Toro HoverPro 450 User manual

FormNo.3381-674RevA

HoverPro450/500/550Machine

ModelNo.02602—SerialNo.314000001andUp

ModelNo.02604—SerialNo.314000001andUp

ModelNo.02606—SerialNo.314000001andUp

Operator'sManual

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.Keepthismanualforfuture

reference.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

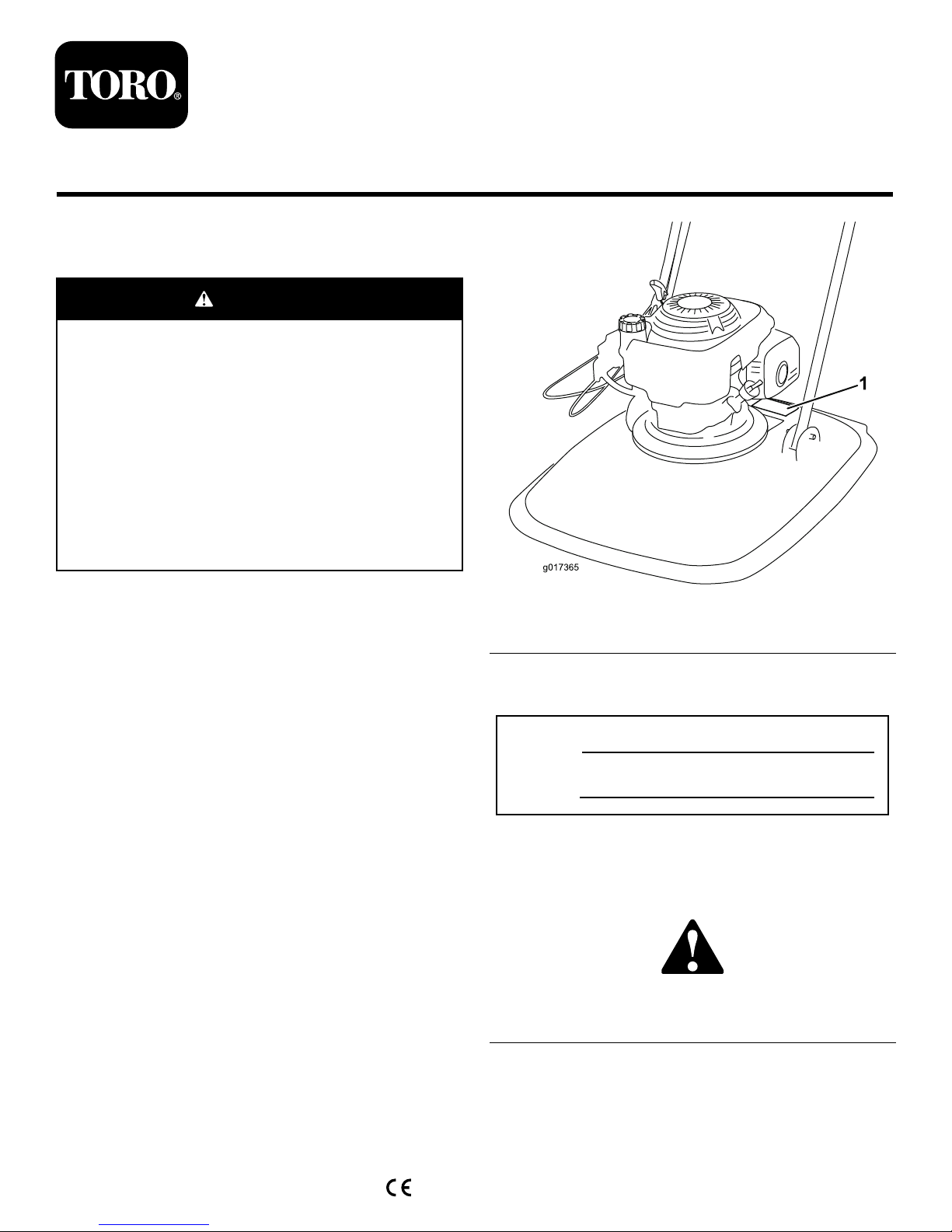

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.

g017365

1

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved*3381-674*A

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1349.Ascongured

tomeetsafety,emission,andoperatingrequirements,the

actualenginehorsepoweronthisclassmachinewillbe

signicantlylower.

Contents

Introduction..................................................................1

GeneralOperation..................................................2

SlopeOperation......................................................3

Children.................................................................3

Service...................................................................3

SoundPressure.......................................................4

SoundPower..........................................................4

Vibration................................................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................7

1AssemblingtheHandle..........................................7

2FillingtheEnginewithOil......................................7

ProductOverview..........................................................9

Operation.....................................................................9

FillingtheFuelTank................................................9

CheckingtheEngineOilLevel.................................10

AdjustingtheCuttingHeight....................................11

StartingtheEngine.................................................11

AdjustingtheChoke...............................................12

StoppingtheEngine...............................................12

OperatingTips......................................................13

Maintenance.................................................................13

RecommendedMaintenanceSchedule(s)......................13

PreparingforMaintenance.......................................15

ReplacingtheAirCleaner........................................15

ChangingtheEngineOil.........................................15

ServicingtheSparkPlug..........................................16

ReplacingtheFlexiblade/Cutterbar...........................16

CleaningtheMachine..............................................17

Storage........................................................................17

PreparingtheMachineforStorage............................17

Troubleshooting...........................................................18

Safety

Thiscuttingmachinecanamputatehandsandfeetand

throwobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjuryordeath.

ThefollowingsafetysectionisadaptedfromANSI

B71.4–2012.

GeneralOperation

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforestarting.

•Donotputhandsorfeetnearorunderthemachine.

•Onlyallowresponsibleadults,whoarefamiliarwiththe

instructions,tooperatethismachine.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Cleartheareaofobjectssuchasrocks,wire,toys,etc.,

whichcouldbethrownbythebladeorcuttingline.Stay

behindthehandlewhentheengineisrunning.

•Besuretheareaisclearofbystandersbeforeoperating.

Stopmachineifanyoneentersthearea.

•Donotoperatemachinebarefootedorwhilewearing

sandals.Alwayswearsubstantialfootwearandlongpants.

•Donotpullmachinebackwardunlessabsolutely

necessary.Alwayslookdownandbehindbeforeand

whilemovingbackward.

•Neverdirectdischargedmaterialtowardanyone.Avoid

dischargingmaterialagainstawallorobstruction.

Materialmayricochetbacktowardtheoperator.

•Stoptheengineofthemachinewhencrossingsurfaces

otherthangrass,andwhentransportingthemachineto

andfromtheareatobecut.

•Stoptheblade(s)ifthemachinehastobetiltedfor

transportationwhencrossingsurfacesotherthangrass,

andwhentransportingthemachinetoandfromthearea

tobemowed.

•Donotoperatemachinewithoutthesafetyprotective

devicesinplaceandworking.

•Neverleavearunningmachineunattended.

•Stoptheengine,waituntilthebladecomestoacomplete

stop,anddisconnectthesparkplugwirebeforecleaning

oruncloggingthemachine.

•Operatemachineonlyindaylightorgoodarticiallight.

•Donotoperatemachinewhileundertheinuenceof

alcoholordrugs.

•Neveroperatemachineinwetgrass.Alwaysbesureof

yourfooting;walk;neverrun.

•Ifthemachineshouldstarttovibrateabnormally,stop

theengineandcheckforthecauseimmediately.Vibration

isgenerallyawarningoftrouble.

2

•Alwaysweareyeprotectionwhenoperatingmachine.

•Seemanufacturer'sinstructionsforproperoperationand

installationofaccessories.Onlyuseaccessoriesapproved

bythemanufacturer.

SlopeOperation

Slopesareamajorfactorrelatedtoslipandfallaccidents,

whichcanresultinsevereinjury.Operationonallslopes

requireextracaution.Ifyoufeeluneasyonaslope,donot

mowit.

•Mowacrossthefaceofslopes;neverupanddown.

Exerciseextremecautionwhenchangingdirectionon

slopes.

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslipandfall

accident.Tallgrasscanhideobstacles.

•Donotmowonwetgrassorexcessivelysteepslopes.

Poorfootingcouldcauseaslipandfallaccident.

•Donotmowneardrop-offs,ditches,orembankments.

Youcouldloseyourfootingorbalance.

•WhenusingtheHoverPro,alwayskeepbothhandson

thehandlebar.

•Whencuttingsteepslopesfromthetopoftheslopeanda

longerreachisneeded,nevertietheHoverProtoarope,

usetheextendedhandlebarkitoption.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity.Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofaresponsibleadultotherthanthe

operator.

•Bealertandturnmachineoffifachildentersthearea.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayblockyourviewofachild.

Service

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedgasolinecontainer.

•Neverremovegascaporaddfuelwiththeengine

running.Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer,rather

thanfromagasolinedispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacegascapandtighten

securely.

WARNING

Exhaustcontainscarbonmonoxide,anodorless,

deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

GeneralService

•Neveroperatemachineinaclosedarea.

•Keepallnutsandboltstighttobesuretheequipmentis

insafeworkingcondition.

•Nevertamperwithsafetydevices.Checktheirproper

operationregularly.

•Keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveany

fuel-soakeddebris.Allowmachinetocoolbeforestoring.

•Ifyoustrikeaforeignobject,stopandinspectthe

machine.Repair,ifnecessary,beforestarting.

•Nevermakeanyadjustmentsorrepairswiththeengine

running.Disconnectthesparkplugwireandground

againstenginetopreventunintendedstarting.

•Machinebladesaresharp.Wrapthebladeorweargloves,

anduseextracautionwhenservicingthem.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Ifgasolineisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillageand

avoidcreatinganysourceofignitionuntilthegasoline

vaporhasdissipated.

3

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Neverpickuporcarryamachinewhiletheengineis

running.

•Stoptheengineanddisconnectthesparkplugwire,make

surethatallmovingpartshavecometoacompletestop:

–Beforeclearingblockages.

–Beforechecking,cleaning,orworkingonthemachine.

–Afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheHoverPro.

–Ifthemachinestartstovibrateabnormally.

–Wheneveryouleavethemachine.

–Beforerefueling.

•Reducethethrottlesettingduringengineshutdownand,

iftheengineisprovidedwithashut-offvalve,turnthe

fueloffattheconclusionofmowing.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.

•Localregulationsmayrestricttheageoftheoperator.

•Alwayswearearprotection.

•Donottiltthemachinewhenstartingtheengine,except

ifthemachinehastobetiltedforstarting.Inthiscasedo

nottiltitmorethanabsolutelynecessaryandliftonlythe

partwhichisawayfromtheoperator.

•Examinethemachineregularlyandreplacewornor

damagedpartsforsafety.

•02602only–Neverreplacethecuttingunitwithmetal

partsandonlyusecuttingheadsandcuttingelements

whicharesuitableforuseattheoperatingspeedofthe

HoverPro450."

SoundPressure

Thismachinehasasoundpressurelevelattheoperator’sear

of90dBA(model02602),88.5dBA(model02604),or88

dBA(model02606)whichincludesanUncertaintyValue(K)

of2dBA.Thesoundpressurelevelwasdeterminedaccording

totheproceduresoutlinedinEN836.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof100

dBA(modelexcept02602)or98dBA(models02604and

02606),whichincludesanUncertaintyValue(K)of2dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Vibration

Measuredvibrationlevelforthelefthand=5.4m/s2(models

02602and02604)or4.0m/s2(model02606)

Measuredvibrationlevelfortherighthand=6.2m/s2(model

02602),4.3m/s2(model02604),4.7m/s2(model02606).

UncertaintyValue(K)=3m/s2(model02602),2.5m/s2

(model02604),or2m/s2(model02606).

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

4

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

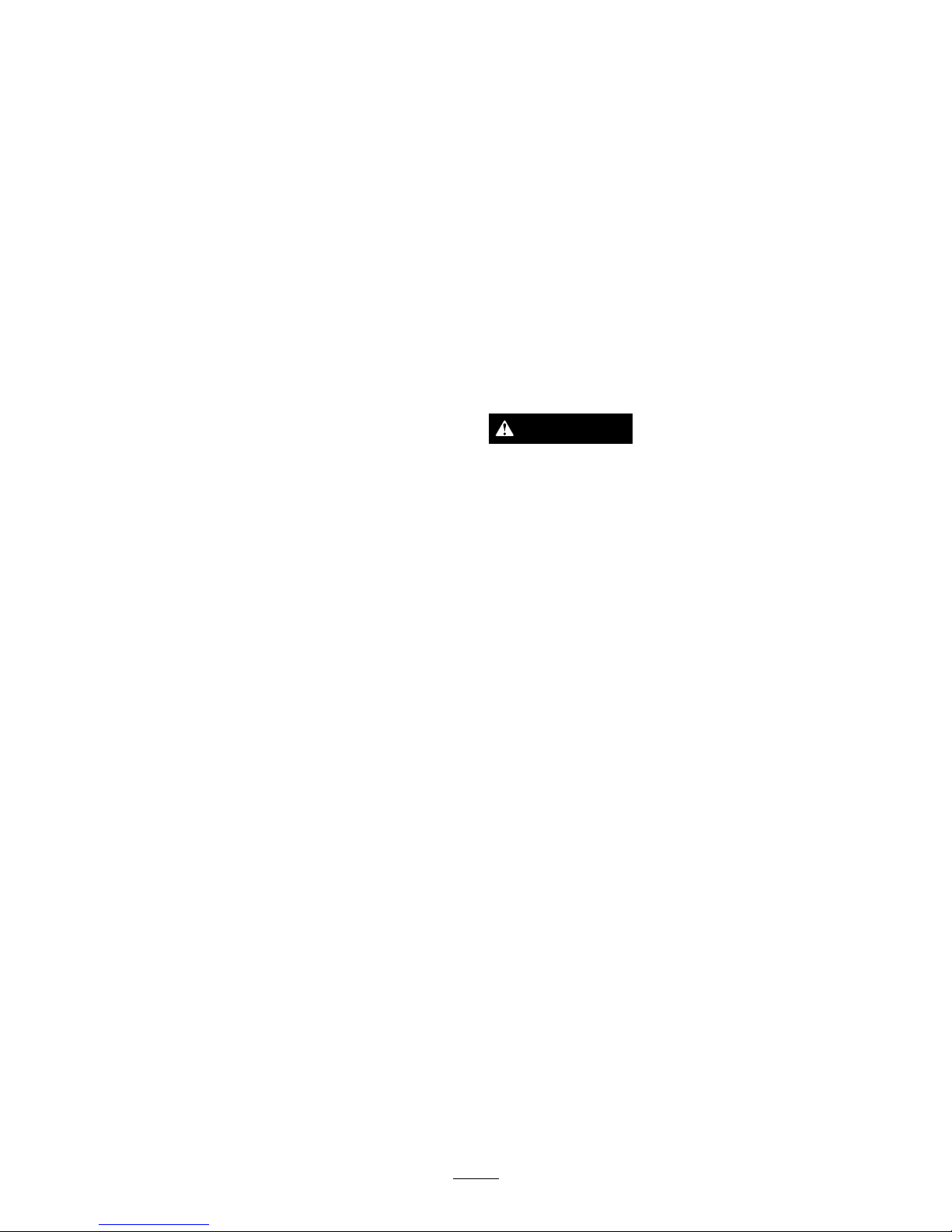

111-5392(model02602)

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

4.Thrownobjecthazard;keepbystandersatleast15m(49ft)

fromthemachine.

2.Cutting/dismembermenthazardofhandorfoot,Flexiblade

line;disconnectthewirefromthesparkplugbeforeworking

onthemachine;nevertmetalcuttingparts.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

3.Warning—weareyeandhearingprotection.

111-5393(models02604/02606)

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

4.Thrownobjecthazard;keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhandorfoot,mowerblade;

disconnectthewirefromthesparkplugbeforeworkingonthe

machine;nevertmetalcuttingparts.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

3.Warning—weareyeandhearingprotection.

5

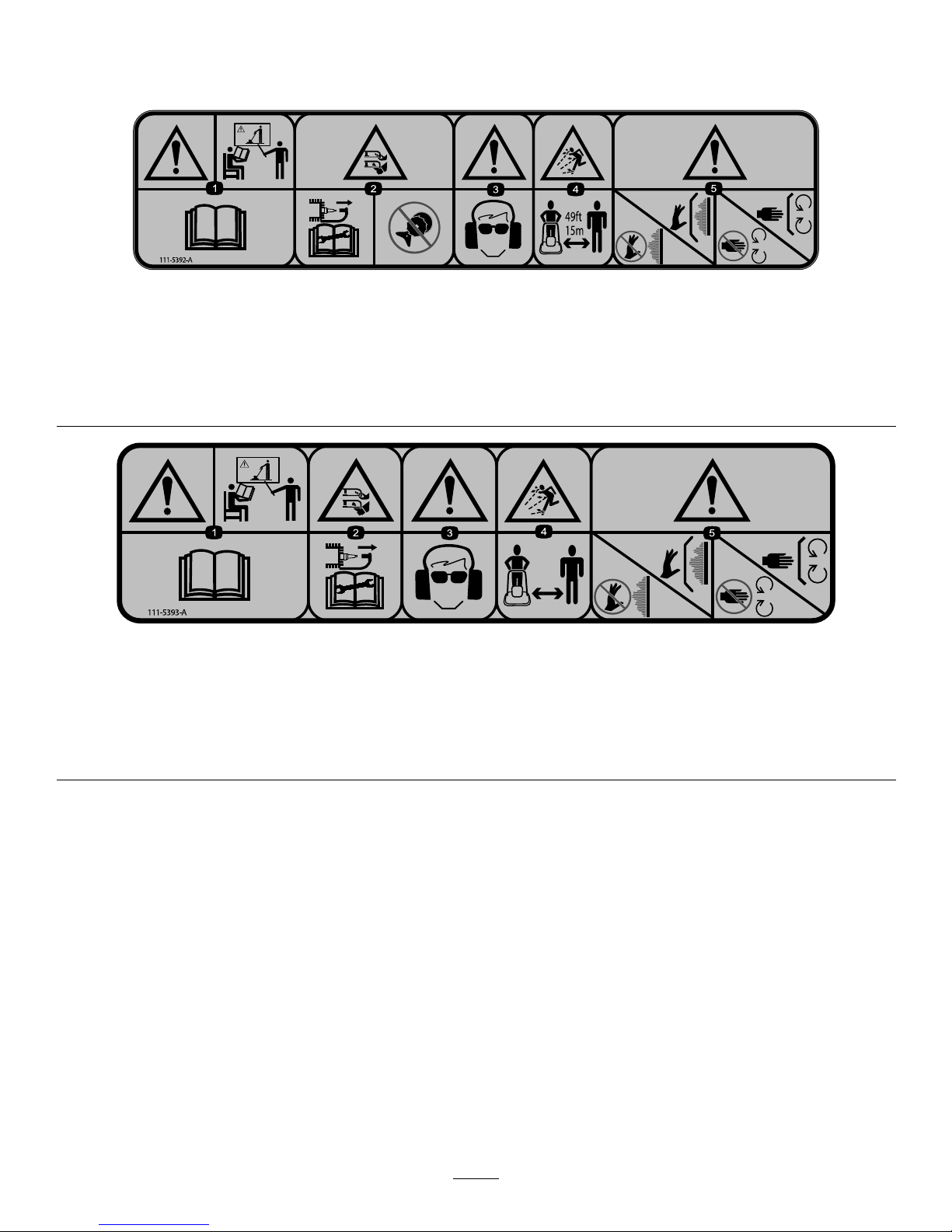

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

g017409

H295124

1.Instructionfororientationofthemachineforservicingthe

cuttingmechanismanddrainingoil.

g017410

H295159

1.Enginestop

1

2

3

g017414

1.Choke3.Run

2.Enginesymbol

6

Setup

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slide2bushesintotheframe.

g017333

1

2

3

4

5

6

Figure3

1.Lowerhandle4.Frame

2.Bushes5.Bolt

3.Nut6.Washers

2.Placethelowerhandlebetweenthebushesandsecure

itwith1handlebarbolt,2washers,and1nut.

Note:Placethelowerhandlebetweenthebusheswith

thekickstopassemblyontherighthandside.

3.Repeatfortheoppositeside.

4.Aligntheholesontheupperhandlewiththelower

handle.

g017328

1

2

3

4

5

Figure4

1.Upperhandle4.Ubolt

2.Handwheel5.Lowerhandle

3.Washer

5.FittheUboltthroughtheupperandlowerhandleand

secureitwithawasherandahandwheel.

6.Attachthethrottleassemblytotheoutsideofthe

handlebarandsecureitwithanutandapanscrew .

Figure5

7

2

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoilin

theengine.Beforestartingtheengine,lltheengine

withoil.

Max.ll:0.59l(20oz.),type:SAE30orSAE10W-30

detergentoilwithanAPIserviceclassicationofSF,SG,SH,

SJ,SL,orhigher.

1.Movethemachinetoalevelsurface.

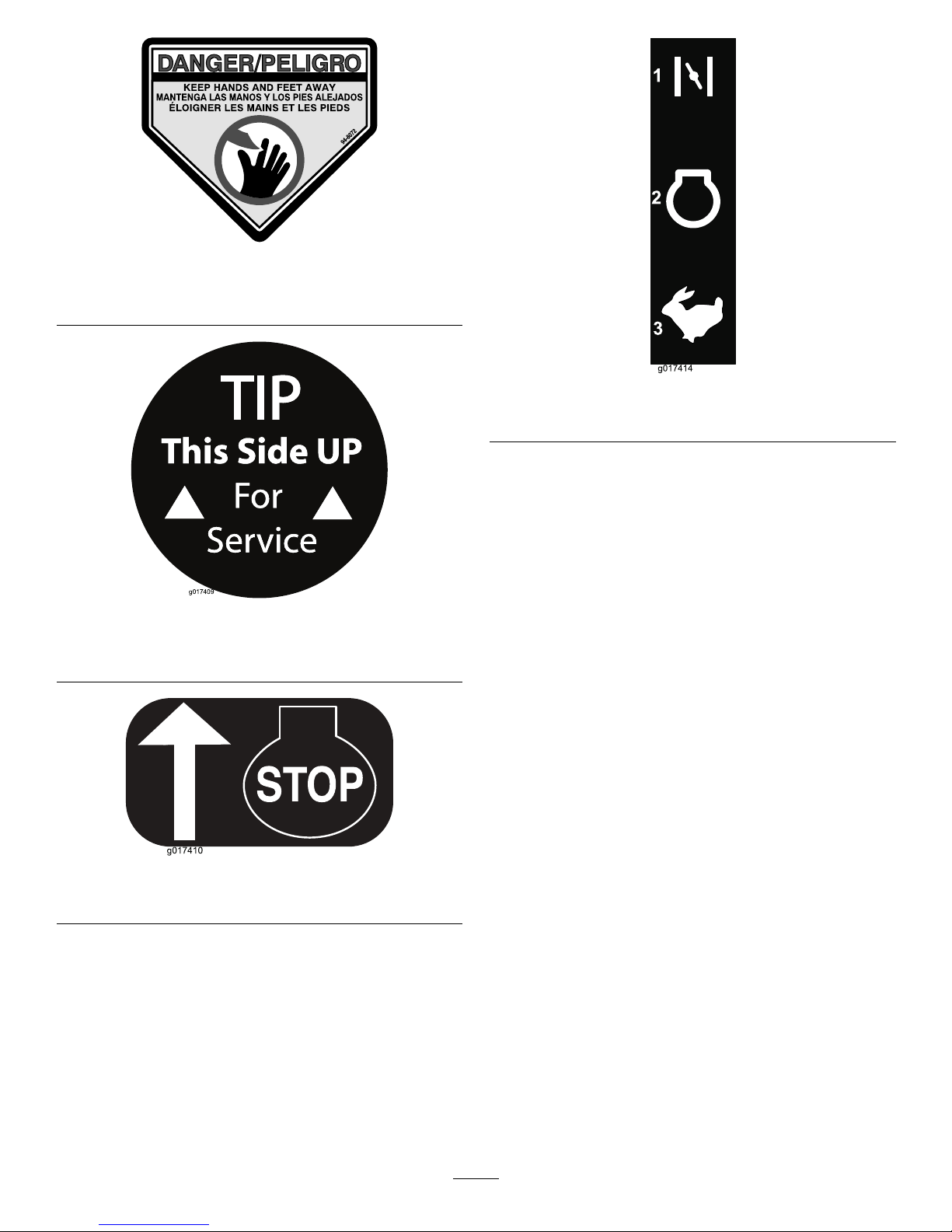

2.Removethedipstick(Figure6).

123

g017332

Figure6

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

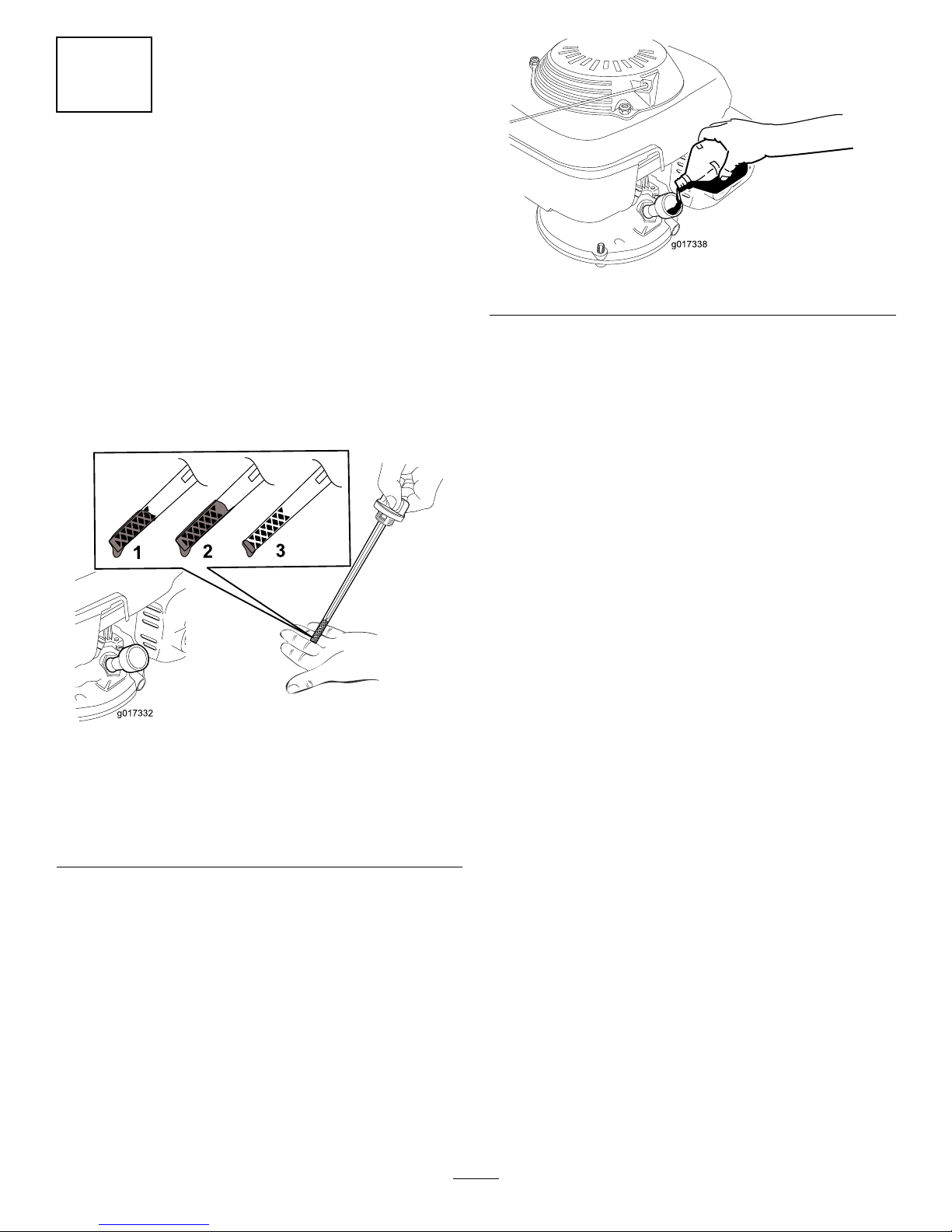

3.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewingin,

theoilllcapintothehole(Figure7).

g017338

Figure7

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure6.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChangingthe

EngineOil.

4.Installthedipstickandhandtightenitsecurely.

Important:

Change the engine oil after the r st 5

operating hour s

;changeityearlythereafter.Refer

toChangingtheEngineOil.

8

ProductOverview

g017341

1

2

3

4

5

6

7

8

9

Figure8

1.Fuelcap6.Handlebarsecuringknob

2.Enginestart7.Exhaustguard

3.Throttlecontrol8.Enginecover

4.Enginestophandle9.Dipstick

5.Handlebar

1

2

3

7

8

9

g017335

4

5

6

Figure9

1.Sparkplug6.Fuelcap

2.Exhaustguard7.Fingerguard

3.Exhaust8.Aircleaner

4.Dipstick9.Carburetor

5.Startergrip

Operation

FillingtheFuelTank

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

directlyonthegroundbeforelling,notina

vehicleoronanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

9

g017340

Figure10

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickandwipeitwithacleancloth.

3.Insert,butdonotscrewin,thedipstickintotheoil

llhole.

4.Removethedipstickandcheckit.

5.Todeterminetheproperoillevelonthedipstick,refer

toFigure11).

123

g017332

Figure11

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

6.Iftheoillevelislow,slowlypouroilintotheoilll

hole,wait3minutes,andchecktheoillevelonthe

dipstickbywipingthedipstickcleanandtheninserting,

butnotscrewingin,theoilllcapintothehole.

Note:Max.ll:0.59l(20oz.)SAE10W-30detergent

oilwithanAPIserviceclassicationofSF,SG,SH,

SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrectas

showninFigure11.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChangingthe

EngineOil.

7.Installthedipstickandhandtightenitsecurely.

Important:

Change the engine oil after the r st 5

operating hour s

;changeityearlythereafter.Refer

toChangingtheEngineOil.

10

AdjustingtheCuttingHeight

WARNING

Adjustingthecuttingheightmaybringyouinto

contactwiththemovingblade,causingserious

injury.

•Stoptheengineandwaitforallmovingparts

tostop.

•Weargloveswhilehandlingtheexibladeor

cutterbar.

CAUTION

Iftheenginehasbeenrunning,themuferwillbe

hotandcanseverelyburnyou.Keepawayfromthe

hotmufer.

Adjustthecuttingheightasdesired.

1.Turnthefuelswitchtotheoffposition.

2.Disconnectthewirefromthesparkplug.

3.Tiltthemachineonitsleftside.

4.Wearingprotectivegloves,removethe

exiblade/cutterbar.

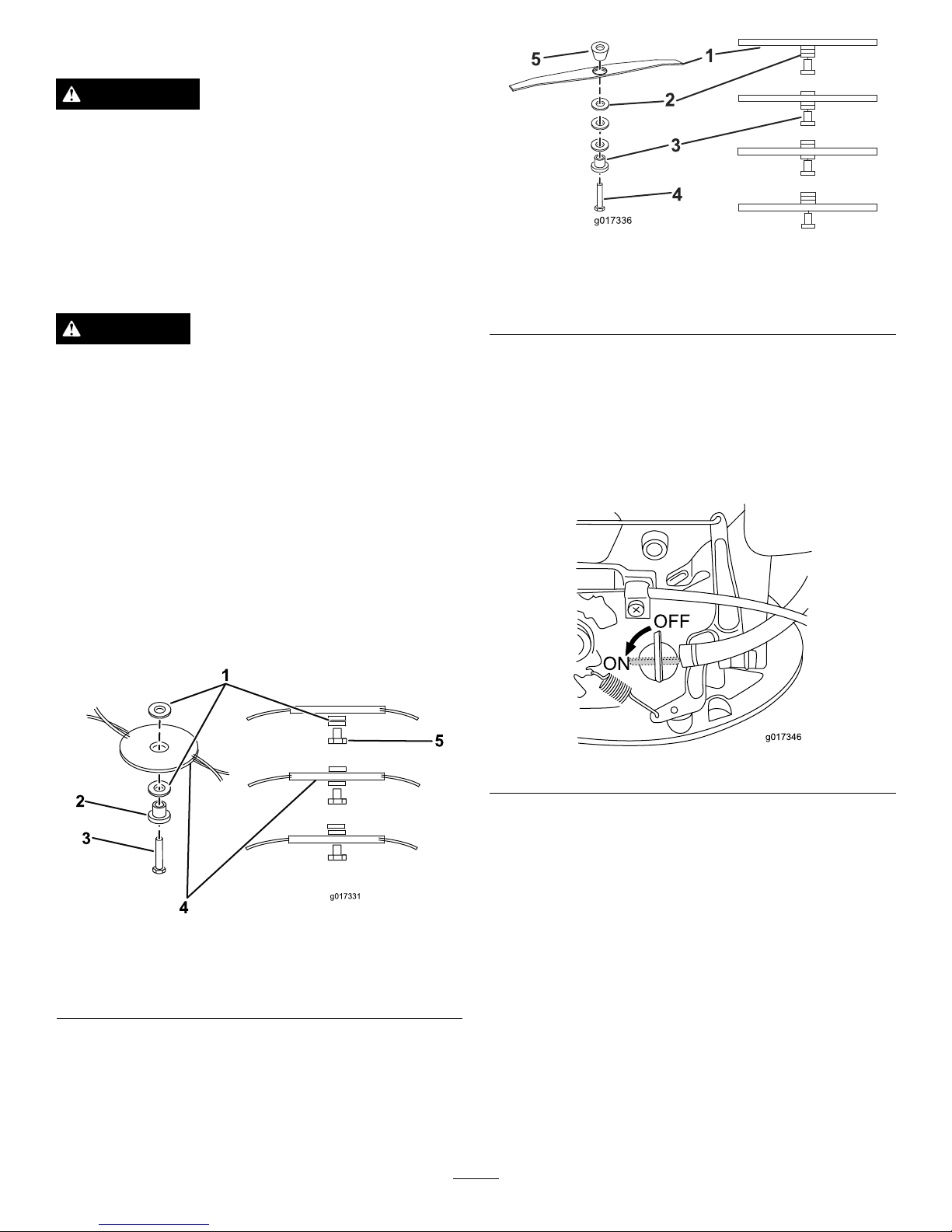

5.Removetheretainingbolt.

6.Repositionthespacerstothedesiredheight,then

reinstalltheexiblade/cutterbar(Figure13,Figure12).

g017331

1

2

3

4

5

Figure12

1.Spacers4.Flexiblade

2.Bladeretainer5.Bladeretainer

3.Bolt

Figure13

1.Cutterbar4.Bolt

2.Spacers5.Largespacer

3.Bladeretainer

Note:Thelargespacermustbepositioneddirectly

belowtheimpelleratalltimes.

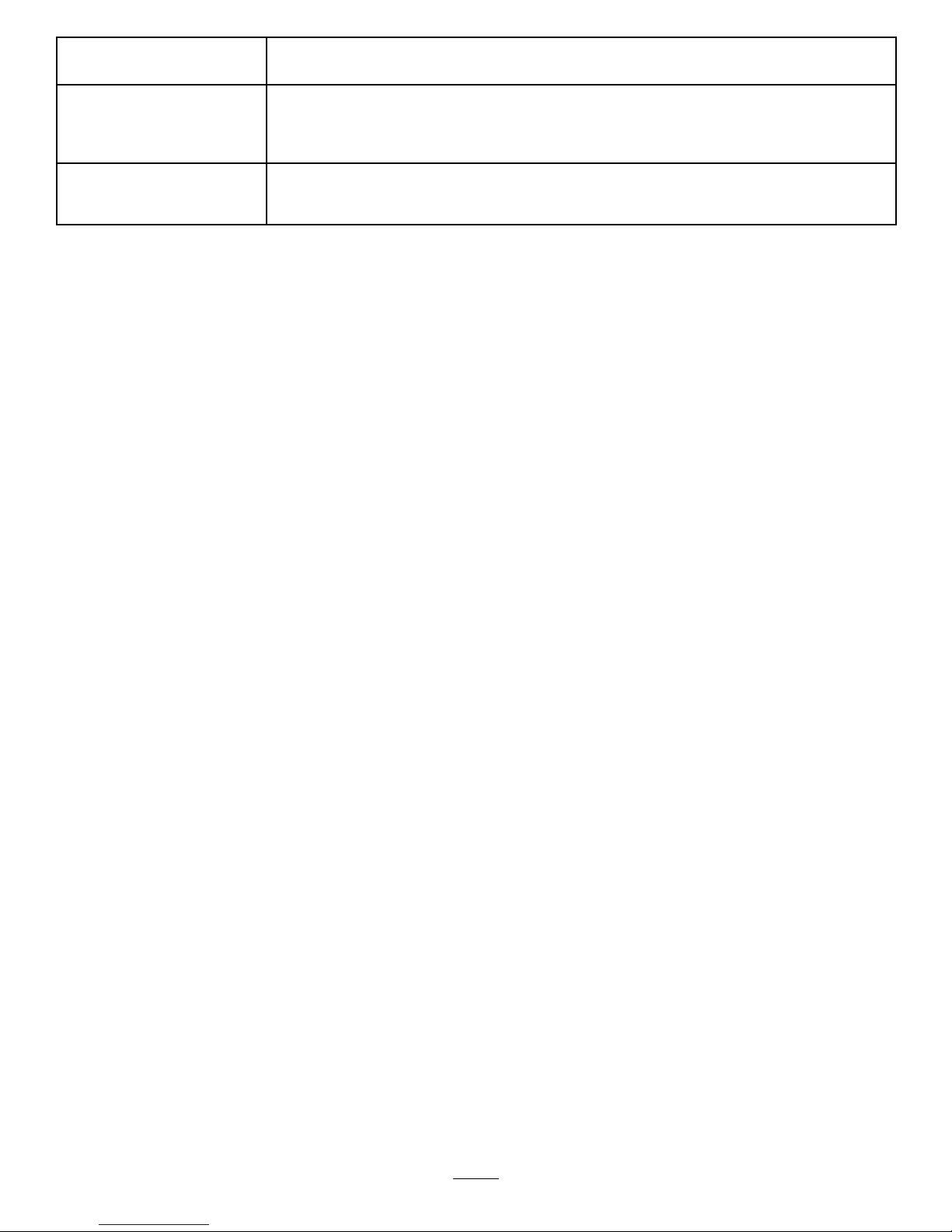

StartingtheEngine

1.Placethethrottlecontroltothechokeposition,ensure

thatthefuelswitchisinthe‘On’position.

OFF

ON

g017346

Figure14

2.Holdtheenginestophandleagainstthehandle.

11

g017334

1

2

Figure15

1.Handle2.Enginestophandle

3.Placeyourfootonthedeckandtiltthemachine

towardsyou(Figure16).

g017329

Figure16

4.Pulltherecoilstarthandle.

Note:Ifthemachinedoesnotstartafterseveralattempts,

contactanAuthorizedServiceDealer.

AdjustingtheChoke

Usethethrottleassemblytoadjustthechoke(Figure17).

g017367

1

2

Figure17

1.Chokeon2.Chokeoff

StoppingtheEngine

ServiceInterval:Beforeeachuseordaily

Tostoptheengine,releasethebladecontrolbar(Figure18).

Important:Whenyoureleasetheenginestophandle,

boththeengineandbladeshouldstopwithin3seconds.

Iftheydonotstopproperly,stopusingyourmachine

immediatelyandcontactanAuthorizedServiceDealer.

12

g017366

Figure18

OperatingTips

GeneralMowingTips

•Cleartheareaofsticks,stones,wire,branches,andother

debristhatthebladecouldhit.

•Avoidstrikingsolidobjectswiththeblade.Never

deliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelystoptheengine,disconnectthewirefrom

thesparkplug,andexaminethemachinefordamage.

•Forbestperformance,installanewbladebeforethe

cuttingseasonbegins.

•ReplacethebladewhennecessarywithaToro

replacementblade.

CuttingGrass

•Cutonlyaboutathirdofthegrassbladeatatime.Donot

cutbelowthe30mm(1.2inch)setting(02602/02604)

or32mm(1.25inch)setting(02606)unlessthegrassis

sparseoritislatefallwhengrassgrowthbeginstoslow

down.RefertoAdjustingtheCuttingHeight.

•Mowinggrassover15cm(6inches)inlengthisnot

recommended.Ifthegrassistoolong,themachinemay

plugandcausetheenginetostall.

•Mowonlydrygrassorleaves.Wetgrassandleavestend

toclumpontheyardandcancausethemachinetoplug

ortheenginetostall.

WARNING

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Mowonlyindry

conditions.

•Alternatethemowingdirection.Thishelpsdispersethe

clippingsoverthelawnforevenfertilization.

•Ifthenishedlawnappearanceisunsatisfactory,tryone

ormoreofthefollowing:

–Replacetheblade/lineorhavethebladesharpened.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Cutthegrassmorefrequently.

–Overlapcuttingswathsinsteadofcuttingafullswath

witheachpass.

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawnshows

throughthecutleafcover.Youmayneedtomakemore

thanonepassovertheleaves.

•Slowdownyourmowingspeedifthemachinedoesnot

cuttheleavesnelyenough.

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevel.

•Ensurethattheenginestopswithin3secondsafterreleasingthebladecontrolbar.

•Cleangrassclippingsanddirtfromunderthemachine.

Every100hours•Checkthesparkplugandreplaceitifnecessary.

13

MaintenanceService

IntervalMaintenanceProcedure

Beforestorage

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•Cleanthecoolingsystem;removegrassclippings,debris,ordirtfromtheengine

aircoolingnsandstarter.Cleanthesystemmorefrequentlyindirtyorhigh-chaff

conditions.

Yearly

•Replacetheairlter;replaceitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

•Replacethebladeorhaveitsharpened(morefrequentlyiftheedgedullsquickly).

14

PreparingforMaintenance

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthesparkplugwirefromthesparkplug

(Figure19)beforeperforminganymaintenance

procedure.

g017342

Figure19

1.Sparkplugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthesparkplugwiretothesparkplug.

WARNING

Tippingthemachinemaycausethefuelto

leak.Gasolineisammable,explosiveand

cancausepersonalinjury.

Runtheenginedryorremovethegasoline

withahandpump;neversiphon.

Important:Alwaystipthemachineontoitsside

withthedipstickdown.

ReplacingtheAirCleaner

ServiceInterval:Yearly

1.Pressdownonthelatchtabsontopoftheaircleaner

cover(Figure20).

1

23

g017339

Figure20

1.Cover3.Filter

2.Latchtabs

2.Openthecover.

3.Removethelter(Figure20).

4.Inspectthelter,andreplaceitifitisdamagedor

excessivelydirty.

5.Inspectthepaperairlter.

A.Ifthelterisdamagedoriswetwithoilorfuel,

replaceit.

B.Ifthelterisdirty,tapitonahardsurfaceseveral

timesorblowcompressedairlessthan207kPa

(30psi)throughthesideofthelterthatfaces

theengine.

Note:Donotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

6.Removedirtfromtheaircleanerbodyandcoverusing

amoistrag.Donotwipedirtintotheairduct.

7.Insertthelterintotheaircleaner.

8.Installthecover.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Yearly

1.Ensurethatthefueltankcontainslittleornofuelso

thatfueldoesnotleakoutwhenyoutipthemachine

ontoitsside.

2.Runtheengineafewminutesbeforechangingtheoil

towarmit.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Disconnectthewirefromthesparkplug.Referto

PreparingforMaintenance.

4.Removethedipstick.

5.Tipthemachineontoitsside,withthedipstickdown,

todraintheusedoiloutthroughtheoillltube.

15

6.Returnthemachinetotheoperatingposition.

7.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewingin,

theoilllcapintothehole.

Note:Max.ll:0.59l(20oz.),type:SAE30orSAE

10W-30detergentoilwithanAPIserviceclassication

ofSF,SG,SH,SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrectas

shownin(Figure21).Ifyouoverlltheenginewithoil,

removetheexcessoilasdirectedin5.

123

g017332

Figure21

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

8.Installthedipstickandhandtightenitsecurely.

9.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Checkthesparkplugafterevery100operatinghours.Usean

ChampionRN9YCsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch)(Figure

22).

G017548

Figure22

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto20N-m(15ft-lb).

8.Connectthewiretothesparkplug.

Replacingthe

Flexiblade/Cutterbar

ServiceInterval:Yearly

Important:

Y ou will need a torque wr ench to install the

blade pr oper l y

.Ifyoudonothaveatorquewrenchor

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladewheneveryourunoutofgasoline.Ifthe

bladeisdamagedorcracked,replaceitimmediately.Ifthe

bladeedgeisdullornicked,haveitsharpenedorreplaceit.

WARNING

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

•Disconnectthewirefromthesparkplug.

•Weargloveswhenservicingtheblade.

1.Disconnectthesparkplugwirefromthesparkplug.

RefertoPreparingforMaintenance.

2.Tipthemachineontoitsside,withtheairlterup.

3.Useablockofwoodtoholdthebladesteady.

4.Removetheblade(turnthebladebolt

counterclockwise),savingallthemounting

hardware.

5.Installthenewblade(turnthebladeboltclockwise)

andallmountinghardware.

Important:Positionthecurvedendsoftheblade

topointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladeboltto

25N-m(18ft-lb).

16

Important:Abolttorquedto25N-m(18ft-lb)is

verytight.Whileholdingthebladewithablock

ofwood,putyourweightbehindtheratchetor

wrenchandtightentheboltsecurely.Thisboltis

verydifculttoovertighten.

CleaningtheMachine

ServiceInterval:Beforeeachuseordaily

WARNING

Themachinemaydislodgematerialfromunderthe

machinehousing.

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•Donotallowbystandersinthearea.

1.Tipthemachineonitsside.

2.Useabrushorcompressedairtoremovegrassand

debrisfromtheexhaustguard,thetopcowl,andthe

surroundingdeckareas.

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor

Storage

WARNING

Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

thefuelasdirectedbytheenginemanufacturer.

2.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

5.Disconnectthewirefromthesparkplug.

6.Removethesparkplug,add30ml(1oz.)ofoilthrough

thesparkplughole,andpullthestarterropeslowly

severaltimestodistributeoilthroughoutthecylinder

topreventcylindercorrosionduringtheoff-season.

7.Installthesparkplugandtightenitwithatorque

wrenchto20N-m(15ft-lb).

8.Tightenallnuts,bolts,andscrews.

17

Troubleshooting

ProblemPossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

1.Connectthewiretothesparkplug.

2.Thefuelcapventholeisplugged.2.Cleanthefuelcapventholeorreplace

thefuelcap.

3.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

Theenginedoesnotstart

4.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

4.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

thefuelcap.

2.Theairlterelementisdirtyandis

restrictingtheairow.

2.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

3.Cleanunderthemachinehousing.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

5.Theengineoillevelistoolow,toohigh,

orexcessivelydirty.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

Theenginestartshardorlosespower

6.Thefueltankcontainsstalefuel.6.Drainandllthefueltankwithfresh

gasoline.

1.Thewireisnotconnectedtothespark

plug.

1.Connectthewiretothesparkplug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

2.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

Theenginerunsrough

3.Theairlterelementisdirtyandis

restrictingtheairow.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

1.Cleanunderthemachinehousing.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Theblademountingboltloose.3.Tightentheblademountingbolt.

Themachineorenginevibrates

excessively

4.Thebladeisbentorisoutofbalance.4.Balancetheblade.Ifthebladeisbent,

replaceit.

1.Youaremowinginthesamepattern

repeatedly.

1.Changethemowingpattern.

2.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Cleanunderthemachinehousing.

Thereisanunevencuttingpattern

3.Thebladeisdull.3.Sharpenandbalancetheblade.

18

InternationalDistributorList

Distributor:Country:PhoneNumber:Distributor:Country:PhoneNumber:

AgrolancKftHungary3627539640MaquiverS.A.Colombia5712364079

BalamaPrimaEngineeringEquip.HongKong85221552163MaruyamaMfg.Co.Inc.Japan81332522285

B-RayCorporationKorea82325512076Mountelda.s.CzechRepublic420255704220

CascoSalesCompanyPuertoRico7877888383Mountelda.s.Slovakia420255704220

CeresS.A.CostaRica5062391138MunditolS.A.Argentina541148219999

CSSCTurfEquipment(pvt)Ltd.SriLanka94112746100NormaGardenRussia74954116120

CyrilJohnston&Co.NorthernIreland442890813121OslingerTurfEquipmentSAEcuador59342396970

CyrilJohnston&Co.RepublicofIreland442890813121OyHakoGroundandGardenAbFinland35898700733

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala5024423277PerfettoPoland48618208416

ForGarderOUEstonia3723846060PratoverdeSRL.Italy390499128128

G.Y .K.CompanyLtd.Japan81726325861Prochaska&CieAustria4312785100

GeomechanikiofAthensGreece30109350054RTCohen2004Ltd.Israel97298617979

GolfinternationalTurizmTurkey902163365993RiversaSpain34952837500

GuandongGoldenStarChina862087651338LelyTurfcareDenmark4566109200

HakoGroundandGardenSweden4635100000SolvertS.A.S.France33130817700

HakoGroundandGardenNorway4722907760SpyprosStavrinidesLimitedCyprus35722434131

HayterLimited(U.K.)UnitedKingdom441279723444SurgeSystemsIndiaLimitedIndia911292299901

HydroturfInt.CoDubaiUnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

HydroturfEgyptLLCEgypt2025194308ToroAustraliaAustralia61395807355

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailat[email protected].

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevH

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevB

Other manuals for HoverPro 450

6

This manual suits for next models

5

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

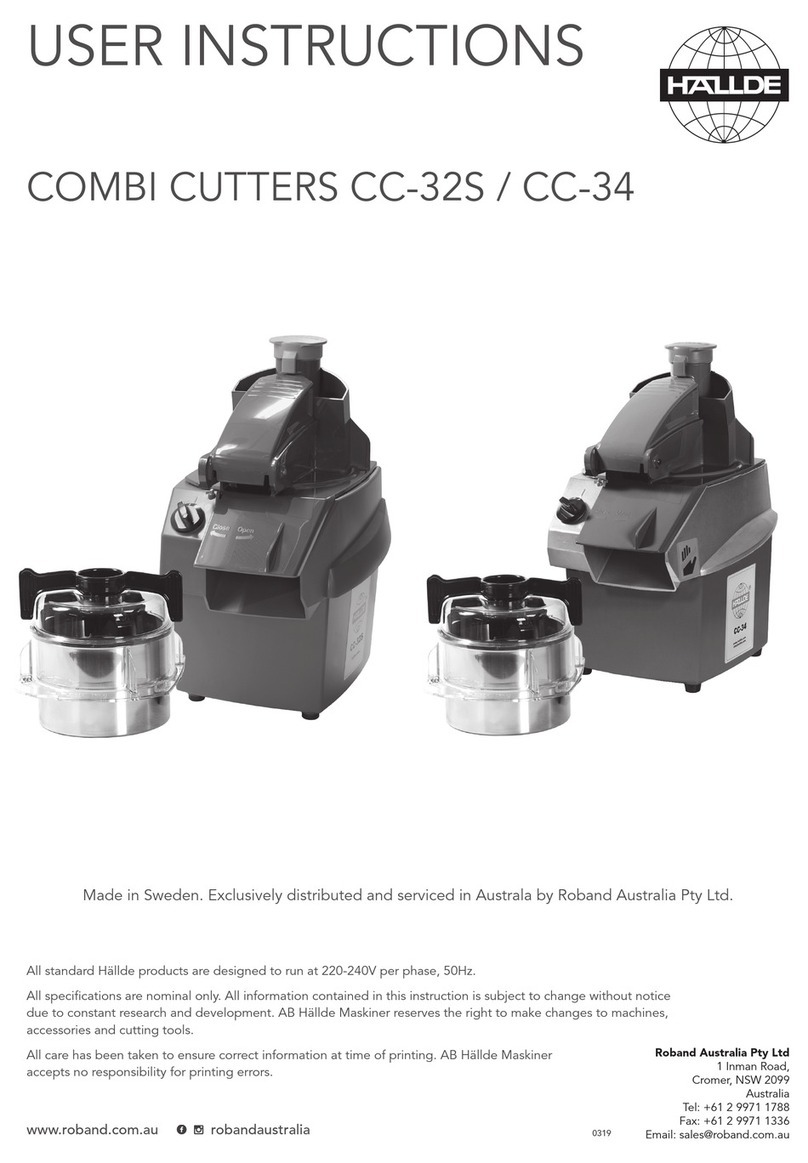

Hallde

Hallde CC-32S User instructions

Pace Technologies

Pace Technologies MEGA-T400S instruction manual

Mul-t-lock

Mul-t-lock KC5 User's operation manual

Logan Graphic Products

Logan Graphic Products 424 user manual

Citizen

Citizen CL-S521 user manual

Central Forge

Central Forge 38173 Set up and operating instructions

RIDGID

RIDGID 246 operating instructions

Ryobi

Ryobi RY18HTX60A manual

Milwaukee

Milwaukee 49-40-6110 Operator's manual

Milwaukee

Milwaukee M18 HUCT Original instructions

Kunshan furi precision machinery

Kunshan furi precision machinery FR-1300A Operation manual

Panasonic

Panasonic EY3552 - 18V METAL SAW operating instructions