Tornatech VPX Manual

V2024.02

INSTALLATION AND MAINTENANCE MANUAL

FOR VARIABLE SPEED ELECTRIC FIRE PUMP

CONTROLLERS MODEL VPX+VPU

V2024.02 2

TABLE OF CONTENTS

Important Safety Information 4

Introduction 6

TechnicalData 6

Installation 7

Storage 7

Seismic 7

Environment 7

Electromagneticcompatibility(EMC) 7

Handling 7

FCCRegulationsandRadioStandardsSpecification(RSS)Rules 7

Location 8

Mounting 8

Floormounting 9

Wallmounting 9

MakingSystemPressureConnections 9

MakingElectricalConnections 9

ImportantPrecautions 10

Procedure 10

Operator interface 12

Methods of starting and stopping 13

VariableSpeedElectricFirePumpmodeswitch 13

VFDmode 13

Bypassmode 13

Methodsofstarting 13

Automaticstart 13

Manualstart 13

Remotemanualstart 13

Remoteautomaticstart,delugevalvestart 13

Emergencystart 13

V2024.02 3

Sequentialstart 14

Teststart 14

Methodsofstopping 14

Manualstop 14

Automaticstop 14

Emergencystop 14

Transfer switch operation sequence 15

Transfertoalternatepowersource 15

Re-transfertonormalpowersource 15

Testtransfersequence 15

Manualoperation 15

Commissioning 17

VFDReforming 17

procedure 17

VFDSettings 17

Graphicdisplayterminal 17

Motorparameters 17

Basicparameters 18

Autotune 18

Procedure 19

Maintenance 20

Patents 21

V2024.02 4

IMPORTANT SAFETY INFORMATION

Warning:

This product can expose you to chemicals including DINP, which is known to the State of Cali-

fornia to cause cancer, and DIDP which is known to the State of California to cause birth

defects or other reproductive harm.

Warning:

This product can expose you to chemicals including lead and lead compounds, which are

know to the State of California to cause cancer and birth defects or other reproductive harm.

Formoreinformationgoto:www.P65Warnings.ca.gov

DANGER

RISK OF ELECTROCUTION

PERSONAL INJURY OR DEATH COULD OCCUR.

ENSURE ALL POWER IS DISCONNECTED BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

V2024.02 5

DANGER

Do not attempt to install or perform maintenance on equipment while it is energized! Death,

personal injury or substantial property damage may result from contact with energized equip-

ment. Always verify that no voltage is present before proceeding and always follow generally

accepted safety procedures. Controller disconnect switch must be in the “off” position in

order to open the enclosure door. Tornatech cannot be liable for any misapplication or incor-

rect installation of its products.

V2024.02 6

INTRODUCTION

VariableSpeedElectricFirePumpcontrollersaredesignedtostartanelectricmotordrivenfirepump.It

isequippedwithaVariableFrequencyDrive(VFD)thatwillregulatethemotorspeed,bycontrollingthe

frequencyappliedtothemotor,inordertomaintainacertainset-pointpressure.Itcaneitherstartthe

firepumpmanuallythroughthelocalstartpushbuttonorautomaticallythroughthesensingofapres-

suredropinthesprinklersystem.Thefirepumpcontrollerissuppliedwithapressuretransducer.The

firepumpcanbestoppedmanuallywiththelocalstoppushbuttonorautomaticallyaftertheexpiration

ofafieldprogrammabletimer.

Itisequippedwithanautomatictransferswitchthatfeedsthecontrollerfromeitherthenormalorthe

alternatepowersource.

TECHNICAL DATA

Rating Value

RatedOperationalCurrentIe AccordingtotheMotor(HP/kW)

RatedOperationalVoltageUe Accordingtothecontrollerratinglabel

RatedOperationalFrequency 50/60Hz

Standardenvironmentaltemperature 4°Cto40°C

Altitude ≤2000m

Relativehumidity 5%to80%

Pollutiondegree 3

ShortCircuitCurrentRatingIcc(SCCR)(A) Accordingtothecontrollerratinglabel

Standarddegreeofprotection NEMAType12

Standbypowerconsumption 200W

V2024.02 7

INSTALLATION

STORAGE

Ifthecontrollerisnotinstalledandenergizedimmediately,Tornatechrecommendsfollowingthe

instructionsinchapter3ofNEMAICS15.

SEISMIC

VariableSpeedElectricFirePumpcontrollersareoptionallyseismicapprovedandhasbeentestedin

accordancewiththeICC-ESAC156,IBC2015&CBC2013standards.Properinstallation,anchoringand

mountingisrequiredtovalidatethiscompliancereport.Refertothismanualanddrawingstodetermine

theseismicmountingrequirementsandlocationofthecenterofgravity(youmayneedtocontactfact-

ory).Theequipmentmanufacturerisnotresponsibleforthespecificationandperformanceofanchor-

agesystems.Thestructuralengineerofrecordontheprojectshallberesponsibleforanchoragedetails.

Theequipmentinstallationcontractorshallberesponsibleforensuringtherequirementsspecifiedby

thestructuralengineerofrecordaresatisfied.Ifdetailedseismicinstallationcalculationsarerequired,

pleasecontactthemanufacturerfortheperformanceofthiswork.

ENVIRONMENT

VariableSpeedElectricFirePumpcontrollersareintendedtobeinstalledinlocationswhereambient

temperaturesarewithin4°Cand40°Candtherelativehumidityiscontrolledbetween5%and80%.

Theyareintendedforpollutiondegree3andshallbeinstalledatanaltitudeofnomorethan2000

meters.Forabnormalinstallationenvironment,consultfactory.

ELECTROMAGNETIC COMPATIBILITY (EMC)

VariableSpeedElectricFirePumpcontrollershavebeentestedforthemoststringentconditionsfor

emissions(EnvironmentB)andimmunity(EnvironmentA),hencecontrollerscanbeinstalledineither

environment.Allcontrollersvariantssharethesameelectronicsandcomplytothosecriteriawithout

requiringadditionalmeasures.

HANDLING

TheweightofeachVariableSpeedElectricFirePumpcontrollerisindicatedonthepackinglabel.Light-

weightcontrollersdonotrequirespecialhandlinginstructions,whileheavycontrollersareequipped

withliftingmeansandshouldbehandledfollowingtheguidelinesspecifiedinTornatech'sdocument

"LargeEnclosureSafeHandlingRequirements_PN12162021".

FCC REGULATIONS AND RADIO STANDARDS SPECIFICATION

(RSS) RULES

TocomplywithFCCandIndustryCanadaRFexposurecompliancerequirements,aseparationdistance

ofatleast20cmmustbemaintainedbetweentheantennaofthisdeviceandallnearbypersons.This

devicemustnotbeco-locatedoroperatinginconjunctionwithanyotherantennaortransmitter.

V2024.02 8

Thisdevicecontainslicence-exempttransmitter(s)/receiver(s)thatcomplywithInnovation,Scienceand

EconomicDevelopmentCanada’slicence-exemptRSS(s).Operationissubjecttothefollowingtwocon-

ditions:

1. Thisdevicemaynotcauseinterference.

2. Thisdevicemustacceptanyinterference,includinginterferencethatmaycauseundesiredoper-

ationofthedevice.

Compliance:CANICES-003(B)/NMB-003(B)

Thisdevicecomplieswithpart15oftheFCCRules.Operationissubjecttothefollowingtwoconditions:

(1)Thisdevicemaynotcauseharmfulinterference,and(2)thisdevicemustacceptanyinterference

received,includinginterferencethatmaycauseundesiredoperation.

Note:ThisequipmenthasbeentestedandfoundtocomplywiththelimitsforaClassAdigitaldevice,

pursuanttopart15oftheFCCRules.Theselimitsaredesignedtoprovidereasonableprotectionagainst

harmfulinterferencewhentheequipmentisoperatedinacommercialenvironment.Thisequipment

generates,uses,andcanradiateradiofrequencyenergyand,ifnotinstalledandusedinaccordance

withtheinstructionmanual,maycauseharmfulinterferencetoradiocommunications.Operationofthis

equipmentinaresidentialareaislikelytocauseharmfulinterferenceinwhichcasetheuserwillbe

requiredtocorrecttheinterferenceathisownexpense.

“Changesormodificationsnotexpresslyapprovedbythepartyresponsibleforcompliancecouldvoid

theuser'sauthoritytooperatetheequipment.”

LOCATION

Consult the appropriate job plans to determine the controller mounting location.

Thecontrollershallbelocatedascloseaspracticaltotheengineormotoritcontrolsandshallbewithin

sightoftheengineormotor.Thecontrollershallbelocatedorprotectedsuchthatitwillnotbedam-

agedbywaterescapingfrompumporpumpconnections.Currentcarryingpartsofthecontrollershall

benotlessthan12in.(305mm)abovethefloorlevel.

WorkingclearancesaroundcontrollershallcomplywithNFPA70,NationalElectricalCode,Article110or

C22.1,CanadianElectricalCode,Article26.302oranyapplicablelocalcodes.

ThestandardcontrollerenclosureisratedNEMAType12.Itistheinstaller’sresponsibilitytoinsurethat

eitherthestandardenclosuremeetstheambientconditionsorthatanenclosurewithanappropriate

ratinghasbeenprovided.Controllersmustbeinstalledinsideabuildingandtheyarenotdesignedfor

outsideenvironment.Thepaintcolormaychangeifthecontrollerisexposedtoultravioletraysfora

longperiodoftime.

MOUNTING

TheVariableSpeedElectricFirePumpcontrollershallbemountedinasubstantialmanneronasingle

incombustiblesupportingstructure.

V2024.02 9

FLOOR MOUNTING

Floormountedcontrollersshallbeattachedtothefloorusingallholesprovidedonthemountingfeet

withhardwaredesignedtosupporttheweightofthecontroller.Themountingfeetprovidetheneces-

sary12in.(305mm)clearanceforcurrentcarryingparts.

WALL MOUNTING

Refer to the controller dimension drawing for necessary mounting dimensions.

Thecontrolleriswallmountedbyusingatleastfour(4)wallanchors,2anchorsforthetopmounting

bracketsand2anchorsforthebottommountingbrackets.Thebracketsaredimensionallyonthesame

centerlineforeaseinmounting.Thereshouldbeaclearanceofatleast6inches(152mm)aroundthe

controllertoallowproperaircirculationaroundtheequipment.

1. Usingeitherthedimensionprintorbymeasuringthedistancebetweenthecenterlinesofthe

lowerbracketslots,transcribethisdimensionontothewall.Note:Thebottomedgeoftheenclos-

ureshouldbeaminimumof12”(305mm.)fromthefloorincasefloodingofthepumproom

occurs.

2. Drillandputanchorsintothewallforthelowermountingbrackets.

3. Markonthewall,thelocationoftheholesintheuppermountingbrackets.

4. Drillandputanchorsintowallfortheuppermountingbrackets.

5. Installboltsandwashersinloweranchors.

6. Alignholesinuppermountingbracketsandinstallboltsandwashersinanchors.

7. Shimanchorsasnecessarytoensurerearofenclosureisverticallevelandenclosureisnot

stressed.

8. Tightenallanchorbolts.

9. Checktobesureenclosuredooropenandclosesfreelyandthatenclosureislevel.

MAKING SYSTEM PRESSURE CONNECTIONS

Thecontrollerrequiresone(1)“SystemPressure”connectionfromthesystempipingtotheenclosure.

Theconnectionfitting,1/2”NPTmaleport,isprovidedontheleftexternalsideoftheenclosureforthis

purpose.RefertoNFPA20forcorrectfieldpipingprocedureofthesensinglinebetweenthepumping

systemandthecontroller.Ifadrainispresent,theconnectiontothedrainisataperedconnectionfor

plastictubing.

MAKING ELECTRICAL CONNECTIONS

TheelectricalwiringbetweenthepowersourceandthefirepumpcontrollershallmeettheNFPA20,

NFPA70NationalElectricalCodeArticle695orC22.1CanadianElectricalCode,Section32-200orany

applicablelocalcodes.Electricalwiringshallbetypicallysizedtocarryatleast125%ofthefullloadcur-

rent(FLCorFLA)ofthefirepumpmotor.

V2024.02 10

IMPORTANT PRECAUTIONS

Alicensedelectricianmustsupervisetheelectricalconnections.Thedimensiondrawingsshowthearea

suitableforincomingpowerandmotorconnections.Nootherlocationshallbeused.Onlywatertight

hubfittingsshallbeusedwhenenteringthecabinettopreservetheNEMAorIPratingofthecabinet.

The installer is responsible for adequate protection of the Variable Speed Electric Fire Pump

controller components against metallic debris or drilling chips. Failure to do so may cause

injuries to personnel, damage the controller and subsequently void warranty.

Priortomakinganyfieldconnections

1. Opendoorofenclosureandinspectinternalcomponentsandwiringforanysignsoffrayedor

loosewiresorothervisibledamage.

2. Verifythatthecontrollerinformationiswhatisrequiredontheproject:

1. Tornatechcatalognumber

2. Motorelectricalnameplateinformationmatchescontrollerratingforvoltage,frequency,

FLAandHP.

3. Project'selectricalcontractormustsupplyallnecessarywiringforfieldconnectionsinaccordance

withtheNationalElectricalCode,localelectricalcodeandanyotherauthorityhavingjurisdiction.

4. Refertotheappropriatefieldconnectiondrawingforwiringinformation.

PROCEDURE

Allfieldconnections,remotealarmfunctionsandACwiringarebroughtintotheenclosurethroughthe

toporbottomconduitentrancesasindicatedonthedimensionaldrawing.

Donotplaceconduitentrancesonthesidesoftheenclosureunlessaglandplateisprovided.

1. Usingahole(conduit)punch,createaholeintheenclosureforthesizeconduitbeingused.

2. Installnecessaryconduit.

3. Pullallwiresnecessaryforfieldconnections,remotealarmfunctions,ACpowerandallother

optionalfeatures.Bringenoughwireinsidetheenclosuretomakeupconnectionstotheappro-

priateline,loadandcontrolterminalblockpoints.Besuretoconsulttheappropriatefieldcon-

nectiondiagramforconnectionpointsandacceptablewiresize.Forproperwiresizing,referto

theNationalElectricalCode,NFPA70.

4. Makeallfieldconnectionstotheremotealarmfunctionsandanyotheroptionalfeatures.

5. Connectmotortocontrollerloadterminals.

6. FindnameplateonVariableSpeedElectricFirePumpmotorandmakenoteofitsfullloadamprat-

ing.

7. VerifyAClinevoltage,phaseandfrequencywiththecontrollerdataplateontheenclosuredoor

priortoconnecting.

8. ConnectACpower.

V2024.02 11

9. Checktoseethatallconnectionsarebothcorrectlywired(inaccordancewiththefieldcon-

nectiondiagram)andtight.

10. Closetheenclosuredoor.

V2024.02 12

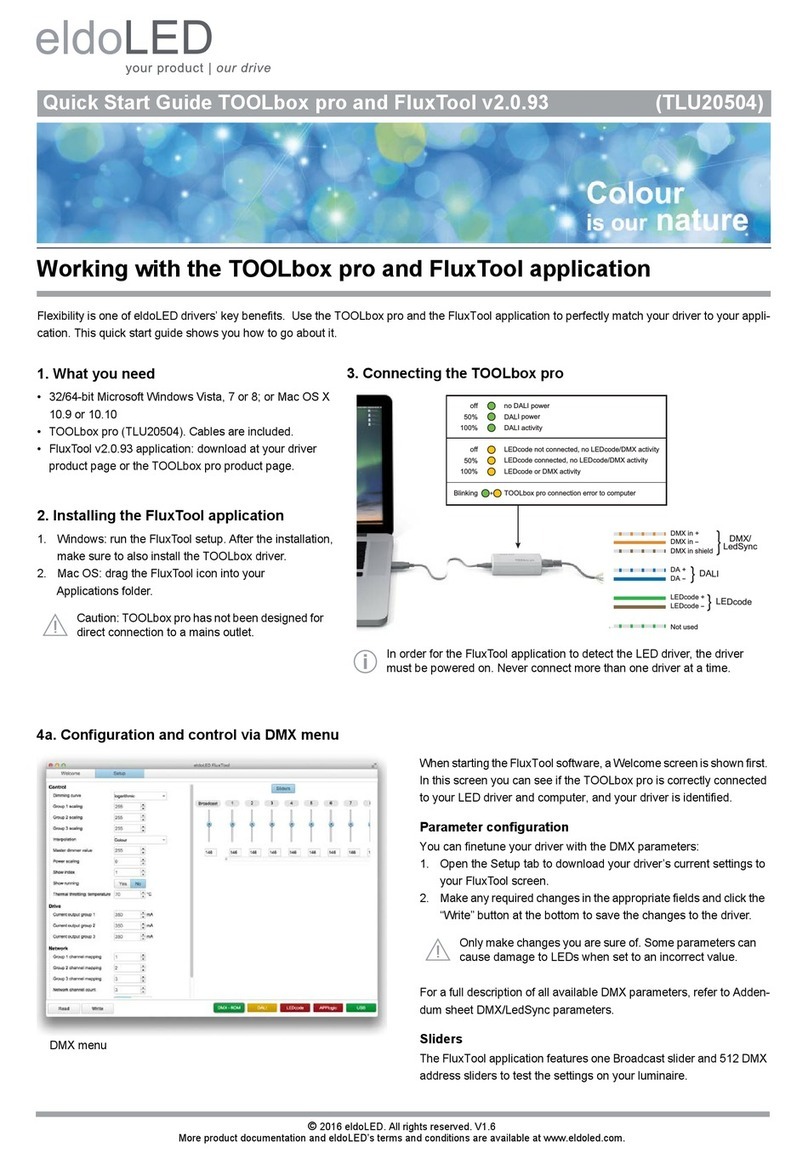

OPERATOR INTERFACE

A. StatusLED

B. Manualstart

C. Stop

D. Transfer-switchtest

E. Runtest

F. Alarmbuzzer

G. Touchscreendisplay

H. Factoryreserved

I. USBkeyconnectorforlogsdownloadandsoftwareupdates

J. EthernetconnectorforstandardTCP/IPcommunication

V2024.02 13

METHODS OF STARTING AND STOPPING

VARIABLE SPEED ELECTRIC FIRE PUMP MODE SWITCH

TheVPX+VPUisequippedwithaVFDmodeswitchthatislocatedundertheVizitouch.Itisprotectedby

alockablecover,andhas2positions;VFDandBYPASS.Ifthemodeswitchchangespositionwhilethe

motorisrunning,themotorwillstopandrestartinthenewmode

VFD MODE

Thisisthenormalmodeofoperation.ThecontrollerwillusetheVFDastheprimarystartingmeans,and

automaticallyswitchtothebypassstartingmeansincaseofaVFDalarm.Oncethecontrollerhasauto-

maticallyswitchedtothebypassstartingmeans,itwillremaininthisstateuntiltheVFDalarmsare

manuallyreset.

Note: When the motor is driven by the VFD, it may run at minimum speed when the system

pressure is above the set point pressure.

BYPASS MODE

Ifrequired,thebypassstartingmeanscanbemanuallyselectedusingthemodeswitch.

METHODS OF STARTING

AUTOMATIC START

Thecontrollerwillstartautomaticallyonlowpressuredetectionbythepressuresensorwhenthepres-

suredropsbelowthecut-inthreshold.

MANUAL START

Themotorcanbestartedbypressingthemanualstartpushbutton,regardlessofthesystempressure.

REMOTE MANUAL START

Themotorcanbestartedfromaremotelocationbymomentarilyclosingacontactofamanualpush-

button.

REMOTE AUTOMATIC START, DELUGE VALVE START

Themotorcanbestartedfromaremotelocationbymomentarilyopeningacontactconnectedtoan

automaticdevice.

EMERGENCY START

Themotorcanbestartedmanuallybyusingtheemergencyhandle.Thishandlecanbemaintainedina

closedposition.

Important: to avoid damaging the contactor, it is recommended to start the motor in this

manner:

1. Shutdownthemainpowerbyusingthemaindisconnectmeans,

2. Pulltheemergencystarthandleandlockitinclosedposition,

3. Turnthepowerbackonbyusingthemaindisconnectmeans.

V2024.02 14

SEQUENTIAL START

Incaseofamultiplepumpapplication,itmaybenecessarytodelaytheautomaticstartingofeach

motortopreventsimultaneousstartingofallmotors.

TEST START

Themotorcanbestartedintestmodemanuallybypressingtheruntestpushbutton,orautomatically

byusingtheperiodictestfeature.

METHODS OF STOPPING

MANUAL STOP

Manualstopisdonebypressingtheprioritystoppushbutton.Notethatpressingthestoppushbutton

willpreventthemotorfromrestartingaslongasthebuttonispressed,plusatwoseconddelay.This

actionhaspriorityoveranyactivedemand,butthemotorwillrestartautomaticallyoncethebuttonis

releasedifthereisany.

AUTOMATIC STOP

This function is never activated by default and must be authorized by the authority having

jurisdiction prior to activating.

Automaticstopispossibleonlyafteranautomaticstart.Whenthisfunctionisenabled,themotoris

automaticallystopped10minutesaftertherestorationofthepressuregiventhatnootherruncauseis

present.The10minutesdelayisadjustable.

EMERGENCY STOP

Theemergencystopisalwayspossibleinanystartingconditionandisdonebyusingthemaindis-

connectingmeanslocatedonthedoor.

V2024.02 15

TRANSFER SWITCH OPERATION SEQUENCE

Thetransfer-switchshallbesuppliedeitherbyasecondutilityorbyanon-sitestandbygeneratorcom-

plyingwiththerequirementsofaLevel1,Type10,ClassXsystemofNFPA110,meaningitshallsupply

powertothefirepumpcontrollerwithin10seconds.

Additionally,thefirepumpcontrollershallbefullyoperationalandreadytostartwithin10seconds

aftertheapplicationofpower.Thosetworequirementscombinedmeansthatthetotaltimeframe

betweenanormalpowerlossandathecontrollerbeingreadytostartonthealternatepower,if

providedbyagenerator,shallbeatmost20seconds.

TRANSFER TO ALTERNATE POWER SOURCE

Whenthenormalpowersourceisoutsideacceptableparametersforatleastthreeseconds,agenerator

startcommandisissued.Thethreeseconddelaycanbeadjustedtohelpmeetthe10secondsrequire-

mentofthegenerator,but doing so increases the risk of nuisance starting of the generatorincaseof

powerbrownouts.Specialconsiderationmustbetakenbeforeeditingthisvalue.

Oncethealternatepoweriswithinacceptableparametersforatleastanotherthreeseconds,thetrans-

fertothealternatepowersourceisinitiated.

RE-TRANSFER TO NORMAL POWER SOURCE

The transfer switch will stay in alternate position, if the motor is running, for as long as the

alternate power source is within acceptable parameters. The re-transfer sequence is enabled

if the motor is not running.

Whenthenormalpowersourceiswithinacceptableparametersforatleastfiveminutes,there-transfer

tothenormalpowersourceisinitiated.Acool-downperiodoffiveminutesmaintainsthegeneratorrun-

ningafterwhichitsstartcommandwillberemoved.

TEST TRANSFER SEQUENCE

Afulltransfersequencecanbeexecutedbymeansofpressingthetransfer-switchtestmembranebut-

ton.

MANUAL OPERATION

Thetransfer-switchisdesignedtobekeptinautomaticmodeatalltimes.Incertainemergencysitu-

ationsrequiringit,thetransfer-switchcanbemanuallyoperated.

Thereis180°betweentheNormalposition(I)andtheAlternateposition(II).Tooperatemanuallythe

TransferSwitch:

1. UsetheDisconnectSwitchestoturnOFFthepowerofbothNormalandAlternatesides.

2. OpenthedooroftheAlternateside.

3. OntheTransferSwitch,puttheselectorswitchinManualmode.

4. Takethehandle,situatedinsidethecontrollerdoorandinsertitinthesquareholeontheTrans-

ferSwitch.

V2024.02 16

5. Turnthehandleclockwise180°totransferfromAlternatetoNormalposition,orcoun-

terclockwise180°totransferfromNormaltoAlternateposition.

6. Removethehandleandputitbackonthesupportinsidethecontrollerdoor.

7. Ifrequired,pulltheemergencystarthandleandlockitinplace.

8. Closethedoorandusingthedisconnectingswitchhandlesputbackthepoweronbothsides.

BE CAREFUL

Do not close the controller door if the handle is still installed in the Transfer Switch.

Do not operate manually the Transfer Switch if the power is still ON.

V2024.02 17

COMMISSIONING

Only an authorized field acceptance provider shall proceed with Variable Speed Electric Fire

Pump controller commissioning. If you do not have the required training and authorization,

contact factory.

Untilcommissioningiscompleted,thecontrollermainscreenisreplacedbythecommissioningmenu

andtheautomaticmodeisdisabled.

VFD REFORMING

ReformingaVFDistheactionofapplyingvoltagetotheVFDpowerpathwithoutrunningamotor.Ifthe

drivewasnotconnectedtoavoltagesourceforanextendedperiodoftime,thecapacitorsmustbe

restoredtotheirfullperformancebeforethemotorisstarted,otherwisetheVFDmaybedamaged.

IftheVFDhasnotbeenstartedforayearormore,aVFD Reforming Requiredwarningwillbeissuedand

thecontrollerwillautomaticallystartinbypassuntilthereformingisdone.Propercontrollermain-

tenanceasperthisdocumentwillpreventreformingfrombeingrequiredundernormalconditions.

PROCEDURE

1. PlacethemodeswitchinVFD mode

2. Enteravalidlevel2password

3. FromtheVFD Configpage,presstheVFD Reformingbutton.

4. Waitforthereformingtocomplete

Note: The reforming operation will be interrupted if a starting request occurs, the mode

switch is changed, or the user cancel the operation. Only a full reforming procedure will reset

the VFD Reforming Required alarm.

Note 2: The reforming time is preset to 1 hour and is the required time for an inactivity

period of 1 year. For a greater inactivity period, consult factory for the proper reforming

time. An insufficient reforming time may lead to a damaged VFD .

VFD SETTINGS

GRAPHIC DISPLAY TERMINAL

TheVFDhasgraphicaldisplayterminalusedforconfiguringtheequipment.Itisnormallyattachedto

theVFDandcanberelocatedontheexterioroftheenclosureviatheprovideddoormountingkit.

Alwaysensurethatthedoormountingkitiseitherproperlyclosedorhasthedisplayproperlymounted

tomaintaintheNEMAType12ratingofthecontroller.

MOTOR PARAMETERS

OntheVFDgraphicdisplayterminal,gototheSimply StartMenu.Verifythatalltheinformationonthis

menuisthesameastheoneonthemotornameplate:

V2024.02 18

1. MotorStandard

1. 50Hz:ThenominalmotorpowerwillbeexpressedinKW

2. 60H:ThenominalmotorpowerwillbeexpressedinHP.

2. NominalMotorPower

3. NominalMotorVoltage

4. Nominalmotorcurrent

5. Nominalmotorfrequency

6. Nominalmotorspeed

7. Maxfrequency

Shouldbesettothenominalmotorfrequency.

BASIC PARAMETERS

ContinueontheSimplyStartmenuandmodifyorvalidatethenextparameters:

1. Accelerationramptime

2. Decelerationramptime

3. Lowspeed

4. Highspeed

RefertotheVFDParametersListforthefactorysettingsvalues.

AUTOTUNE

TheautotuneprocedureallowstheVFDtoacquireelectricalmotorcharacteristicsandenhancetheVFD

performance.Itisrecommendedtoperformtheautotuneonlyonceduringthefirststartup.

Performtheautotuneonastoppedandcoldmotorasheatcaninfluencethetuningresult.

WhiledoingtheAutotunetheVFDwillscanthemotorandacquireinformationaboutthemotor.

BeforestartingtheAutotuneontheVFD,readthewholeprocedure.Thenperformstepbystep.

1. PlacetheModeswitchontheVFDposition.

2. OntheVizitouch.Enteralevel2password.

3. GototheVFD ConfigpageandpresstheVFD Autotunebutton.TheVPxwillclosetheVFDisol-

atingcontactors.ThiswillenergizetheVFDpowerpathandallowittobeconnectedtothe

motor.TheVFDisolatingcontactorswillremainclosedfor3minutes.Duringthattime,youcan

performtheAutotuneontheVFDdisplay.

4. OntheVFDGraphicDisplayTerminal,gototheSimply Startmenu

5. GototheAutotuningparameterandpressOKtoentertheAutotuningpage.

6. SelectApply AutotuningandpressOK.

V2024.02 19

7. AWarningwillbedisplayedonscreen.PressOK.

8. Autotunewillbeperformed.YoucanvalidateitiscompletedbygoingontheSimply Startmenu

andassertthattheAutotuning StatusissettoAutotuning Done.

9. OntheVizitouch,presstheStopbuttonontheAutotunepopup.

Note: during this process, the motor might make small movements. Noise development and

oscillations of the system are normal. This may take for several seconds, do not interrupt the

process.

PROCEDURE

Tocommissionthecontroller:

1. SecurethedoorinclosedpositionthenputthecircuitbreakerdisconnectingmeansinONpos-

ition.

2. Loginwithyourpasswordandcompletethefirststartupmenuonthescreen.

3. MakesuretheprocedureiscompletedwiththeVFDsettoconstantspeedmode.

4. Forthree-phasemotors,incaseofincorrectrotationonthebypassstartingmeans,power off the

controllerandswaptwowiresatthecontactorloadside,thenpowerthecontrollerbackon.

5. IncaseofincorrectmotorrotationontheVFDstartingmeans,goonthegraphicaldisplayter-

minalandchangetheOutput phase rotationPHrparameterontheComplete settings > Motor

parameter > Motor Controlmenu.

6. Onceallthenecessarystepsarecompletedandthatyouareloggedinwithyourpassword,the

"ServiceDone"buttonwillbecomeonline.

7. Pressthe"ServiceDone"buttononceyouaresatisfiedwiththereadingsandparameters.

8. Downloadthelogstosaveinyourreport.

9. Tofinalizethecontrollercommissioning,itisimportanttorefertotheVPx Complete Setup pro-

ceduretoadjusttheadvancedparametersoftheVFD.ThiswillassuretheVFDresponsecorrectly

andinatimelymannertoapressuredrop.

V2024.02 20

MAINTENANCE

Tornatechcontrollersarecoveredbyalimitedwarrantyandbackedbya10-yearsservicelifeoruntil

supplylast,providedthatproperinstallation,commissioning,useandmaintenanceofthecontrolleris

madeasperthisdocument,NFPA25,andanymaintenancestandardapplicable.

Propercontrollerperformancemustbeassertedatleastonceamonthbyexecutingthefollowing:

1. Withthesystembeingatnominalpressure,ensurethatthepressurereadingiswithintolerances

2. PerformateststartsequenceonboththeVFDandthebypassstartingmeansandverifythat

1. Themotorstartswhenthepressurefallsbelowcut-in

2. Therearenoalarms

3. Thereisnonuisancetripping

4. Themotorstartsproperlyandisabletoacceleratewithintheexpectedtime

5. Themotorrotatesintheappropriatedirection

6. Thepumpisabletorisethepressureabovethecut-out

7. Themotorstopswhenthepressureisabovecut-outaftertheconfiguredtestduration

time

Inadditiontotheabove,thefollowingpreventativemaintenancemustbeperformedatleastonceyear:

1. Turnoffthecontroller

2. Doavisualinspectionoftheexteriorofthecontroller

3. Opentheenclosureanddoavisualinspectionoftheinteriorofthecontroller

4. Makesurethatthereisnodustaccumulationinsidethecontroller

5. Cleanthefansandairoutletfiltersfromdustaccumulation

6. Inspectthetightnessofeachdeadcable

7. Putthecontrollerbackinservice

This manual suits for next models

1

Table of contents

Other Tornatech Controllers manuals