7

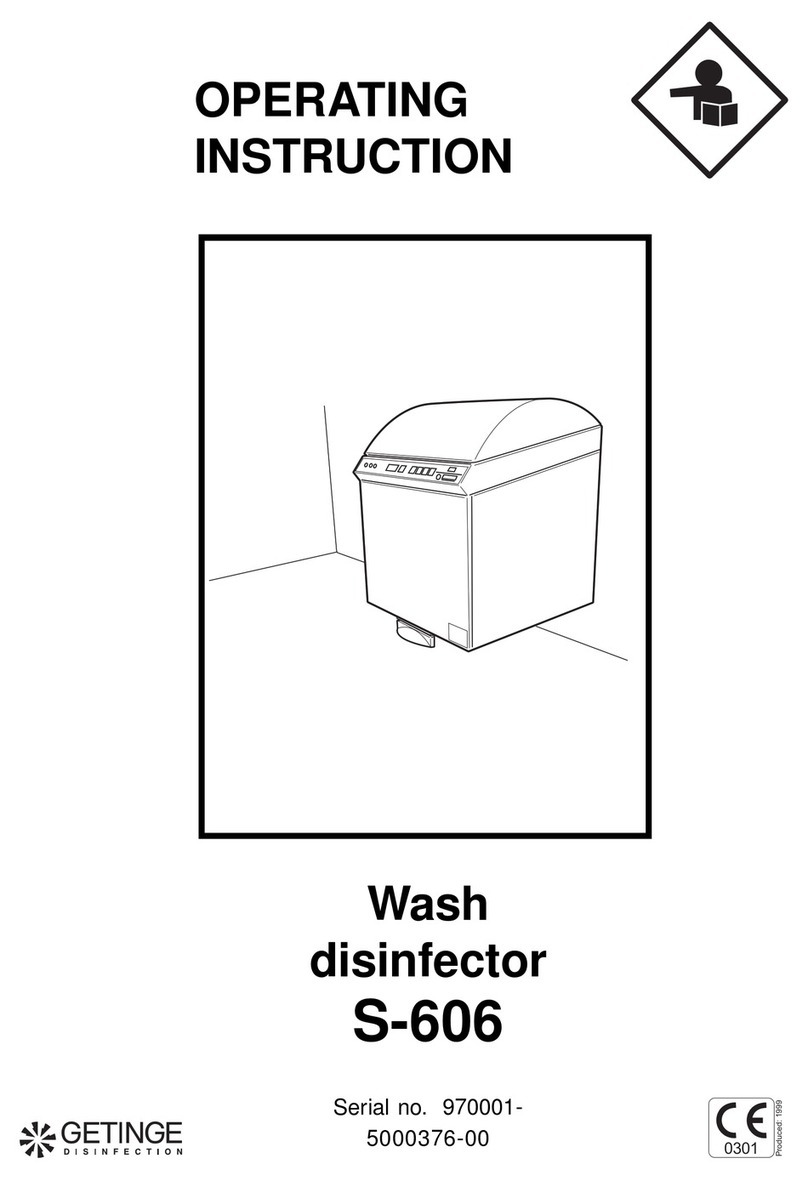

Decomat 4656Operating instructions

9803

Rinsing P01

047°C 00:30

Programming buttons (see

”Service instructions”) Remaining

program time

Operation

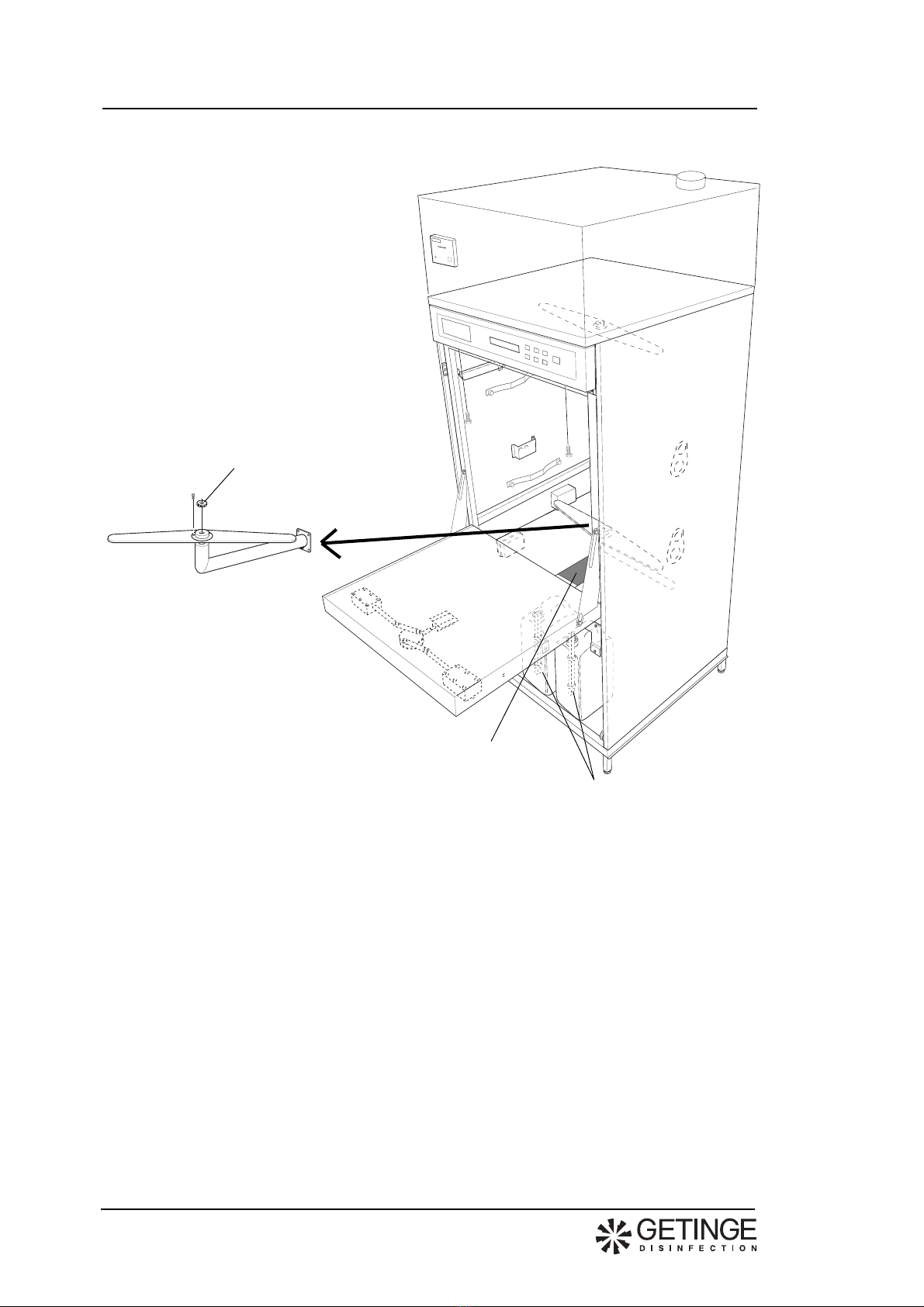

• Place the dishware in the trolley and roll it into the machine. How to arrange

the dishware on the trolley is demonstrated in the goods arrangement chart.

• Ensure that the spray arms can rotate freely without touching the dishware.

Close the door.

• Choose a program using the program selector buttons A- F. The upper line

of the display will then show the name and number of the program chosen. If

no program is available under the program button that was chosen, the

message ”NOT PROGRAMMED” will be displayed.

• Press the Gbutton. The yellow lamp will light throughout the program

sequence, and the current phase of the program, eg, ”Rinsing”, the actual

temperature and the remaining program time will be displayed.

• On completion of the program, the green lamp will light and the door will be

unlocked (door on the cleaned side if fitted with two doors).

• Empty the machine (and close the door on the cleaned side if fitted with two

doors).

• If the same program is to be repeated it is not necessary to press a program

selector button, just press the Gbutton.

• If the same program is to be repeated it is not necessary to press a

programselector button, just press the Gbuttom.

• The yellow lamp will flash for 10 seconds when the Gbuttom is pressed.

During this period the program can be interrupted by pressing Gonce more.

Note.

The display window goes dark after 30 minutes and i automatically

activated again on starting or when choosing a program.

Yellow: Process in progress

Green: Process completed

Red: Not disinfected

Actual temperature

in washing

chamber

Program selection

buttons Washing program

start button

Program number

Before starting: Selected program

During process: Program phase (eg,

”Rinsing”)

V200