Content

1Safety.........................................................................................................................................................................3

1.1 Introduction..................................................................................................................................................3

1.2 Intended Use............................................................................................................................................... 3

1.3 Safety Instructions for Commissioning...................................................................................................3

1.4 Safety Instructions for Operation............................................................................................................. 3

1.5 Safety Instructions for Servicing.............................................................................................................. 3

1.6 Safety Features........................................................................................................................................... 4

1.7 Warning Labels............................................................................................................................................4

1.8 Disposal of Used Oil...................................................................................................................................6

1.9 Machine Demolition....................................................................................................................................6

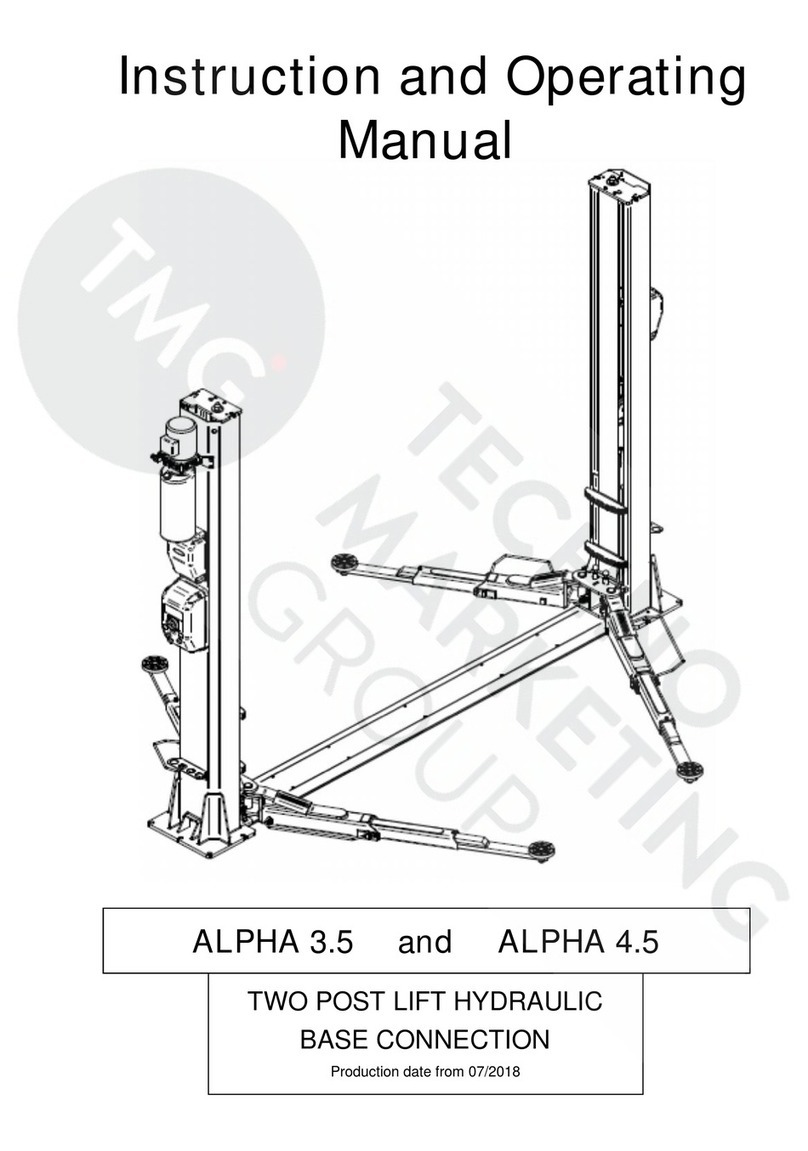

2. Structure Drawing:................................................................................................................................................ 6

3. Main Technical Mechanism Parameters Table................................................................................................8

3.1 Products Specifications ...........................................................................................................................8

3.2 Parts Identification and Features............................................................................................................. 8

4. Packing, transport and storage.......................................................................................................................... 9

4.1 Packing......................................................................................................................................................... 9

4.2 Lifting and handling.................................................................................................................................... 9

4.3 Storage and stacking of packages..........................................................................................................9

4.4 Delivery and check of packages.............................................................................................................. 9

5 Installation............................................................................................................................................................. 10

5.1Working Site............................................................................................................................................... 10

5.2 Installation..................................................................................................................................................10

6. Operation instruction..........................................................................................................................................15

6.1 Operation Rules for mechanism System..............................................................................................14

6.2 Operating Steps for Electrical Control System................................................................................... 14

6. 3 Operation Flow:........................................................................................................................................14

6.4 Use lifting arm........................................................................................................................................... 16

7 Maintenance and Troubleshooting................................................................................................................... 18

8 Troubleshooting....................................................................................................................................................17

9 Parts Breakdown ................................................................................................................................................19

1 Exploded Drawing........................................................................................................................................18

2 Parts List........................................................................................................................................................20

3 Hydraulic Diagram....................................................................................................................................... 20

WWW.TMGINDUSTRIAL.COM P02/21 Toll Free:1-877-761-2819