5500 Programming

Quick Guide

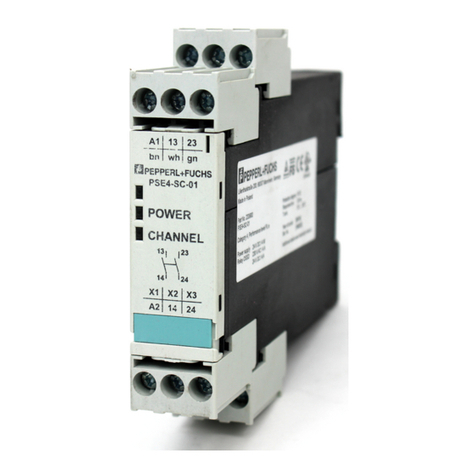

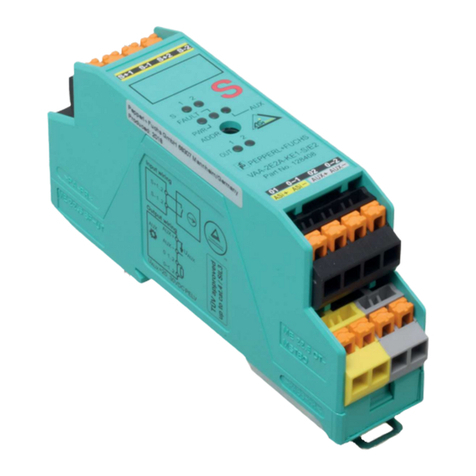

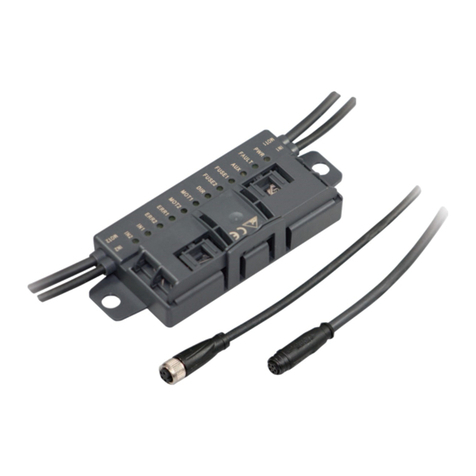

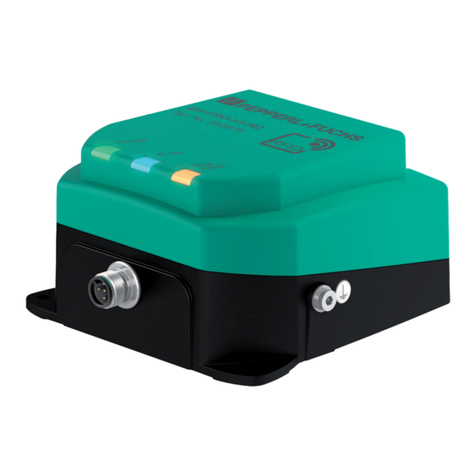

Operating Elements of the Controller

The 5500 controller has four pushbuttons and five LEDs.

If the button is pressed longer than 5 seconds, the 5500 controller

will go into the programming mode.

The entries appear in the following sequence:

DISPLAY PARAMETER DEFAULT

PASSWORD / SET Enter PSW settings 0000

PURGE / PROGRAM Program modes 3

PURGE / TIME Purging time 00:30

ENCLOSUR/PRESS P1 Gas: 0.3” (0.8mbar)

Min pressure Dust: 0.7” (1.8mbar)

ENCLOSUR/PRESS P2 Alarm pressure 0.8” (2 mbar)

ENCLOSUR/PRESS P3 Purging pressure 3.0” (7.5 mbar)

ENCLOSUR/PRESS P4 Max pressure 6.0” (15 mbar)

LEAKAGE / HYST Leakage comp 0.5” (1.25 mbar)

PROGRAM /K2 K2 function K1

SHUT-OFF / DELAY Delay shut-off K1 0 sec

NUMBER/ OF Pt100 2 max for Pt100 0

TEMP PT1 /SV1 SV1 on above PT1 35 °C

TEMP PT2 / SV1 SV1 on above PT2 35 °C

TEMP PT1 / K2 K2 on above PT1 45 °C

TEMP PT2 / K2 K2 on above PT2 45 °C

TEMP PT1 / K1 K1 on above PT1 50 °C

TEMP PT2 / K1 K1 on above Pt2 50 °C

BYPASS / N Y E Bypass off/on/External N

UNITS / M I Metric or Imperial I

TEMP / ENABLED Temp function enable N

CHANGE / PASSWORD Change password ------

Power On

MENU STRUCTURE

PASSWORD

ENCLOSUR

PRESS P1

PURGE

PROGRAM

ENCLOSUR

PRESS P2

Purge

Time

ENCLOSURE

PRESS P4

ENCLOSURE

PRESS P3

LEAKAGE

HYST

SHUT-OFF

DELAY

NUMBER

OF PT100

TEMP PT1

SV1

TEMP PT2

SV1

TEMP PT1

K2

TEMP PT2

K2

TEMP PT1

K1

PROGRAM

K2

TEMP PT2

K1

BYPASS

UNITS

M I

TEMP

DISABLED

CHANGE

PASSWORD

PASSWORD

EXIT

SET

5 sec.

LED LED Color Description

K1 Green Contact K1 is energized

K2 Amber Contact K2 is energized

P/SV1 Blue Safe pressure P1

Amber SV1 is energized

BYPASS Amber Bypass ON

PT100 Red Pt100 fault

Purge time is set in Min:Sec (000:00).

Hold either key down to adjust the set time more quickly.

Pressure P1 is the minimum allowed pressure for

safe use.

Minimum value is 0.3” for gas and 0.7” for dust.

Program Application Purge Operation Specifics

Purge 1 Gas Immediate

Purge

• Purge starts on power up (SV1)

• After purging Enclosure contacts (K1) energize

• If max. Press (P4) is reached, SV1 turns off

• Enclosure power ON during loss of pressure (K1)

• Alarms can be set for low pressure/temp. (K2)

• Pressure compensation turns on below (P2)

Purge 2 Gas Delayed

Purge

• Purge starts above P1 pressure (SV1)

• After purging Enclosure contacts (K1) energize

• If max. Press (P4) is reached, Sv1 turns off

• Enclosure power on during loss of pressure (K1)

• Alarms can be set for low pressure/temp. (K2)

• Pressure compensation turns on below (P2)

Purge 3 Gas Delayed

Purge

• Purge starts above P1 pressure (SV1)

• After purging, enclosure contacts (K1) energize

• If max. Press (P4) is reached, SV1 turns off

• Immediate shut-down during loss of pressure (K1)

• Alarms can be set for low pressure/temp. (K2)

• Pressure compensation turns on below (P2)

Purge 4 Gas Immediate

Purge

• Purge starts on power up (SV1)

• After purging, enclosure contacts (K1) energize

• If max. Press (P4) is reached, Sv1 turns off

• Enclosure power on during loss of pressure (K1)

• Alarms can be set for low pressure/temp. (K2)

• Pressure compensation turns on below (P3)

• Intended for continuous purge applications

Purge 5 Dust Clean

Enclosure

• In dust atmosphere purging is not required

• Enclosure must be cleaned

• Pressure above (P1), Enclosure contact on (K1)

• Enclosure power ON during loss of pressure (K1)

• Alarms can be set for low pressure/temp. (K2)

• Pressure compensation turns on below (P2)

Pressure P2 is used for low pressure function.

Compensation for leakages for certain functions

will activate SV1 when below P2.

Pressure P3 is used to activate the time for purging.

Pressure above P3 indicates proper flow for purging.

In Program 4, P3 will start continuous flow compensation.

Purge time

To advance up

To advance down

For EXIT out of parameter and RESET

Enter purge settings and select function

Pressure P4 is a maximum overpressure value. In reaching

this value, the display will read ‘MAX’.

If P4 is achieved during purging, SV1 will shut off until

pressure is below P4.

ENCLOSURE / PRESS P1

ENCLOSURE / PRESS P2

ENCLOSURE / PRESS P3

ENCLOSURE / PRESS P4

SET

5 sec.

LED Indication

At any time during

purge settings