tornos MultiAlpha 6x32 Installation instructions

Copyright ©1999-2011TORNOS SA CH-2740 MOUTIER http://www.tornos.ch

SAFETY INSTRUCTIONS

MultiAlpha 6x32

English version translated from the original version 300940 en

Attention !

Document to be kept to refer to it later on.

Attention !

Before handling the machine, each user is held to read first this instruction !

MultiAlpha 6x32

300940 en - 03/11

Behaviour in the event of an emergency

1. Stay calm --> 2. Think --> 3. Act

Raise the alarm

Who?

What?

Where

How many?

Others

Ambulance _____________________

Police _____________________

Fire brigade _____________________

Poisoning _____________________

Doctors _____________________

Hospital _____________________

Person raising the alarm

What happened?

Place, street name, number, access, floor

Number of people involved

Any particular dangers, hazardous chemical, etc.

Accident 1. Make the dangerous area secure.

2. Raise the Alarm.

3. Give first aid.

4. Inform the ambulance staff.

Position (s) of first aid box:

__________________________________________________________________

Fire 1. Notify the fire brigade.

2. Find shelter for yourself and others.

3. Close all windows and doors.

4. Inform the fire brigade staff.

5. Put the fire out.

Evacuation 1. Notify the people in danger and evacuate them.

2. Leave the premises using the stairs.

3. Go to the assembly point.

Assembly point: __________________________________________

Person in charge of keeping the emergency numbers, first aid boxes and training up-to-date:

_______________________________________________________________________________________________________

source suvaPro

Mandatory !

Apply the regulations in force in your company. If there are no regulations, you

can adapt the above example to your country’s legislation and to the specific

needs of your company.

MultiAlpha 6x32

300940 en - 03/11

>>>

MultiAlpha 6x32

300940 en - 03/11

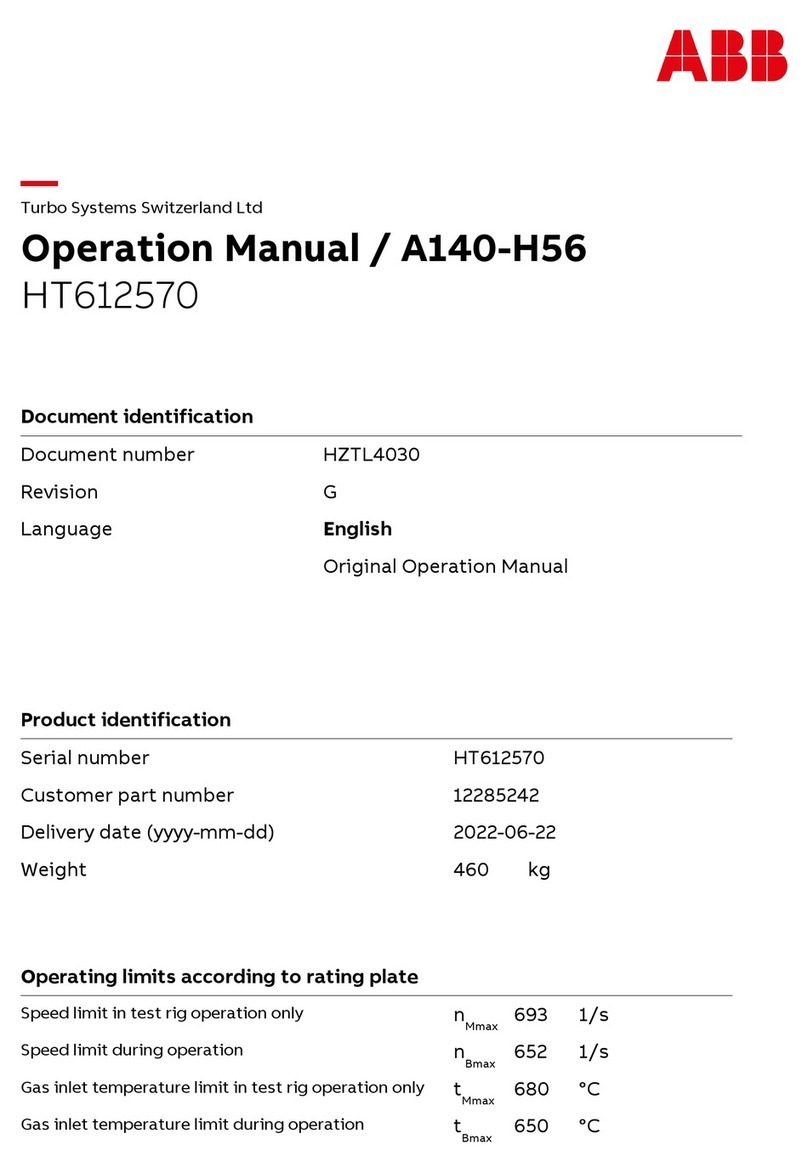

I. Identification

I.1. Document

Safety instructions MultiAlpha 6x32

No 300940 en

Version Manager

Version Date Description

03/11 31 March 2011 First version

I.2. Manufacturer

TORNOS SA

Rue Industrielle 111

CH-2740 MOUTIER / SUISSE

Tél. +41 (0)32 494 44 44

Fax +41 (0)32 494 49 03

www.tornos.ch

I.3. Product

- MultiAlpha 6x32

MultiAlpha 6x32

300940 en - 03/11

>>>

MultiAlpha 6x32

300940 en - 03/11

>>>

MultiAlpha 6x32

300940 en - 03/11

TABLE OF CONTENTS

1. Generalities 1-1...................................................

1.1. General information 1-1..............................................

1.1.1. Conformity to standards and directives 1-1...............................

1.1.2. Suitable use 1-1..........................................................

1.2. Safety principles 1-2.................................................

1.3. Significance of the safety instructions 1-2..............................

1.4. Failure to observe the safety regulations 1-2...........................

1.5. Operating instructions and advice 1-2................................

1.6. Definition of pictograms 1-3..........................................

1.6.1. General pictograms 1-3..................................................

1.6.2. Specific pictograms 1-5..................................................

2. Individual protection 2-1...........................................

2.1. General rules 2-2....................................................

2.1.1. Laser 2-2................................................................

2.2. Safety to observe during production 2-3..............................

2.3. Safety to observe during maintenance 2-4............................

2.3.1. Operator maintenance 2-5..............................................

2.3.1.1 ISO maintenance symbols 2-5.................................................

2.3.2. Technician maintenance 2-6.............................................

2.3.2.1 Skills 2-6......................................................................

2.3.2.2 Parts 2-6.....................................................................

2.3.2.3 Safety precautions to take during maintenance work 2-7........................

2.4. Safety in the event of a fault 2-8......................................

2.4.1. Skills 2-8.................................................................

2.4.2. Parts 2-8.................................................................

3. Work environment 3-1.............................................

3.1. Order and cleanliness 3-2............................................

3.2. Conditions of use of the machine 3-2.................................

3.3. Oil spray and fume extraction 3-2....................................

3.3.1. Oil spray and fume extractor 3-3.........................................

3.3.1.1 Use 3-3......................................................................

3.3.1.2 Safety rules to comply with during installation 3-3...............................

3.4. Quality of the floor 3-5...............................................

3.5. Safety clearance 3-5................................................

3.6. Noise 3-6............................................................

3.7. Environment 3-6.....................................................

3.7.1. Machine Use 3-6.........................................................

3.7.2. Scrapping 3-6...........................................................

3.7.3. Regulations in force 3-6..................................................

MultiAlpha 6x32

300940 en - 03/11

4. Lubricants 4-1.....................................................

4.1. Lubricating 4-2......................................................

4.1.1. Restrictions 4-2...........................................................

4.1.2. Lubricant equivalence table 4-2..........................................

4.2. Cutting liquid 4-2....................................................

4.2.1. Restrictions 4-2...........................................................

4.2.2. Precautions to take during handling 4-3..................................

4.2.3. Cutting liquid equivalence table 4-3......................................

4.2.4. Optimising the cutting liquid use temperature 4-3.........................

4.2.5. Emulsion 4-3.............................................................

4.2.5.1 Restrictions 4-3...............................................................

4.2.6. High pressure unit 4-4....................................................

4.2.7. Cutting liquid cooling system 4-4.........................................

5. Machine Use 5-1..................................................

5.1. General rules 5-2....................................................

5.2. Handling the machine safely 5-3.....................................

5.2.1. Machine power on 5-3..................................................

5.2.2. Turning the machine off 5-4..............................................

5.3. Stopping the machine without turning it off 5-5........................

5.3.1. Intervention with machine in operation 5-5................................

5.3.2. Intervention with machine at a standstill 5-5...............................

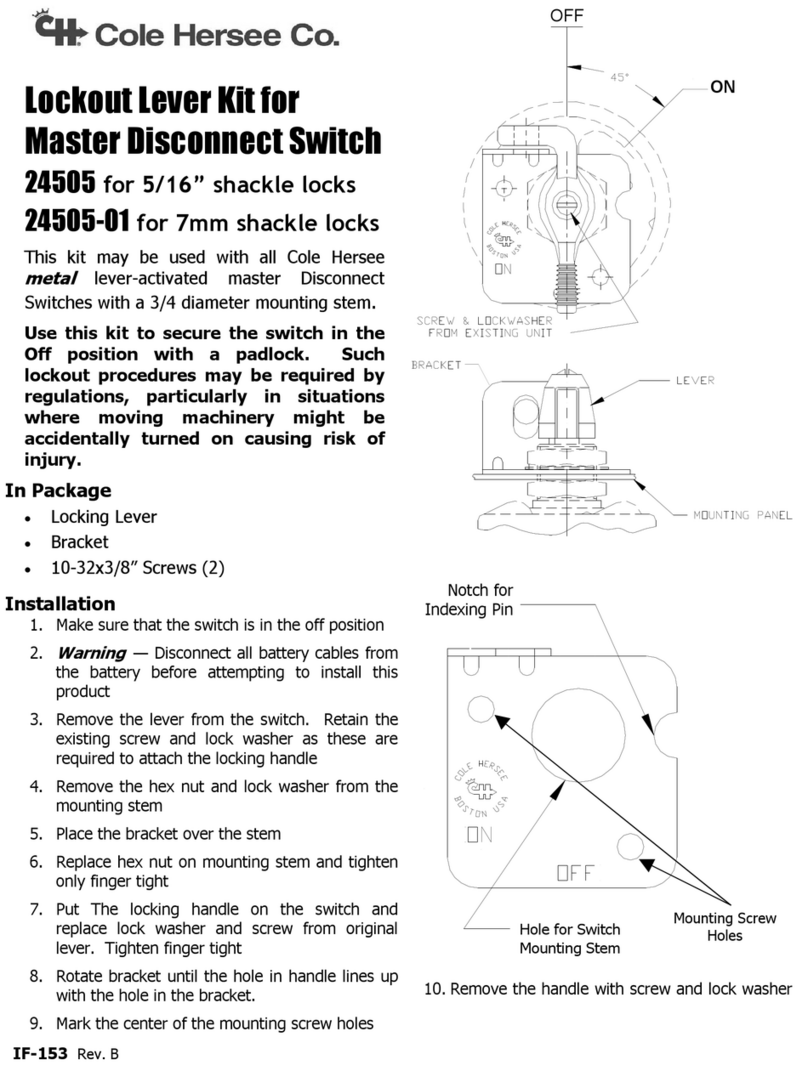

5.4. Locking the machine energy sources for maintenance tasks 5-6.......

5.4.1. Release and locking 5-6.................................................

5.5. Emergency stop 5-7.................................................

5.5.1. Restarting 5-7............................................................

5.6. Opening/closing the electrical cabinet 5-8...........................

5.6.1. Opening the door on the AP1 power plate 5-8............................

5.6.2. Opening the door on the CNC AP3 plate 5-9.............................

5.6.3. Opening the rear door 5-10...............................................

5.6.4. Moving back the cabinet 5-11............................................

5.6.5. Opening the access panel to the entry transformer 5-12....................

5.7. Opening/closing of doors in loading and unloading zones 5-13.........

5.7.1. Opening procedure 5-14..................................................

5.7.2. Closing procedure 5-14...................................................

5.8. Opening/closing machining doors 5-16................................

5.8.1. Definition of CONTINUOUS CYCLE and SETTING mode 5-18..................

5.8.2. Locking 5-18..............................................................

5.8.3. Unlocking 5-18............................................................

5.8.3.1 Unlocking in CONTINUOUS CYCLE mode 5-18....................................

5.8.3.2 Unlocking in SETTING mode 5-19................................................

5.9. Signal lamp 5-25......................................................

MultiAlpha 6x32

300940 en - 03/11

6. Machine protection parts 6-1......................................

6.1. General rules 6-2....................................................

6.1.1. Safety device check 6-2.................................................

6.1.2. Cleaning the machining areas 6-3........................................

6.1.3. Removable chip tank 6-4................................................

6.1.4. Danger in the loading zone 6-5...........................................

6.1.5. Danger in the machining area 6-8........................................

6.1.6. Danger in the controlled parts unloading zone 6-10........................

6.1.7. Danger in the palletising zone 6-11........................................

6.2. Machine protection components 6-12.................................

6.2.1. Regular replacement of transparent guards 6-12...........................

6.2.2. Detection and locking of closed doors 6-14................................

6.3. Electrical protection parts 6-15........................................

6.3.1. Electrical connection 6-16.................................................

6.3.2. Earthing 6-17.............................................................

6.3.3. Earthing of doors 6-18.....................................................

6.3.4. Circuit breaker 6-19.......................................................

6.4. Pneumatic protection part 6-20.......................................

6.4.1. Pneumatic connection 6-20...............................................

7. Fire prevention 7-1................................................

7.1. Fire prevention 7-2...................................................

7.2. Fire prevention device 7-4............................................

7.3. Minimum room volume 7-4...........................................

7.4. Ventilation of premises 7-4...........................................

8. Barfeeder 8-1.....................................................

8.1. Barfeeder 8-2........................................................

MultiAlpha 6x32

300940 en - 03/11

>>>

Safety instructions MultiAlpha 6x32 - 1. Generalities

300940 en - 03/11 1-1

1. Generalities

Mandatory !

Before handling / operating the machine, read first the:

- “GENERALITIES AND WRITING CONVENTIONS” booklet;

- this document.

1.1. General information

This document is written based on the information available at the moment of its

publication.

TORNOS SA may not be held responsible, however, in case of errors or omissions.

The original language of this document is French.

The information contained in this document is the property of TORNOS SA which

is intended exclusively for internal customer usage, and may not be disclosed to

or reproduced for third parties.

1.1.1. Conformity to standards and directives

“CE” Marking indicates conformity with the European standards in terms of

safety, health, the environment and the protection of users.

1.1.2. Suitable use

The indications given in this manual must be respected, particularly safety instruc

tions.

1. Generalities - Safety instructions MultiAlpha 6x32

300940 en - 03/11

1-2

1.2. Safety principles

Attention ! Before handling the machine, each user is held

to read firste this instruction !

The user should read and understand this manual before handling and/or operat

ing the machine.

For any further information, please contact the manufacturer or your local repres

entative.

Attention ! Failure to follow these instructions may cause

serious accidents !

All machine users such as:

- the owner;

- servicemen, installation staff, maintenance staff or other related people;

- user, operator, commissioner, programmer, operator, mechanic;

must under all circumstances read and strictly observe the following instructions.

These instructions also apply for the options, components, installations, devices

and systems relating to the machine.

1.3. Significance of the safety instructions

All the safety and protection instructions provided in this manual must be

observed in order to avoid all reversible and irreversible personal injuries, material

damage or environmental pollution. Similarly, the legal regulations, accident pre

vention and environmental protection measures, as well as technical regulations

aimed at appropriate and risk-free work methods in force in the country and

place of use of the machine must be respected.

1.4. Failure to observe the safety regulations

Failure to observe the safety and protection regulations, as well as the existing

legal and technical regulations could result in reversible or irreversible personal

injuries, material damage or environmental pollution.

Caution !

TORNOS SA shall not be held liable if these instructions are not followed.

1.5. Operating instructions and advice

The operating instructions and advice provided by the supplier with the machine

or after its delivery must be passed on to anyone handing and/or operating the

machine or responsible for it in any way.

These persons must read and strictly follow these instructions.

The instructions must be kept up-to-date and stored in a clean place. Anyone

likely to work on the machine should have access to the instructions.

Safety instructions MultiAlpha 6x32 - 1. Generalities

300940 en - 03/11 1-3

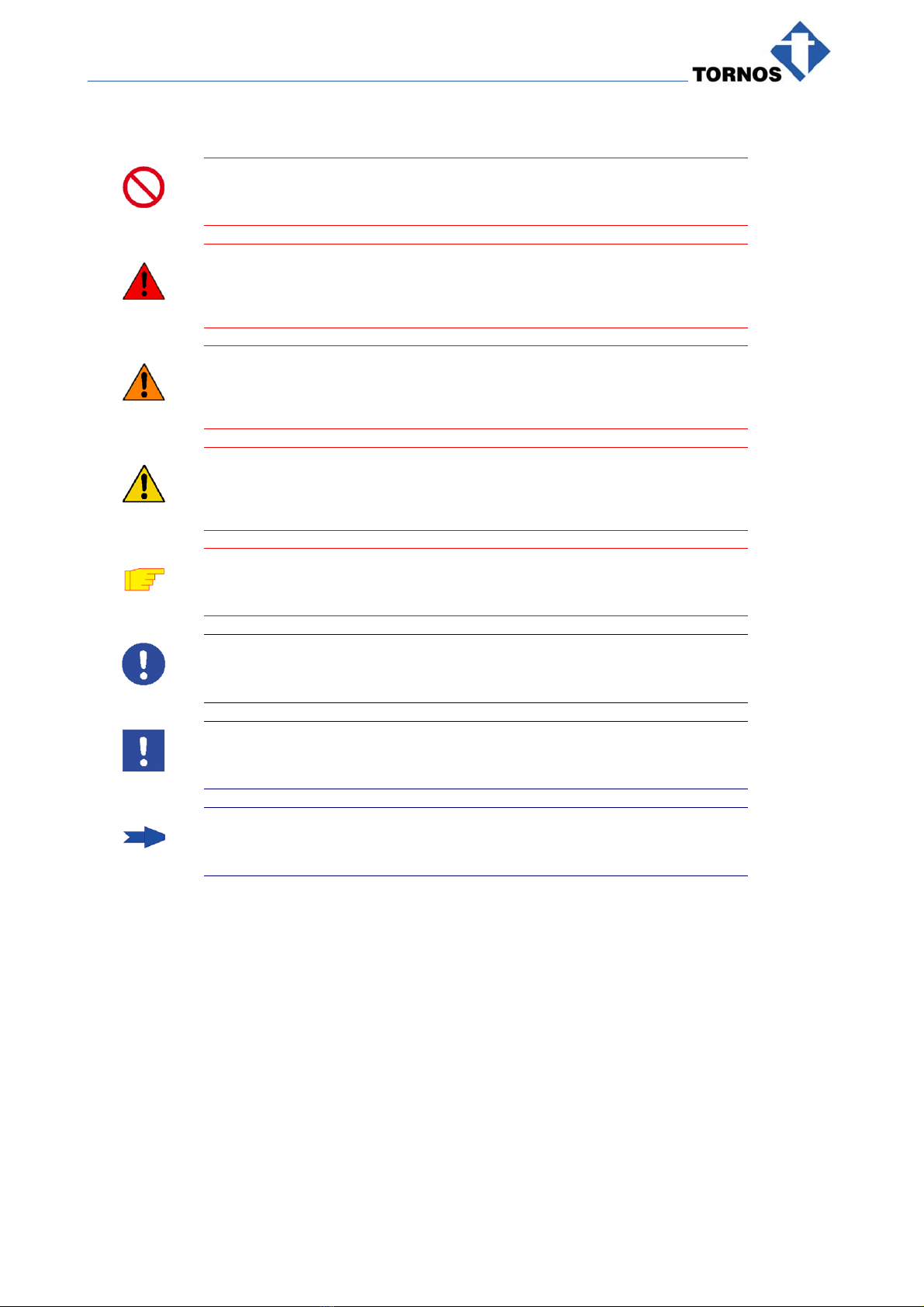

1.6. Definition of pictograms

1.6.1. General pictograms

Note !

Warning and danger pictograms are used in this manual and on the machine.

They indicate safety instructions, providing safety related information:

-for the control and safe use of the machine by exposed persons, the

operators,

- as well as for the environment and the machine.

The user is required to respect and ensure these safety instructions are respected.

If the regulations in the country of installation are stricter, the latter apply.

Note !

The danger level is determined according to the following rule:

1 = Light danger.

2 = Minor danger.

3 = Average danger.

4 = Major danger.

1. Generalities - Safety instructions MultiAlpha 6x32

300940 en - 03/11

1-4

Pictogram Definition Danger

Level

Prohibition !

Prohibiting indication to be absolutely respect. 4

Danger !

Indicates a direct serious warning. Indicates a serious danger of death or serious

injury.

4

Warning !

Indicates a machine element or action which may cause serious injury or affect

health.

3

Attention !

Indicates incorrect actions which may cause injury or serious damage to the

machine or environment.

2

Caution !

Warning, preventive process to take into account. 1

Mandatory !

Directive, measure to apply.

Info !

Comment related to safety.

Note !

General comment - technical.

Safety instructions MultiAlpha 6x32 - 1. Generalities

300940 en - 03/11 1-5

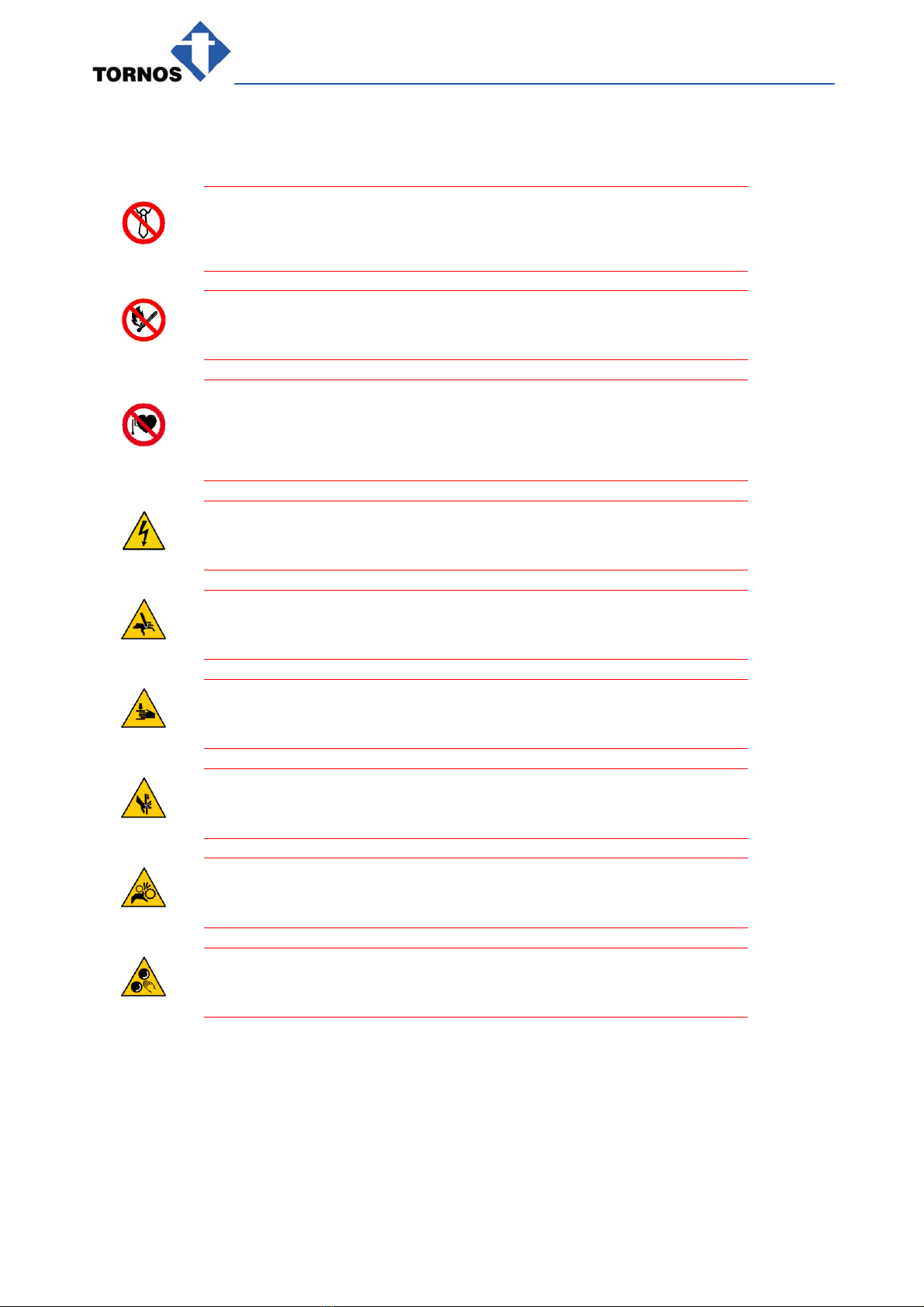

1.6.2. Specific pictograms

Pictogram Definition Danger

Level

Prohibition !

Wearing loose clothing, long hair, necklaces, rings and all other objects exposes the

operator to the risk of being drawn in or crushed.

4

Prohibition !

Naked flames and smoking strictly prohibited. 4

Prohibition !

Pacemakers forbidden.

It is strictly forbidden for anyone fitted with a pacemaker to operate the spindle

motors or quill drives.

4

Danger !

Electrical danger. 4

Danger !

Danger of crushing. 4

Danger !

Danger of crushing. 4

Danger !

Danger of being cut. 4

Danger !

Danger of being drawn in or crushed. 4

Danger !

Danger of being snatched. 4

1. Generalities - Safety instructions MultiAlpha 6x32

300940 en - 03/11

1-6

Pictogram Definition Danger

Level

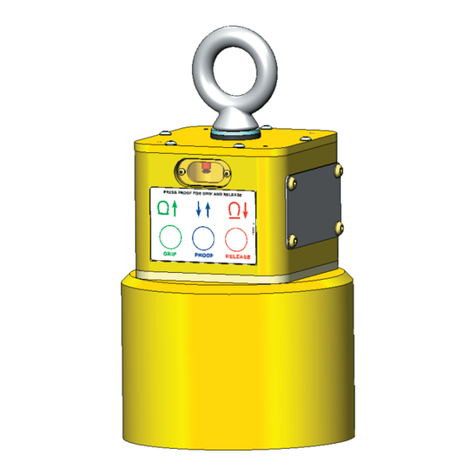

Danger !

Suspended load. 4

Danger !

Exposure to magnetic field.

When working on the spindle motors or quill drives, the operator is exposed to the

significant magnetic field of the rotor.

4

Danger !

Danger of being burned. 3

Danger !

Danger of falling. 2

Danger !

Danger of slippage and injury. 2

Danger !

Presence of laser beam. 4

Danger !

Presence of sharp chips. 2

Mandatory !

Wear gloves.

Mandatory !

Protective headsets must be worn.

Safety instructions MultiAlpha 6x32 - 1. Generalities

300940 en - 03/11 1-7

Pictogram Definition Danger

Level

Mandatory !

Goggles or eye protection devices are mandatory.

Mandatory !

Wear safety shoes.

Mandatory !

Perform all maintenance as described in the chapter entitled Maintenance.

Mandatory !

Padlock mandatory.

Mandatory !

Lubrication mandatory.

Mandatory !

Goggles or eye protection devices against ionising rays are mandatory

(laser, UV, infrared).

Mandatory !

Consult the documentation.

1. Generalities - Safety instructions MultiAlpha 6x32

300940 en - 03/11

1-8

>>>

Table of contents

Other tornos Industrial Equipment manuals