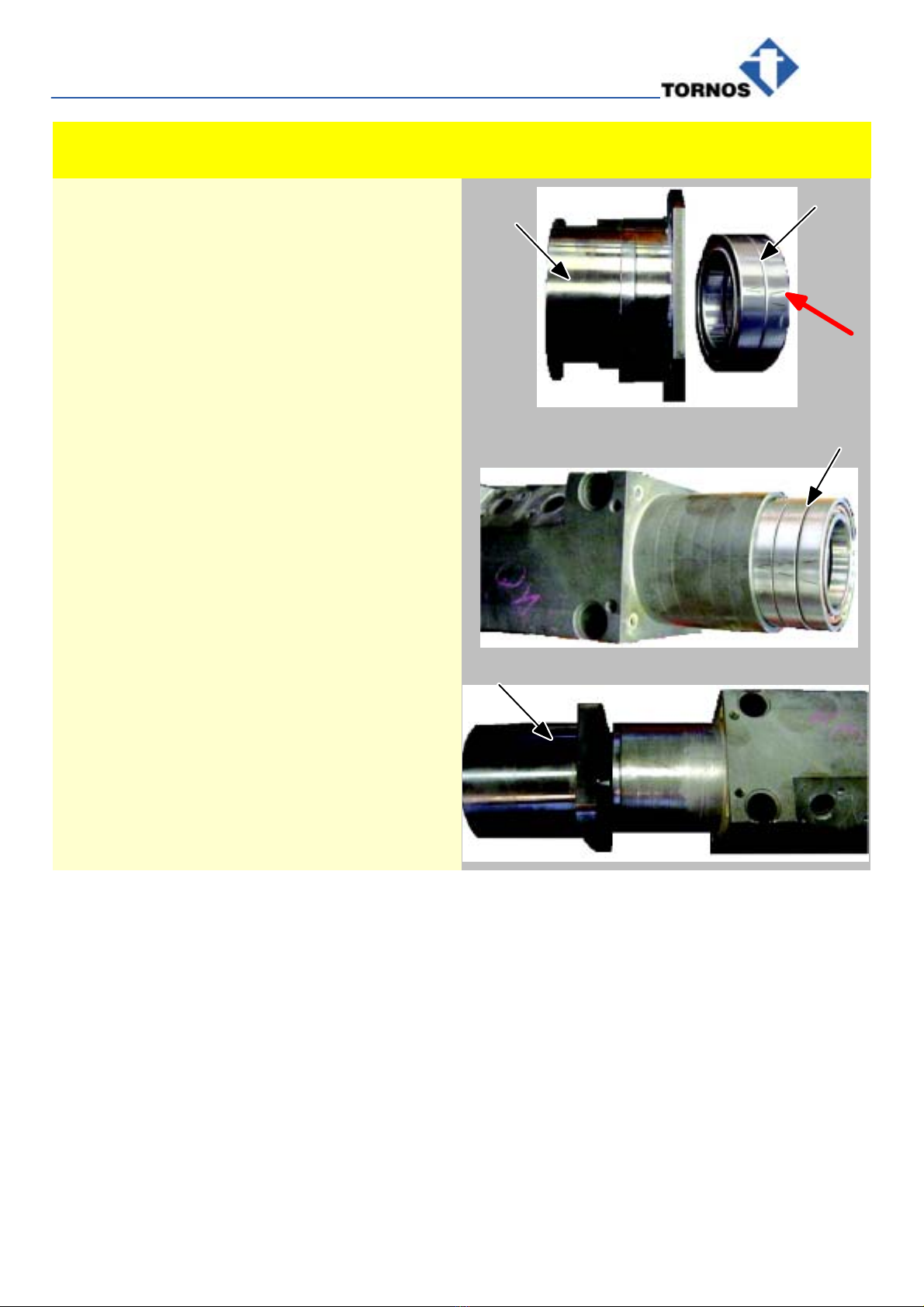

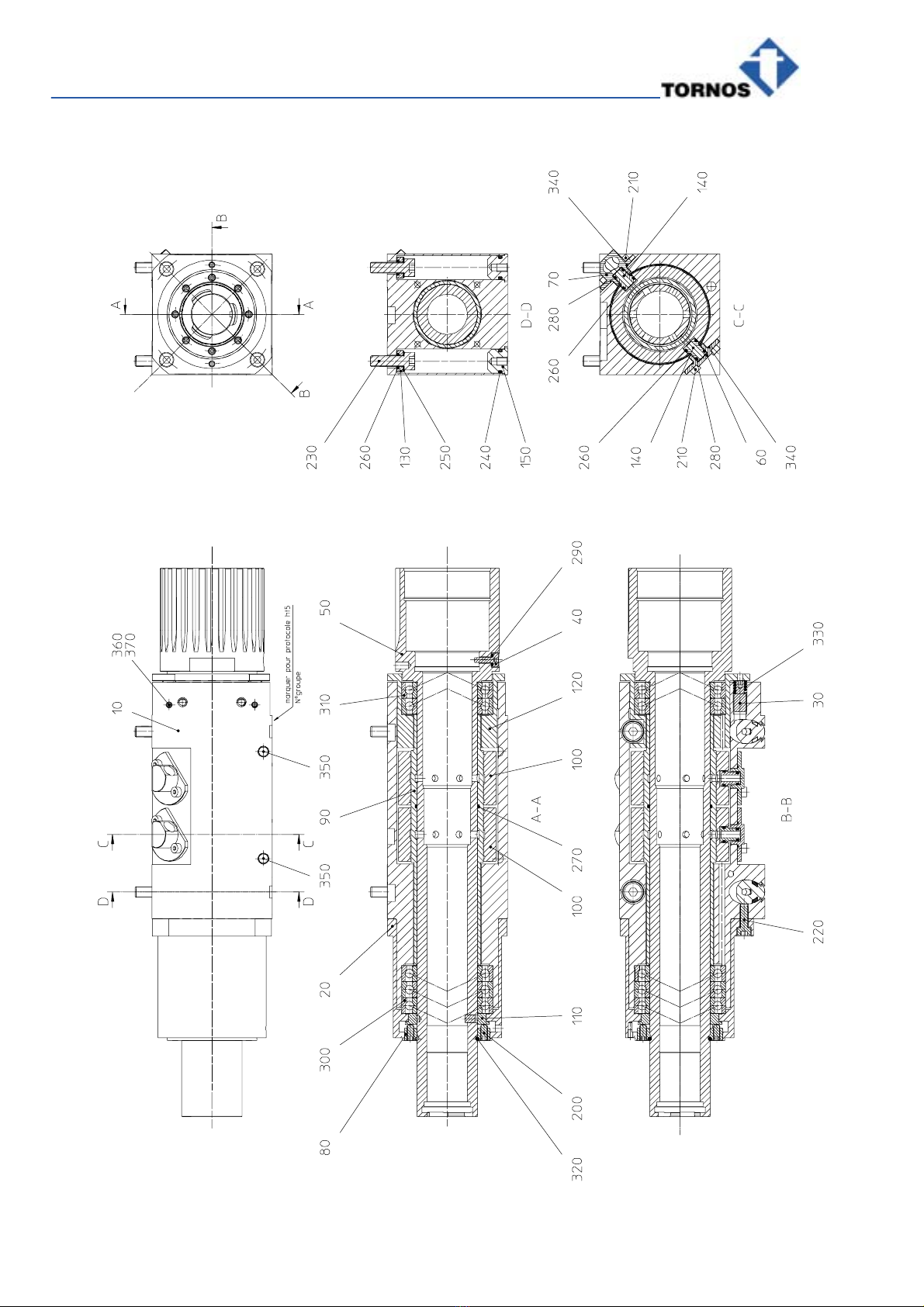

tornos DECO 20 Headstock Revision Manual

Table of contents

Other tornos Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Proluxe

Proluxe DPR2000 Operation manual

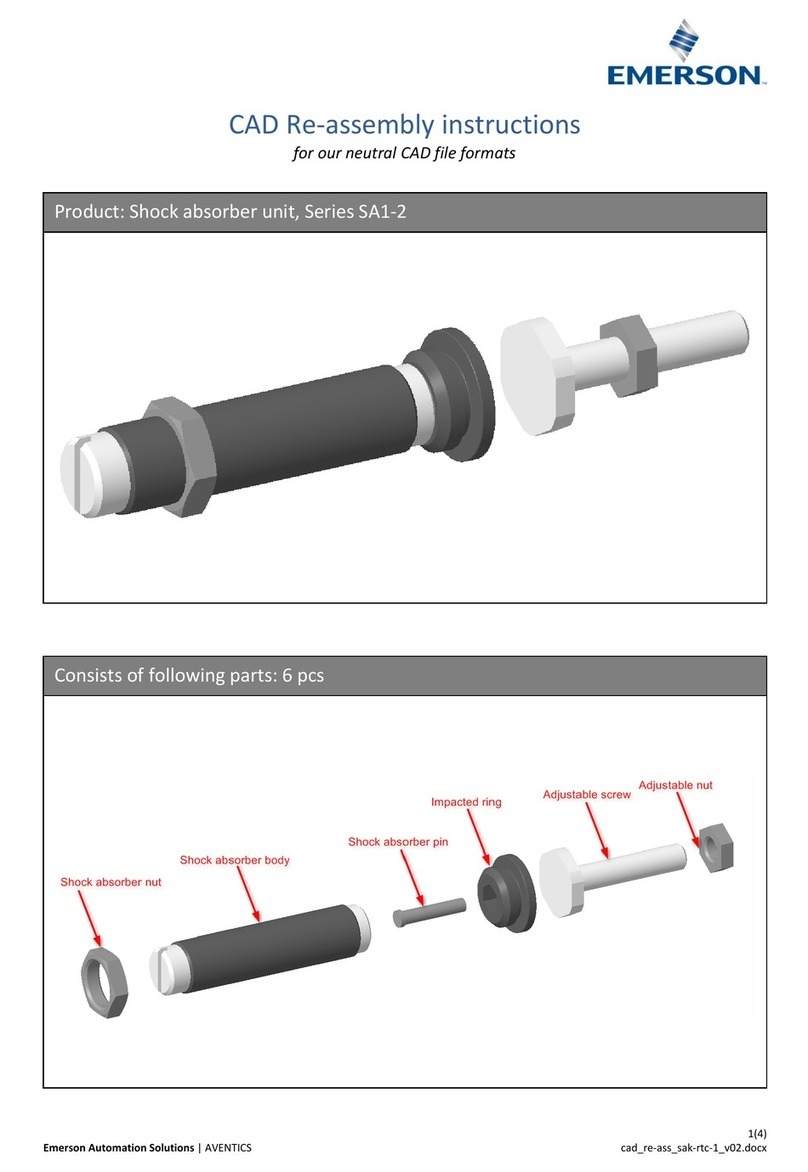

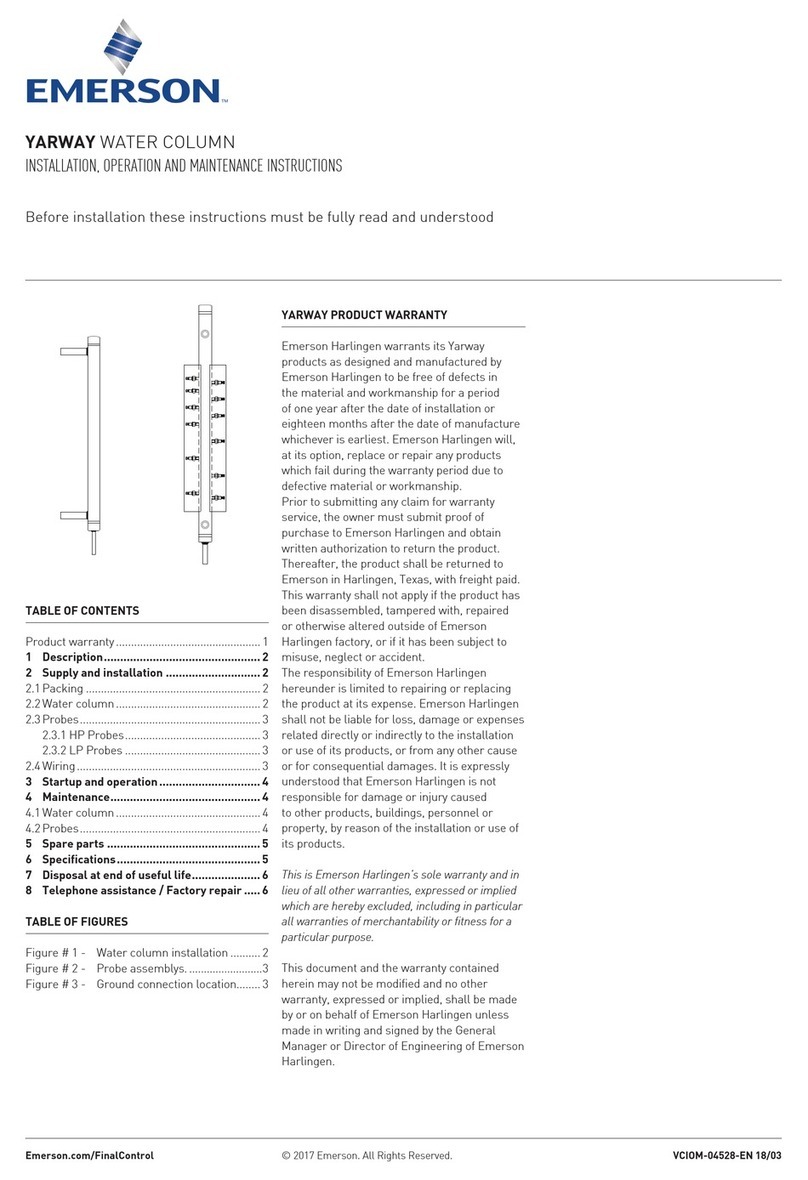

Emerson

Emerson SA1-2 Series RE-ASSEMBLY INSTRUCTIONS

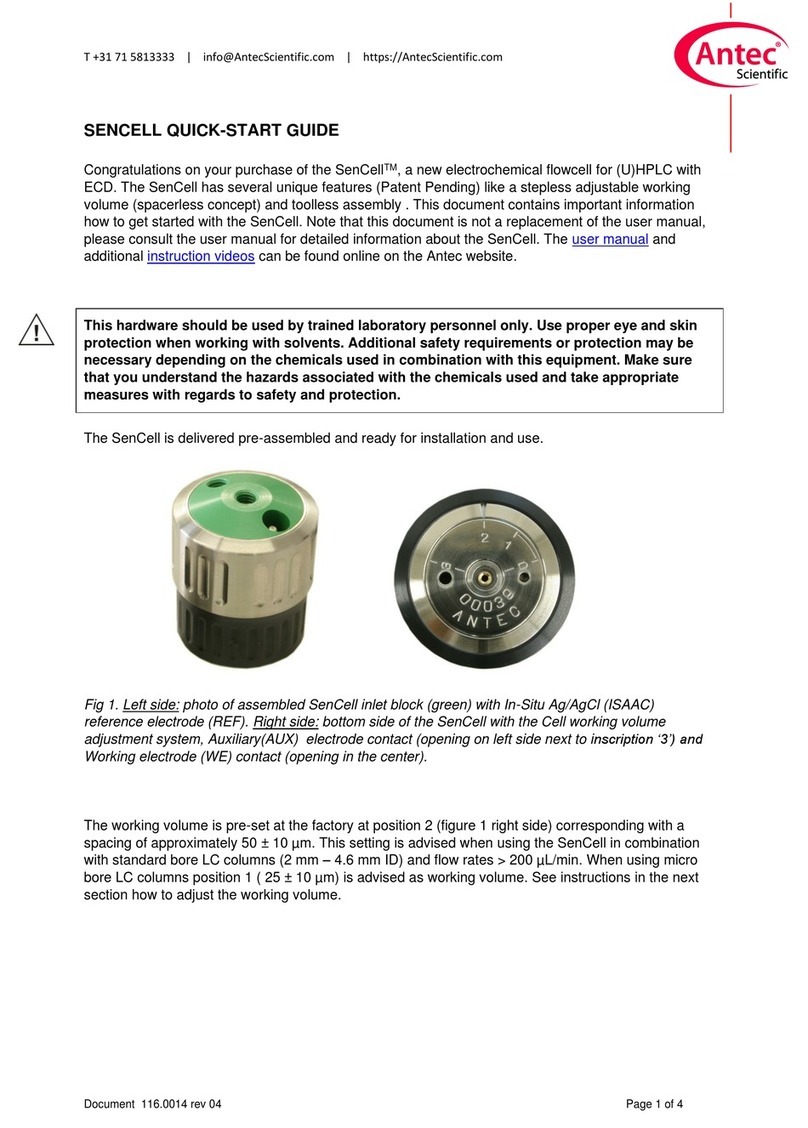

Antec Scientific

Antec Scientific SenCell quick start guide

Georg Fischer

Georg Fischer Signet 2630-X instructions

Emerson

Emerson Yarway Installation, operation and maintenance instructions

Altra Industrial Motion

Altra Industrial Motion Warner Electric PB-120 installation instructions

B&R

B&R Power Panel 500 Series user manual

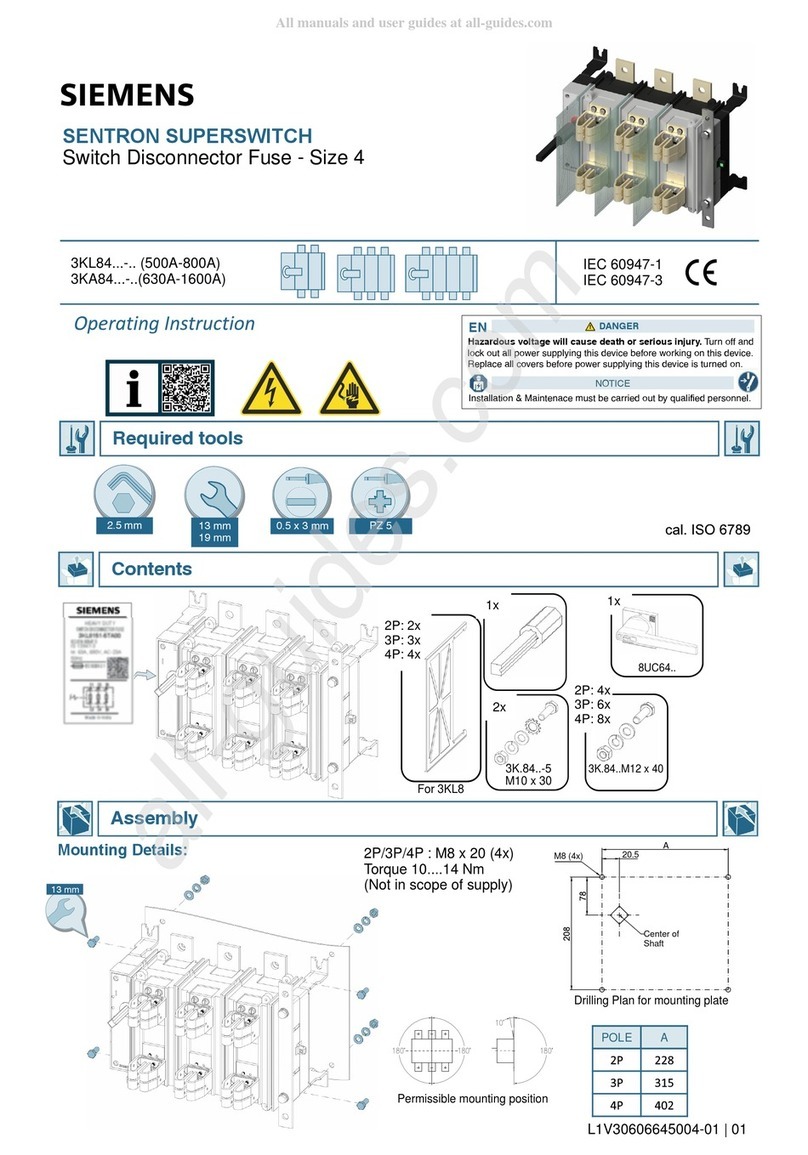

Siemens

Siemens SENTRON SUPERSWITCH 3KL84 Series Operating instruction

Koganei

Koganei YMDA Series Compact & direct mounting

Metso Outotec

Metso Outotec Lokotrack ST3.8 DRIVING INSTRUCTION

Barford

Barford SR124 Operator's manual & parts list

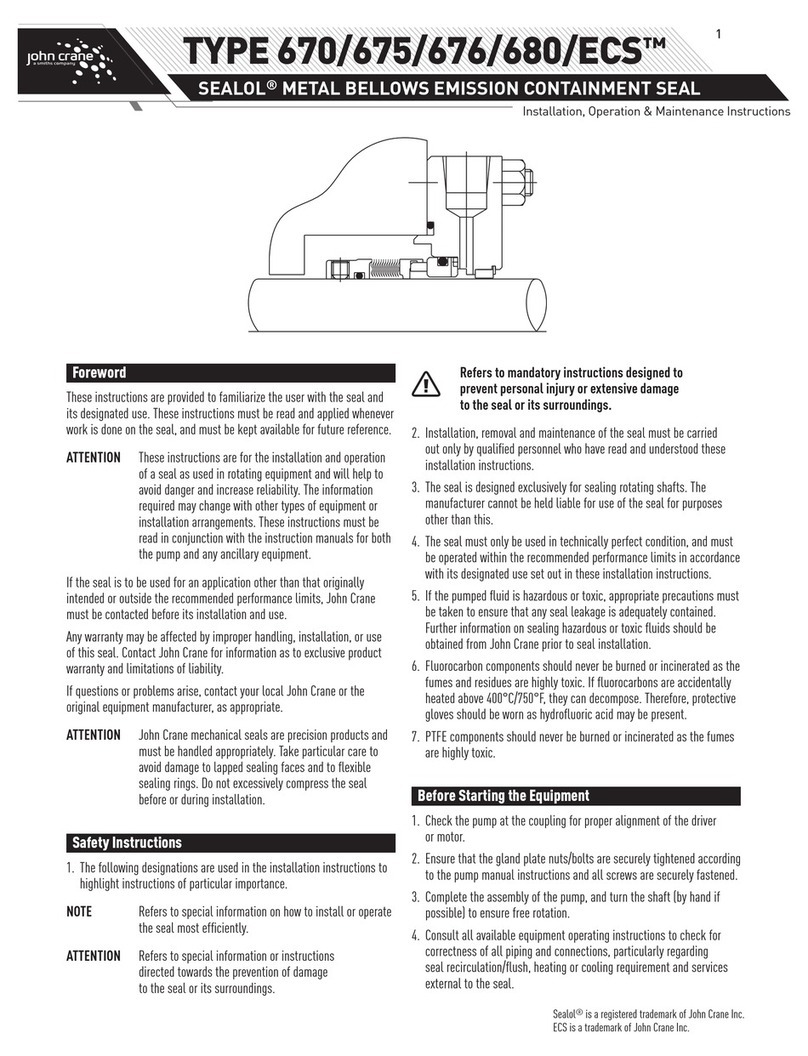

John Crane

John Crane SEALOL 670 Installation, operation & maintenance instructions