TLV BB1N User manual

172-65143M-04 (BB1N·BBF1N) 7 October 2021

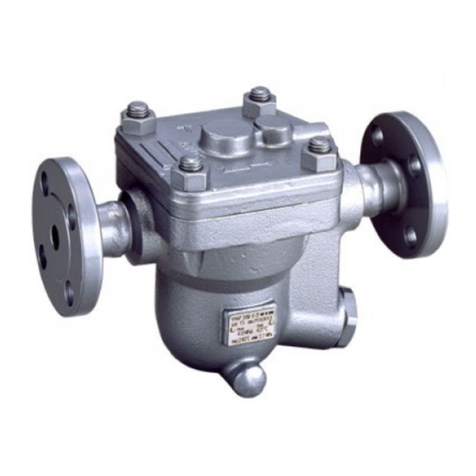

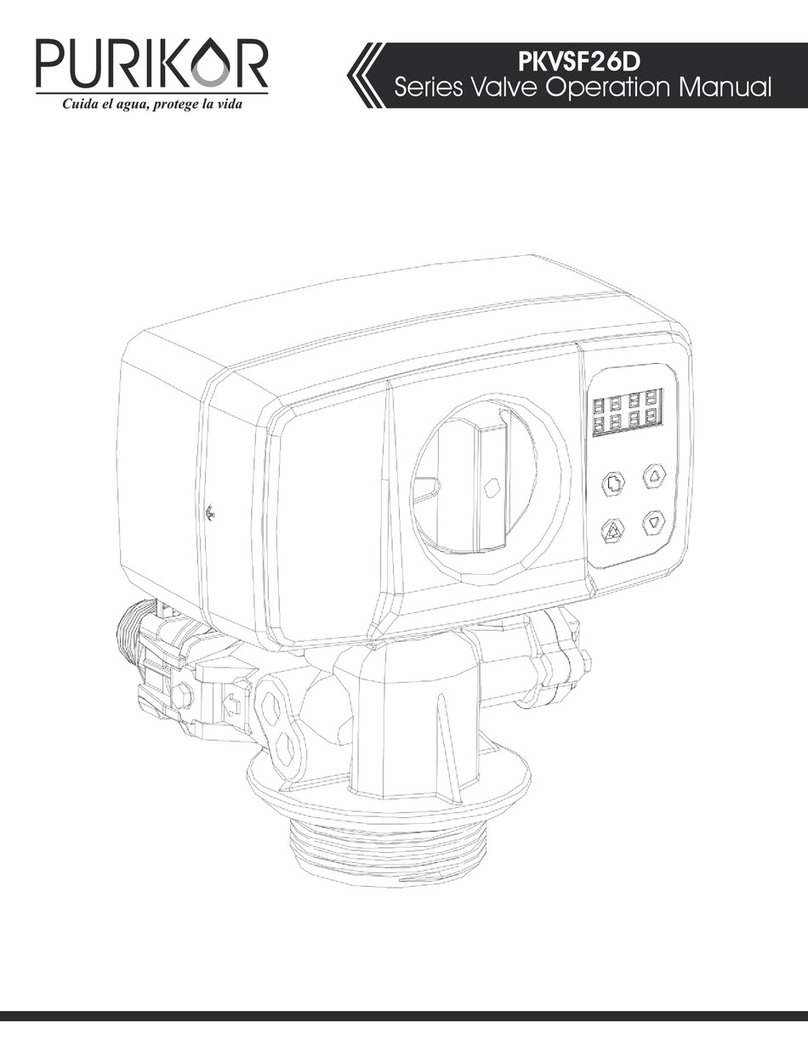

Ball Butterfly Valve

BB1N · BBF1N

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

1

Contents

Introduction ........................................................................ 1

Safety Considerations........................................................ 2

Specifications..................................................................... 4

Configuration...................................................................... 5

Installation.......................................................................... 6

Maintenance....................................................................... 7

Disassembly/Reassembly.................................................. 8

Troubleshooting ............................................................... 14

TLV EXPRESS LIMITED WARRANTY............................ 15

Service............................................................................. 17

Introduction

Thank you for purchasing the TLV ball butterfly valve.

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

The TLV ball butterfly valve offers a combination of the superior sealing properties

of the ball valve and the smooth rotary movement of the butterfly valve.

If detailed instructions for special order specifications or options not contained in

this manual are required, please contact TLV for full details.

This instruction manual is intended for use with the models listed on the front

cover. It is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future reference.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment, and

valve opening/closing should be carried out only by trained maintenance

personnel.

The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may occur

as a result of erroneous handling, three different types of cautionary items are

used to indicate the degree of urgency and the scale of potential damage and

danger: DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance, and

repair. Furthermore, TLV accepts no responsibility for any accidents or

damage occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates an urgent situation which poses a threat of death or serious

injury

Indicates that there is a potential threat of death or serious injury

Indicates that there is a possibility of injury or equipment/product

damage

DO NOT use for toxic, flammable or otherwise hazardous fluids.

Use only for fluids listed in the specification table. This product is for

intended use only. Improper use may result in such hazards as damage to

the product or malfunctions that may lead to serious accidents.

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct contact

with product outlets.

Failure to do so may result in burns or other injury from the discharge of

fluids.

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the

product has cooled to room temperature.

Disassembling or removing the product when it is hot or under pressure

may lead to discharge of fluids, causing burns, other injuries or damage.

Continued on the next page

DANGER

WARNING

CAUTION

WARNING

CAUTION

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

3

Be sure to use only the recommended components when repairing

the product, and NEVER attempt to modify the product in any way.

Failure to observe these precautions may result in damage to the product

and burns or other injury due to malfunction or the discharge of fluids.

Do not use excessive force when connecting threaded pipes to the

product.

Over-tightening may cause breakage leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Do not stand on or apply body weight to the handle.

The handle may break, resulting in injury or other accidents.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

4

Specifications

DO NOT use for toxic, flammable or otherwise hazardous fluids.

Use only for fluids listed in the specification table. This product is for

intended use only. Improper use may result in such hazards as damage

to the product or malfunctions that may lead to serious accidents.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Model

BB1N

BBF1N

Connection

Screwed

Flanged

Size (mm)

15, 20, 25, 32, 40, 50

Max. Operating Pressure (MPaG) PMO

1.0

Max. Operating Temp. (°C) TMO

185

Max. Allowable Pressure (MPaG) PMA*

1.0

Max. Allowable Temp. (°C) TMA*

185

Applicable Fluid

Steam, water, air

Cv Values

(Cv US)

Size

(mm)

BB1N

BBF1N

15

9.6

8.0

20

18.4

15.5

25

29.0

26.0

32

50.2

47.0

40

81.5

78.0

50

135.0

135.0

(1 MPa 10.197 kg/cm2)

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS

Avoid using the ball valve in the half-open position, as it may result in damage to the

valve seat. Be sure to use it in the fully open or fully closed positions.

Also, do not use with slurries.

Specifications for special order products may vary. Check the drawings, etc. for

specifications.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

5

Configuration

Handle Unit (Both BB1N and BBF1N)

Valve Unit

No.

Name

No.

Name

No.

Name

1

Body

8

Bushing

16

Gasket

2S

Inlet Union

9

Gasket

17

Stem Packing

2F

Flange

10

Valve Shaft

18

Seal

3

Ball

11

Spindle

19

Guide Bushing

4

Valve Seat

12

Holder

20

Holder Screw

5

Washer

13

Washer

21

Flange Bolt

6

Belleville Washer

14

Belleville Washer

7

O-ring

15

Gland Seat

No.

Name

1

Handle

2

Bushing

3

Belleville Washer

4

Handle Bolt

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

6

Installation

DO NOT use for toxic, flammable or otherwise hazardous fluids.

Use only for fluids listed in the specification table. This product is for

intended use only. Improper use may result in such hazards as damage

to the product or malfunctions that may lead to serious accidents.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Do not stand on or apply body weight to the handle. The handle may

break, resulting in injury or other accidents.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Before installation, be sure to remove all protective seals.

2. Before installing the product, blow out the inlet piping to remove any piping scraps, dirt

and oil. Close the inlet valve after blowdown.

3. There are no inlet or outlet restrictions for installation.

4. To facilitate maintenance of screwed products, the installation of a union at the outlet

is recommended.

If there is a problem, determine the cause by using the “Troubleshooting” section in this

manual.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

7

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Valve Seat Replacement

Replacement of the valve seat with a new valve seat after approximately 100,000 cycles

depending on fluid quality and operation conditions will allow for prolonged use of the

product.

For instructions on valve seat replacement, see the Disassembly/Reassembly section.

Additional Tightening of the Valve Unit Gland Section

It is possible to further tighten the gland section in the valve unit. Where there is leakage

from the gasket or seal, tighten the gland section further using the following instructions:

1. Detach the handle unit (see instructions on p. 8).

2. Tighten, using the following steps:

1) Loosen the holder screw.

2) Tighten the holder further in with a socket wrench.

3) Retighten the holder screw.

Cautions when applying additional tightening:

Do not tighten the holder completely the first time. Do not tighten the holder any

more than is necessary to stop leakage.

If leakage continues even after the holder has been tightened, replace worn parts.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

8

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble.

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

Detaching/Reattaching the Handle and Valve Units

Part

During Disassembly

During Reassembly

During Inspections

Handle Bolt

Remove with a hex key

Coat threaded portions with

anti-seize, and tighten to

the proper torque

—

Bushing

Remove the bushing

Reinsert the bushing

—

Belleville

Washer

Remove the Belleville

washer

Reinsert the Belleville

washer

—

Handle

Remove the handle

Reattach the handle

Check for damage, or

deformation, particularly

the area in contact with

the spindle

(1 N·m 10 kg·cm)

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

9

Disassembly/Reassembly of the Valve Unit Gland Section

Part

During Disassembly

During Reassembly

During Inspections

Holder Screw

Remove with a hex key

For stainless steel valve

bodies, coat the threaded

portions with anti-seize

and tighten to the proper

torque

—

Holder

Remove with a socket

wrench

For stainless steel valve

bodies, coat the threaded

portions with anti-seize

and tighten to the proper

torque

—

Guide Bushing

Remove guide bushing

Reinsert guide bushing

Check for wear

Seal

Remove the seal

Use a new part

—

Stem Packing

Remove the packing

Use a new part

—

Spindle

Remove the spindle

Reinsert the spindle

Check both faces for

deformation. Check

for wear, damage and

corrosion

Valve Shaft

Remove the valve shaft

Reinsert the valve shaft

Check for wear or

deformation

Gland Seat

Remove the gland seat

Use a new part

—

Washer

Remove the washer

Reinsert the washer

Check for damage or

deformation

Belleville

Washer

Remove the Belleville

washer

Reinsert the Belleville

washer, referring to the

drawing on the following

page for proper orientation

Check for damage or

deformation

Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket

if damaged or deformed,

referring to the drawing on

the following page for

proper orientation.

—

(1 N·m 10 kg·cm)

NOTE: 1. Reassemble the gland section after reassembling the valve section (see the

Disassembly/Reassembly of the Valve Section in the Disassembly/Reassembly

section).

2. When reinserting the spindle and valve shaft into the ball:

for the screwed model, finger-tighten the inlet union; for the flanged model, finger-

tighten the flange bolt. This serves as preparation for centering the ball.

When reassembly is completed, tighten the valve holder.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

10

Disassembly/Reassembly of the Valve Section

Screwed:

Part

During Disassembly

During Reassembly

During

Inspections

Inlet

Union

Remove with a socket

wrench or monkey wrench

For stainless steel valve bodies, coat the

threaded portions with anti-seize and

tighten to the proper torque

—

(1 N·m 10 kg·cm)

Flanged:

Part

During Disassembly

During Reassembly

During

Inspections

Flange

Bolt

Remove with socket wrench or box wrench

For stainless steel valve

bodies, coat the threaded

portions with anti-seize and

tighten to the proper torque

—

Flange

Remove the flange

Reattach the flange

—

(1 N·m 10 kg·cm)

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

11

Common Items for both Screwed and Flanged Models:

Part

During Disassembly

During Reassembly

During Inspections

Gasket

Remove the gasket

Replace with new gasket

—

Valve Seat

(Inlet Union Side)

Remove the valve seat

Replace with new valve

seat

—

O-ring

Remove the O-ring

Replace with new O-ring,

insert into the valve seat

—

Washer

Remove the washer

Reinsert the washer

Check for wear or

deformation

Belleville Washer

Remove the Belleville

washer

See the drawing below for

proper orientation of the

Belleville washer

Check for wear or

deformation

Ball

Remove the ball

Insert the ball

Check the sealing area

for scratches, wear, etc.

Valve Seat (Body

Side)

Remove the valve seat

Replace with new valve

seat

—

O-ring

Remove the O-ring

Replace with new O-ring

—

Washer

Remove the washer

Reinsert the washer

Check for wear or

deformation

Belleville Washer

Remove the Belleville

washer

See the drawing below for

proper orientation of the

Belleville washer

Check for wear or

deformation

Bushing

Remove the bushing

Replace with new bushing

—

NOTE: Clean, then check the inside of the body for scratches and erosion.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

12

Table of Tightening Torques

Part Name

Size

Torque

Distance Across Flats

mm

Nm

mm

Handle Bolt

15 - 25

3

3

32 - 50

23

8

Holder Screw

15 - 50

1.2

2

Holder

15 - 25

50

17

32 - 50

80

27

Inlet Union

15

100

27

20

150

32

25

200

41

32

300

50

40

500

60

50

700

70

Flange Bolt

15 (M8)

20

13

20 (M10)

35

17

25 (M12)

50

19

32 (M12)

60

19

40 (M16)

80

24

50 (M16)

80

24

NOTE:

-Coat all threaded portions with anti-seize.

-If drawings or other special documentation were supplied for the

product, any torque given there takes precedence over values

shown here.

(1 Nm 10 kgcm)

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

13

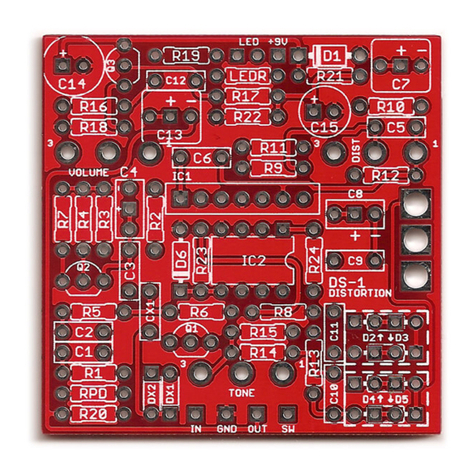

Exploded View

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

14

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When the product fails to operate properly, use the following table to locate the cause and

remedy.

Problem

Cause

Remedy

Fluid leaks from the

outlet

The sealing area of the valve has build-

up or is scratched, or if the o-ring is

scratched or damaged

Clean or replace parts

Fluid leaks from the

gland section

There is build-up, scratches or wear on

the seal, stem packing or gasket

Apply additional tightening, clean or

replace parts

The valve does not

move or remains

half-open

The valve seat or ball have build-up, if

the valve seat is deformed, or if the ball

turns smoothly.

Clean or replace parts

The handle is worn or deformed

Replace with new handle

Fluid leaks from

Gasket deterioration or wear

Replace with a new gasket

inlet union or flange

connections

The inlet union or flange bolt is loose

Tighten it to the proper torque

The valve seat

becomes damaged

Check for the occurrence of water

hammer

Examine the piping for problems

that can cause water hammer

The valve is being used in the half-open

position

Use fully open or fully closed

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

15

TLV EXPRESS LIMITED WARRANTY

Subject to the limitations set forth below, TLV CO., LTD., a Japanese corporation (“TLV”),

warrants that products which are sold by it, TLV International Inc. (“TII”) or one of its group

companies excluding TLV Corporation (a corporation of the United States of America),

(hereinafter the “Products”) are designed and manufactured by TLV, conform to the

specifications published by TLV for the corresponding part numbers (the

“Specifications”) and are free from defective workmanship and materials. The party from

whom the Products were purchased shall be known hereinafter as the “Seller”. With

regard to products or components manufactured by unrelated third parties (the

“Components”), TLV provides no warranty other than the warranty from the third party

manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by persons other than TLV, TII or

TLV group company personnel, or service representatives authorized by TLV; or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and maintenance

by persons other than TLV or TLV group company personnel, or service

representatives authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV, TII or

TLV group companies; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the

Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water,

nitrogen, carbon dioxide and inert gases (helium, neon, argon, krypton, xenon and

radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the

Product.

Duration of Warranty

This warranty is effective for a period of one (1) year after delivery of Products to the first

end user. Notwithstanding the foregoing, asserting a claim under this warranty must be

brought within three (3) years after the date of delivery to the initial buyer if not sold

initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY OPERATION

OF LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT NEGATED HEREBY,

ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN DURATION TO ONE (1)

YEAR FROM THE DATE OF SHIPMENT BY THE SELLER.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS WARRANTY OR

UNDER ANY IMPLIED WARRANTIES NOT NEGATED HEREBY (INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE), IS

REPLACEMENT; PROVIDED: (a) THE CLAIMED DEFECT IS REPORTED TO THE SELLER IN

WRITING WITHIN THE WARRANTY PERIOD, INCLUDING A DETAILED WRITTEN

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

16

DESCRIPTION OF THE CLAIMED DEFECT AND HOW AND WHEN THE CLAIMED DEFECTIVE

PRODUCT WAS USED; AND (b) THE CLAIMED DEFECTIVE PRODUCT AND A COPY OF THE

PURCHASE INVOICE IS RETURNED TO THE SELLER, FREIGHT AND TRANSPORTATION

COSTS PREPAID, UNDER A RETURN MATERIAL AUTHORIZATION AND TRACKING NUMBER

ISSUED BY THE SELLER. ALL LABOR COSTS, SHIPPING COSTS, AND TRANSPORTATION

COSTS ASSOCIATED WITH THE RETURN OR REPLACEMENT OF THE CLAIMED DEFECTIVE

PRODUCT ARE SOLELY THE RESPONSIBILITY OF BUYER OR THE FIRST END USER. THE

SELLER RESERVES THE RIGHT TO INSPECT ON THE FIRST END USER’S SITE ANY

PRODUCTS CLAIMED TO BE DEFECTIVE BEFORE ISSUING A RETURN MATERIAL

AUTHORIZATION. SHOULD SUCH INSPECTION REVEAL, IN THE SELLER’S REASONABLE

DISCRETION, THAT THE CLAIMED DEFECT IS NOT COVERED BY THIS WARRANTY, THE

PARTY ASSERTING THIS WARRANTY SHALL PAY THE SELLER FOR THE TIME AND

EXPENSES RELATED TO SUCH ON-SITE INSPECTION.

Exclusion of Consequential and Incidental Damages

IT IS SPECIFICALLY ACKNOWLEDGED THAT THIS WARRANTY, ANY OTHER EXPRESS

WARRANTY NOT NEGATED HEREBY, AND ANY IMPLIED WARRANTY NOT NEGATED

HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR ITS TLV GROUP

COMPANIES WILL IN ANY EVENT BE LIABLE FOR, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, INCLUDING, BUT NOT LIMITED TO LOST PROFITS, THE COST OF DISASSEMBLY

AND SHIPMENT OF THE DEFECTIVE PRODUCT, INJURY TO OTHER PROPERTY, DAMAGE TO

BUYER’S OR THE FIRST END USER’S PRODUCT, DAMAGE TO BUYER’S OR THE FIRST END

USER’S PROCESSES, LOSS OF USE, OR OTHER COMMERCIAL LOSSES. WHERE, DUE TO

OPERATION OF LAW, CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER THIS

WARRANTY, UNDER ANY OTHER EXPRESS WARRANTY NOT NEGATED HEREBY OR UNDER

ANY IMPLIED WARRANTY NOT NEGATED HEREBY (INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE) CANNOT BE

EXCLUDED, SUCH DAMAGES ARE EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE

PRICE OF THE DEFECTIVE PRODUCT. THIS EXCLUSION OF CONSEQUENTIAL AND

INCIDENTAL DAMAGES, AND THE PROVISION OF THIS WARRANTY LIMITING REMEDIES

HEREUNDER TO REPLACEMENT, ARE INDEPENDENT PROVISIONS, AND ANY

DETERMINATION THAT THE LIMITATION OF REMEDIES FAILS OF ITS ESSENTIAL PURPOSE

OR ANY OTHER DETERMINATION THAT EITHER OF THE ABOVE REMEDIES IS

UNENFORCEABLE, SHALL NOT BE CONSTRUED TO MAKE THE OTHER PROVISIONS

UNENFORCEABLE.

Exclusion of Other Warranties

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND ALL

OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY

DISCLAIMED.

Severability

Any provision of this warranty which is invalid, prohibited or unenforceable in any

jurisdiction shall, as to such jurisdiction, be ineffective to the extent of such invalidity,

prohibition or unenforceability without invalidating the remaining provisions hereof, and

any such invalidity, prohibition or unenforceability in any such jurisdiction shall not

invalidate or render unenforceable such provision in any other jurisdiction.

172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

17

Service

For Service or Technical Assistance: Contact your TLV representative or your regional TLV office.

In Europe:

Daimler-Benz-Straße 16-18, 74915 Waibstadt, Germany

Tel:

Fax:

[49]-(0)7263-9150-0

[49]-(0)7263-9150-50

Units 7 & 8, Furlong Business Park, Bishops Cleeve, Gloucestershire GL52

8TW, U.K.

Tel:

Fax:

[44]-(0)1242-227223

[44]-(0)1242-223077

Parc d’Ariane 2, bât. C, 290 rue Ferdinand Perrier, 69800 Saint Priest,

France

Tel:

Fax:

33–(0)4-72482222

[33]-(0)4-72482220

In North America:

13901 South Lakes Drive, Charlotte, NC 28273-6790, U.S.A.

Tel:

Fax:

[1]-704-597-9070

[1]-704-583-1610

In Mexico and Latin America:

Av. Jesús del Monte 39-B-1001, Col. Hda. de las Palmas, Huixquilucan,

Edo. de México, 52763, Mexico

Tel:

Fax:

[52]-55-5359-7949

[52]-55-5359-7585

In Oceania:

Unit 8, 137-145 Rooks Road, Nunawading, Victoria 3131, Australia

Tel:

Fax:

[61]-(0)3-9873 5610

[61]-(0)3-9873 5010

In East Asia:

36 Kaki Bukit Place, #02-01/02, Singapore 416214

Tel:

Fax:

[65]-6747 4600

[65]-6742 0345

Room 5406, No. 103 Cao Bao Road, Shanghai, China 200233

Tel:

Fax:

[86]-(0)21-6482-8622

[86]-(0)21-6482-8623

No.16, Jalan MJ14, Taman Industri Meranti Jaya, 47120 Puchong,

Selangor, Malaysia

Tel:

Fax:

[60]-3-8065-2928

[60]-3-8065-2923

252/94 (K-L) 17th Floor, Muang Thai-Phatra Complex Tower B,

Rachadaphisek Road, Huaykwang, Bangkok 10310, Thailand

Tel:

Fax:

[66]-2-693-3799

[66]-2-693-3979

#302-1 Bundang Technopark B, 723 Pangyo-ro, Bundang, Seongnam,

Gyeonggi, 13511, Korea

Tel:

Fax:

[82]-(0)31-726-2105

[82]-(0)31-726-2195

In the Middle East:

Building 2W, No. M002, PO Box 371684, Dubai Airport Free Zone, Dubai, UAE

Email:

In Other Countries:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-427-1818

[81]-(0)79-425-1167

Manufacturer:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-422-1122

[81]-(0)79-422-0112

This manual suits for next models

1

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

Racal Instruments

Racal Instruments 1260-50A user manual

GEM

GEM 615 operating instructions

Epson

Epson RX8804CE Applications manual

Victaulic

Victaulic FireLock 758-LPA Series Installation, Maintenance, & Testing Manual

axing

axing SKM 1-04 Operation instructions

Desin Instruments

Desin Instruments DAS-8000 quick guide