Tornador® is a registered trademark of ECP Inc. ©2021

Tornador® covered by one or more of the following: U.S. Patent Nos. 6,883,732; 8,480,011; 8,690,077; 9,475,071; 10,182,696; 10,189,034; 10,343,177; 10,562,078; 10,730,062;

Taiwanese Patent No. I617360; U.S. Design Pat. Appl. Nos. 29/756,918; 29/756,919; 29/756,920; 29/756,921; 20150000705; 20150375272; Taiwan Application No. 103135808.

Page 2

INSTRUCTIONS FOR USE

Check all contents and read instructions carefully.

First you must have a Z-020 Tornador®Black in good working condition to use the ZV-200

Tornador®Velocity Vac.

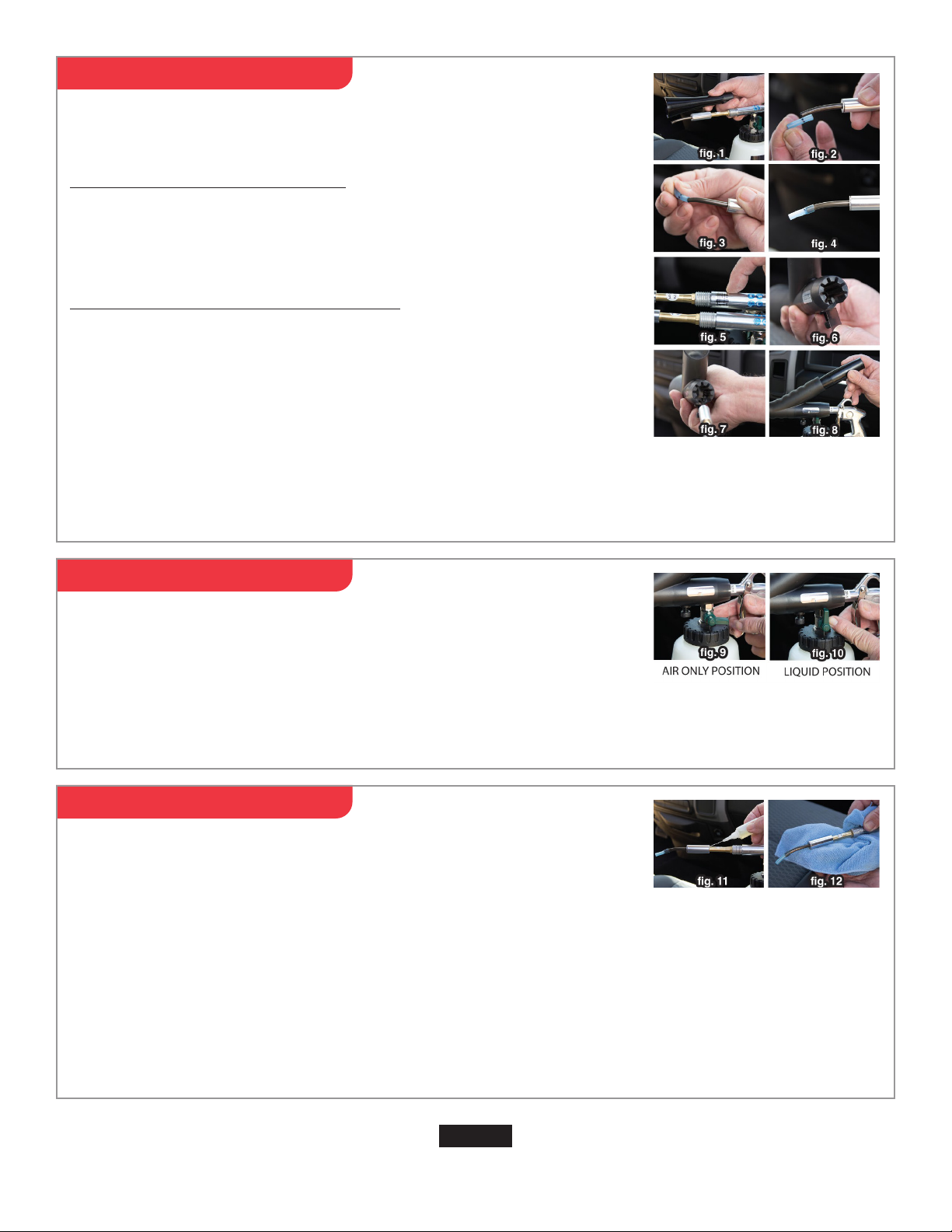

Installing the Flexible Tube (part # VT-120)

Step 1: Remove cone from Z-020 TORNADOR®BLACK. fig. #1

Take supplied small exible tube (part # VT-120) and press onto the rotation set as shown

in fig. #2 and 3 on the right.

NOTE: In order for the rotation set to rotate properly and obtain full function, be sure the

exible tube duplicates the nished step shown in g. #4.

Installing the ZV-200 Velocity Vacuum Attachment

Fig 5. Before place the vacuum attachment onto the TORNADOR®Z-020 BLACK, be sure

the valve body is free of labels or dirt that may interfere with the attachment. DO NOT

FORCE the attachment. The part should install easily if the valve body is clean and free of

labels.

Fig 6. Inside the parts bag you will nd a Flat Plastic Key used to seat the attachment to

the valve body. Place the Flat Plastic Key into place.

Fig 7. Once the Flast Plasatic Key is in place, slide the Vacuum Attachment onto the gun

assembly furthest back meting the gun handle. Next tighten Screw (part # VS-023) rmly

to gun assembly. DO NOT OVER TIGHTEN!

Fig 8. Place the Reducer (part # VR-200) into Vacuum Attachment then attach your Flexible Wet/Dry Vacuum Hose onto the

Reducer. Connect to WET DRY VACUUM ONLY!

For best results and control, use two hands during operation. Grasp the attachment with one hand and use the other hand to

control the gun assembly; depressing the trigger to begin use.

CARE & MAINTENANCE

• Maintain proper air pressure. DO NOT EXCEED 90 psi.

• DO NOT USE ACIDIC OR HIGH ALKALINE CLEANERS. Use only neutral pH cleaners

to avoid damage to rotation set.

• As for many tools, common maintenance procedures will ensure optimal

performance and tool life. Keep It Clean!

• NOTE: Be sure the tool has been disconnected from the air source and vacuum hose has been removed before performing

any maintenance.

• Depending on the time and type of use, always take time to remove the attachment and inspect for dirt build up or trapped

debris. Rinse attachment, then using pneumatic oil or a think lubricant, oil rotation set often. See fig. #11. Reinstall

attachment for next use.

• When using the Velocity Vac, you will notice a substantial amount of dirt and debris that will be disrupted by the rotation set.

This happens after waking up the fabric or carpet bers when loosening the dirt. Keeping the attachment free of dirt build-up

will ensure longer run times.

• To prolong the life of the rotation set and maintain peak performance, be sure no dirt build up has formed around the rotation

set. See fig. #12.

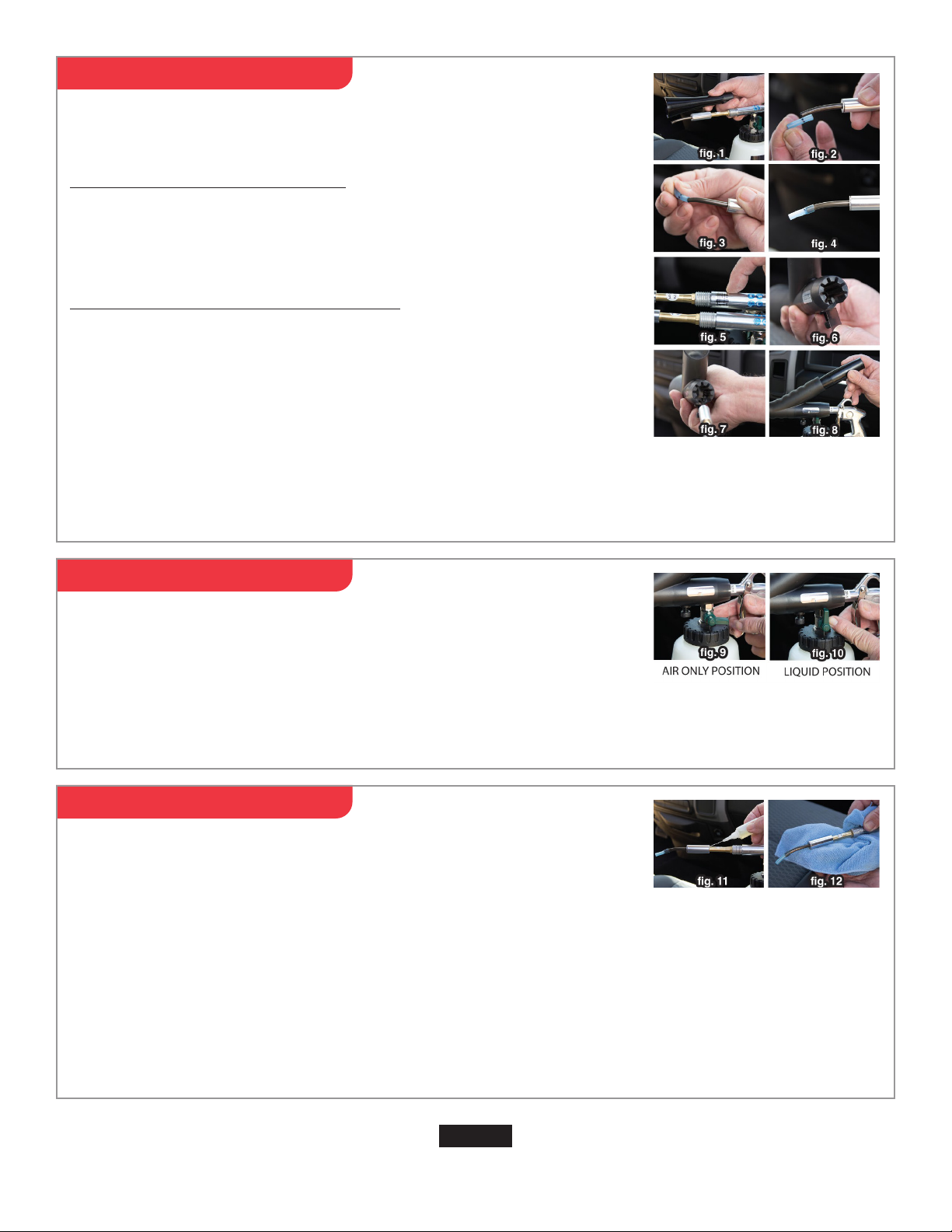

CLEANING STEPS & TIPS

1. Remove large debris rst. Start by turning on your wet-dry vacuum.

2. Connect air source and then with tool in hand, turn the Green Air Reverse Switch

downwards to the “Air Only” position. See fig. #9.

3. With vacuum on and air connected, depress trigger and begin initial vacuuming. This

will assure that any loose dirt and debris will not interfere with the liquid stage and

avoid mixing unwanted liquid and dirt during the process.

4. Next, USING APPROVED AND PROPERLY DILUTED CLEANING SOLUTION, turn the Green Air Reverse Switch upright to

“Liquid Position”. See fig. #10. With the vacuum on and air connected, begin cleaning process. Repeat if necessary. NOTE:

For heavy stains, pre-spot the area to be cleaned, then follow with the ZV-200 Tornador®Velocity Vac.