4× RC1/4, BSPT1/4or NPT1/4)

Maximum Air Supply Pressure

0.6 MPaG (85 psig)

Motive Medium

Oil-free air, filtered to 5 µm

Air Consumption

At air supply pressure 0.4 MPaG: 0.16 Nm3/h

(55 psig: 5.65 ft3/h)

Electrical Input Signal/Resistance

4 to 20 mA DC / approximately 300 Ω

Electrical Connection Port

PG11

Protection Class

IP54 (dust and splash-proof type)

Allowable Ambient Temperature Range

-10 to 60 C (14 to 140 F)

Material

Die cast aluminum/synthetic resin

Air Supply Pressure

Size

Pressure Supplied

to Filter Regulator

Air Pressure Supplied to

Positioner

Air Pressure Supplied to

Actuator

(Spring Range)

15 –50 mm

(1/2–2 in)

0.40 –0.60 MPaG

(55 –85 psig)

0.38 MPaG

(54 psig)

0.21 –0.33 MPaG

(30 –48 psig)

(1 MPa = 10.197 kg/cm2)

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

6

Valve

Size mm (in)

15 (1/2)

20 (3/4)

25 (1)

40 (11/2)

50 (2)

Maximum Operating

Pressure (PMO)

See nameplate

Maximum Operating

Temperature (TMO)

See nameplate

Applicable Fluid*

Steam, Water, Air

Valve Plug & Stem/

Valve Seat Material

Stainless steel

Valve Characteristic

Equal percentage

Stroke (Travel)

15 mm (9/16 in)

Rangeability

50:1

Cv and Kvs

Values

Cv (US)

3.5

6.0

9.0

27

40

Cv (UK)

2.9

5.0

7.5

23

33

Kvs (DIN)

3.0

5.1

7.7

23

34

Valve Leakage Rate

(Leak Rate Class)

Less than 0.01% of the rated Cv and Kvs value

(IEC/ANSI/EN Class IV)

Condensate Drainage

Port

Rc(PT)1/2, BSPT1/2or NPT1/2

(1 MPa = 10.197 kg/cm2)

*Do not use for toxic, flammable or otherwise hazardous fluids.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

7

Configuration

Size: 15 –25 mm

No.

Part Name

M*

R*

1

Actuator Body

2

Pressure Gauge

3

Bushing

4

Specifications Sticker

5

Guide Bushing

6

Valve Bonnet Nut

7

Valve Bonnet

8

Stuffing Box V-rings

9

Stuffing Box Washer

10

Stuffing Box Spring

11

Valve Plug & Stem

12

Valve Bonnet Gasket

13

Bolt

14

Flange

15

Valve Bonnet Guide

16

Valve Bonnet Guide Gasket

17

Body

18

Valve Seat

19

Valve Seat Gasket

20

Cover Plug

21

Cover Plug Gasket

22

Nameplate

23

Gasket

24

Bolt

25

Nut

26

Stem Bracket Connector Plate Set

27

Drain Plug

Size: 40, 50 mm

No.

Part Name

M*

R*

1

Actuator Body

2

Pressure Gauge

3

Bushing

4

Specifications Sticker

5

Guide Bushing

6

Valve Bonnet Nut

7

Valve Bonnet

8

Stuffing Box V-rings

9

Stuffing Box Washer

10

Stuffing Box Spring

11

Valve Plug & Stem

12

Valve Bonnet Gasket

13

Bolt

14

Flange

15

Valve Bonnet Guide

16

Valve Bonnet Guide Gasket

17

Body

18

Valve Seat

19

Valve Seat Gasket

20

Cover

21

Cover Gasket

22

Nameplate

23

Gasket

24

Bolt

25

Nut

26

Stem Bracket Connector Plate Set

27

Cover Bolt

28

Drain Plug

*Replacement parts are available only in the following kits:

M = Maintenance Kit R = Repair Kit

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

8

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly and adjustment and

valve opening/closing should be carried out only by trained maintenance

personnel.

Check to make sure that the piping where the product is to be installed is

constructed properly. If the piping is not correctly constructed, the valve may not

perform optimally.

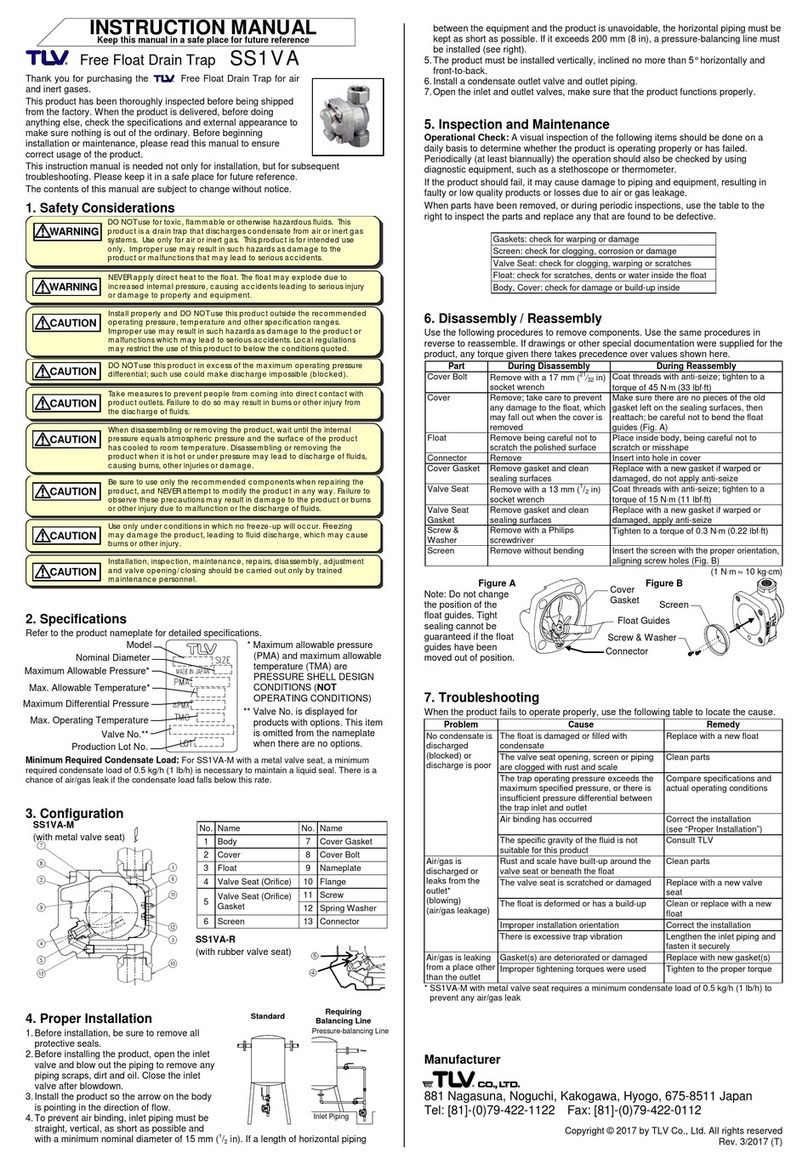

1. Blowdown

Before installing the CV-COSR unit, be sure to blow down all piping thoroughly.

If this is not possible, perform a blowdown using the bypass valve. Blowdown

is especially important for newly installed piping or after the system has been

shut down for a long period of time.

2. Removing any Protective Caps and Seals

Before installation, be sure to remove all protective seals and caps.

(Found in 2 locations, on the product inlet and outlet.)

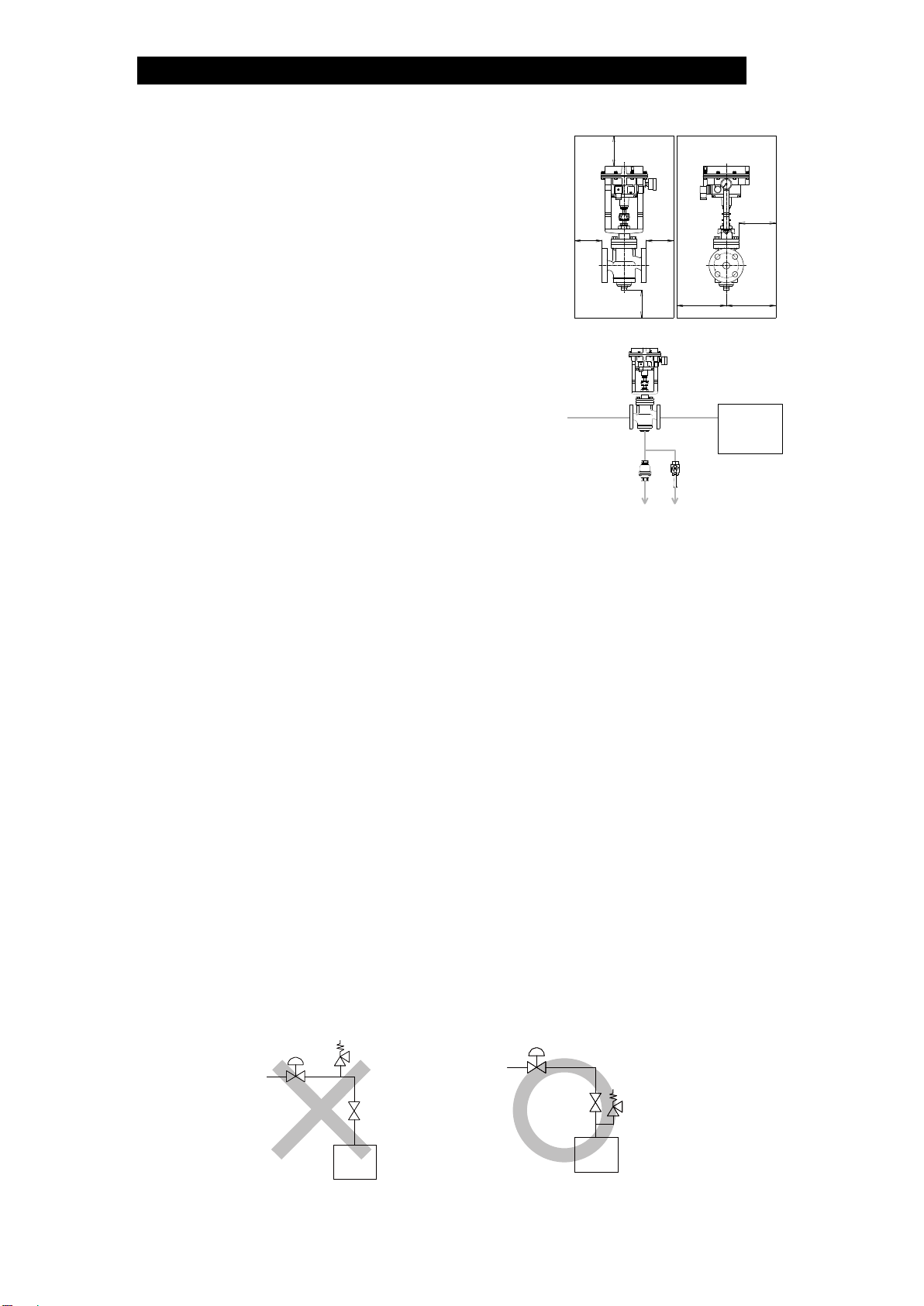

3. Installation Orientation

Install the CV-COSR so that the arrow mark on

the body points in the direction of fluid flow.

If the CV-COSR is going to be used with the drain

plug in place, there are no further restrictions on

the installation orientation. If a blow valve or a

steam/air trap is going to be installed, the CV-

COSR should be installed horizontally in the

piping with the actuator at the top.

4. Piping Support

Install the CV-COSR, paying attention to avoid excessive

load, bending and vibration. Support the inlet and outlet

pipes securely.

① ②

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

9

5. Maintenance Space

Leave sufficient space for maintenance, inspection

and repair.

6. Drainage Port Usage Example

The threaded condensate drainage port at the

bottom of the body makes possible installation of

a blow valve or steam/air trap. Because the

condensate drainage port is located on the

primary side of the CV-COSR, condensate

flowing in the primary side piping can quickly be

eliminated, contributing to prevention of valve

seat erosion and rapid start-up of the equipment.

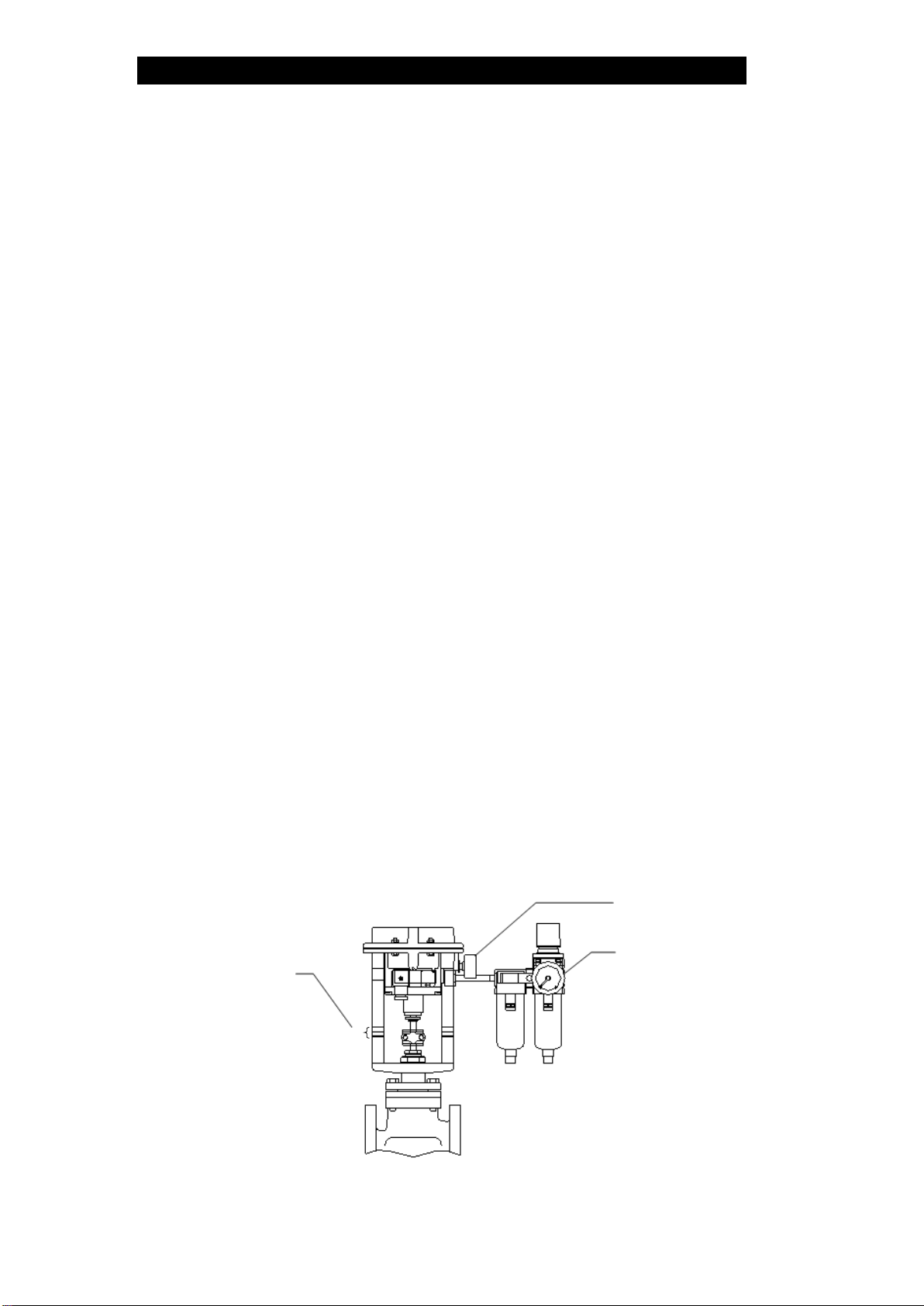

7. Accessories

Always install a shut-off valve, pressure gauge and bypass lines at both inlet and

outlet. Ball valves, which will not retain condensate, are recommended for inlet

and outlet shut-off valves. The bypass pipe should be at least 1/2of the size of the

inlet (primary side) pipe.

8. Installation Environment

Check the installation environment to make sure that the ambient temperature

does not exceed the actuator ambient temperature limit and that no corrosive

gasses are present.

9. Shut-off Valve Installation

Though the CV-COSR adequately performs the function of a shut-off valve

initially, extended use will result in a drop in its performance as an isolation valve.

Be sure to install a separate shut-off or automatic valve if complete isolation is

needed.

10. Safety Valve Installation

When installing a safety valve, be sure not to install it between the control valve

and the shut-off valve. It must be installed near the equipment it is to protect,

on the outlet side of the shut-off valve.

Safety Valve

Safety Valve

Drainage Pit

Approx.

300 mm

(12 in)

100 mm

(4 in)

100 mm

(4 in)

110 mm

(41/2in)

100 mm

(4 in)

400 mm

(16 in)

400 mm

(16 in)

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

10

11. Avoid Foreign Matter and Water Hammer

Do not install in locations in the piping where foreign matter accumulates or

where impact from water pressure (water hammer) occurs.

12. Piping Gaskets

Be careful that the piping gaskets do not protrude outside the inner bore of the

flange.

The type of medium being used and the temperature must be taken into account

in order to select a gasket of a suitable material.

13. Air Line Blowdown/Purge

Before connecting the air lines for the motive air that is to be piped to the

actuator, blow out the air in the lines to purge any dirt, foreign matter, oil or water

from inside of the piping.

14. Quality of Motive Air

Supply to the actuator only clean air that does not contain water, oil or foreign

matter.

To prevent malfunction due to contamination of the air supply, installation of the

optional air filter regulator (5µ filter) and mist separator (0.3µ filter) as a set is

recommended.

If air quality results in operation failure, the entire actuator unit (including the

integrated positioner) must be replaced.

If there is a problem in operation, determine the cause using the “Troubleshooting”

section in this manual.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

11

Electrical Wiring

Make sure the power supply is OFF before carrying out work on the

wiring or inspections involving disassembly. If such work is carried out

with the power on, there is a danger that equipment may malfunction or

electric shock may occur, leading to injury or other accidents.

CAUTION

Make sure that wiring work requiring a special license is carried out only

by qualified personnel. If carried out by unqualified personnel,

overheating or short circuits leading to injury, fires, damage or other

accidents may occur.

CAUTION

Connecting the Electrical Plug Connector

1. Loosen the screw (1) in the center section of the electrical wiring plug connector

by using a screwdriver.

2. Pull the entire plug connector out of the actuator. Be careful not to lose the rubber

gasket (5).

3. Insert a screwdriver into the notch (4) in the terminal plug (3) and remove the

terminal plug (3) from the plug connector case (2).

4. Insert the input signal wiring through the wiring connection port (6) and connect

the wiring to the 1(+), 2(-) and ground terminals at the symbols imprinted on the

terminal plug (3), taking care not to reverse the polarity.

5. Reinsert the connected terminal plug (3) into the plug connector case (2).

When inserting the terminal plug (3) into the plug connector case (2), the

orientation of the wiring connection port may be altered by rotating the terminal

plug (3) 90or 180.

6. Reinsert the plug connector into the actuator. Make sure to correctly align the

male and female pins. Remember to reinsert the rubber gasket (5) between the

plug connector and the actuator.

7. Retighten the screw (1) in the center section of the electrical wiring plug connector

by using a screwdriver.

Connector

Screw

NOTE: Use shielded cable to avoid noise interference in the electrical wiring.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

12

Operational Check

Before beginning steady operation, perform an operational check by following the

steps outlined below:

1. Close the shut-off valves on the CV-COSR inlets and outlets. Check operation

without yet starting the flow of fluid (steam, water or air).

2. Check to make sure the designated air pressure is being supplied to the pneumatic

positioner. (Air pressure: 0.38 MPaG (54 psig))

NOTE: If the air supply pressure is incorrect, adjust it using an inlet air reducing valve.

NOTE: If an air reducing valve is attached, check the reading on its pressure gauge.

3. Turn on the power to the controller operation signal source, etc. (referred to

hereinafter as the controller).

4. Set the operation signal output from the controller to the CV-COSR to 0% (4 mA).

5. Check the CV-COSR valve travel and the actuator air supply pressure.

Valve Travel: Fully closed (valve travel 0%)

Air Pressure: 0 MPaG (check the pressure gauge on the pneumatic positioner for

the air pressure)

NOTE: If the air pressure is not 0 MPaG (0 psig), refer to the "Adjusting the Zero/

Span" section of this product Instruction Manual and adjust the zero.

6. Set the controller operation signal to 100% (20 mA).

7. Check the CV-COSR valve travel and the actuator air supply pressure.

Valve Travel: Fully open (valve travel 100%)

Air Pressure: Approximately 0.38 MPaG (54 psig) (check the pressure gauge on

the pneumatic positioner for the air pressure)

NOTE: If the valve travel differs widely from 100%, refer to the "Adjusting the

Zero/Span" section of this product Instruction Manual and re-adjust the

span and the zero.

NOTE: If the control valve does not move from the fully closed position, check to

see if the wires for the controller and control valve have any breaks, short-

circuits, or have their polarity reversed (+ and –are reversed).

8. Set the controller operation signal to 50% (12 mA).

9. Make sure valve travel is smooth and without vibration.

NOTE: If the valve is vibrating vertically, it may be being caused by noise on the

signal wiring. Check to see if there is a possible source of noise nearby.

Actuator Air Supply Pressure

Positioner Air Supply

Pressure Gauge

Valve Travel Gauge

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

13

Adjusting the Zero/Span

1. After connecting the air piping, operate the air pressure reducing valve to maintain

the positioner air supply pressure at 0.38 MPaG (54 psig) (reverse action).

2. Connect a current generator or a controller for input of an operation signal of 4 to

20 mA.

3. Loosen the cover plate screw and open the cover plate.

4. Pull out the jumper pin. (Be sure not to lose it.)

5. Set the operation signal output from the current generator or controller to 4 mA

(0%).

6. Turn the zero adjustment dial slowly until the valve just begins to open (the

actuator pressure gauge just beings to move). (The valve must NOT be open.)

NOTE: Turning counterclockwise causes the valve to begin to open earlier.

7. Change the operation signal to 4.1 mA (1%) and check to make sure the valve

begins to open.

8. Change the operation signal to 4 mA (0%) and check to make sure the valve is

completely closed (the actuator pressure gauge is completely at zero).

9. Change the operation signal to 20 mA (100%), and make sure that the stroke

indicator reads in the vicinity of 100%.

If it does not, use a precision flat-head screwdriver to turn the span adjustment

potentiometer until it is close to 100%.

NOTE: Turning clockwise increases the stroke (travel).

10. Each modification of the span results in a zero shift. Repeat the above correction

procedure until both the zero and span are correct.

11. After completing the adjustment, insert the jumper pin securely into their previous

position and close the cover.

Stroke Guide

Zero/Span Adjustment

100%

50%

0%

Stroke Gauge

Span Adjustment

Potentiometer

Jumper Pin

Cover Plate

Zero Adjustment

Dial

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

14

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

An inspection of the following items should be done on a daily basis to determine

whether the product is operating properly or has failed. Periodically (at least

biannually) the operation should also be checked.

In the event of failure (malfunction), also refer to the "Troubleshooting" section for

remedies.

Inspection Item

Inspection Points

Remedy for Failure (Malfunction)

Leakage from valve

(when the valve is

closed)

Visual inspection or stethoscope

inspection; is the outlet side

pressure or temperature elevated,

or is there the sound of the

medium flowing?

Adjust the zero/span; if that does

not solve the problem, replace

with a new valve plug & stem and

valve seat

Leakage from gland

area

Visual inspection; is fluid leaking

from the gap between the gland

and the valve stem, or are there

signs it has leaked previously?

Coat the gland and the valve

stem with grease; if that does not

solve the problem, replace with

new V-rings

Air leakage from

actuator

Visual inspection or stethoscope

inspection; can the sound of a

large amount of air leaking from

the actuator area or the exhaust

tap during stable actuator

operation always be heard?

Replace with a new actuator unit

Leakage from the

gaskets between

any pressurized

parts

Visual inspection; is fluid leaking

from the gasket areas on

pressurized parts?

Apply additional tightening (refer

to recommended torque) or

replace with new gaskets

Leakage from

pressurized parts

such as body and

valve bonnet

Visual inspection; is fluid leaking

from pressurized parts such as

the body or valve bonnet?

Replace any pressurized parts at

leak locations

Operating conditions

Visual inspection; does the actual

valve travel differ from the

designated operation signal value?

Readjust the air pressure

reducing valve and positioner

zero and span; if that does not

solve the problem, refer to the

"Troubleshooting" section

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

15

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

NOTE: Be sure to coat all threaded portions of the valve seat and bolts with anti-seize.

Perform the following procedure before beginning disassembly:

1. After connecting the air piping, operate the air pressure reducing valve to maintain

the positioner air supply pressure at 0.38 MPaG (54 psig).

2. Connect a current generator or a controller for input of an operation signal of 4 to

20 mA.

Removing/Reattaching the Stem Bracket Plates

Part

During Disassembly

During Reassembly

—

Set the actuator air supply

pressure to 0 MPaG (0 psig)

to maintain the valve in the

fully closed position.

Set the actuator air supply

pressure to 0 MPaG (0 psig) to

maintain the valve in the fully

closed position.

Check to make sure the valve

stem and actuatorstem are in

firm contact with each other.

Bolts and

Nuts

Remove with a socket wrench

Consult the table of tightening

torques and tighten to the

proper torque

Stem

Bracket

Plate

Take the bracket apart

(separates into 2 plates)

After aligning the plates, tighten

the nuts and bolts while making

sure the gap between the

plates is even on both sides

CAUTION

Be careful not to pinch your fingers between the

valve stem and actuator stem!

Disassembling/Reassembling the Valve and Actuator Sections

Part

During Disassembly

During Reassembly

The actuator unit

orientation can be

changed.

—

Set the operation signal input

to 12 mA (50%)

Make sure the gap between

the valve stem and the

actuator stem is open

Set the operation signal input

to 12 mA (50%)

Make sure the gap between

the valve stem and the

actuator stem is open

Valve

Bonnet Nut

Remove with an open-end

wrench

Consult the table of tightening

torques and tighten to the

proper torque

CAUTION

Be careful not to pinch your fingers between the

valve stem and actuator stem!

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

16

Disassembling/Reassembling of the Body Section

Part

During Disassembly

During Reassembly

Guide Bushing

Loosen slightly with a socket wrench to

make the following procedure easier

Consult the table of tightening torques

and tighten to the proper torque

Bolts for flange

Remove with a socket wrench

Tighten the bolts evenly, while checking

to make sure that there is no catching

or biting when the valve plug is seated

in the valve seat; after tightening to the

rated torque, check to make sure that

the valve plug & stem moves up and

down smoothly; make sure to tighten

evenly

Flange

Pull up and off, being careful not to

damage the valve plug & stem or valve

seat

Reattach, being careful not to damage

the valve plug & stem or valve seat

Insert the valve bonnet into the gasket

housing securely and without tilting

Valve Bonnet

Valve Bonnet

Gasket

Remove the gasket and clean sealing

surfaces

Be sure to replace with a new gasket;

do not coat with anti-seize

Valve Bonnet

Guide

Pull up and off, being careful not to

damage the valve plug & stem or valve

seat

The difference between the inner

diameter of the body and the outer

diameter of the valve bonnet guide is

very small, so make sure that it does

not tilt and get caught when pulling the

valve bonnet guide up and off

Reattach, being careful not to damage

the valve plug & stem or valve seat

The difference between the inner

diameter of the body and the outer

diameter of the valve bonnet guide is

very small, so make sure that it does

not tilt and get caught when inserting

the valve bonnet guide

Valve Bonnet

Guide Gasket

Remove the gasket and clean sealing

surfaces

Replace with a new gasket if warped or

damaged

Valve Plug &

Stem

Pull up and out, being careful not to

damage the plug & stem

Reattach, being careful not to damage

the plug & stem

Valve Seat

Remove with a socket wrench

Consult the table of tightening torques

and tighten to the proper torque

Valve Seat

Gasket

Remove the gasket and clean sealing

surfaces

Replace with a new gasket if warped or

damaged

Valve Bonnet Guide

Gasket

Valve Plug & Stem

Valve Seat

Valve Seat Gasket

Body

Bolt

Flange

Guide Bushing

Valve Bonnet

Valve Bonnet

Gasket

Valve Bonnet

Guide

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

17

Removing/Reattaching the Cover Plug and Cover

Part

15 –25 mm

40, 50 mm

During Disassembly

During Reassembly

Drain Plug*

Remove with an appropriate

tool; be careful of residual

fluid flowing out from inside

the body

Wrap threaded portion with

sealing tape; consult the

table of tightening torques

and tighten to the proper

torque

Cover Plug

Uses a screwed connection;

remove with an appropriate

tool

Consult the table of

tightening torques and

tighten to the proper torque

Cover

Remove cover bolts with an

appropriate tool

Consult the table of

tightening torques and

tighten cover bolts to the

proper torque

Cover Plug

Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket if

warped or damaged

*When a steam/air trap or blow valve is connected to the bottom of the body, piping

connected to the steam/air trap or the blow valve should be removed.

15 –25 mm

40, 50 mm

Body

Cover Plug Gasket

Cover Plug

Cover

Cover Bolt

Drain Plug

Disassembling/Reassembling the Gland and its Components

In the procedure below, first partially loosen the guide bushing and then remove the

valve plug & stem before removing the other parts. (The procedure is most easily

performed if the bushing is loosened while it is attached to the valve body.)

Part

During

Disassembly

During Reassembly

Guide

Bushing

Stuffing Box

Washer

Stuffing Box

Spring

Valve Bonnet

Stuffing Box

V-rings

BLK

BLK

WHT

BLK

BLK

Sectional View of

Stuffing Box V-rings

Guide

Bushing

Remove with a

socket wrench

Consult the table of

tightening torques and

tighten to the proper torque

Stuffing Box

V-rings

Pull up and out

Make sure to reassemble the

V-rings in the proper

orientation; coat the groove

with heat-resistant silicon

grease; reattach the V-rings

with their grooves facing

downward

Stuffing Box

Washer

Pull up and out

Reinsert

Stuffing Box

Spring

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

18

Parts Inspection

When parts have been removed, use the following table to inspect the parts and

replace any that are found to be defective.

Inspection Item

Gasket(s): Check for warping and damage

(Graphite gaskets MUST be replaced if disassembled)

Stuffing Box V-rings: Check for warping or damage

Valve Plug & Stem, Valve Seat: Check for damage or scratches

Table of Tightening Torques

Part

15 mm (½ in)

20 mm (¾ in)

25 mm (1 in)

40 mm (1½ in)

50 mm (2 in)

Torque

Dist.

Across

Flats

Torque

Dist.

Across

Flats

Torque

Dist.

Across

Flats

Torque

Dist.

Across

Flats

Torque

Dist.

Across

Flats

N·m

(lbf·ft)

mm

(in)

N·m

(lbf·ft)

mm

(in)

N·m

(lbf·ft)

mm

(in)

N·m

(lbf·ft)

mm

(in)

N·m

(lbf·ft)

mm

(in)

Bolts and Nuts for

Stem Bracket Plates

7

(5.1)

8

(5/16)

7

(5.1)

8

(5/16)

7

(5.1)

8

(5/16)

7

(5.1)

8

(5/16)

7

(5.1)

8

(5/16)

Valve Bonnet Nut

150

(72)

36

(113/32)

150

(72)

36

(113/32)

150

(72)

36

(113/32)

150

(72)

36

(113/32)

150

(72)

36

(113/32)

Guide Bushing

(Valve Bonnet

Section)

120

(88)

24

(15/16)

120

(88)

24

(15/16)

120

(88)

24

(15/16)

120

(88)

24

(15/16)

120

(88)

24

(15/16)

Bolts for Flange

40

(29)

17

(21/32)

40

(29)

17

(21/32)

40

(29)

17

(21/32)

40

(29)

17

(21/32)

50

(37)

19

(3/4)

Valve Seat

100

(73)

30

(13/16)

100

(73)

30

(13/16)

125

(92)

36

(113/32)

250

(185)

50

(131/32)

300

(220)

60

(23/8)

Cover Plug

250

(185)

41

(15/8)

250

(185)

41

(15/8)

350

(260)

46

(113/16)

—

—

—

—

Cover Bolt

—

—

—

—

—

—

60

(44)

17

(21/32)

70

(51)

19

(3/4)

Drain Plug

40* (29*) N·m (lb·ft) 14 (9/16) mm (in)

(1 N·m ≈ 10 kg·cm)

* These values represent tightening torques for threads that are wrapped with 3 - 3.5 turns of sealing

tape.

172-65587MA-02 (CV-COSR Pneumatic Control Valve) 3 Jun 2019

19

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When the product fails to operate properly, use the following table to locate the

cause and remedy.

Problem

Cause

Diagnosis

Remedy (Countermeasure)

Valve Leakage

The pressure of the

air supply to the

positioner is too high

Check the pressure of the air

supply to the positioner and

confirm product specifications

Adjust the pressure of the air

supply for the positioner to

match the pressure in the

product specifications

The positioner’s zero

point is miscalibrated

Check the actuator air supply

pressure (on the positioner’s

pressure gauge) when the

operation signal is at 4 mA

If the pressure on the pressure

gauge is elevated (not 0

MpaG (0 psig)), adjust the

positioner’s zero point

The inlet pressure for

the valve is too high

Check the inlet pressure for

the valve

Operate at an inlet pressure of

1.0 MPaG (150 psig) or less

The valve plug and

valve seat are off-

center

Move the valve plug & stem up

and down and check to see if it

catches

Reassemble the valve bonnet

section correctly

There is a problem

with the sealing

surfaces of the valve

plug and valve seat

Check the valve plug and

valve seat

Replace with a new valve plug

& stem and valve seat

The valve does

not travel

beyond a certain

point

The bellowphragm in

the actuator is broken

Check to see if a large amount

of air is leaking from the

exhaust tap

Replace with a new positioner/

actuator unit

[Check to make sure that the

valve is not operating

(traveling) too often and that

the ambient temperature is not

too high]

The positioner’s

internal parts are

broken

(The diaphragm is

cracked, etc.)

Check to see if any unusual

noise is coming from the

positioner

Replace with a new positioner/

actuator unit

[Check to make sure that the

valve is not operating

(traveling) too often and that

the ambient temperature is not

too high]

There is insufficient

air supply pressure to

the positioner

Check the pressure of the air

supply to the positioner and

refer to product specifications

Adjust the supply air pressure

for the positioner

(Confirm product

specifications)

Malfunction of the

signal system

Check to make sure the

controller is emitting a 4 to 20

mA signal and that the wires

are not disconnected, etc.

Inspect the controller and

repair the signal wiring if

necessary

Continued on next page

Table of contents

Other TLV Control Unit manuals