tornos Deco 7a User manual

IT −DECO 7a/10a

TORNOS SA −CH−2740 MOUTIER −http://www.tornos.ch Printed in Switzerland Copyright (c)1999−2004

MOUNTING Y1Y2 LINEAR GUIDES

TT5497 en

∆Warning ! Failure to comply with the safety regulations may cause serious accidents.

These instructions are based on the information available at the moment of their publication. Although

the very best has been done to make them as comprehensive and precise as possible the instructions

do not purport either to cover all details of the hardware and software or to anticipate every con-

tingency.

TORNOS S.A. neither give any guarantee nor accept any liability for the exactitude and the suffi-

ciency of the information contained in this document.

The contents of the instructions remain the property of TORNOS S.A. who reserve the right to modify,

complete or correct them at any time.

The original language of the instructions to be referred to is French. The hazards of misinterpreting

the instructions can be considerably reduced by following the training courses organized and offered

by TORNOS S.A.

The CE-marking indicates conformity with the European standards

of safety, health, environment and protection.

TORNOS S.A.

Rue Industrielle 1 1 1

CH−2740 MOUTIER / SUISSE

Tél. 032 / 494 44 44

Fax 032 / 494 49 03

TORNOS TECHNOLOGIES

IBERICA

Pol. Ind. El Congost

Avda. St Julia, 206 Nave 8

E−08400 GRANOLLERS

Tel. (34) 93 846 59 43

Fax (34) 93 849 66 00

TORNOS−TECHNOLOGIES

DEUTSCHLAND

Karlsruher Str. 38

D−75179 PFORZHEIM

Tel. 07231/ 910 70

Fax 07231/ 910 750

TORNOS TECHNOLOGIES

ITALIA SRL Via Einstein, 24

I−20090 ASSAGO / MI

Tel. 02 45 77 17 01

Fax 02 45 70 16 48

TORNOS TECHNOLOGIES

FRANCE

Boîte postale 330

ST−PIERRE EN FAUCIGNY

F74807 LA ROCHE

S / FORON CEDEX

Tél. 04 50 038 333

Fax 04 50 038 907

TORNOS TECHNOLOGIES

US CORPORATION

70 Pocono Road PO. Box 325

BROOKFIELD CT 06804 / USA

Tel. (203) 775−4319

Fax (203) 775−4281

TORNOS TECHNOLOGIES UK Ltd Tornos House

Whitwick Business Park Coalville

Leicestershire

LE67 4JQ

Tel. 01530 513100

Fax 01 530 814212

IT MONTING −DECO 7a/10a

Chap. / 3TT5497 en −12/04

Differentiation of degrees of risk

These instructions indicate a number of safety measure symbols which appear also on the machine

and are intended to protect the user, his/her effects and the environment from injuries and damage

as applicable.

Below, you will find the safety symbols, their headings and definitions. Please, read these first before

you continue.

∆Danger !

indicates a direct danger of death or serious injury.

∆Warning !

indicates an object or action which may cause death or serious injury.

∆Caution !

indicates an object or action which may cause injury or serious damage.

∆Attention !

indicates incorrect actions or such that may cause damage.

⊗Prohibition !

indicates an action or operation prohibited because of evident or alleged hazards.

⇒Info :

Gives information or comment related to safety.

⇒Note :

Gives information unrelated to safety

Important Safety Indications

∆Warning !

Read the instruction before operating the machine.

Should the user disregard the instructions of this manual, TORNOS SA declines any liability

whatsoever.

∆Attention !

Certain maintenance works are absolutely necessary to ensure good operation of the

machine. They are given in the MAINTENANCE SCHEDULE on the machine

(or see Instructions: OPERATION-MAINTENANCE).

∆Caution!

TORNOS SA disclaims all responsibility for any modifications carried out by the customer to

the machine, and to its related equipment and software, without agreement ratified by

TORNOS SA.

IT MONTING −DECO 7a/10a

Chap. / 4 TT5497 en −12/04

∆Caution !

Make sure the axis belts are changed by a professional who has attended a TORNOS mainte-

nance training !

Before you change the belt of a vertical axis, lock the carriage to keep it from sliding down in

free fall !

∆Warning !

First thing to do before any maintenance work :

−Turn off and lock Main Switch to stop the machine.

−Wear gloves to avoid injury from metal chips or sheeting.

−Do not touch the motor enclosure when it is still hot !

∆Caution !

Change the belt when its condition has visibly deteriorated :

−A notch is cracked.

−A notch is broken.

−The protective strip is damaged.

−The steel cords appear at the side.

∆Caution!

TORNOS SA disclaims all responsibility for any modifications carried out by the customer to

the machine, and to its related equipment and software, without agreement ratified by

TORNOS SA.

IT MONTING −DECO 7a/10a

Chap. / 1TT5497 en −12/04

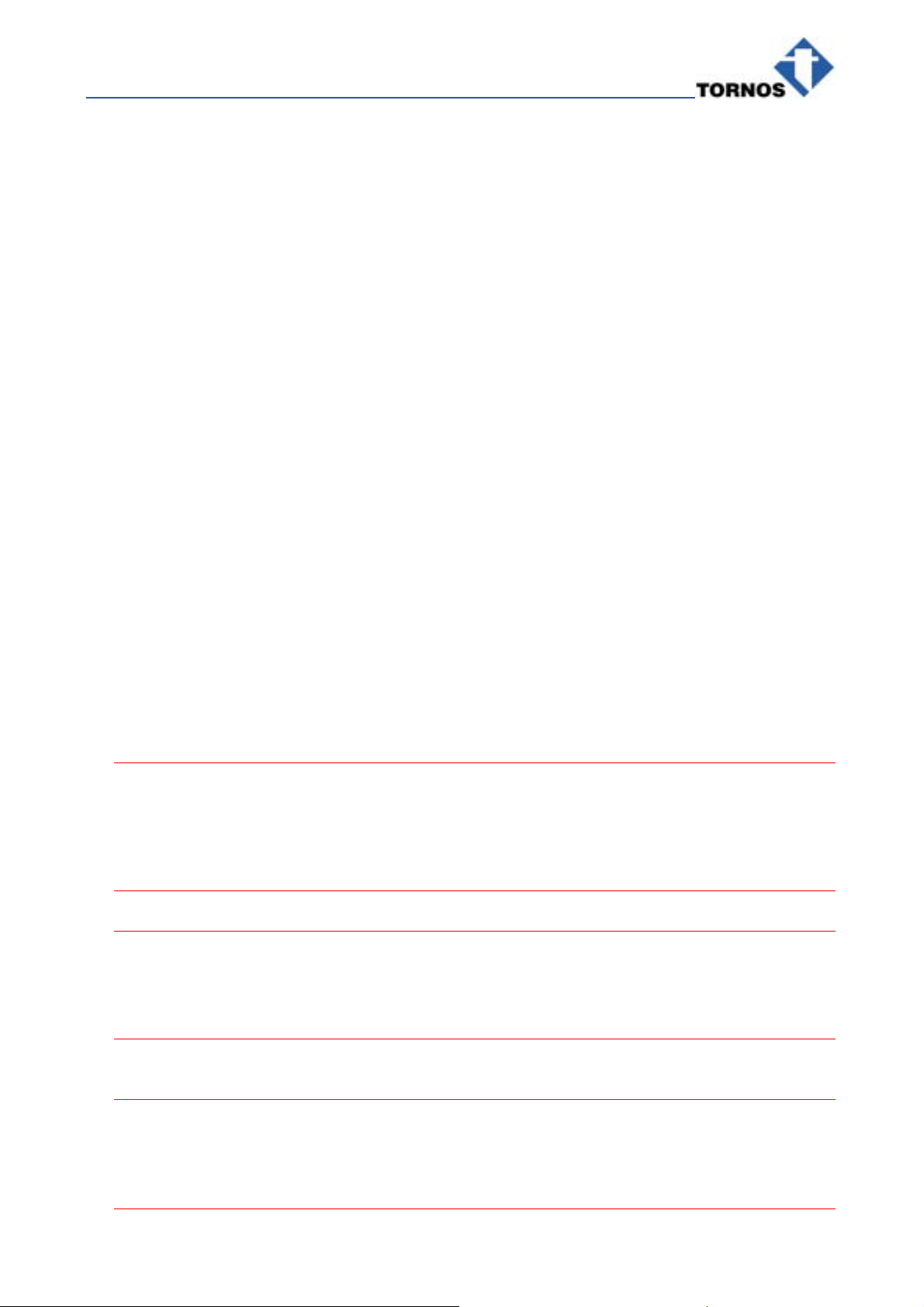

TECHNICAL INSTRUCTION FOR MOUNTING Y1Y2 LINEAR GUIDES ON

DECO 7/10

GENERAL DATA

Group Identification : 305015 compound slide for frontwork gang – guides DN 15 lg 236

ident. 241621

305016 compound slide for backwork gang −guides DN 15 lg 236

ident. 241621

Tools: 1 torque wrench 05 à 20 Nm

1 hex socket long. 130mm

(for torque wrench)

1 comparator (0.002) with magnetized base.

⇒RECOMMENDATION : When replacing guides, it is recommended to change the holder

eccentrics (561096 Pos 0190).

What to do ? Notes

PREPARATION :

Unpack the linear guides ; remove the

O−Rings located on the greasing plates of

each ball carriage and set them aside to

prevent misplacing them.

Using a ruler, make sure that the greasing

plate height is not greater than the support

surface of the ball carriages.

Clean off all the protective oil residue from the

support surfaces of the guides and carriages.

Hone the base of the guides (rails).

MOUNTING (ASSEMBLY):

Place the linear guides DN 15 ( Ident. 241621

Pos. 0280) on the ”x” frontwork gang carriage

(561134 Pos. 090) or the ”x” backwork gang

carriage (561142 Pos. 050)... ...to obtain the reference surfaces of the

guides and carriages opposite the

eccentrics.

Push the carriages to one end of the guides in

order to insert the first 4 fastening screws for

each guide M4x14 (020162 Pos. 0400/0390)

and tighten slightly.

Move the carriages to the other end and insert

the last 4 screws M4x14 and tighten slightly.

Torque the eccentrics (561096 Pos. 0190) by

alternating from the center to left / right to

6 Nm.

Torque to 6Nm

IT MONTING −DECO 7a/10a

Chap. / 2 TT5497 en −12/04

What to do ? Notes

Torque the fastening screws M4x14 of the

guides (rails) following the same procedure as

for the eccentrics to 6 Nm

Torque 6Nm

Insert the 2−piece caps delivered as a guide

accessory into the fastening screw holes of

the guides (Insert the drilled plastic washer

first and then the teflon cap and using a flat

tool press into the hole. Check that the

carriages move freely without binding).

Reinstall the O−Rings in their recess in the

greasing plates at each end of the ball

carriages. Grease the O−Rings to hold them

in their recess.

MOUNTING THE FRONTWORK AND BACKWORK GANGS ON A CARRIAGE:

Place the frontwork gang or backwork gang,

respectively, 561140 / 561143 Pos. 030, on

the linear guide carriages.

Insert the 16 screws M5x16 (Ident. 020175

Pos. 0370/0360) and tighten slightly by

alternating left / right.

( By X)

Torque the eccentrics (561096) on the

carriages to 6 Nm starting from the outer

eccentrics to the inner eccentrics.

Fully torque the fastening screws of the gang

on the ball carriages to 11 Nm by alternating

left / left.

(By X).

TEST / ALIGNMENT

With the compound slide for front/backwork

gang assembly laid flat on the bench, insert

only for this test in the 6 mm dia. bores the

frontwork gang / backwork gang, respectively

(561140 / 561143 Pos 030), 2 cylindric cotter

pins h6, or equivalent.

Using a comparator with its magnetic base

placed on the ”x” gang carriage, gauge the

side of the two cotter pins. An error of 0.006

mm is allowable. If the error should be greater

than this reference value, completely repeat

the torquing operation. To solve the problem, it

is possible to touchup the support surface of

the ball carriages on the front/backwork

gangs, respectively (561140 / 561143 pos.

030), by polishing it.

IT MONTING −DECO 7a/10a

Chap. / 3TT5497 en −12/04

What to do ? Notes

INSTALLING THE BALLSCREW :

Insert the ballscrew (561102 Pos. 0180) in its

recess on the gang carriage (Pos 030)... ... by aligning the gang carriage / ballscrew

greasing holes.

Secure it with 6 screws M5x16 (Pos.

0370/0360) and torque to 11 Nm after

adjusting the clearance in the middle.

Mount the 2 roller bearings (561131 Pos.

0140) and the 2 rings (561119 Pos. 0150) on

the ends of the ballscrew...

...(without fully tightening the screws M4x12

(020161 Pos. 0410/ 0400)).

Move the Y front/backwork gang carriage

(561140 / 561143 Pos. 030) to the Up position

and, using a pin wrench, torque the upper nut

of the ballscrew (561443 Pos. 0196)

to 12 Nm.

Insert the 2nd nut of the ballscrew (561443

Pos. 0196) without fully tightening so that the

first thread of the ballscrew is visible.

Using the ballscrew, make one complete

down−to−up travel of the Y front/backwork

gang carriage to allow mounting the elements.

Move the Y front/backwork gang carriage to

the middle position and torque the 6 screws

M4x12 (020161 Pos. 0410/0400) of the 1st

bearing to 6 Nm.

Move the Y front/backwork gang carriage to

the Down position. Attention : Make sure that

the ball carriages remain completely on their

linear guides. Push the 2nd bearing (561131

Pos. 140) toward the inside of the assembly to

completely realign the clearance and torque to

6 Nm.

Once again move the Y front/backwork gang

carriage to the Up position (“end of travel”)

and torque the 4 screws M5x10 (020173 Pos.

0380 / 0370) securing the ring 561119 (Pos.

150) to 11 Nm.

Move the Y front/backwork gang carriage to

the opposite “end of travel” and torque the 4

screws M5x10 securing the second ring to 11

Nm (idem above).

IT MONTING −DECO 7a/10a

Chap. / 4 TT5497 en −12/04

What to do ? Notes

TEST:

Position the comparator with the feeler gauge

against the ballscrew surface.

Screw/unscrew once or twice the nut of the

ballscrew (561443 Pos. 0196) so that the

roller bearings are correctly installed in the

ring.

Tighten the nut, adjust the comparator to “0”

and preload the ballscrew to 0.06 mm.

Check how the system operates as it travels

from “end to end”.

Check on the machined true diameter at the

end of the ballscrew its variation in roundness.

A maximum tolerance of 0.005 mm is allowa-

ble. If necessary, readjust.

IT MONTING −DECO 7a/10a

Chap. / 5TT5497 en −12/04

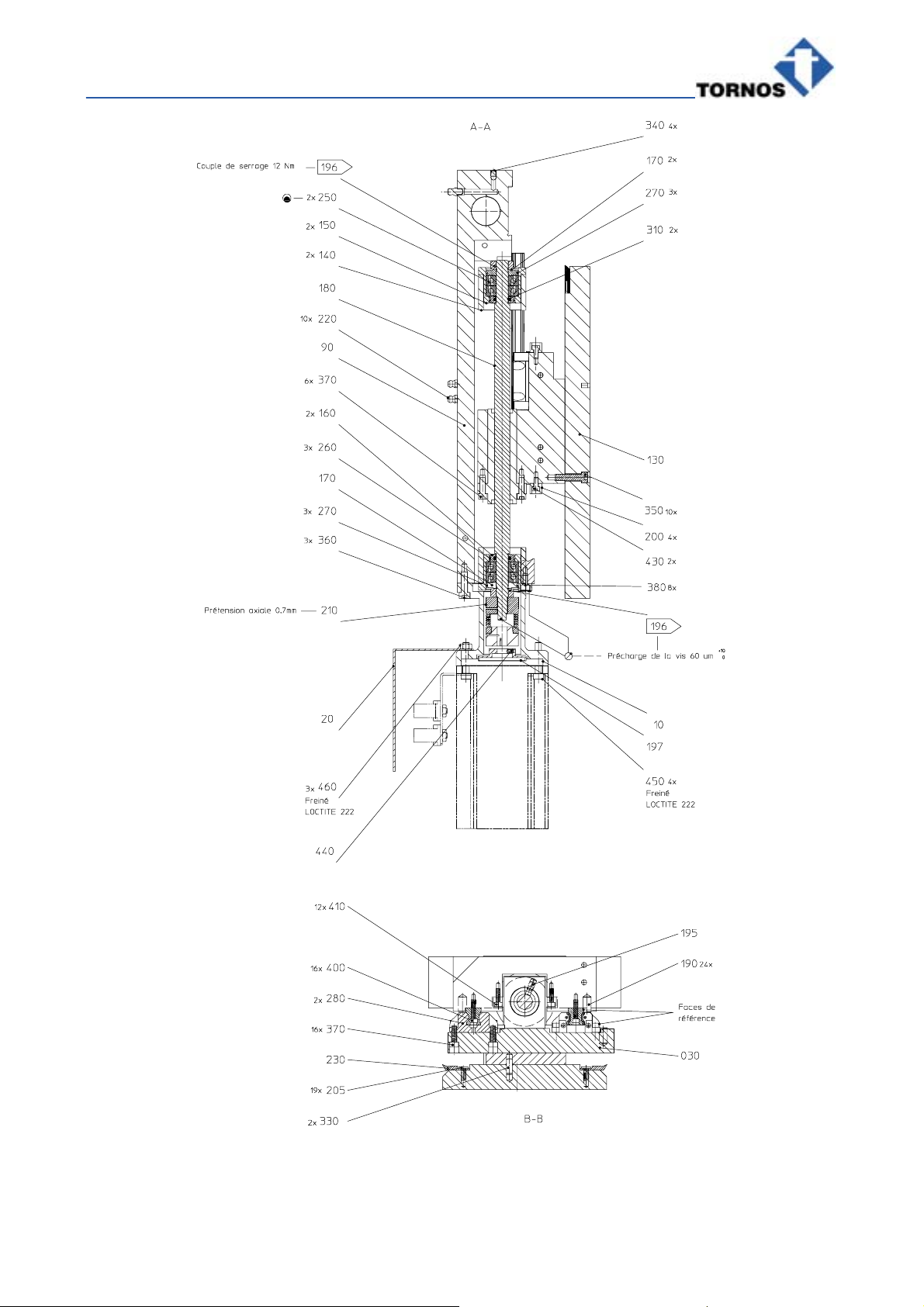

305015f1

IT MONTING −DECO 7a/10a

Chap. / 6 TT5497 en −12/04

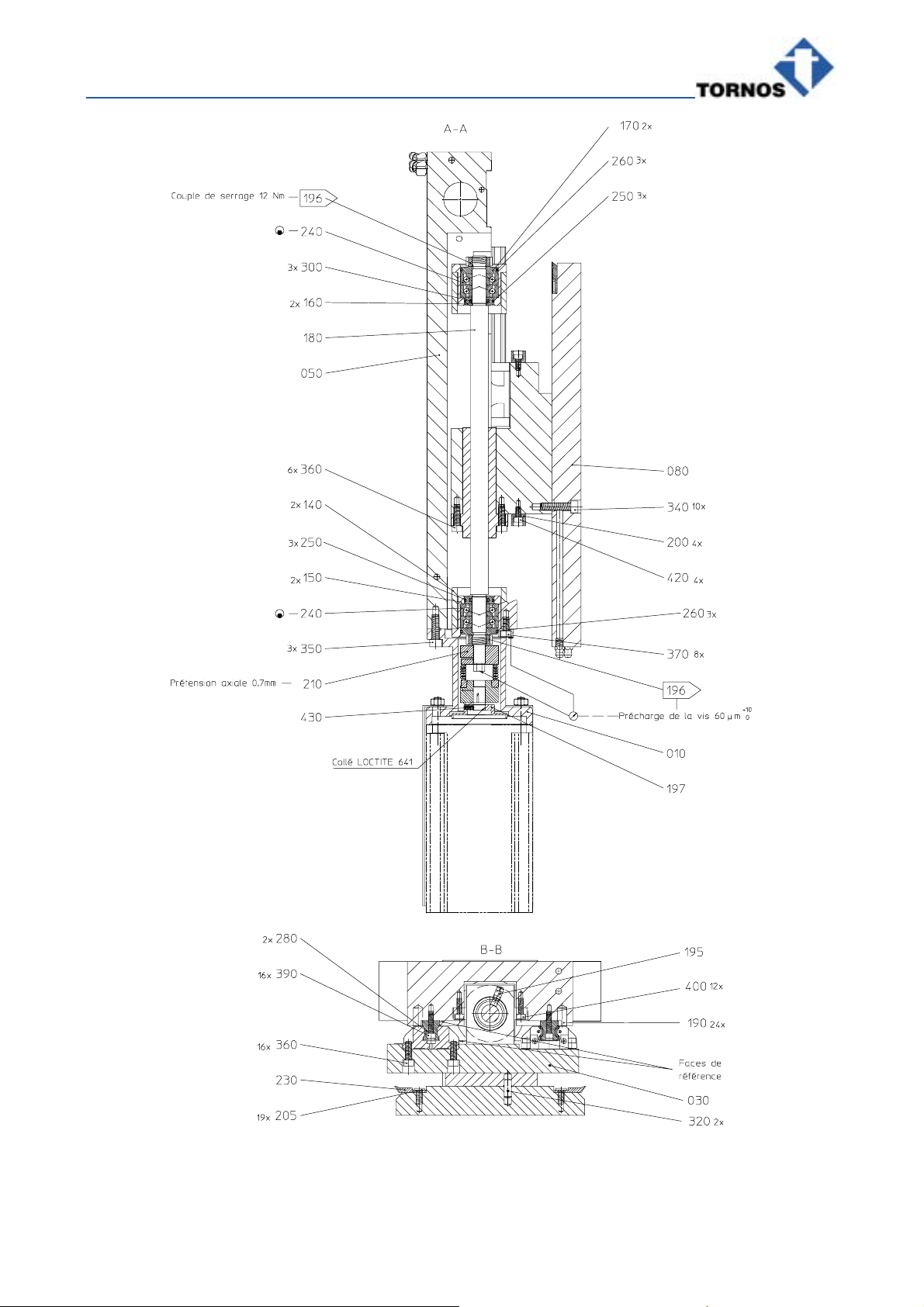

305016f1

This manual suits for next models

1

Table of contents

Other tornos Industrial Equipment manuals