Toray TMR140 Series User manual

AIRE-064-1-6

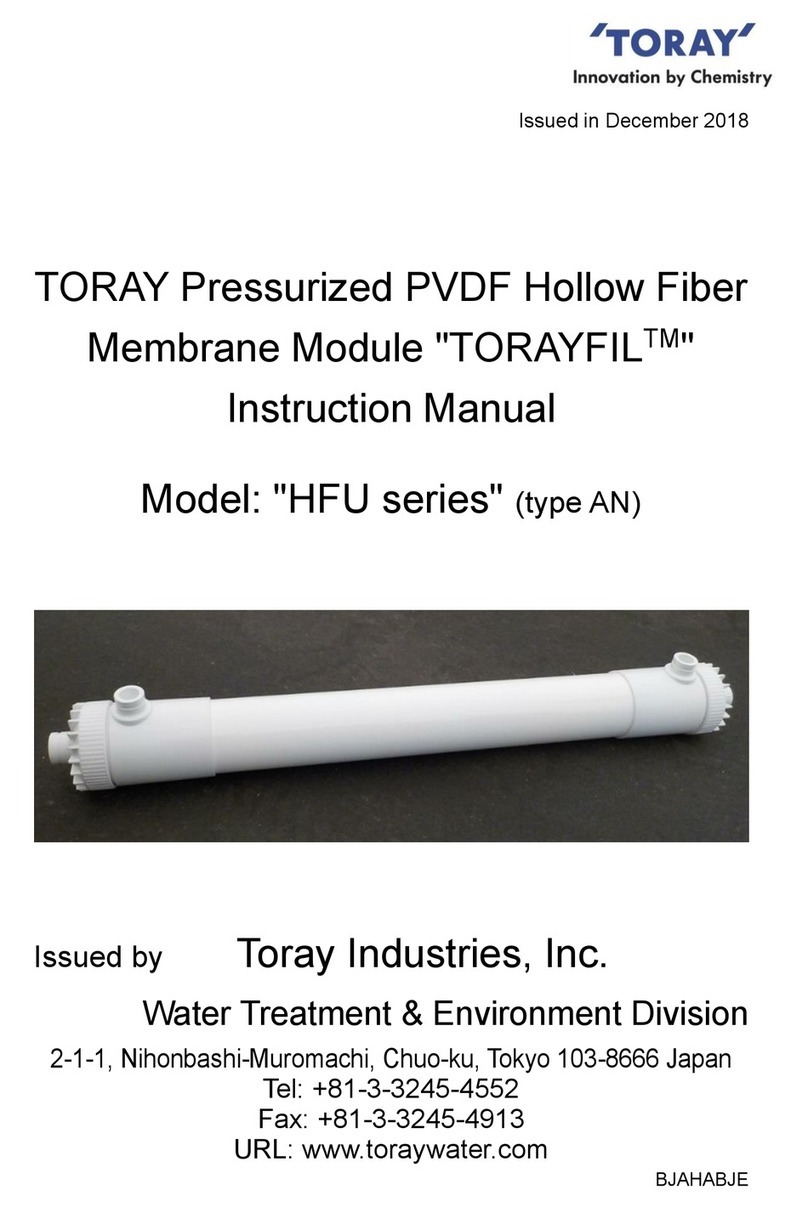

Submerged Membrane Module

for MBR

TORAY “MEMBRAY”

“TMR140 Series”

Instruction Manual

Toray Industries, Inc.

Water Treatment Division

1-1, Nihonbashi-muromachi 2-chome, Chuo-ku, Tokyo 103-8666 Japan

Tel: +81-3-3245-4542

Fax: +81-3-3245-4913

URL: http://www.toraywater.com

Published: April 2013

AIRE-064-1-6

Content

I. INTRODUCTION ..................................................................................................................... 1

1. Features of MBR ................................................................................................................... 1

2. Outline of “TMR140 Series”................................................................................................... 2

II. FOR SAFE OPERATION OF “TMR140 SERIES”.................................................................. 5

1. Unpacking and Installation .................................................................................................... 5

2. Operation and Maintenance.................................................................................................. 6

3. Chemical Cleaning of Element.............................................................................................. 7

III. SPECIFICATIONS AND PERFORMANCE OF “TMR140 SERIES” ...................................... 9

1. Specifications of Element ...................................................................................................... 9

2. Specifications of Polyurethane Permeate Tube.................................................................... 9

3. Specifications and Performance of “TMR140 Series” Module............................................ 10

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “TMR140 SERIES”......................... 12

1. Standard Time Chart ........................................................................................................... 12

2. Flow Diagram of Membrane Filtration................................................................................. 13

3. Layout of “TMR140 Series” Modules in Membrane Submerged Tank ............................... 18

4. Piping................................................................................................................................... 21

V. INSTALLATION OF “TMR140 SERIES”............................................................................... 23

1. Preparatory Procedure ........................................................................................................ 23

2. Unloading/lifting Products.................................................................................................... 23

3. Checking Products .............................................................................................................. 24

4. Storage Products................................................................................................................. 24

5. Installation Products ............................................................................................................ 25

VI. START OF OPERATION...................................................................................................... 30

1. Clean Water Operation........................................................................................................ 30

2. Seeding Sludge Injection..................................................................................................... 31

3. Actual Filtration Operation................................................................................................... 31

VII. OPERATION CONTROL ...................................................................................................... 33

1. Standard Operating Conditions........................................................................................... 33

2. Operating Parameters ......................................................................................................... 35

3. Basic Control Philosophy .................................................................................................... 36

4. Daily Inspection ................................................................................................................... 37

VIII. MAINTENANCE OF “TMR140 SERIES” .............................................................................. 40

1. Maintenance Items and Maintenance Frequency............................................................... 40

2. Air Diffuser Cleaning............................................................................................................ 41

3. Chemical Cleaning of Element............................................................................................ 43

4. Chemical Agents Available for Chemical Cleaning............................................................. 43

5. Handling of Chemical Agents.............................................................................................. 44

6. Chemical Cleaning Procedure............................................................................................. 47

7. Lifting Procedure ................................................................................................................. 52

AIRE-064-1-6

8. Storage Products after Use................................................................................................. 53

9. Disposing Procedure ........................................................................................................... 54

IX. REPLACEMENT PARTS LIST ............................................................................................. 55

X. TROUBLESHOOTING.......................................................................................................... 56

XI. APPENDIX ............................................................................................................................ 57

Symbols used in this manual

This symbol is used to indicate an imminent hazardous situation

which, if not avoided, will result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, can result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, may result in injury or property damage.

DANGER

!

WARNING

!

CAUTION

!

AIRE-064-1-6

1

I. INTRODUCTION

Toray "MEMBRAY" is the submerged membrane module suitable for the membrane

bioreactor (MBR) that has been developed based on the polymer science and the membrane

fabrication technologies accumulated for a long time in Toray Industries, Inc.

"TMR140 Series" is a standard model of "MEMBRAY". This manual explains MBR's features

and describes the specifications of "TMR140 Series" and its safe operations including

installation, operation, maintenance procedures and peripheral equipments. Operators

should thoroughly read this manual to ensure stable operation.

1. Features of MBR

The process flow of the conventional activated sludge system (CAS) and MBR are shown in

Fig.I-1 and Fig.I-2, respectively.

MBR provides the following advantages:

(1) Small Footprint

Unlike CAS, MBR separates sludge within aeration tank using membranes, thus eliminate

the space for preparing sedimentation tank. Also with membrane, MBR can hold higher

concentration of activated sludge in the aeration tank, so its volume can be reduced. As a

result, MBR provides smaller footprint compared to CAS.

(2) High quality of treated water

MBR removes suspended solid (SS) from the sludge liquid with membrane much more

certainly than conventional sedimentation process. MBR also rejects microorganisms such

as Escherichia coli and Cryptosporidium efficiently.

Sedimentation Tank

Waste

water

Aeration Tank

Discharge

Wastewater

Discharge or Reuse

Reuse

RO

membrane

Submerged

M

embrane

Module

Membrane

Submerged

Tank

Fig. I-1 CAS Flow

Fig. I-2 MBR Flow

AIRE-064-1-6

2

2. Outline of “TMR140 Series”

“TMR140 Series” is the membrane module composed of the element block and the aeration

block. The element block contains a number of membrane elements stacked at equal

clearance, each of which has flat sheet membranes attached on both sides of ABS panel.

Each element is connected via polyurethane tube to the permeated water manifold. The

aeration block consists of coarse-bubble air diffusers to supply scouring air (see Fig.I-3).

This module is used submerged in sludge liquid.

The following shows the features of “TMR140 Series”.

Fig. I-3 Appearance of “TMR140-100S”

Element

Coarse Air

diffuser

Tube

Permeated water Manifold

Element block

Aeration block

AIRE-064-1-6

3

(1) Shape of Element

The membrane element is a flat sheet type as shown in Fig.I-4. At the normal filtration

operation, the sludge accumulated on the membrane surface is cleaned up effectively with

upward water stream generated with the scouring air supplied from the air diffusers installed

at the bottom side (Fig.I-5). This mechanism ensures stable filtration, since the membrane

does not easily admit of sludge adherence to its surface.

In addition, thanks to the long element design (1.6 m), a larger membrane area is achieved

per footprint, allowing effective use of diffused air.

Fig. I-4 Structure of Element

Fig. I-5 Filtration Principle of Activated Sludge

Supporting panel

Permeated Water

Nozzle

Membrane

1.6 m

0.5

m

Air

Element

Supporting

panel Membrane

Permeated

water

Activated sludge particle

Membrane

Air

AIRE-064-1-6

4

(2) Membrane Structure

The flat sheet membrane consists of PVDF (Polyvinylidene Fluoride) functional layer and the

base layer of PET (polyester) non-woven fabric. This structure gives the membrane superior

physical strength and high chemical resistance.

(3) Membrane Pore Size

Numerous small-size pores are distributed evenly over the membrane surface with a sharp

pore-size distribution. This structure gives an outstanding high treated water quality and an

excellent water permeability, making the membrane highly resistant to clogging (see Fig.I-6

and Fig.I-7) compared to other membranes. The average pore size is 0.08 micron meter.

Fig. I-6 Membrane Surface (photo)

Fig. I-7 Pore Size Distribution

Other Membrane

Toray PVDF Membrane

Pore Size (micron)

東レ

BF014

クボタ

0

0.5

1.0

1.5

0.2

0.4

0.6

0.8

PVDF

Membrane

東レ

BF014

クボタ

0

Number of pore (10

12/m2)

Toray PVDF Membrane

3.0 micron 3.0 micron

Oth

er Membrane

AIRE-064-1-6

5

II. FOR SAFE OPERATION OF “TMR140 SERIES”

Before using “TMR140 Series”, please thoroughly read this Instruction Manual and follow the

instructions described in this manual, especially the safety precautions shown below. The

details of each precaution are described in the relevant chapter

1. Unpacking and Installation

When lifting “TMR140 Series” or its part, please attach chains or

slings to it and raise it straight upward calmly to prevent it from

shaking. Please never allow any person under lifted article.

Please use chains or slings compatible with lifting weight when

lifting "TMR140 Series" or its part.

Check the condition of each part before lifting and never use

damaged one. Never stand below the membrane module when

lifting. Be careful of the balance of the module when lifting.

When lifting TMR140-200D or 400DW, do not lift upper element

blocks and lower element blocks all together. Upper/lower element

block has to be lifted separately.

When installing “TMR140 Series” module, please set up a foothold

in advance. Never climb the module. Please use protective

equipment to ensure the safety of workers.

At transportation, storage and installation, please take appropriate

measures to protect "TMR140 Series" or its part from damage.

Please don't put any heavy objects on the module. Please take

care to protect the module from collision with other objects.

Please do not leave "TMR140 Series" for hours in the place where

the temperature is higher than 40 degree C or in the place exposed

to direct sunlight. Especially ABS supporting panel may be

deteriorated with direct sunlight, ultraviolet ray.

Please take adequate measures to protect “TMR140 Series” from

sparks caused by welding, fusion cutting or grinding throughout the

entire process from installation work to operation startup.

Please protect “TMR140 Series” from freezing at any time.

Please don't pressurize the permeate side of "TMR140 Series”.

DANGER

!

DANGER

!

DANGER

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

DANGER

!

DANGER

!

AIRE-064-1-6

6

Please install the screen with openings of 3.0 mm or under before

the membrane submerged tank. It is recommended to use the

mesh type screen. Overflow or waste carryover must be avoided at

any time.

2. Operation and Maintenance

Don't use permeated water for drinking.

Before discharging the treated water to the environment or reusing

it, make sure to analyze its quality and confirm that the water

quality meets the intended purpose.

Don't burn the membranes without appropriate facilities since

harmful Hydrogen fluoride (HF) gas is generated

at burning.

When dispose membranes, please apply a service of a qualified

waste disposing company.

When the clean water operation, charging clean water to the

membrane submerged tank with the air discharge valve open to

release air from the elements. After charging water, close the air

discharge valve.

Don’t use the ground water, which contains considerable amount

of iron, manganese, calcium or silica, for the clean water operation

as it may cause the clogging of the membrane.

Don't continue the clean water operation unnecessarily.

A long-time filtration of clean water tends to cause the clogging.

Once the membrane gets wet, keep it wet. If the wet membrane is

dried up again, the permeability of the membrane might be

decreased seriously.

When feeding the seeding sludge, be sure to remove foreign

substances from it with the screen (with openings of 5mm or

under).

Don't do the filtration operation without supplying the scouring air in

a right way, or the membrane will be clogged severely.

Don't put in the activated sludge liquid chemicals, toxic agents, oils

or other substances that may adversely affect activated sludge.

ABS supporting panel may get chemical cracks by some organic

solvent, such as alcohols and oils, and some synthetic detergents. So

don't make ABS panel contact such materials.

Please avoid abrupt changes of operating conditions, especially

pH, temperature and the suction pressure of the membrane even

within the range of the standard operating conditions (Table VII-1).

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

AIRE-064-1-6

7

Please replace the renewal parts periodically or when the

deterioration is detected at the inspection.

Prevent “TMR140 Series” from freezing at any time.

Please take care not to dry the membranes when taking "TMR140

Series" out of the liquid for the inspection or the maintenance. If

the wet membrane is dried up again, the permeability of the

membrane might be decreased seriously.

Please stop the scouring air when the filtration operation stops

except for the following conditions:

1) In case of applying intermittent filtration, do not stop the

scouring air for each relaxation period.

2) In case that the plant operation stops for a while, aeration is

applicable for mixing or aeration demand, however, the flow rate

should be controlled minimal.

Please don’t re-use the old permeate tubes once disconnected

from the nozzles since the connection tightness of the tubes are

reduced.

3. Chemical Cleaning of Element

The chemical agents used for the chemical cleaning are harmful to

the health. When handling chemicals, please read their material

safety data sheet (MSDS) in advance and make sure to wear

necessary protectors such as protective goggles and protective

gloves.

If the chemical agents stick to your skin or clothes, immediately

wash it away with enough amount of running water.

If the chemical agents enter your eyes, immediately wash it away

with enough amount of running water and see the doctor.

If any abnormality is found in the equipment during chemical

cleaning, immediately stop operation and check it.

If chemical is injected forcibly directly with the chemical feed pump

or by any other means, the internal pressure of the elements will

increase and the elements will get damaged. Be sure to inject

chemical with the pressure of lower than 10 kPa (100 mbar).

WARNING

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

WARNING

!

AIRE-064-1-6

8

When injecting the chemical agents at the chemical cleaning,

please confirm beforehand that the modules are completely

submerged in the liquid and the liquid level of the membrane

submerged tank is higher by more than 500 mm than the top of the

module.

Please store the chemical agents in a dark cold place free from

direct sunlight.

Please use the appropriate tank or the container, for storing the

chemical agent, made of the material having enough corrosion

resistance to each chemical agent.

Don't mix sodium hypochlorite with heavy metals or acids. In

particular, toxic chlorine gas is generated when mixing sodium

hypochlorite and acids.

Don't mix sodium hypochlorite with oxalic acid or citric acid, or toxic

chlorine gas is generated.

Please stop the scouring air during the chemical cleaning, or the

membrane elements might be damaged.

WARNING

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

WARNING

!

AIRE-064-1-6

9

III. SPECIFICATIONS AND PERFORMANCE OF “TMR140 SERIES”

1. Specifications of Element

TableIII-1 and Fig.III-1 shows the specifications and the appearance of the element for

TMR140 Series, respectively.

Table III-1 Specifications of Element (TSP-50150)

Model name TSP-50150

Membrane configuration Flat sheet

Application Filtration of activated sludge

Filtration method Suction filtration

Nominal pore diameter ( m) 0.08

Effective membrane area (m

2

) 1.4

Dimensions (mm) Total width 515

Total height 1,608

Thickness 13.5

Weight (kg) Dry 4.8

Wet (Reference) 8.0

Main material Membrane PVDF and PET non-woven fiber

Supporting panel ABS resin

515 mm Permeated water nozzle

50 mm

1608 mm

Fig.III-1 Appearance of Element

2. Specifications of Polyurethane Permeate Tube

Table III-2 shows the specifications of Tube.

Table III-2 Specifications of Polyurethane Permeate Tube

Material Thermoplastic polyether-polyurethane

TPU-ARET*1

Inside diameter / outside diameter / total length (mm)

8/11/380

*Allowable temperature limit: 60 degree C

*1 The material name due to the ISO-18064.

AIRE-064-1-6

10

3. Specifications and Performance of “TMR140 Series” Module

Table III-3 shows the specifications of “TMR140 Series” modules.

Table III-3 Specifications of Module

Model name TMR140-

050S

TMR140-

100S

TMR140-

200W

TMR140-

200D

TMR140-

400DW

Number of membrane elements 50 100 200 200 400

Element block (EBL) structure 1 EBL 1 EBL 2 EBLs

jointed

Double Deck

with 2 EBLs

4 EBLs (2x2)

Dimensions*1

Width (mm) 810 810 840 810 840

Length (mm) 950 1,620 3,260 1,620 3,260

Height (mm) 2,100 2,100 2,100 4,160 4,160

Weight (kg)

Module (dry) 400 695 1,430 1,365 2,710

Aeration block (dry) 40 65 150 65 150

Element block (dry) 360 630 1,280 1,300 2,560

Element block

(sludge clogging)*2 690 1,240 2,480 2,500 4,980

Material

Frame 304 stainless steel

(316LSS is available as option)

Diffuser, Permeated water

manifold

304 stainless steel

(316LSS or Polypropylene *7 is available as option)

Element fixing gaskets EPDM rubber

Connection

flange*3

Manifold ANSI

1 1/2 inch

ANSI

2 inch

ANSI

3 inch

ANSI

2 inch

ANSI

3 inch

Air diffuser ANSI

1 1/4 inch

ANSI

1 1/2 inch

ANSI

2 inch

ANSI

1 1/2 inch

ANSI

2 inch

Operating

range

Temperature 5-40 degree C

pH

*4

of liquid 5-10

MLSS Not higher than 18,000 mg/L

Trans-membrane pressure Not higher than 20 kPa (200 mbar)

Cleaning chemicals feed

pressure Not higher than 10 kPa (100 mbar)

Cleaning chemicals and

chemicals concentration

Sodium hypochlorite (effective chlorine concentration)

:2,000-6,000 mg/L(pH is around 12)

Oxalic acid :0.5-1.0wt%

Citric acid :1.0-3.0wt%

Scouring Air Flow rate *5

(NL/min/Module) *6 500 - 1,000 1,000 - 2,000

2,000 - 4,000

1,300 - 2,000

2,600 - 4,000

*1 The total dimensions excluding the connection tube

*2 The weight assumed in the case of sludge clogging between elements.

*3 The flange dimensions are described in the drawings attached to this manual. UNI (ISO) flange is also

available as option.

*4 Except when the chemical cleaning with the designated chemical agents..

*5 The air supply equipment such as blower shall be designed based on the standard operating conditions

shown in Table VII-1.

*6 “NL” means air volume as being 0 degree C and 101.325 kPa (1 atm).

*7 Please contact Toray if you would like to use Polypropylene diffuser/permeated water manifold. Additional

information will be provided.

AIRE-064-1-6

11

Table III-4 and III-5 shows the performance of ”TMR140 Series” modules.

Table III-4 Permeate water quality

Model name TMR140-

050S

TMR140-

100S

TMR140-

200W

TMR140-

200D

TMR140-

400DW

Permeate

water

quality*1

TSS (mg/L) *2 Not higher than 3.0

Turbidity (NTU) *3 Not higher than 1.0

*1 This value can be attained when operated under the standard operating conditions as specified in this

Instruction Manual during a period specified separately by Toray.

*2 Measuring method of TSS is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2540D, Total Suspended Solids Dried at 103-105 degree C or ISO 11923.

*3 Measuring method of NTU is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2130, Turbidity or ISO 7027.

Table III-5 Flow capacity (Reference value)

Model name TMR140-

050S

TMR140-

100S

TMR140-

200W

TMR140-

200D

TMR140-

400DW

Continuous

Filtration

Flow (m3/d)

Sewage 8 - 53 15 - 105 30 - 210 30 - 210 60 - 420

Industrial wastewater

8 - 35 15 - 70 30 - 140 30 - 140 60 - 280

*4 This value is just a reference value and not a guarantee value of Toray. Sustainable operating filtration

flow capacity varies among the plant depending on the type of wastewater, total process design and

operating condition. In case of industrial wastewater application, it is strongly recommended to conduct

a pilot test before membrane tank designing.

AIRE-064-1-6

12

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “TMR140 SERIES”

The standard filtration pattern time chart, the schematic flow diagram of the membrane

filtration, the layout of “TMR140 Series” modules in the membrane submerged tank, and the

piping procedures are described in this section. These would help you design the membrane

filtration process with “TMR140 Series”.

1. Standard Time Chart

Two kinds of the filtration patterns are available with "TMR140 Series". Usually intermittent

filtration (filtration with relaxation) is adopted and details are shown below, whereas

sometimes simple continuous filtration can also be applied. In both cases aeration shall be

done continuously while filtrating.

In the case of the intermittent filtration, the filtration is suspended (“relaxed”) for a short

period at certain intervals while the air scouring continues, as shown in Fig.IV-1. While the

filtration is suspended, the membrane surface is cleaned up more effectively with the

scouring air due to the absence of suction. Although the automatic system control for

periodical start and stop of the filtration is required, the intermittent filtration is recommended

for stable and efficient membrane filtration. The recommended time cycle for the intermittent

filtration is 9-minute filtration and 1-minute relaxation.

Please stop the scouring air when the filtration operation stops except for the following

conditions:

1) Each relaxation period in case of applying intermittent filtration.

2) In case that the plant operation stops for a while, aeration is applicable for mixing or

aeration demand, however, the flow rate should be controlled minimal.

Fig.IV-1 Recommended Time Chart for Intermittent Filtration

Filtration

Air diffusion

Continuous

Filtration: 9 min.

Relaxation: 1 min.

Cycle of 10 minutes

F1: Average flow rate for treatment capacity

and membrane area calculation

F2: Filtration flow rate for suction pump

capacity calculation

F1

F2

AIRE-064-1-6

13

Membrane Module

FIC

FI

L

H

L:CLOSE

H:OPEN

L:OPEN

H:CLOSE

Permeate water outlet

Manifold

Lower Limit alarm

Air Outlet

Feed

Chemical

Air

D

iffuser

Membrane

Submerged

Tank

PIA

PIA

“U-shape”

2. Flow Diagram of Membrane Filtration

Two schematic flow diagrams of the membrane filtration process are shown below. One is for

the gravity filtration with water head difference and the other is with suction pump. Major

necessary peripheral devices for membrane filtration process are described in the latter part

of this section.

In any case, the fine screen with openings of 3.0 mm or under should be installed before the

membrane submerged tank, or the modules might be polluted and clogged severely with

trashes brought with the raw water.

It is also recommended to prepare enough capacity of the buffer tank (flow equalization tank)

prior to the MBR process to equalize BOD load and filtration flow capacity so as to enable

stable operation of the biological treatment and membrane filtration process.

(1) Gravity filtration configuration

The filtration can be performed with using a natural water head differential pressure

generated from a vertical distance between the liquid level of the membrane submerged

tank and the level of the permeate water outlet (see Fig. IV-2).

Fig. IV-2 Schematic Flow Diagram for Gravity Filtration

In order to obtain enough suction pressure for the filtration considering the friction loss of

pipe and valves, the permeate water outlet should be located sufficiently below the liquid

LS

Wastewater

Fine Screen

FIC: Flow Rate Indicator/Controller

LS : Level Switch

PIA: Pressure Indicator/Alarm

FI : Flow Meter

AIRE-064-1-6

14

level of the membrane submerged tank (normally 3 m below water level or lower).

It is recommended that the piping from the permeate water manifold to the permeate water

outlet should directly penetrate the tank wall, as shown in Fig.IV-2. Also if the permeate

water outlet is located in the open air, it is recommended to make the outlet pipe U-shape to

seal the piping with water.

The permeate water flow is controlled with the automatic control valve (the permeate control

valve). When the liquid level of the membrane submerged tank gets to the lower limit, this

control valve fully closes the permeate water line to stop the filtration. When the liquid level

gets to the higher limit, the automatic shutter valve on the raw water feed line closes its line

to stop raw water coming.

In this gravity filtration, the air accumulated in the permeate water line should be discharged once

a day at least; otherwise the effective water head is reduced seriously. The air purge nozzle

should be installed at the highest position of the permeate water line and the automatic shutter

valve (the air purge valve) is recommended to be installed on the line just before the nozzle. (As

shown in Fig.IV-2) Stopping the filtration (fully closing the permeate control valve) and opening

the air purge valve for a few minutes, the air is easily purged.

AIRE-064-1-6

15

Membrane Module

Air diffuser

FIC

Permeate water

Manifold

PIA

Lower limit alarm

Air outlet

Feed

chemical

FI

L

H

L:OPEN

H:CLOSE

L:CLOSE

H:OPEN

VFD or auto valve

PIA

(2) Pump suction configuration

Fig. IV-3 illustrates the general configuration for pump suction filtration.

Fig.IV-3 Schematic Flow Diagram for Pump Suction Operation

The permeate water flow is controlled by a flow meter and a suction pump with an automatic

control valve or by a flow meter and a suction pump with VFD control. In case water level in

the membrane submerged basin gets to the lower limit, filtration has to be stopped. If the

water level reaches the upper limit, the level controller will stop raw water inflow.

In some cases with this pump suction configuration, an equipment may be needed to

discharge the air accumulated in the permeate water line. A range of methods can be applied

for this air removal such as vacuum pump, ejector or manual water injection. Please contact

TORAY or refer to the engineering manual for the details.

(3) Necessary devices for membrane filtration process

Major necessary peripheral devices to operate membrane filtration process are explained

below. Some other devices than mentioned below might be required case by case.

Raw water

Fine screen

FIC : Flow rate indicator/Controller

LS : Level Switch

PIA : Pressure indicator/Alarm

FI : Flow indicator

LS

AIRE-064-1-6

16

PIA

a mm

P1

P2

PIA

b mm

a. Fine screen

The wastewater should be treated by screen with openings of 3.0 mm or under

before flowing into the membrane submerged tank, otherwise the modules are

polluted and clogged with foreign substances seriously. It is recommended to use

the mesh type screen. Overflow or waste carryover must be avoided at any time.

b. Flow control device

A flow rate controller, a flow meter combined with an automatic control valve, or a

flow meter combined with VFD controlled suction pump should be installed on the

permeate water line to control the flow rate of permeate water. In the case of

operating a number of “TMR140 Series” modules simultaneously in one train, it is

advised to install one flow rate controller for one train of the modules.

c. Differential pressure measurement & calculation

For trans-membrane pressure (TMP) determination the differential pressure (in the

permeate line and water level) has to be measured and calculated, either by

installing two pressure sensors and calculating the readings in the PLC or by using a

differential pressure device.

In the former case, one pressure gauge should be installed on the permeate water

line and the other one in the membrane submerged tank, to monitor the

trans-membrane pressure. In case of operating a number of “TMR140 Series”

modules simultaneously in one train, it is advised to install one differential pressure

measuring instrument for one train of the modules.

[Example]

Fig.IV-4 Differential Pressure Measurement & Calculation

AIRE-064-1-6

17

a = 1,000 mm (= 10 kPa, 100 mbar), b = 3,000 mm (= 30 kPa, 300 mbar)

PIA readings;

Filtration (pump ON) Relaxation (pump OFF)

P1 (kPa) 29 30

P2 (kPa) -15 -10

In this case, differential pressure (dP) is calculated as follows;

dP= (P1Filtration - P1Relaxation) - (P2Filtration - P2Relaxation)= (29) - (30) - [(-15)-(-10)]= 4 kPa

d. Air supply unit (such as a blower)

This unit supplies air to the air diffusers of "TMR140 Series" module. The air flow

rate supplied to the module should be always within the range of "Scouring Air Flow

Rate" indicated in Table III-3.

e. Air flow meter.

An air flow meter is recommended to be installed to check the flow rate of the

scouring air supplied to the module. In case of operating a number of “TMR140

Series” modules simultaneously in a train, it is advised to install at least one air flow

meter for each train.

f. Suction pump

A suction pump is required in the case of pump suction configuration. Accurate flow

rate control is needed for the suction pump with VFD control. The use of a volute

pump (centrifugal pump) or volumetric pump (screw pump) with self-priming function

is recommended.

g. Level sensor

Level sensor is necessary to be installed in the membrane submerged tank to

monitor and control the liquid level of the membrane tank and to calculate the TMP

in PLC.

h. Siphon breaking piping

In case of pump suction, filtration flow may not be stopped by stopping suction

pump if the discharge point of the permeate water is lower than water level of the

membrane submerged basin. This siphon flow has to be avoided and permeate flow

has to be stopped whenever pump stops.

Please install the screen with openings of 3.0 mm or under before

the membrane submerged tank. It is recommended to use the mesh

type screen. Overflow or waste carryover must be avoided at any

time.

CAUTION

!

Other manuals for TMR140 Series

1

This manual suits for next models

5

Table of contents

Other Toray Control Unit manuals

Popular Control Unit manuals by other brands

PPA

PPA Central Agility Pop Connect user manual

W.E.ST.

W.E.ST. MDR-133-U Technical documentation

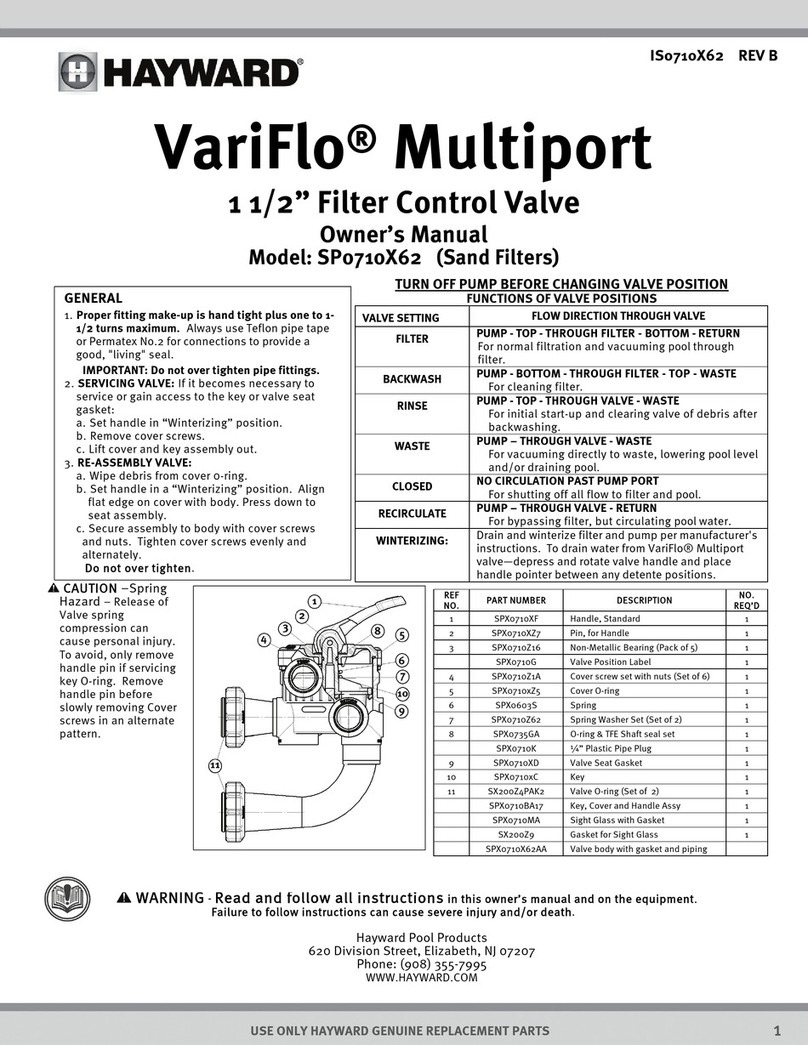

Hayward

Hayward VariFlo Multiport SP0710X62 owner's manual

Assured Automation

Assured Automation 38 Series Installation, operation & maintenance manual

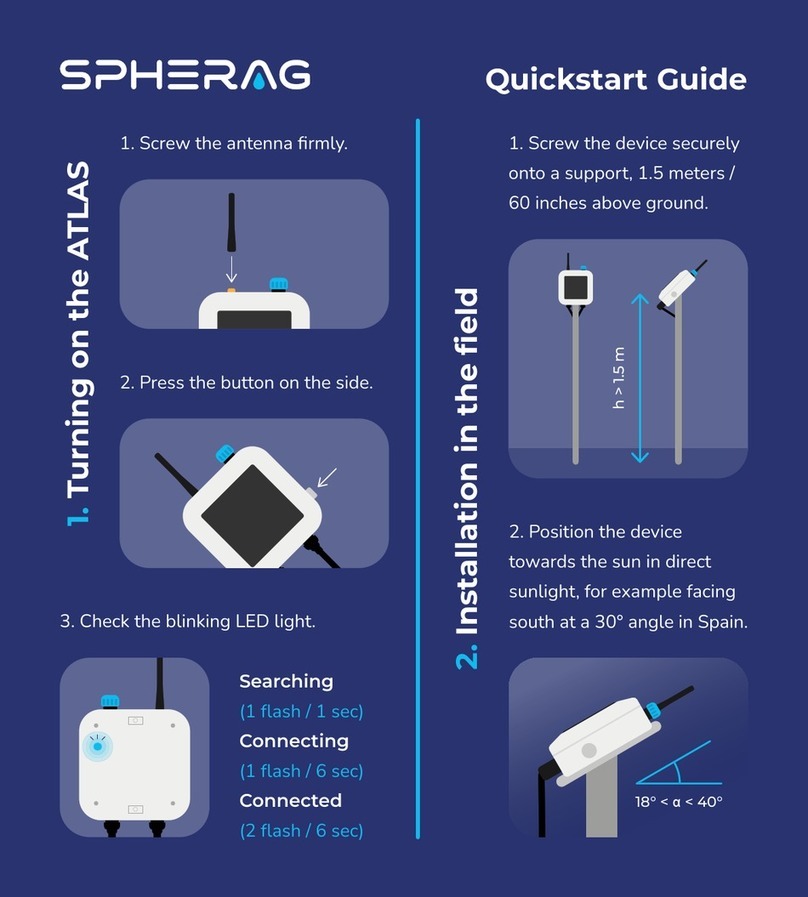

spherag

spherag ATLAS 2 quick start guide

ProSoft

ProSoft ProLinx 6104-WA-PDPM Setup guide

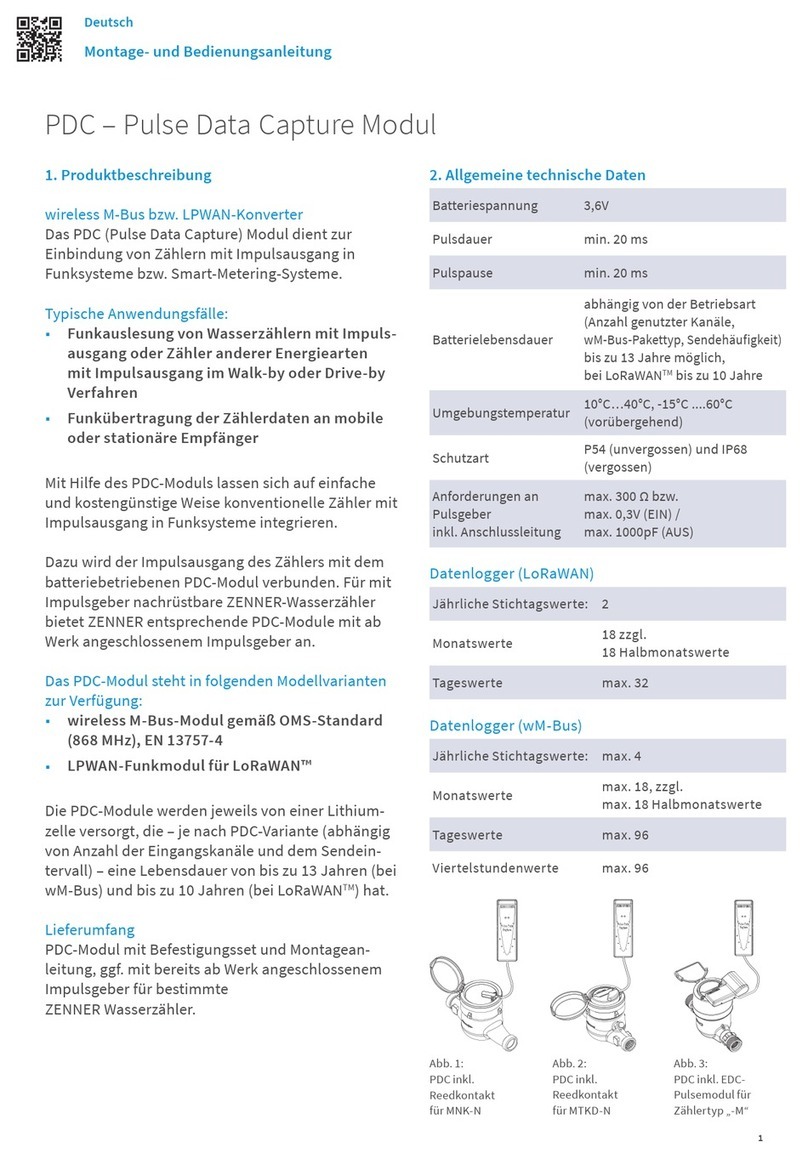

Zenner

Zenner PDC Installation and operating instructions

Bluetti

Bluetti D300S manual

ADLINK Technology

ADLINK Technology cExpress-EL user guide

Watts

Watts BT-FR02-RF Installation and user guide

Johnson Controls

Johnson Controls NIE39 installation instructions

ADEMCO

ADEMCO TeleSmart Installation and setup guide