W W W . T M G I N D U S T R I A L . C O M P 6 / 1 7 T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

Installation steps

Step 1 : Review the whole structure and choose the proper installation site

Choose a solid level ground area to set up the building. Do not install in an area

where the floor is soft, a wetland, can not take the weight, or keep the building steady.

We strongly recommend to install the building on a concrete foundation with all

expansion bolts to secure all baseplates. Do not use any anchor spikes!

Watch the surroundings! Do not set up the building near any snowdrifts. The fabric

cover can hold up a certain amount of falling leaves, light debris and wind resistance,

however, large, fast or sharp falling items and big wind might punch or tear the fabric

materials. Keep the building surroundings clear to avoid potential damages.

Be careful with power and heat sources. Do not keep heat sources near the cover. Do

not expose the building to open flame.

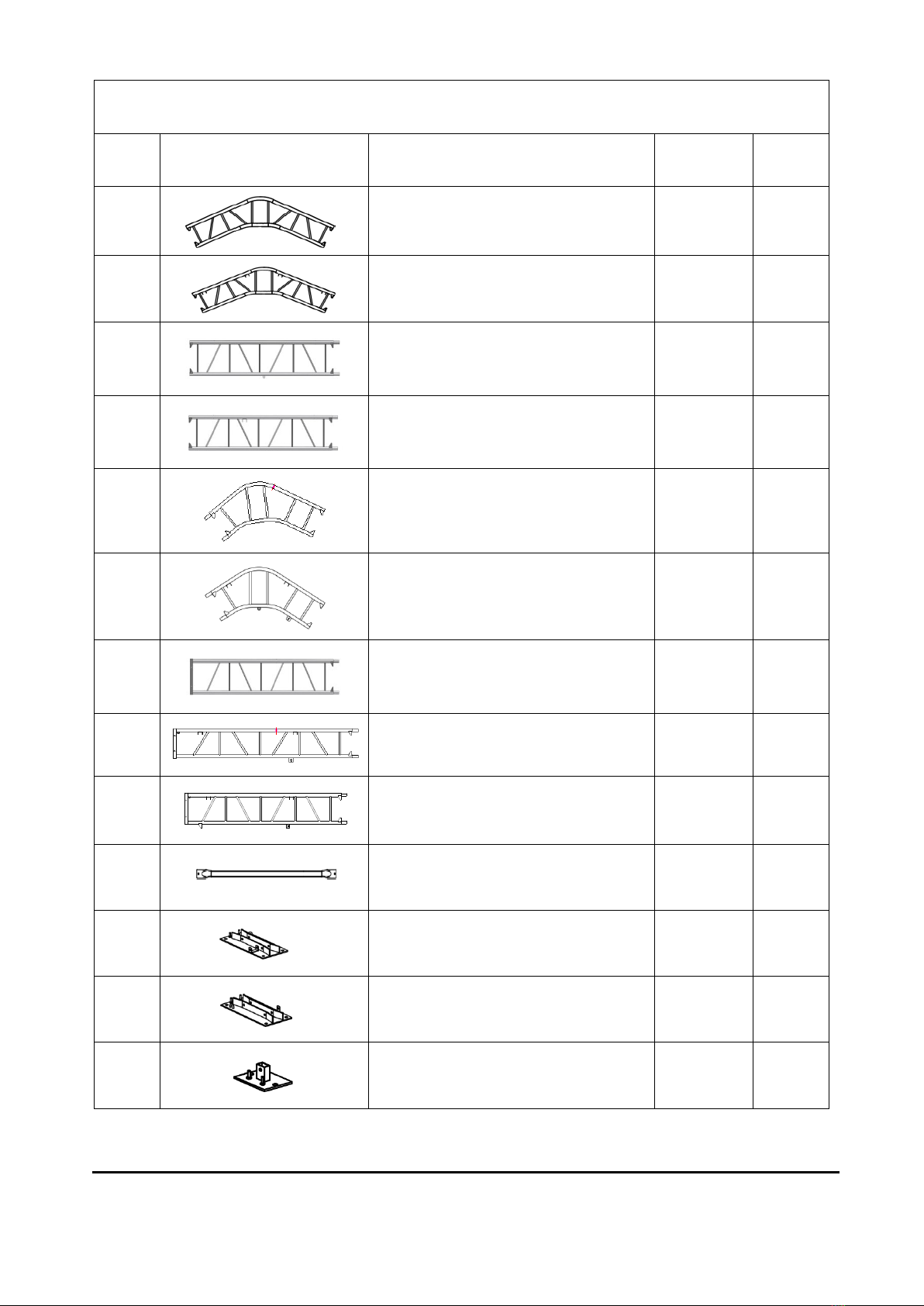

Review the whole frame structure diagram as shown in figure 1, decide the

roll up door position, and make sure you will have about 3 ft clearance around

the building.

Draw a rectangular square base line showing all positions of base plates and

front and rear doors. The diagonal X and Y must be equal. ( Refer to figure1)

Baseplates : all baseplates must be bolted firmly with expansion bolts(#7B). It

is concrete expansion bolt.

Baseplate installation is as below and all baseplates are required to install and

tie firmed on this step. (refer to figure 1)

-

(4) Baseplates (#5L, #5R)

-

(18) Baseplates (#7)

-

(4) Baseplates (#6L, #6R)

-

(96) Expansion bolts (#7B)

Figure 1