tormek T-1 User manual

FOR HOUSEHOLD USE

2

EN

General information

• Read all instructions carefully before using the machine.

• To protect against risk of electrical shock do not expose the machine to rain and do

not use in damp environments. Do not put the machine in water or other liquids.

• This appliance is not intended for use by children or by persons with reduced

physical, sensory, mental capabilities, or lack of experience and knowledge. Close

supervision is necessary when any appliance is used near children. Children should

not play with the appliance.

• Turn the appliance OFF, then unplug from the outlet when not in use. Always unplug

the appliance before assembling or disassembling parts and before cleaning. To

unplug, grasp the plug and pull from the outlet. Never pull from the power cord.

• Avoid contacting moving parts.

• Do not operate any appliance with a damaged cord or plug, after the appliance

malfunctions, or after the appliance is dropped or damaged in any manner. Please

information on examination, repair, or adjustment.

• The use of attachments not recommended or sold by Tormek may cause re, electric

shock or injury.

• Do not use outdoors.

• Do not let the cord hang over the edge of a table or counter.

• Do not let the cord contact hot surfaces, including a stove.

• Carefully route the power supply cord to avoid damage from the knife blade while

sharpening.

• SAVE THESE INSTRUCTIONS

Sharpening and honing

• The Tormek T-1 is only intended for sharpening and honing kitchen knives. Only use

the machine for its intended purpose. Follow the instructions.

• Tormek’s accessories are specially made for Tormek machines and must not be used

on any other grinding machine.

Safety

Automatic overheat protection

The Tormek T-1 has a recommended maximum operating time of 30 minutes per hour. The

motor has an automatic overheat protection system that will shut off the motor if it reaches a

certain temperature. Note: If the motor shuts off, always turn off the machine by pressing

the power button as the motor will resume operation once it cools down.

3

EN

• Do not force the machine. Gentle pressure not only works better, it is safer.

• Make sure your hands are dry and clean of grease and oil.

• Do not wear loose clothes, gloves, ties, rings, necklaces, etc. that can get trapped in

the moving parts.

• Protect long hair with a hair net. Wear non-slip shoes.

• Stand or sit in a stable position and with a good balance while you work with the

machine.

• Avoid body contact with grounded surfaces (ex. pipes, elements, refrigerator, stove,

etc.).

• Keep your hands and ngers away from the area between the guide and grinding

wheel.

• Keep a close eye on your work, use common sense, and do not use the machine

when you are tired.

Condition of the machine

• Check that the machine is undamaged and working properly before use. Do not use

the machine if the power switch does not switch on and off.

• Check that the power cable is undamaged on a regular basis. If it is damaged, have it

replaced by qualied personnel. This also applies to an extension cable if one is used.

• Unplug the plug from the electrical socket before cleaning or performing maintenance

on the machine, and when replacing the grinding wheel or honing wheel.

• Use only genuine Tormek grinding wheels. Maximum diameter 150 mm and maximum

width 18 mm. Hole diameter 12 mm.

• Never tug at the cable to unplug the plug. Make sure the cable is not close to any

sharp edges, oil, or sources of heat.

Workplace

• Connect the machine to a grounded socket with the voltage and period number (Hz)

as indicated on the machine plate.

• Do not use the grinding machine in the vicinity of ammable gases or uids, or in a

dangerous environment, ex. Wet or damp premises, and do not expose it to rain.

• Make sure that any tools (ex. wrenches, adjustable wrenches) are removed from the

machine before starting it.

• Position the machine on a at and stable surface. Keep the working area clean.

Untidy surfaces and benches cause accidents. Make sure you have good lighting.

• Children and unauthorised personnel should be kept at a safe distance from the

working area.

4

EN

Instructions on grounding

• In the event of faults or open circuits, grounding reduces the risk of electric shock by

diverting the current. This machine is equipped with a grounded cable and plug. The

plug must be connected to a matching electrical socket installed and grounded in

accordance with applicable laws and regulations.

• Do not modify the original plug – if it does not plug into the electrical socket, contact

an authorized electrician to install a suitable electrical socket.

• Incorrect connection of the grounded plug may result in electric shock. The insulated

ground cable is green, with or without yellow stripes.

• Check with an authorized electrician or service personnel if you have not fully

understood the instructions, or if you are doubtful that the machine is properly

grounded.

• Only use an extension cable with a grounded plug and grounded electrical sockets

that the machine’s plug ts into.

• Repair or replace a damaged or worn cable immediately.

After work

• Always turn the machine off and unplug the machine. Never unplug the machine

when the machine is running/switched on.

• Store the machine in a locked area and out of reach of children and unauthorized

personnel.

Machine plate for Tormek T-1

Spare parts and repairs

This machine meets applicable safety standards. Repairs must be performed by qualied

personnel using genuine spare parts. Incorrectly performed repairs may cause serious

injury to the user.

HOUSEHOLD TYPE

ARTICLE NO: T-1 ALO/EUR

SERIAL NO:

DATE:

Made in Sweden by Tormek AB

www.tormek.com

220-240 V, 50-60 Hz, 120 W

HOUSEHOLD TYPE

Made in Sweden by Tormek AB

www.tormek.com

100-115 V, 50-60 Hz, 120 W

ARTICLE NO: T-1 ALO/NA

SERIAL NO:

DATE:

3196221

5

EN

Tormek warranty

The Tormek warranty is valid for 8 years, 5 years + 3 years after registering the machine at

tormek.com, from the date of purchase. This includes all parts for your Tormek T-1 in the

event of material and manufacturing faults. The Tormek warranty guarantees the function

of your machine but does not cover normal wear and tear, misuse, or mishandling. Valid

together with purchase receipt.

If your Tormek T-1 needs service – contact the place of original purchase. Problems

can often be solved by phone or by a spare part being sent. Do not return the machine

without an agreement with, or return authorization from, the place of purchase.

Tormek AB

Torphyttevägen 40

711 34 Lindesberg

SWEDEN

Tel.: +46 581 147 90

Email: [email protected]

6

EN

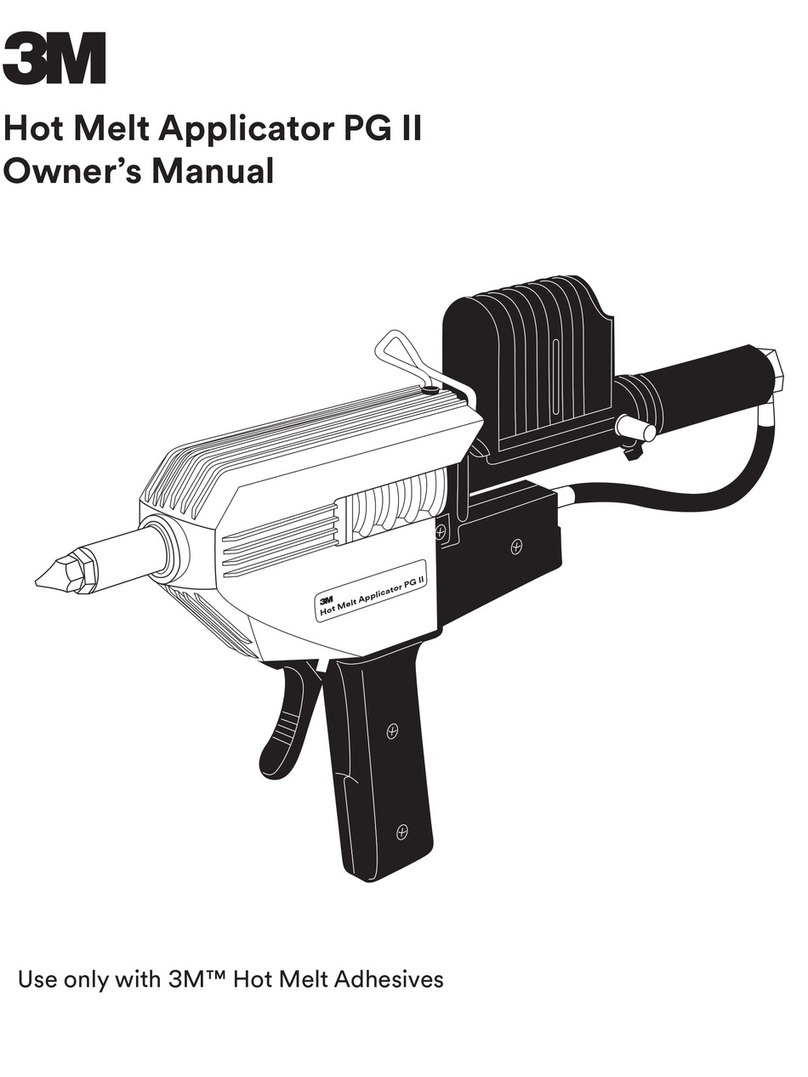

Knife sharpening for the kitchen

The Tormek T-1 Kitchen Knife Sharpener is a quick, easy, and clean way to sharpen knives in

the convenience of your own kitchen. This advanced development of the traditional diamond

bench stone, combined with the patented sharpening angle guide, makes it possible

to sharpen kitchen knives at home with the same or better results than a professional

sharpening service. The Tormek T-1 sharpening method consists of two steps: sharpening

on the diamond grinding wheel, followed by honing on the composite honing wheel.

Instructions

SPECIFICATIONS, TORMEK T-1 KITCHEN KNIFE SHARPENER

DIMENSIONS

Width 8" (204 mm)

Depth 7¾" (196 mm)

Height 7" (181 mm)

WEIGHT

Weight of machine: 11.9 lbs (5.4 kg)

GRINDING WHEEL

DF-150 Conical Diamond Wheel Fine

∅5"× " (150 × 18 mm)

Max 200 rpm

HONING WHEEL

∅6 ¼"× 1 3/16" (160 × 30 mm)

MATERIAL

Fully cast in zinc, powder coated

Lower section in impact resistant ABS

plastic

MOTOR

Single phase AC motor 120 W (input power)

220–240 V, 50–60 Hz

or 100–115 V 50–60 Hz

Maintenance-free

Runs at low noise, 45 dB

Min. 10,000 hours of operating time

WARRANTY

8-year warranty. 5 years + 3 years when

registering the machine at tormek.com

PATENT

See tormek.com/patents for all patents

Unlimited

KNIFE BLADE LENGTH

½"–2"

(12–60 mm)

KNIFE BLADE HEIGHT

Up to 3/16"

(5 mm)

KNIFE BLADE WIDTH

For indoor, home use only. Do not use in wet or damp places.

7

EN

15° 15°

30°

Example of angle setting

and result: A common angle

for kitchen knives is 30°. Set

the indicator to 15° sharpening

angle, which results in 30°

total angle on the knife.

Instructions for sharpening and honing

15° setting results

in 30° edge angle.

1. Set the desired edge angle

Which edge angle should I use?

In general, a small edge angle is better at cutting, while a larger edge angle is stronger and

lasts longer. For example, a knife that will be used for meat should have a larger edge angle

than a thinner llet knife or vegetable knife. The composition of the steel will also affect

which angle is most suitable. A high-quality knife blade, even with a smaller edge angle,

generally retains its sharpness better than a lower quality knife blade.

Japanese knives are sharpened with a slightly smaller angle compared to European knives.

Some knives are only sharpened on one side. In which case, 20–25° is a suitable edge angle

for that side.

You can typically get details about the recommended edge angle for your particular knife

from the knife manufacturer.

Tip! Save time by always sharpening

the knife to the same edge angle.

You will remove the least amount of

steel during each grinding. Plus, your

knives will last longer!

Always clean and dry the knife before sharpening. The grinding wheel’s performance may

be affected by food residue or other contaminants.

Upon rst usage, the diamond wheel will seem aggressive and will give a rough surface.

After a short break-in period, the diamond crystals on the wheel will stabilize to a uniform

level and provide a ner surface. This normally takes between 2–5 grindings.

If necessary, clean the grinding wheel with a nylon brush. Always store the machine in a

dry place.

The Tormek T-1 Kitchen Knife Sharpener is delivered fully assembled. The only thing you

need to do is read the instructions and plug it in. Good luck with your sharpening!

SUGGESTIONS FOR EDGE ANGLES

20 – 30°

25 – 40°

25 – 30°

Important points to remember before you start

8

EN

Make sure the knife is clean before you start sharpening. Press the power switch to start the ma-

chine. Insert the knife into the guide and lower it towards the grinding wheel. Slide the knife back

and forth at a steady pace across the grinding wheel applying a light pressure. Guide the knife so

that it is in contact against the whole width of the grinding wheel. Follow the shape of the edge

right up to the tip. Allow the guide to control the angle. Moving the knife back and forth 2–3 times is

enough if you have a) a normally worn knife, and b) you are sharpening at the same angle as before.

Feel that a “burr” is formed along the entire edge. The burr forms on the opposite side of the blade

that was just sharpened on the grinding wheel.

2. Position the knife and start sharpening

The guide has a magnet on the

underside that collects steel

particles while sharpening.

It helps to keep the grinding

wheel clean.

If you experience that the

magnet interferes with the

sharpening (some knives have a

tendency to attach themselves

to it) you can easily remove it.

On knives where the handle catches the guide – loosen and move

the guide on the shaft so that the entire knife blade can move

across the grinding wheel.

Turn the knife around and

sharpen the opposite side in

the same way.

Tip! Clean the magnet us-

ing a dry cloth or kitchen

paper towel.

Tip! To repeat an existing

edge angle, you can

use the Marker Method.

Color the bevel with a

permanent marker. With

the machine switched off,

slide the knife through

the guide as if you were

sharpening it and see

where the marker is

rubbed away. Adjust the

angle and repeat until the

color is removed from the

entire bevel.

Note: The plastic part of the guide that is closest to the

diamond grinding wheel may get slightly worn during the

first few sharpenings. This is completely normal and a part

of the run-in process.

9

EN

Note: If the “burr” is not

honed off properly, the

knife may be experienced

as dull, even though it is

newly sharpened.

After sharpening, a “burr” is

created. It needs to be honed

off in order to obtain a sharp

and durable edge.

Before you start honing, make sure that the honing wheel

rotates away from the edge. Otherwise the knife will cut into the

honing wheel and you risk being injured.

Slide the knife back and forth across the honing wheel applying

light pressure. Make sure you do not have too steep of an angle

as you could round off your newly sharpened edge resulting in a

blunt knife. A couple of times on each side is usually sufficient.

The number of times may vary depending on steel grade. You

now have a completely sharpened knife!

3. Hone the knife to a final finish

Tip! Depending on steel

grade, the “burr” may

bend, flipping from one

side of the knife to the

other. Sometimes it is best

to alternate from side to

side when honing.

Tip! Moisten the

composite honing wheel

with water using a damp

sponge or paper towel.

This will reduce friction

and can make the edge

even finer.

10

EN

Service and maintenance

Remove the self-adhesive pads from both the clamp and the

guide. Replace with new pads.

Slide the guide off the shaft and remove the clamp.

Replacing the Knife Protection Pads

Tip! With the Knife

Protection Pads removed,

clean out any sharpening

particles between the

clamp and the guide.

Cleaning the magnet

Unclip the magnet from the

guide and wipe away the

sharpening dust using a dry

cloth or kitchen paper towel.

Note: The shapes of the

Knife Protection Pads are

different for the guide and

clamp.

11

EN

ASSEMBLY: Thread on the

diamond grinding wheel nut

counterclockwise. Hold the dia-

mond grinding wheel with one

hand and tighten the nut with a

19 mm wrench. Note: The nut

is locked counterclockwise

because it has left-handed

threads.

Pull the composite honing

wheel and shaft out slightly so

the diamond grinding wheel can

be removed past the guide.

DISASSEMBLY: Hold the

diamond grinding wheel with

one hand and loosen the grind-

ing wheel nut using a 19mm

wrench. Note: The nut is

loosened clockwise because

it has left-handed threads.

Replacing the diamond grinding wheel

Replacing the composite honing wheel

Loosen the honing wheel by

holding the composite honing

wheel with one hand and

loosening the honing wheel

nut using a 19 mm wrench.

Remove the whole shaft from

the machine housing.

12

Next, install the wave washer.

The wave washer slides onto

the shaft from the grinding

wheel side.

DISASSEMBLY: Hold the

diamond grinding wheel with

one hand and loosen the grind-

ing wheel nut using a 19mm

wrench. Note: The nut is

loosened clockwise because

it has left-handed threads.

Finish by reinstalling the grind-

ing wheel. Remember that the

nut on the grinding wheel side

has left-handed threads and is

locked counterclockwise.

When everything has been

assembled in the order shown

in the illustration above and the

wave washer is in place, it is

time to slide the shaft through

the machine housing.

ASSEMBLY: Place the flat drive

wheel washer onto the shaft.

Insert the drive wheel lock pin

into the hole in the shaft. Install

the drive wheel followed by

the honing wheel. Tighten the

nut. Ensure that all parts are

assembled in the order shown

in the illustration.

1

2

3

4

5

12

EN

Spare parts list – Tormek T-1

M

* Not shown in the drawing.

Pos Designation Quantity Part no.

1 Magnet 1 5370

2 Clamp for the guide 1 3115

3 Knife Protection Pads 1+1 6040+6015

4 Zinc part for the guide 1 2015

5 Knob screw 1 1185

6 Indicator for the guide 1 3075

7 Honing wheel nut M12 1 0100

8 PW-160 Composite

honing wheel

1 3670-07

9 Drive wheel 1 3208-07

10 Washer for drive wheel 1 5081

11 Wave washer 1 5410

12 Screw for handle 1 5025

13 Handle 1 0820

14 Housing 1 2550

15 Swing shaft 1 1030

16 Bushing for swing shaft* 3 3121

17 Spacer spring for the motor* 1 0520

18 Motor 80 W* 1 6095 (230V)

6105 (115V)

19 Grinding wheel nut M12

with left-hand thread

1 0060

20 Grinding wheel 1 6090

21 Grommet 1 6085

22 Main shaft 1 1025

Pos Designation Quantity Part no.

23 Lock pin for drive wheel* 1 5071

24 Main shaft bearing 2 3061

25 Shaft 1 1420

26 Screw M4×8* 2 5600

27 Toothed lock washer* 2 5021

28 Lower section 1 3085

29 Power switch 1 6110

30 Inner wiring* 1 6100

31 Insulation sleeve* 3 3105

32 Screw M5×10 4 5590

33 Rubber foot 4 3095

34 Counterhold spring for motor 1 0515

35 Power cable rack* 1 6031 (EUR)

6041 (CH)

6043 (US)

6050 (JP)

6053 (GB)

6055 (AU)

6057 (ZA)

Table of contents

Other tormek Tools manuals