5

General Information

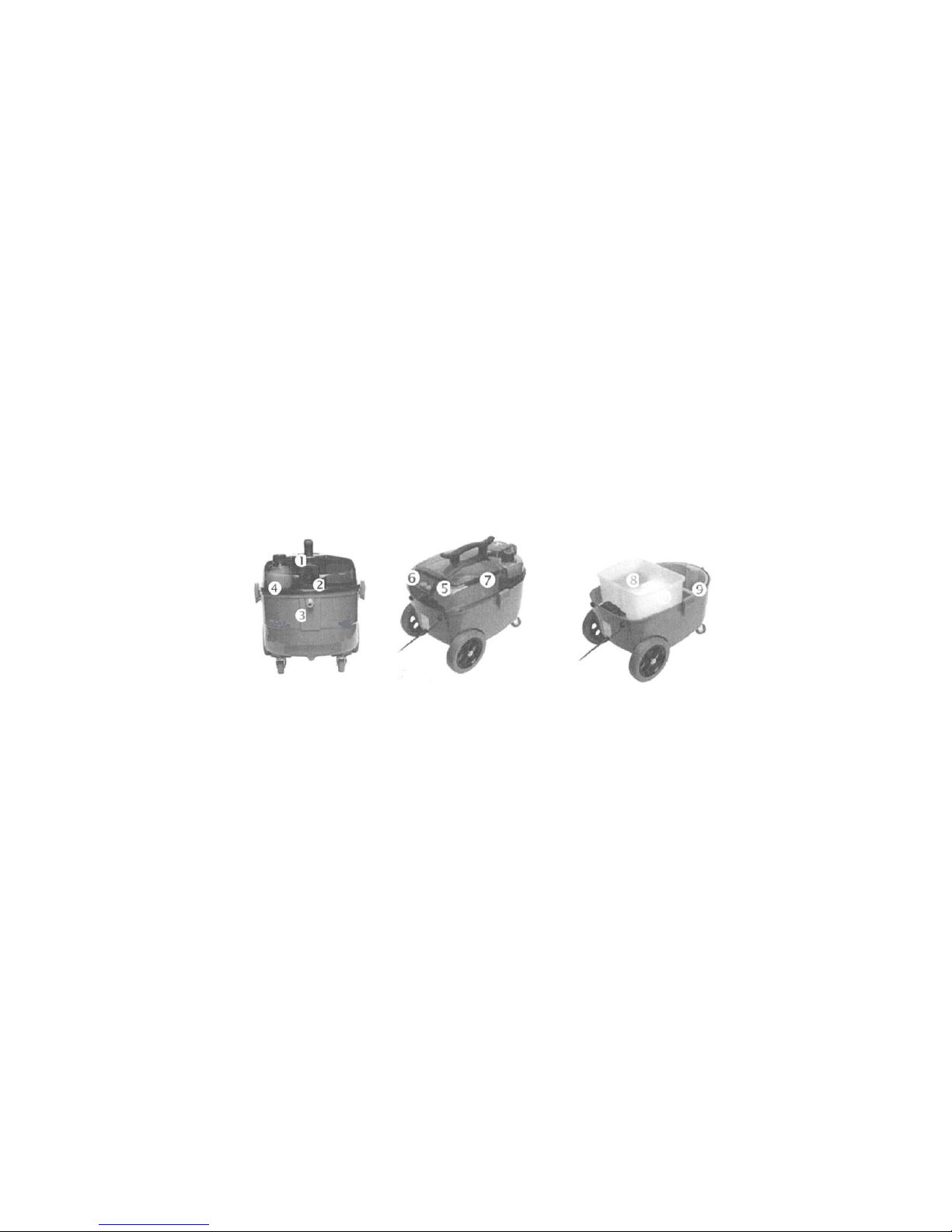

The Marathon 350 carpet soil extraction machine is designed for the efcient cleaning of carpets and upholstery. It has been designed

for the professional user to ensure long service life and safe operation.

We recommend that any user not familiar with carpet cleaning should read these instructions fully before using the machine. Please

contact Tornado Industries for questions on the contact details provided at the back.

This machine must only be used for the manufacturer’s approved application. The Marathon 350 is designed for the cleaning and

removal of normal carpet soil. Do not use the machine where it is suspected that the carpet or upholstery contains health endangering

dust or debris such as asbestos or chemical waste. If this is suspected, do not proceed. Contact your supervisor or Tornado Industries

for advice.

The following instructions contain important information about the machine and safety advice of the operator.

Equipment must be operated, serviced and maintained in accordance with the manufacturer’s instructions. If in doubt, contact the

supplier of your machine.

Important Safety Advice

When using electrical equipment basic safety precautions should be followed including the following.

• Read all instructions carefully before use.

• Keep children and unauthorized persons away from the machine when in use.

• Do not leave the machine connected to the electricity supply when not in use; always remove the plug from the socket-outlet.

• Switch off the machine before removing the plug

• When unplugging, pull the plug and not the supply cord.

• Do not operate switches or touch the main plug with wet hands as this may cause electric shock.

• Do not operate the machine with a damaged supply cord or plug, or after the machine malfunctions or is damaged in any way.

Contact an authorized Service Agent for repair or adjustment.

• The plug of the power supply cord must be removed from the socket-outlet before commencing cleaning of the machine or

undertaking maintenance operations.

• The power supply cord must be regularly inspected for signs of damage. If the power supply cord is damaged, it must be

replaced.

• Do not use where hazardous dust is present.

• Do not use in an explosive atmosphere.

• Do not pick up oil or other ammable material with the machine.

• Take care when using the machine near the top of stairs.

Guidelines for The Operator

• Operators must be fully trained in the use of the machine in accordance with these instructions, able to perform user maintenance

and the correct selection of accessories.

• Operators should be physically capable to maneuver, transport and operate the machine.

• Operators should be able to recognize unusual operation of the machine and report any problems.

• Wear suitable footwear to avoid slipping.

• Wear suitable clothing to keep dry and warm.

• Where possible, implement job rotation and adequate rest periods to avoid continuous use of the same muscles.

• Do not leave the machine running unattended.

• Do not allow children to crawl on carpets until it is thoroughly dry.

• Keep cleaning solutions away from children and pets at all times.

• Do not smoke when using the machine.

• Caution – This machine is for indoor use only and should not be used or stored outdoors or in wet conditions.

• Warning – Should water emit from the machine exhaust, switch off immediately and refer to instructions for “Using the

Machine”.