TOP DC CUT 20 User manual

PLASMA CUTTER

OPERATOR'S MANUAL

www.topacdc.com Amazon Store Facebook

MODEL: CUT 20

CONTENTS

Please save these instructions. This manual contains important safety and operating

instructions. Read all instructions and follow them with each use of this product.

S

SERVICE

AFETY INFORMATION 1-3

SPECIFICATIONS 4

SET-UP 4-5

OPERATION 5-6

MAINTENANCE 7-8

9-10

TROUBLE SHOOTING

…………...……………………………….…………….…………….

……………………...……………………………….……………….……………….

10

……………………...……………………………….……………….………………

……………...……………………………….………….……

……………...……………………………….…………….…………….

.……………………………….……………….……………….

………………..……………...……………………………….………….……

SAFETY INFORMATION

1

In this manual, on the labeling, and all other information provided with this product:

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE is used to address practices not related to personal injury.

People with pacemakers should consult their physician(s) before using. Electromagnetic

fields in close proximity to heart pacemaker could cause pacemaker interference or

pacemaker failure. In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with Power Switch locked on.

• Properly maintain and inspect to avoid electrical shock.

• Any Power Cord must be properly grounded. Ground Fault Circuit Interrupter (GFCI)

should also be implemented – it prevents sustained electrical shock.

ELECTRIC SHOCK CAN KILL!

• Do not touch any electrical components that may be live.

• Separate yourself from the Plasma Cutter circuit by using insulating mats to prevent

contact from the work surface.

• Improper use of a Plasma Cutter can cause electric shock, injury and death! Read

all precautions described in this manual to reduce the possibility of electric shock.

READ INSTRUCTIONS!

• Thoroughly read and understand this instruction manual before using the

Plasma Cutter.

• Keep this instruction booklet.

• The Plasma Cutter power switch is to be in the OFF position and the power supply

is to be disconnected when performing any maintenance or consumable changes.

• Always wear dry, protective clothing and leather welding gloves and insulated footwear.

• Always operate the Plasma Cutter in a clean, dry, well-ventilated area. Do not operate

the Plasma Cutter in humid, wet, rainy or poorly ventilated areas.

• Be sure that the work piece is properly supported and grounded prior to beginning an

electric Plasma Cutter operation.

•The electrode and work (or ground) circuits are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare skin or wet clothing.

• Disconnect from power supply before assembly, disassembly or maintenance of the

torch or contact tip.

• Always attach the ground clamp to the piece to be welded and as close to the weld

area as possible. This will give the least resistance and best cut.

• Do not breathe fumes that are produced by the cutting operation. These fumes are

dangerous and can cause serious respiratory damage.

Keep your head and face out of cutting fumes.

• Always work in a properly ventilated area. Wearing an OSHA-approved respirator when

cutting is recommended!

ELECTROMAGNETIC FIELDS MAY BE DANGEROUS!

• Anyone with a cardiac pacemaker or other implanted medical device should stay away

•Exposure to electromagnetic fields while plasma cutting may have other health effects

from any plasma cutting before consulting a doctor.

Powerful electromagnetic fields emitted by Plasma Cutters can interfere with

operation, causing malfunction and possible death.

which are not known.

FUMES AND CUTTING GASES CAN BE DANGEROUS!

2

• Never cut coated materials including but not limited to: cadmium plated, galvanized,

lead based paints.

CUTTINGSPARKS CAN CAUSE FIRE OR EXPLOSION!

•Do not operate Plasma Cutter in areas where flammable or explosive vapors are

present.

• Always keep a fire extinguisher nearby while cutting.

• Use welding blankets to protect painted surfaces, dash boards, engines, etc.

• Ensure power supply has properly rated wiring to handle power usage.

• Do not use on or near combustible surfaces.

• Remove all flammable items within 35 feet of the cutting arc.

sparks. To prevent injury, wear approved safety glasses.

• Cutting, brushing, hammering, chipping, and grinding can cause flying metal chips and

3

• Use a shield with the proper filter (a minimum of #11) to protect your eyes from sparks

and the rays of the arc when cutting or when observing open arc cutting (see ANSI

Z49.1 and Z87.1 for safety standards).

• Use suitable clothing made from durable flame-resistant material to protect your skin.

Protect nearby individuals with a non-flammable barrier.

• If other persons are in the area of cutting use welding screens to protect bystanders

from sparks and arc rays.

ARC RAYS CAN BURN EYES AND SKIN!

• Electric cutting operations cause sparks and heat metal to temperatures that will

cause severe burns!

• Use protective gloves and clothing when performing any Plasma Cutter operations.

Always wear long pants, long-sleeved shirts and leather welding gloves.

• Make sure that all persons in the cutting area are protected from heat, sparks and

ultraviolet rays.

• Use additional face shields and flame resistant barriers as needed.

• Never touch work piece until it has completely cooled.

HOT METAL WILL BURN!

FLYING METAL CHIPS CAN CAUSE INJURY!

SPECIFICATIONS

SET-UP

4

Input Voltage 120VAC

15A plug

120VAC

20A plug

Output Range 10-16A 10-20A

Rated Duty Cycle 60%@16A 35%@20A

Maximum OCV 400V

Quality Cutting Thickness 3mm 6mm

Maximum Cutting Thickness 4mm 10mm

Input Air Pressure 45-55 psi

The rated Duty cycle refers to the amount of plasma cutting that can be done within a

measured amount of time. The Plasma Cutter has a duty cycle of 60% at 15 Amps.

It is easiest to look at your cutting time in blocks of 10 Minutes and the Duty Cycle being

a percentage of that 10 Minutes. If cutting at 15 Amps with a 60% Duty Cycle, within a 10

Minute block of time you can cut for 4 Minutes with 6 Minutes of cooling time allowed for

the cutter.

ELECTRIC SHOCK CAN KILL!

Disconnect from power supply before assembly or maintenance

• After a proper 20 Amp, 120 VAC, 60 Hz current source is determined, be sure the

appropriate circuitry and breakers are in place.

• DO NOT plug unit in at this time and make sure the Power Switch located on the upper

right corner of The Rear Panel is in the OFF position.

• Install a quick-disconnect air fitting compatible with your air line into the 1/4” NPT fitting

located on the upper left corner of the Rear Panel.

• Attach the Torch Air Supply Line to the lower right corner of the Front Panel by

threading in place. Note: “Finger-Tighten” securely but do not over tighten.

•Attach the Torch Switch Connector Cable to the Multi-Pin Connector located second

from right of the Lower Front Panel. Note that the semi-circular notch of the inner

female plug must align with the semi-circular male key of the metal shell. Push plug

securely in place then thread the metal locking ring in onto the metal shell. “Finger-

Tighten” securely but do not over tighten.

• Attach the Ground Lead located at the Lower Left Corner of the Front Panel. Note that

the semi-circular notch of the inner female plug must align with the semi-circular male

key of the metal shell. Push plug securely in place then rotate the plug 1/2 turn in a

Clockwise direction until it locks.

OPERATION

1. Before attempting to use this unit on an actual project or object of value, practice on

a similar material as there is a moderate learning curve necessary before achieving

proficiency in cutting.

2. Set the Air Pressure to the appropriate pressure with the Knob located at the rear

panel.

To set: Pull the Knob Shell outward to unlock, rotate it clockwise to raise pressure and

Counter-Clockwise to lower pressure. Push Knob Shell inward to lock in place.

3. The Pressure Indicating Gauge is located at the rearpanel, next to the Air Pressure

Knob and is set at 40 to 55 PSI depending on metal composition and thickness.

ARC RAYS CAN BURN SKIN AND EYES!

• Use a shield with the proper filter (a minimum of #11) to protect your eyes from sparks

and the rays of the arc when cutting or when observing open arc cutting (see ANSI

Z49.1 and Z87.1 for safety standards).

• Use suitable clothing made from durable flame-resistant material to protect your skin.

Protect nearby individuals with a non-flammable barrier.

CUTTING SPARKS CAN CAUSE FIRE OR EXPLOSION!

• Use a shield with the proper filter (a minimum of #11) to protect your eyes from sparks

and the rays of the arc when cutting or when observing open arc cutting (see ANSI

Z49.1 and Z87.1 for safety standards).

• Use suitable clothing made from durable flame-resistant material to protect your skin.

Protect nearby individuals with a non-flammable barrier.

present.

•Always keep a fi re extinguisher nearby while cutting.

• Do not operate Plasma Cutter in areas where flammable or explosive vapors are

5

7. To begin cutting, depress the Torch Trigger to ignite the pilot arc. The RED “ ”

indicator lamp should illuminate the tip of the torch must be

touching or within a short distance to the work piece to begin the cut.

DANGER: Plasma Arc consists of superheated, electrified air which will quickly and

violently vaporize almost anything in its path.

8. With practice, you will be able to exercise precise control over this extremely powerful

device, harnessing its energy to create clean, precise and intricate cuts in many forms of

steel and iron up to 1/8" thick.

9. While you practice, experiment with different speeds. You will find that thinner

materials will allow a faster motion while thicker materials will require a slower motion to

achieve a through cut.

10. A good form of practice is to attempt a series of straight lines while creating the

cleanest edge possible with a minimum of molten material remaining on the cut edge.

This minimizes the cleanup of the edge with a grinder or fi le. Another excellent

technique is to practice cutting your initials out of a piece of steel.

4. Place the Ground Cable Clamp on a clean, bare area of your workpiece. Scrape, wire

brush, fi le or grind a bare area if necessary to achieve a good ground.

5. Make sure the Tip is not making contact with anything or anyone then set the

“ON/OFF” switch to the “ON” position. The GREEN “ON” indicator lamp should illuminate.

6. The best results are achieved by holding the Tip at a 90° angle to the desired cut line

of your work piece.

• Ensure power supply has properly rated wiring to handle power usage.

•Do not use on or near combustible surfaces.

• Remove all flammable items within 35 feet of the cutting arc.

CUT 20 Plasma Cutter-Air Pressure and Amperage Settings

Metal Thickness 1/32" 1/16" 3/32" 1/8"

Amps 15 15 18 20

PSI 40 45 50 55

*NOTE: These settings are guidelines only and may need to be adjusted based on

your techniques and type of metal being cut.

6

MAINTENANCE

POWER UNIT CARE & MAINTENANCE

• The Plasma Cutter has a moisture separator which requires draining each time you

have completed work with the unit. This feature is located on the underside rear corner

and is drained by keeping the unit level and gently pulling down on the drain fitting

• Constantly inspect the torch tip for excessive erosion, molten metal accumulation

burning. If damaged, it must be replaced.

• Before each use, inspect ALL electrical connections, cables, supply line, torch, air

supply, housing and controls for damage. If any damage or wear is noted, DO NOT

USE THE UNIT.

• Always store the unit in a safe, clean and dry environment.

TORCH MAINTENANCE

The Plasma Cutter has a number of consumable parts that will need to be replaced

over time. If wear or slag build up is noticed on any of the torch components, replace

them immediately to avoid damage to the torch. Worn components will also contribute

to poor cutting and difficult arc starting.

7

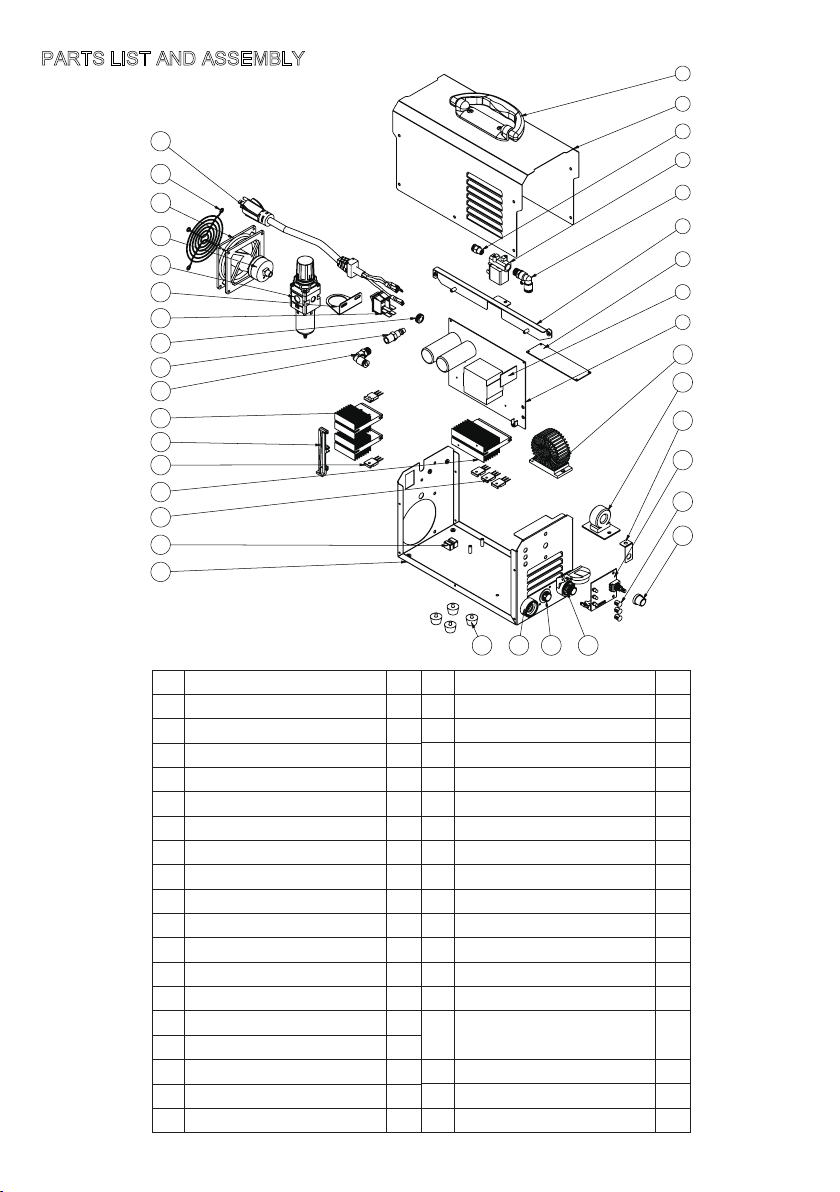

1

2

3

4

5

6

7

10

8

9

11

12

13

14

15

36

34

33

32

31

27

30

25

26

24

23

22

21

18 17 16

28

29

19

20

35

8

NO. Part Name QTY

1 Handle 1

2 Top Cover 1

3 Pneumatic Joint 1

4 Magnetic valve 1

5 Elbow 1

6 Bracket 1

7 High frequency PCB 1

8 Control PCB 1

9 Main PCB 1

10 Output choke 1

11 ARC PCB 1

12 Angle iron 1

13 Panel PCB 1

14 Chimney 3

15 Knob 1

16 Quick connector 1

17 Aviation plug 1

18 Quick connector 1

19 Foot pad 4

20 Bottom cover 1

21 PCB clip 1

22 Fast recovery diode 3

23 Rectifier heatsink 1

24 IGBT 2

25 Support 1

26 IGBT heatsink 2

27 Elbow 1

28 Connector 1

29 Convenient ring 1

30 Switch 1

31 Bracket 1

32 Reducing Valve 1

33 Header 1

34 DC fan 1

35 Fan cover 1

36 Power cable 1

NO. Part Name QTY

PARTS LIST AND ASSEMBLY

TROUBLESHOOTING

9

Trouble Experienced Possible reasons Likely Solutions

All LEDs OFF when turn

ON the machine

1. No input power

2. Power Switch is OFF

1. Verify that circuit breaker

hasn’t been tripped in

your main power panel.

Resent if needed

2. Ensure “Power Switch”

is in the on “1” position.

Green LED flashing Input voltage too low or too

high Verify input power source

Yellow LED solid, and no

output, fan operating

properly

Machine has reached its

duty cycle

Allow machine to cool down

with fan running.

Yellow LED flashing Insufficient air pressure or

air flow

Make sure input air pressure

is within 45-55psi

Red LED flashing

Shield cup not installed in

position or consumables

missing or consumables

worn badly

Check consumables and

shield cup are installed

properly. Replace

consumables if they are

worn badly.

Improper ground

connection

Make certain that the work

piece is contacted properly

by the Earth Clamp and that

the work piece is properly

cleaned near the Earth

Clamp and the welding

location

Improperly sized or

excessively worn Nozzle

Verify that Nozzle is the

proper size for the Cutting

Torch used. Check that the

hole in the tip is not de-

formed, enlarged, or dirty. If

needed, replace Nozzle with

proper size and type

Output current is too low Increase output current

through clockwise adjusting

the knob. Make sure proper

input power is supplied.

Material being cut is too

thick

Refer to SPECIFICATIONS

to choose material with

proper thickness. Or change

to a more powerful plasma

cutter to cut the material with

thickness exceeds the limit.

Cutting speed is too fast slower torch travel speed

Torch is too tilted

Adjust cutting angle and

make sure torch head is

vertical to the workpiece

Consumables are worn out

Check the consumables

condition and replace the

worn parts if necessary

Insufficient cutting

penetration

does not igniteArc

10

Excessive slag formation

Consumables are worn out

Replace worn consumables,

then reassemble Torch

tightly

Improper cutting speed

Increase cutting speed if

slag formed at the bottom, or

decrease if slag formed at

the top of workpiece.

No gas flow

Nozzle Plugged

Clean Nozzle. If damaged,

replace

Air supply hose blocked

Check air supply hose, and

hose within Cutting Torch

cable

Cutting arc not stable

Loose Torch cable or

Ground Clamp cable

Check to ensure that all

connections are tight.

Unstable line voltage

Check the line voltage and, if

there are problems with the

wires, have a licensed

electrician remedy the

situation.

Cutting current is too low

Increase cutting current

through turning the knob

clockwise.

Torch travels too fast

Slow down the cutting speed

Torch consumables worn

out

Check nozzle, shield cup, or

electrode, replace if needed.

Thank you for purchasing our plasma cutter. Your purchase includes our free 1-year limited

warranty. If you have any questions or issues about your product, Welcome to contact us at

topacdc01@gmail.com

Please have your order number available when asking for support.

SERVICE

Table of contents