TMB FloppyFlex User manual

USER MANUAL

TMB 24/7 Technical Support

US/Canada: +1 818.794.1286

Toll Free: 1 877.862.3833 (877.TMB.DUDE)

UK: +44 (0)20.8574.9739

Toll Free: 0800.652.5418

e-mail: techsuppor[email protected]

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 2 -

FloppyFlex User Manual

FloppyFlex-Manual-v2.0

Effective 22 August 2022

© Copyright 2022, TMB

All rights reserved

TMB authorizes its customers to download and print this

electronically published manual for professional use only. TMB

prohibits reproduction, modification or distribution of this document

for any other purposes, without express written consent.

Specifications are subject to change without notice. The information

in this document supersedes all previously supplied information

before the effective date listed above. TMB has confidence in the

accuracy of the document information herein but assumes no

responsibility or liability for any loss occurring as a direct or indirect

result of errors or exclusions whether by accident or any other cause.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 3 -

LIMITED WARRANTY ..................................................................................................................................................................4

PRODUCT OVERVIEW .................................................................................................................................................................5

LARGE 270° PROFILE |STS –GENERAL SPECIFICATIONS.............................................................................................................................6

SMALL 160° PROFILE |STS –GENERAL SPECIFICATIONS ............................................................................................................................7

FLAT 160° PROFILE |FTB –GENERAL SPECIFICATIONS ..............................................................................................................................8

FLAT 160° PROFILE |STS –GENERAL SPECIFICATIONS...............................................................................................................................9

MINI 120° PROFILE |FTB –GENERAL SPECIFICATIONS............................................................................................................................10

MINI 120° PROFILE |STS –GENERAL SPECIFICATIONS ............................................................................................................................10

CARE AND HANDLING............................................................................................................................................................... 11

CUTTING FLOPPYFLEX............................................................................................................................................................... 14

MINI TOOL KIT .................................................................................................................................................................................14

CUTTING MARKS ...............................................................................................................................................................................14

TERMINATING FLOPPYFLEX ...................................................................................................................................................... 16

SIDE NUMBERING SYSTEM ..................................................................................................................................................................16

EZ CONNECT SYSTEM.........................................................................................................................................................................16

INSERTING THE SPREADER ...................................................................................................................................................................17

EZ CONNECT TERMINATION INSTRUCTIONS ............................................................................................................................................18

MOUNTING FLOPPYFLEX .......................................................................................................................................................... 22

ALUMINUM MOUNTING PROFILES ........................................................................................................................................................22

ALUMINUM PROFILE INSTALLATION GUIDELINES......................................................................................................................................25

FREQUENTLY ASKED QUESTIONS.............................................................................................................................................. 31

LEAD-IN LENGTHS..................................................................................................................................................................... 33

RETURN PROCEDURE................................................................................................................................................................ 34

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 4 -

LIMITED WARRANTY

FloppyFlex is warranted by TMB against defective materials or workmanship for a period of three (3) years

from the date of original sale by TMB.

TMB’s warranty shall be restricted to the repair or replacement of any part that proves to be defective and for

which a claim is submitted to TMB before the expiration of the applicable warranty periods.

This Limited Warranty is void if the defects of the Product are the result of:

•Opening the casing, repair, or adjustment by anyone other than TMB or persons specifically authorized by

TMB

•Accident, physical abuse, mishandling, or misapplication of the product.

•Damage due to lightning, earthquake, flood, terrorism, war, or act of God.

TMB will not assume responsibility for any labor expended, or materials used, to replace and/or repair the

Product without TMB’s prior written authorization. Any repair of the Product in the field, and any associated

labor charges, must be authorized in advance by TMB. Freight costs on warranty repairs are split 50/50:

Customer pays to ship defective product to TMB; TMB pays to ship repaired product, ground freight, back to

Customer.

This warranty does not cover consequential damages or costs of any kind.

A Return Merchandise Authorization (RMA) Number must be obtained from TMB prior to return of any defective

merchandise for warranty or non-warranty repair. For all repairs please contact TMB Tech Support Repair using

the contact information below or email TechSupportRepairNA@tmb.com.

US UK

527 Park Ave. 21 Armstrong Way

San Fernando, CA 91340 Southall, UB2 4SD England

Tel: +1 818.899.8818 Tel: +44 (0)20.8574.9700

Fax: +1 818.899.8813 Fax: +44 (0)20.8574.9701

tmb-info@tmb.com tmb-info@tmb.com

www.tmb.com www.tmb.com

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 5 -

PRODUCT OVERVIEW

FloppyFlex and FloppyFlex Digital are world class professional grade, flexible IP68*, IP67 and IP20 LED “neon”. It’s

the perfect replacement for glass neon, easy to use, long lasting & durable. Suitable for many projects and

installations including indoor, outdoor, signage & architectural. Single Color, RGB, Digital RGB, Digital RGBW and

Dynamic White with side-to-side (STS) and front-to-back (FTB) bend options.

*IP68 Rated configurations available by special order

FloppyFlex

•Easy to use and install.

•Wide range of accessories for joining, terminating, mounting, and powering.

•Available in RGB, White (2100, 2500, 2700, 3000, 3500, 4000, 4500, 5000, 5700, 6500K)

Red, Green, Blue, Yellow, Amber, and Orange

•Large 270°, Small and Flat 160° STS bend; Flat 160° FTB bend versions.

•Custom colors available.

FloppyFlex Digital

•Smooth soft edges, seamless color blending.

•Auto-addressing allows for quick setup and patching.

•Large 270° and Small 160° STS bend; Flat 160° FTB bend versions.

•Available in Digital RGB and RGBW, with multi-pixel control.

•Unlimited and unprecedented possibilities.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 6 -

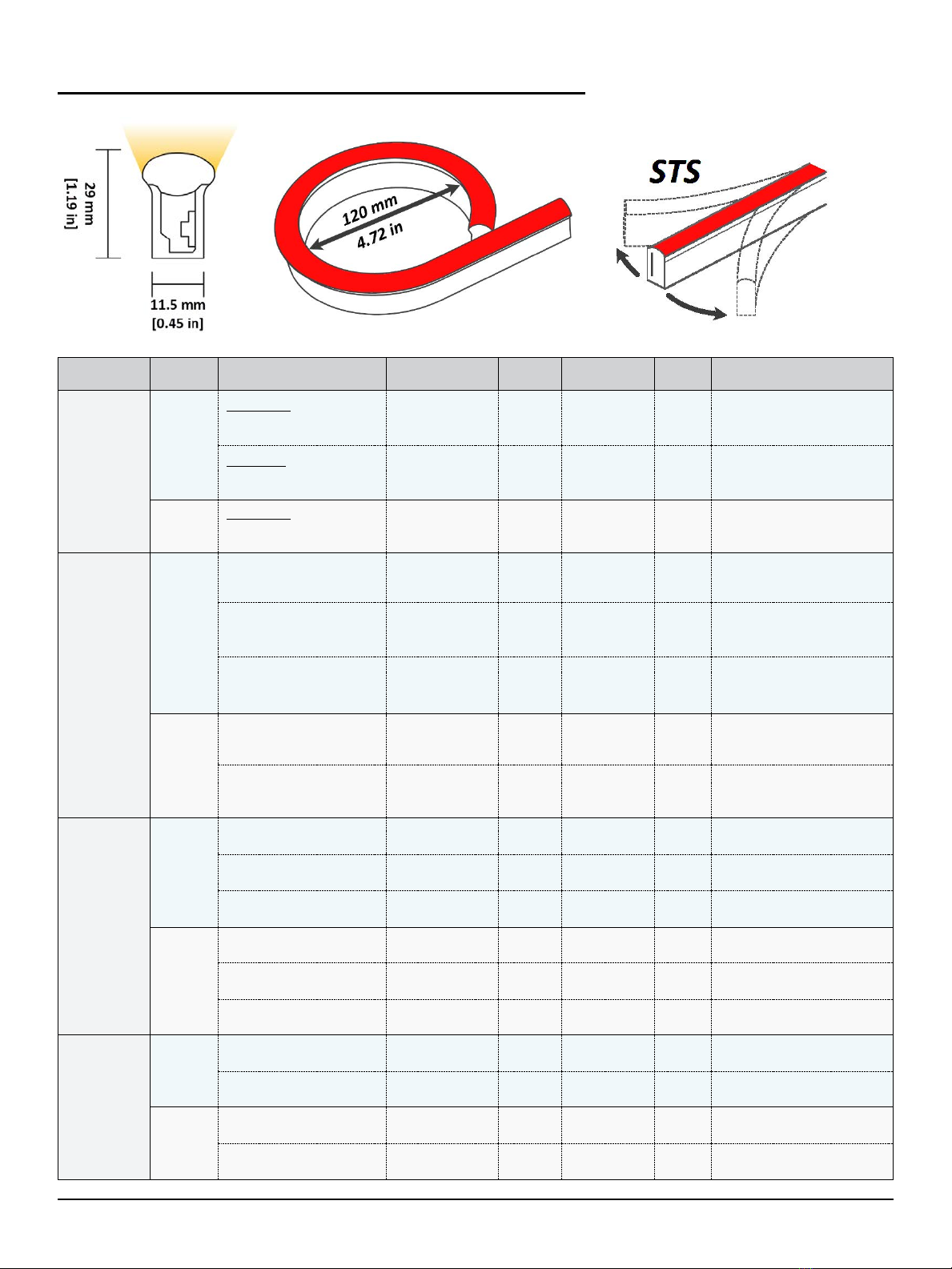

LARGE 270° PROFILE |STS –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K, 5000K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC

Red 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue, Yellow, Orange 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Pink, Purple 100 mm [3.94 in]

24 VDC TBD 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Variable Color

PVC

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive 3x2

Silicone

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 45 °C

[-40 to 113 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive 3x2

Digital Pixel

PVC RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 3-wire DMX via FloppyDrive Digital

Silicone RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 7 -

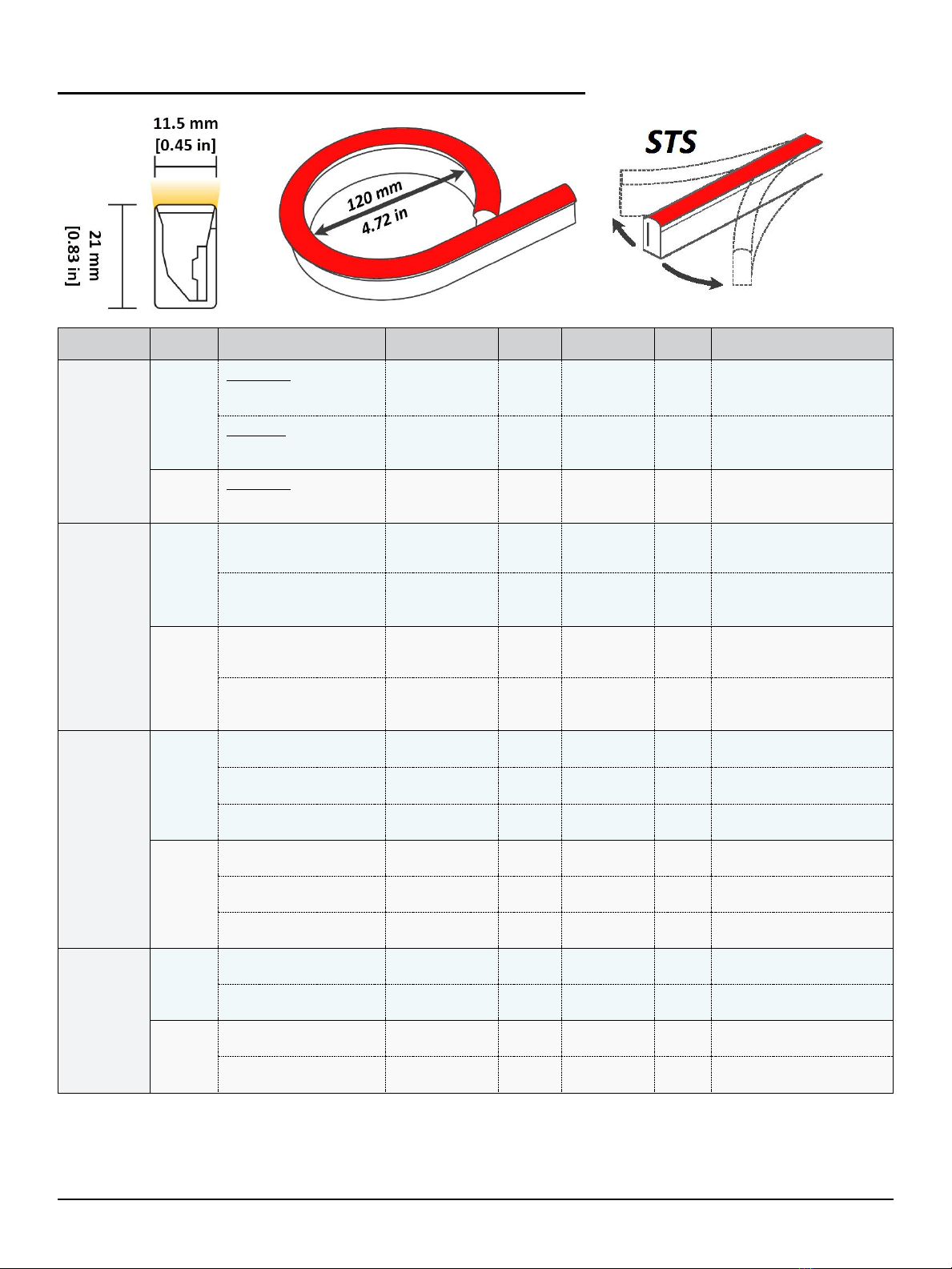

SMALL 160° PROFILE |STS –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K, 5000K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC

Red 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue, Yellow, Orange 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Variable Color

PVC

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive 3x2

Silicone

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 45 °C

[-40 to 113 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive 3x2

Digital Pixel

PVC RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 3-wire DMX via FloppyDrive Digital

Silicone RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 8 -

FLAT 160° PROFILE |FTB –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K, 5000K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K, 5000K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Variable Color

PVC

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive 3x2

Silicone

RGB 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 4-wire DMX via FloppyDrive 4x2

RGBW 100 mm [3.94 in]

[6 LEDs] 24 VDC -40 to 45 °C

[-40 to 113 °F] 5-wire DMX via FloppyDrive 5x2

Dynamic White 2200K-5700K 83.34 mm [3.28 in]

[12 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive 3x2

Digital Pixel

PVC RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -20 to 35 °C

[-4 to 95 °F] 3-wire DMX via FloppyDrive Digital

Silicone RGB 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

RGBW 125 mm [4.92 in]

[7 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 3-wire DMX via FloppyDrive Digital

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 9 -

FLAT 160° PROFILE |STS –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K, 5000K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Nichia LED

2500K, 2700K, 3000K,

3500K, 4000K, 4500K,

5000K, 5700K

100 mm [3.94 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone

Red, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Green, Blue 83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 10 -

MINI 120° PROFILE |FTB –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC Red, Green, Blue, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Red, Green, Blue, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

MINI 120° PROFILE |STS –GENERAL SPECIFICATIONS

Category Housing Color Options

Minimum Cut

Length

Voltage

Operating

Temp

Wiring Control

White Light

PVC Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -20 to 45 °C

[-4 to 113 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Epistar LED

2100K, 2700K, 3000K,

3500K, 4000K, 5700K

83.34 mm [3.28 in]

[6 LEDs] 24 VDC -40 to 55 °C

[-40 to 131 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Colorful Light

PVC Red, Green, Blue, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -20 to 50 °C

[-4 to 122 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

Silicone Red, Green, Blue, Amber 125 mm [4.92 in]

[9 LEDs] 24 VDC -40 to 60 °C

[-40 to 140 °F] 2-wire DMX via FloppyDrive 2x2

Line-side MLV Dimming (with

compatible transformer)

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 11 -

CARE AND HANDLING

FloppyFlex LED neon contains electronic components and LEDs. While the flexible housing enhances

durability, FloppyFlex does require proper care and handling. Treated correctly, per the guidelines below,

FloppyFlex will provide many years of reliable service and beautiful colors.

FloppyFlex is available in six profile versions, descriptive of the lens or illuminated surface:

270˚ Large, 160˚ Small, 160˚ Flat (FTB), 160˚ Flat (STS), Mini (STS) and Mini (FTB). The handling and

installation rules below apply to all versions

•Never twist or Bend FloppyFlex in the

wrong direction

Inappropriate twisting or bending during

unpacking or installation can damage the

internal PCB or LEDs.

Side-to-Side (STS) specified direction allows

horizontal bending along the length of the

product.

Front-to-Back (FTB) specified direction

allows vertical bending along the lens

surface, forming the convex or concave arc

of a circle.

•Avoid continuous rolling and un-rolling

whenever possible

If you are using FloppyFlex in a temporary

installation or touring application that requires

ongoing re-installation and transportation, we

suggest the product be built into set pieces or

scenic elements using sections of aluminum

mounting profiles.

If you do require constant un-reeling and

reeling for a project, we suggest the

FloppyFlex be stored on a rotating reel or

drum when not in use. FloppyFlex can also

be rolled up on a flat surface and stored in its

original packing box.

DO NOT hand-coil as you would do with a

cable. Make sure any crew handling the

product fully understand these instructions

for best outcomes.

•Observe the minimum bending

diameter for each product

Bending past the minimum diameter can

damage the internal PCB or LEDs.

Large and Small Profile minimum bending

diameter: 4.72” (120 mm)

Flat Profile minimum bending diameter: 11.8”

(300 mm)

Mini Profile minimum bending diameter: 3.94”

(100 mm)

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 12 -

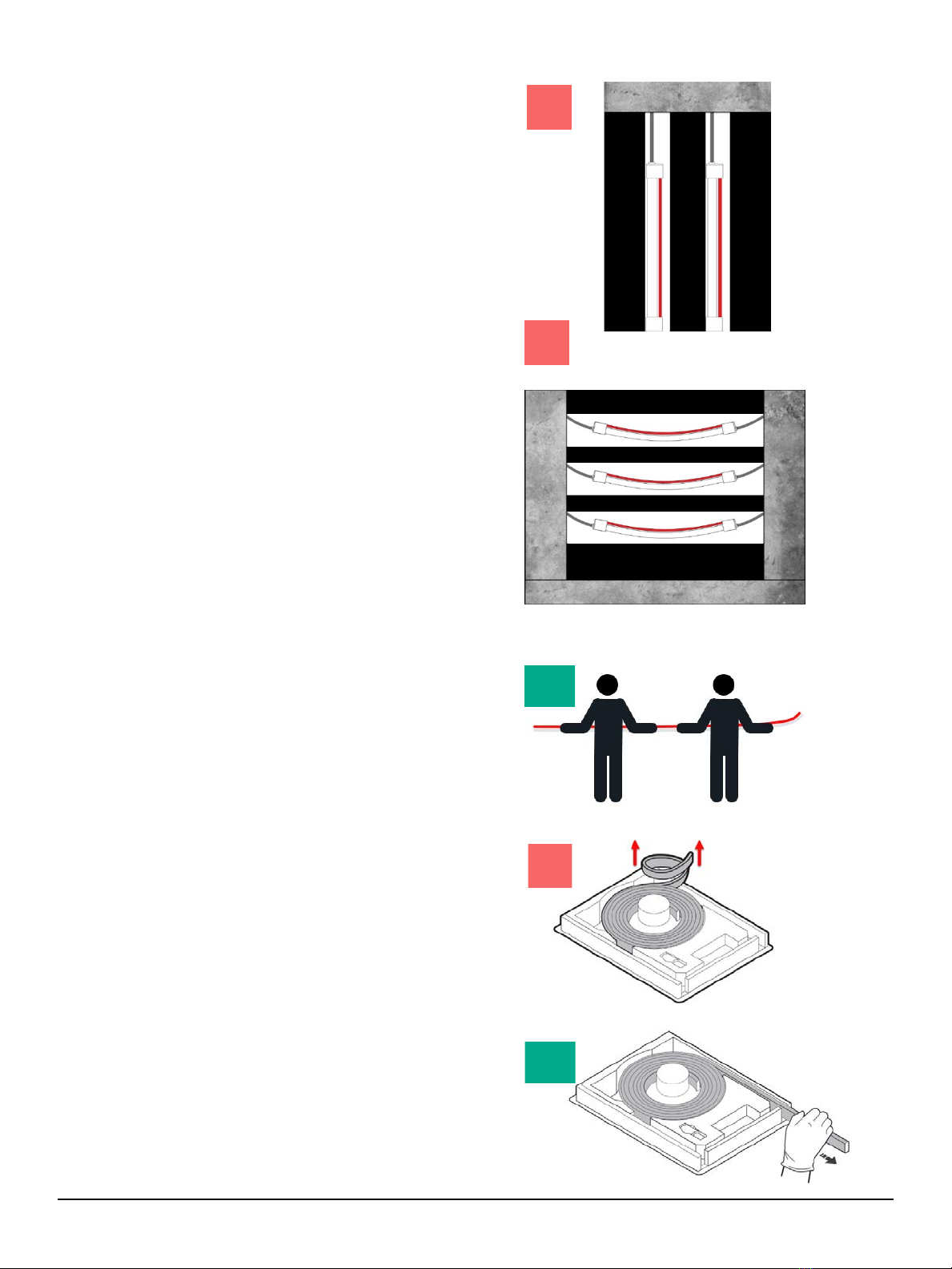

•Do not hang or suspend FloppyFlex in

the air

FloppyFlex must be mounted on a stable

surface with the appropriate aluminum

mounting profiles.

DO NOT allow FloppyFlex to freely hang

loose from trussing or scaffolding during

installation.

When handling FloppyFlex in lengths greater

than 2 meters, make sure to have a second

person helping to support the product while

the first person secures the product into

place.

Inadequate support during FloppyFlex

installation can damage the internal PCB

orLEDs.

•Avoid shock or impact when installing

or storing FloppyFlex

NEVER use a hammer or other implement to

force FloppyFlex into place by striking or

pounding.

NEVER run over FloppyFlex with fork-lift,

trolley, scene-cart, or any other vehicle. Do

Not walk or step on FloppyFlex.

Excessive stress on the body or connectors

of FloppyFlex can result in detachment or

damage to the internal PCB or LEDs.

•Install FloppyFlex in the appropriate

aluminum mounting profiles

NEVER puncture FloppyFlex with staples,

nails, screws, or any other sharp objects

during installation. Doing so will void the

warranty.

Always check for any sharp edges or

protruding foreign objects inside the

aluminum mounting profile before installing

FloppyFlex.

See Installation Guidelines section below

for best practice installation instruction

•Safe unboxing Molded Assemblies

Molded Assemblies ship in special boxes

with inserts designed for easy un-coiling.

These often have gloves included to help

keep smudges and fingerprints off the

illumination edge of FloppyFlex.

NEVER pull FloppyFlex out of the box from

the center or twist it backwards. Use the box

as intended. Thread the FloppyFlex end

through the box insert and pull gently to un-

coil.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 13 -

•Safe unboxing Unterminated Reels

Bulk unterminated FloppyFlex ordered in

large quantities arrives on reels of various

lengths depending on type.

Reels are shipped with a plastic axel which

installs through the center hole and allows

the reels to rotate in the shipping box.

Always make sure the reel with un-coil

overhand, so that the orientation of the

FloppyFlex is as horizontal as possible.

Additional hands are needed to support

FloppyFlex if unboxing and cutting long runs

over 2 meters. It is best to prop up the reel on

a platform which is level with a long table or

bench surface to support the length as

horizontally flat as possible.

NEVER pull FloppyFlex from a reel resting on

the ground sideways or any other angle

which may violate care and handling

instructions.

•Safe Coiling FloppyFlex Assemblies

Some projects may require test-fitting

FloppyFlex, or may only have rough length

measurements for installation and mounting

points

In these cases, we encourage specifying bulk

lengths of unterminated FloppyFlex and an

assortment of our our EZ Connect system

components for DIY termination in the shop

or onsite (see instructions below).

Completed FloppyFlex assemblies often

need to travel from shop to field or from one

location to another.

The best course of action for short-term

storage and transportation of completed

assemblies is to coil FloppyFlex relative to its

bending direction: Side-to-Side (STS) or

Front-to-Back (FTB).

Cutting and termination should take place on

a long, flat surface such as a workbench or

table. From this position, start from one end

and coil the FloppyFlex back onto itself,

forming a circle with diameter no smaller than

the minimum bending diameter of the type.

Continue coiling the FloppyFlex around itself

until a complete circle with multiple rings is

formed. At this point you may use Velcro ties

to secure and hold the assembly together.

Keep the assembly flat by layering cardboard

above and below. Several Coiled assemblies

can be stacked and transported in this

manner.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 14 -

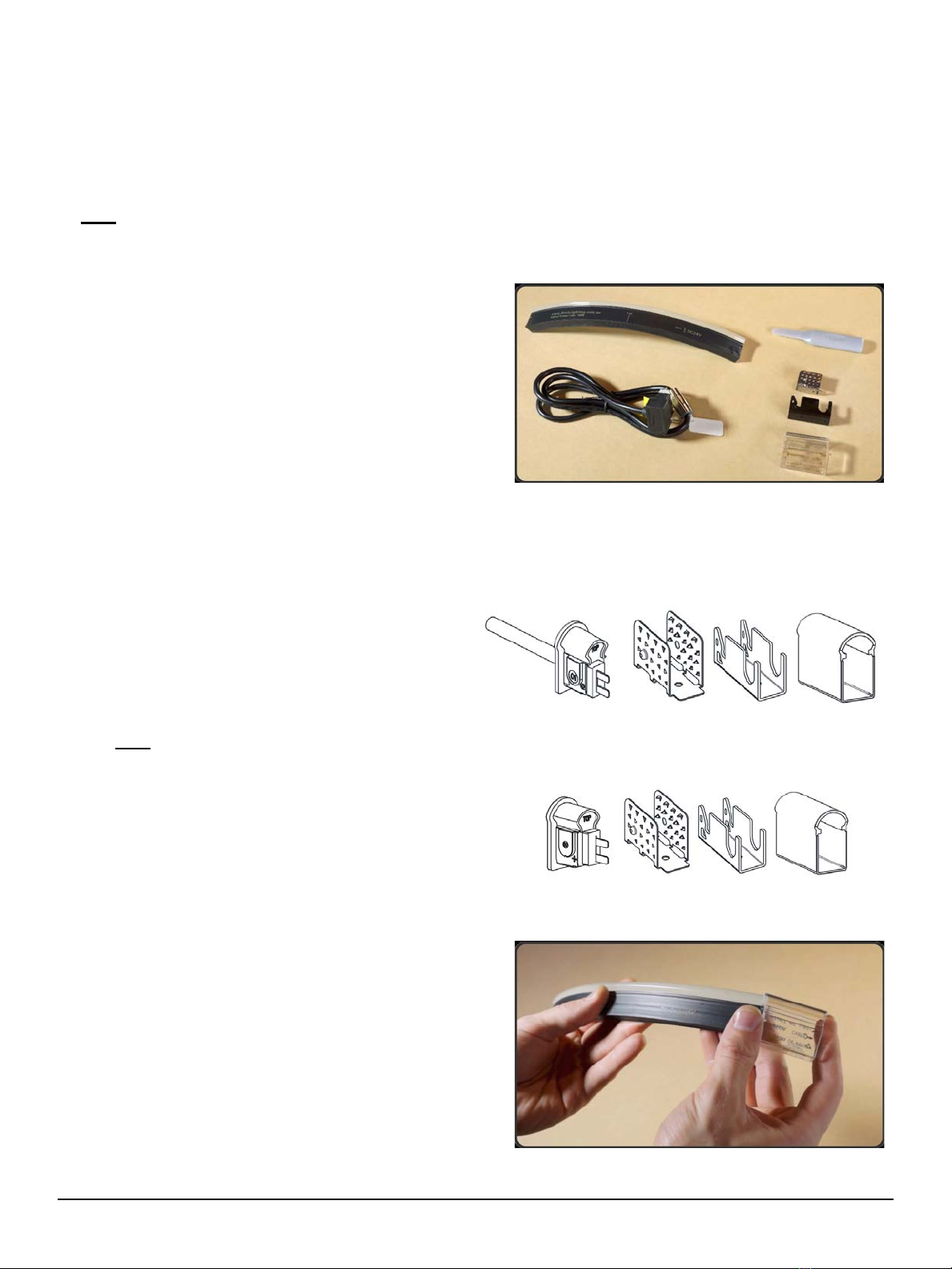

Cut Mark

Ratcheting Cutter

Used to accurately cut FloppyFlex

at 90˚ angles

Grippers

Used to install some specialized

FloppyFlex connectors

(Not needed for EZ Connect)

Insertion Spreader

Used to

create insertion gap

behind PCB to input connector

prongs

CUTTING FLOPPYFLEX

MINI TOOL KIT

The FloppyFlex Mini Tool Kit is available with necessary tools for cutting and terminating FloppyFlex

assemblies. The Mini Tool Kit contains a ratcheting cutter, insertion spreader, and grippers. The larger of

the two spreaders are used for FloppyFlex Large, Small and Flat profile products, while the smaller spreader

is used for FloppyFlex Mini profile. We highly recommend using the Mini Tool Kit for optimal results and

reduced risk of damage to the product.

CUTTING MARKS

FloppyFlex contains an inner flexible PCB which is designed with segments of LEDs (sometimes referred to

as pixels) that are repeated throughout the length of the product. Each segment is identical and can fully

function as a standalone run of FloppyFlex. The length of each segment is specified as the Minimum Cut

Length and are indicated on the exterior body with a dotted line Cut Mark. These cut marks indicate safe

cutting locations which can be terminated as either input or output side of a FloppyFlex run.

Different styles of FloppyFlex can have varying

amounts of LEDs per segment which affects the

Minimum Cut Length. Please refer to the product’s

individual specification sheet for more information.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 15 -

Cutting Instructions

FloppyFlex Cutting Instructions are applicable to all types of STS and FTB FloppyFlex. Cutting FloppyFlex

is a quick and easy process with minimal tools and is adaptable for preparing FloppyFlex in the shop

beforehand or in the field. Visit https://tmb.com/floppyflex/ for a full instructional video demonstration.

•STEP 1 –Prepare for Cutting

Locating the desired cut mark on a length of

raw FloppyFlex. Prepare the cutters by

opening the jaws completely, so that the

cutting blade is fully extended.

Be sure to follow all care and handling

procedures for FloppyFlex to prevent

incorrect bending and twisting.

•STEP 2 –Alignment

Place the base of the Floppyflex towards the

back of the cutter jaws so that the illumination

side is the furthest away from the blade.

Line up the FloppyFlex cut mark with the

blade’s path to ensure a straight and safe cut.

If necessary, ratchet down the blade closer to

the FloppyFlex body by repeatedly squeezing

the handle. Be sure to stop the blade just

before cutting to determine proper alignment.

•STEP 3 –Begin Cutting

Once the FloppyFlex is aligned with the

blade, continue ratcheting down the blade to

begin cutting.

The ratcheting cutter is designed to make

cutting incremental. You will repeat handle

squeezing several times to complete the

cutting process

•STEP 4 –Inspection

Once the blade has cut through the entire

FloppyFlex Body, remove the newly cut

sections from the ratcheting cutter.

Inspect the cleanly cut edges. Make sure the

cuts are at exactly 90 degrees

(perpendicular) to the length of FloppyFlex

and there are no deformities in the edges or

PCB.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 16 -

EZ Connect End Entry Power Feed

EZ Connect End Cap

TERMINATING FLOPPYFLEX

SIDE NUMBERING SYSTEM

The FloppyFlex internal PCB is not symmetrically located within the housing, meaning each end will have a

different PCB placement and will only marry with the appropriate EZ-Connector. After cutting, inspect end

and note which numbered side is visible, “01” or “02”. The visible number determines which style of

connection must be used.

Note: Most single and variable color FloppyFlex options can be powered from either end, but

FloppyFlex Digital products only operate in one direction, with control signal input on side “01”.

EZ CONNECT SYSTEM

EZ Connect components are used to terminate a raw cutting of FloppyFlex. Connector pins are inserted into

side 01 or 02 and directly contact the copper leads of the inner PCB. The main connector is then sealed into

place with compression fittings and a silicone gasket, all housed in a durable cover. Correct installation will

result in a water-resistant, IP67 rated assembly.

EZ Connect power feeds link FloppyFlex to a

power supply or driving controller via cable. A wide

variety of EZ Connect configurations are available

with feed cables oriented in end, side, or bottom

entry for both side 01 and side 02.

EZ Connect End Caps terminate the end of a

FloppyFlex run and insulate it from surrounding

surfaces.

EZ Connect Jumpers connect two or more pieces

of FloppyFlex together (with respect to max run

lengths).

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 17 -

Insertion Spreader

Placement

PVC

Strip

PCB

Correct placement – behind the PCB

Incorrect placement – in front of the PCB

INSERTING THE SPREADER

The inner components of FloppyFlex are hermetically sealed inside a PVC or silicone housing that offers

little clearance for connector installation. Using the insertion spreader tool, users can separate the flexible

PCB from the PVC insulating strip and create a “pocket” for the connector input. This allows easy access to

the copper conductors of the flexible PCB and ensures proper connectivity between the conductors and

connector pins.

Placement of the Insertion Spreader is important as is insertion depth. Pay close attention and understand

the cross-section of components before attempting to insert the spreader. If the spreader is incorrectly

seated in front of the PCB, there may be damage to the PCB components, which will make the first segment

inoperable. If damage does occur, and the first segment malfunctions, remove it with the cutter and continue

to the next segment.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 18 -

Side 01 EZ Connect Power Feed Components

Side 02 EZ Connect End Cap Components

Side 01 EZ Connect Power Feed Components

EZ CONNECT TERMINATION INSTRUCTIONS

FloppyFlex Termination instructions are applicable to all types of STS and FTB FloppyFlex and all variations

of EZ Connect Power Feeds, End Caps and Jumpers. Terminating FloppyFlex is a quick and easy process

with minimal tools and is adaptable for preparing FloppyFlex in the shop beforehand or in the field. Visit

tmb.com for full instructional videos.

Note:Custom FloppyFlex assemblies with molded connections are also available with factory lead time.

Contact sales@tmb.com for more information.

•STEP 1 - Gather Components

Most standard FloppyFlex assemblies will

need the following materials:

Raw FloppyFlex (cut to desired length)

Side 01 EZ Connect Power Feed

Side 02 EZ Connect End Cap

Insertion Spreader

Each EZ Connect option has a set of

common components, all of which are

necessary to install correctly to achieve IP67

rating:

Connector w/ silicone gasket

Compression Support Frame

Anti-Skidding plate

Plastic Snap Cover

Note: The Termination instruction example in

this User Manual is a standard side 01 EZ

Connect Power Feed with Large 270° Profile

STS.

Specialized FloppyFlex assemblies with EZ

Connect Jumpers or side 02 EZ Connect

Power Feeds follow the same instructions

and concepts for termination.

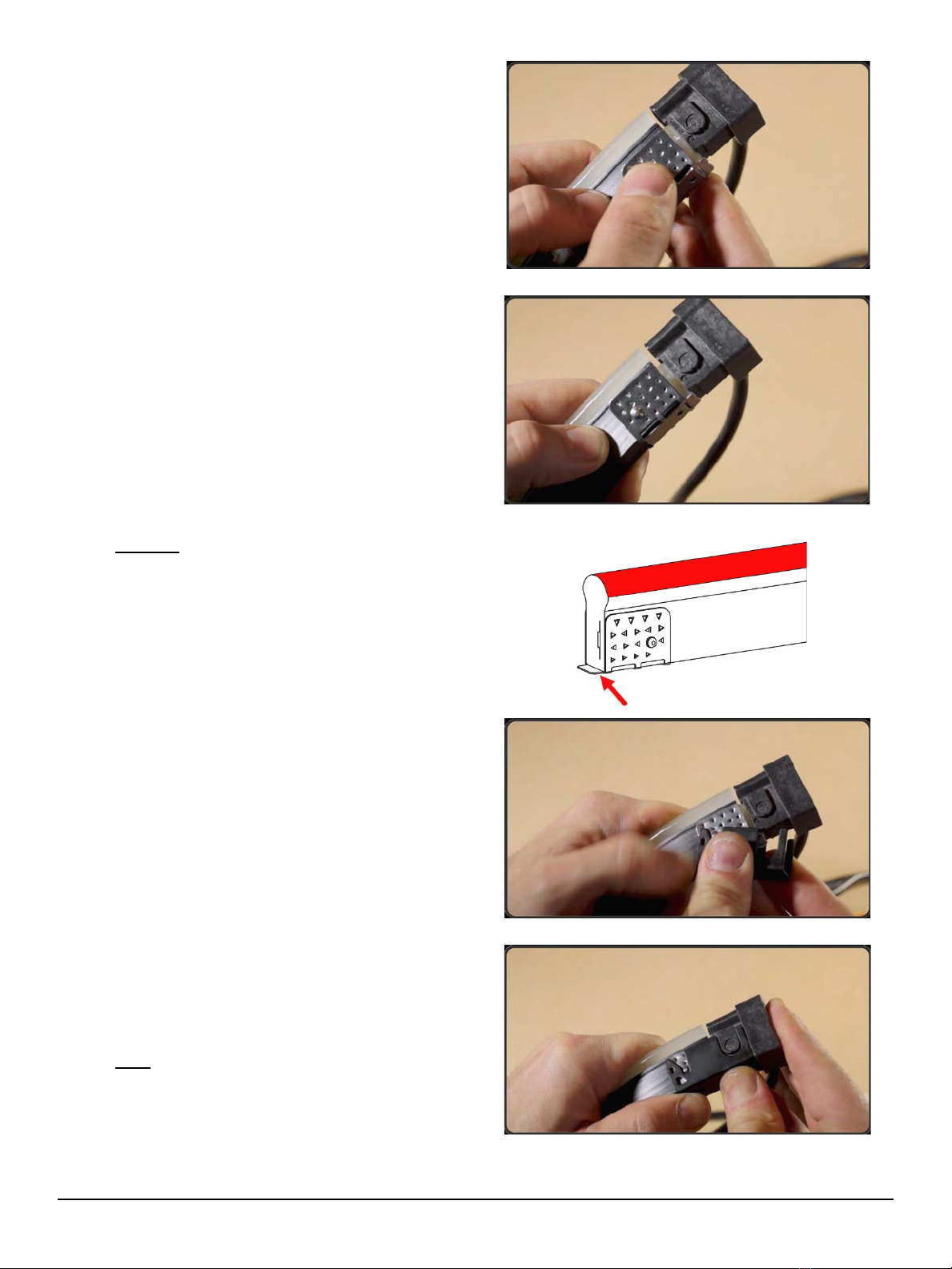

•STEP 2 –Prepare Plastic Snap Cover

Slide the plastic snap cover over the body of

the FloppyFlex and place it a few inches

away from the assembly end to leave room

for next steps.

When installing the snap cover, directionality

matters. Pay attention to the instruction

printed on the bottom of the piece.

The snapping end of the cover is indicated

with an arrow and should point towards the

assembly end.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 19 -

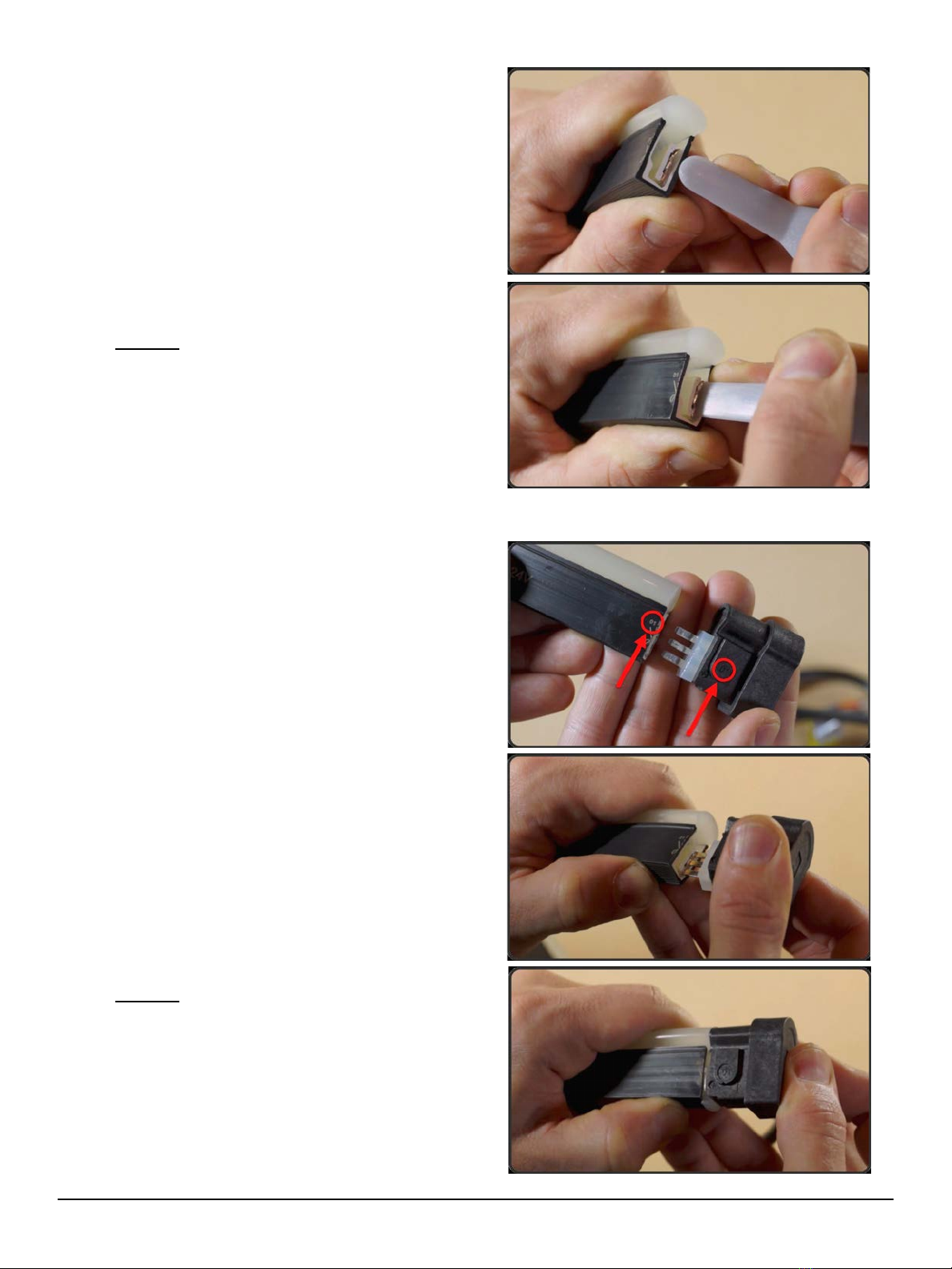

•STEP 3 –Insertion Spreader

Grab the assembly end and face it towards

you so that you can inspect the cross-section

of internal components.

Locate the flexible PCB and gently insert the

spreader behind the copper belt. If done

correctly, the insertion spreader should be in

the gap created between the PCB and the

PVC insulation strip.

Insert the spreader not more than 10 mm or

about ½ in and move up and down 3-5 times

to widen the cavity.

Warning: Proper insertion placement is

extremely important. Inserting the spreader

into the front side of the PCB may damage

LEDs and other components.

•STEP 4 –Install the Connector

Each connector is imprinted with 01 or 02

label on the body to help identify the style.

Each cut mark of FloppyFlex will indicate if

the assembly end is either side 01 or 02. Look

for this label on the edge of the assembly end

and match the number with the appropriate

connector style.

Once you have located the correct connector,

gently insert the pins of the connector into the

gap created by the insertion spreader.

Maintain a straight alignment and do not

force the connector into place.

The connector is correctly seated when the

silicone gasket is in contact and compressed

by the assembly end of the FloppyFlex.

When installing an EZ connect Power Feed,

The FloppyFlex assembly is now safe to

connect to power and/or drivers to test

connection. Make sure to disconnect power

before continuing to next steps.

Warning: Gentle pressure is all that should

be required to install connector. If you are

experiencing abnormal resistance, it is

possible that connector pins are splitting

around the PCB or may be installed

incorrectly on the front side of PCB.

If this occurs, simply remove the connector,

inspect for any damage, and repeat Step 3 to

reopen the cavity.

FloppyFlex User Manual Version 2.0 - 22 August 2022 - 20 -

•STEP 5 –Install Anti-Skidding Plate

The Anti-Skidding Plate is designed to grip

onto the FloppyFlex body and provide

leverage to install the Compression Support

Frame.

The wings of the metal Anti-Skidding plate

are intentionally flexible and are intended to

facilitate easier installation.

To install the plate, use fingers to unfold the

wings slightly wider than the width of the

FloppyFlex body. Then position the plate so

that the edge of the frame aligns exactly with

the clean edge of the FloppyFlex.

There is a slight lip on the bottom of the plate,

which should overlap the edge of the

FloppyFlex and align with the bottom of the

silicone connector gasket.

Once aligned, push the bottom of the plate

into place, making sure the plate hugs the

body as closely as possible. Use fingers to

squeeze the plate wings onto the FloppyFlex

until they successfully bite into the housing.

Warning: Improper alignment may result in

the IP67 rating being compromised. Water

ingress failure due to incorrect assembly is

not covered by warranty.

•STEP 6 –Install Compression Support

Frame

The Compression Support Frame is a strong

metal support designed to interface with

strength member points on the Anti-Skidding

Plate and connector to effectively lock the

connector onto the FloppyFlex end. It

ensures the completed assembly cannot

easily be removed.

Align the frame so that the “U” cutout faces

the connector side.

Slide the frame over both the connector and

Anti-Skidding Plate and apply even pressure

until the plate is flush along the bottom of the

plate and connector with no gaps around the

frame.

Note: The Compression Support Frame is

intended to fit tightly. Installing the Frame

correctly may sometimes require additional

force on the connector to push it towards

FloppyFlex end until the frame can snap into

place.

This manual suits for next models

1

Table of contents

Other TMB Lighting Equipment manuals