Toro MK3 User manual

FormNo.3393-413RevB

MK3200mm(8in)or250mm

(10in)CuttingUnit

ModelNo.02800—SerialNo.315000001andUp

ModelNo.02801—SerialNo.315000001andUp

ModelNo.02802—SerialNo.315000001andUp

ModelNo.02810—SerialNo.315000001andUp

ModelNo.02811—SerialNo.314000001andUp

ModelNo.02812—SerialNo.315000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3393-413*B

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanauthorizedToro

distributorandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbers

arelocatedontheleftsideofthecuttingunit.Write

thenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................4

1PreparingtheMachine.....................................4

2InspectingtheCuttingUnit...............................4

3ConvertingtheCuttingUnitfromLeftto

RightConguration.........................................4

4AdjustingtheHand-WheelAssemblies............5

5InstallingtheCuttingUnittothe

Machine..........................................................6

6LubricatingtheCuttingUnit..............................6

ProductOverview.....................................................7

Specications....................................................7

Attachments/Accessories...................................7

Operation..................................................................8

OperatingtheCuttingUnit..................................8

AdjustingthePivotKnuckle................................8

AdjustingtheHeightofCut.................................8

ClearingtheCuttingCylinders............................9

Maintenance...........................................................10

CheckingtheCuttingUnittoBedknife

Contact.........................................................10

GreasingtheCuttingUnit..................................10

CheckingtheRear-RollerBearing

Adjustment.....................................................11

CheckingRearRollerScraperWire

Tension..........................................................11

AdjustingtheContactBetweentheCylinder

andBottomBlade.........................................12

BacklappingtheCuttingUnit.............................13

GrindingtheCuttingUnit...................................13

ReplacingtheBottomBlade.............................14

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013.

Improperuseormaintenanceofthisequipment

canresultininjuryordeath.Toreducethe

potentialforinjuryordeath,complywiththe

followingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingthecutting

unit.

•Lowerthecuttingunitstotheground,engagethe

parkingbrake,shutofftheengine,andremovethe

keyfromtheignitionswitchwheneveryouleave

themachineunattended.

•Besurethatthecuttingunitsareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal40-13-010

40-13–010

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

decal63-13-039

63–13–039

1.Height-of-cutadjustment

decal214053

214053

1.On-cutadjustment

3

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Preparethemachine.

2Nopartsrequired–Inspectthecuttingunit.

3Nopartsrequired–Convertthecuttingunitfromlefttoright

conguration.

4Nopartsrequired–Adjustthehand-wheelassemblies.

Pin1

Cap-headscrew2

Plainwasher2

5Springwasher2

Installthecuttingunitstothemachine.

6Nopartsrequired–Lubricatethecuttingunits.

WARNING

Theedgesofthecuttingcylinderandbottom

bladearesharp,andcontactwiththemcan

causeinjury.

Takecaretoavoidthesharpedgesofthe

cuttingcylinderandbottombladewhenlifting

orworkingonthecuttingunit.

WARNING

Thecuttingunitisheavy;liftingthecutting

unitimproperlycouldcauseinjury.

Usesuitableliftingequipmentwhenremoving

thecuttingunitfromthecartonandduring

installation.

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurface.

2.Lowerthecuttingunitscompletelytotheground.

3.Shutofftheengineandremovethekey.

4.Engagetheparkingbrake.

5.Ensurethatthereisnopressureinthehydraulic

system.

6.Setthebattery-disconnectswitchtotheOFF

position.

2

InspectingtheCuttingUnit

NoPartsRequired

Procedure

1.Checkthatallpartsaredeliveredcorrectly.

2.Removethecuttingunitfromthecartonand

checkthatalllooseitemshavebeensupplied

correctly.

3.Ifanyitemsaremissingcontactyourauthorized

Torodistributor.

4

3

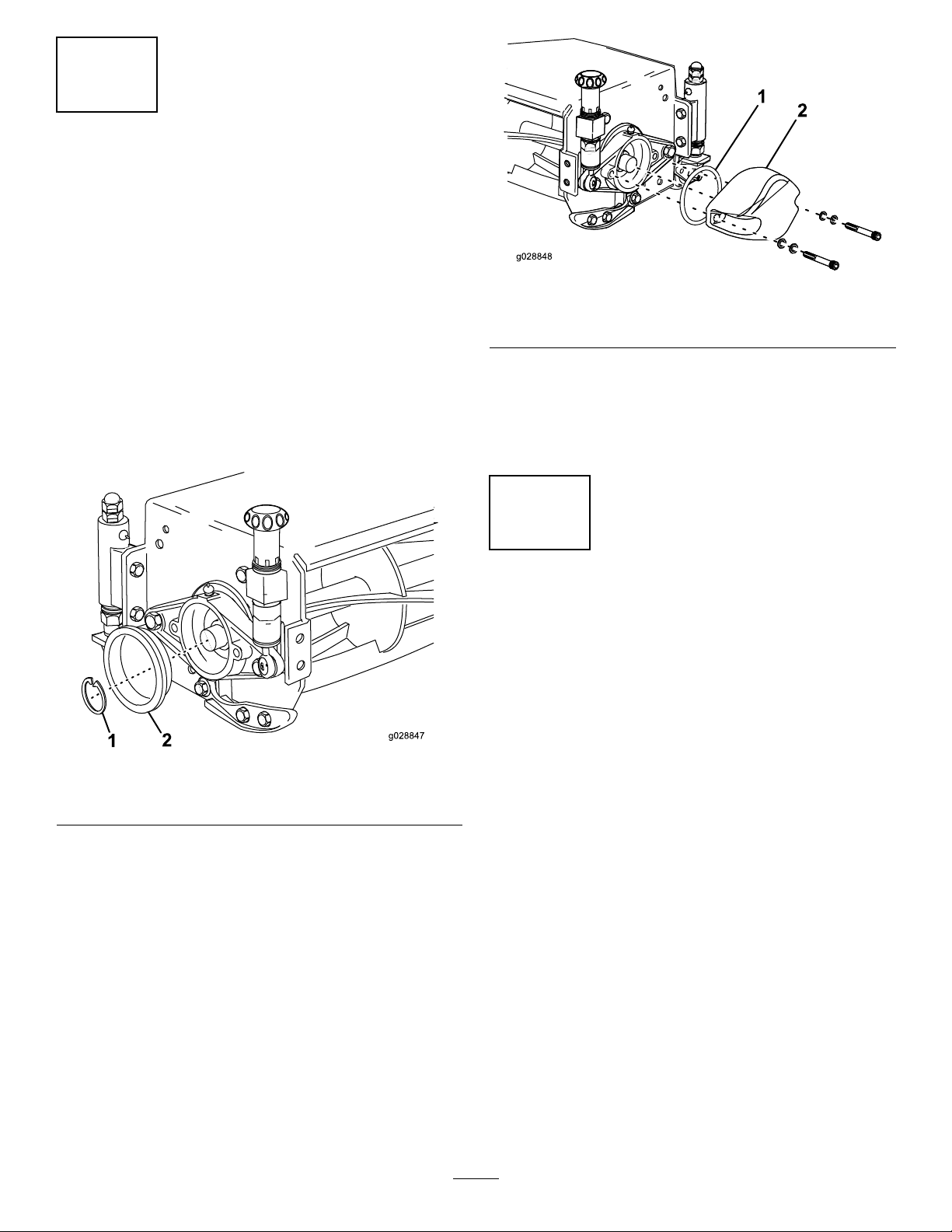

ConvertingtheCutting

UnitfromLefttoRight

Conguration

NoPartsRequired

Procedure

1.Removetheprotectivecoveranddiscardit

(Figure2).

2.Removethesnapring(Figure2).

Note:Thesnapringisttedtothedriveend

only.

g028847

Figure2

1.Snapring2.Protectivecover

3.RemovethecounterweightandO-ringand

installthemtothenon-driveend(Figure3).

g028848

Figure3

1.O-ring2.Counterweight

4.Tighteneachofthe2socket-headcapscrews

toatorqueof80N·m(59ft-lb).

5.Installthesnapringtothedriveend.

6.Repeattheprocedurefortheothercuttingunits.

4

AdjustingtheHand-Wheel

Assemblies

NoPartsRequired

Procedure

1.Removethenut,bolt,andwasherfromthe

alternativeholeposition(Figure4).

2.Removethe2nuts,2washers,springwasher,

andbearing-adjusterpinthatattachesthe

hand-wheelassemblytothecuttingunit,and

thenremovethehand-wheelassembly(Figure

4).

5

g028992

Figure4

1.Bolt5.Nut

2.Alternativeholeposition6.Springwasher

3.Hand-wheelassembly7.Bearing-adjusterpin

4.Washer

3.Adjustthehand-wheelassemblysothatthe

fasteningcenteriscorrect.

4.Installthehand-wheelassemblyinthe

alternativeholeposition.

5.Installallfastenersandtightensecurely.

6.Repeattheprocedurefortheothercuttingunits

asnecessary.

5

InstallingtheCuttingUnit

totheMachine

Partsneededforthisprocedure:

1Pin

2Cap-headscrew

2Plainwasher

2Springwasher

Procedure

Note:Wheninstallingthecuttingunittothemachine,

youmayneedtoadjustthepositionofthehand-wheel

assemblies.Referto4AdjustingtheHand-Wheel

Assemblies(page5).

1.Unlatchandlowertherelevantarmtothe

ground.

2.For200mmcuttingunitsonly:

Removethepinassemblyalreadyttedtothe

arm,anddismantletheM24nut,M24washer,

nutcap,andpear-dropbushing.Installthese

itemsontothe353mmlongpinsuppliedwiththe

cuttingunit.Fitthisassemblyontothearm.

For250mmcuttingunitsonly:

Usingthe400mmlongpinalreadyttedtothe

arm,removethenutcap,nut,andwasherfrom

thepin.

3.Slidethecuttingunitontothepinuntilthearm

bushmateswiththepivotcasting.

4.InstalltheM24washerandlocknutandtighten.

5.Loosenthenutby1/8to1/4turntoallowthe

cuttingunittopivotfreely.

6.Attachthecuttingunitmotortothedriveendof

thecuttingunitusingthefastenersalreadytted

tothemotormounting.

7.Tightentheboltstoatorqueof80N·m(59ft-lb).

6

LubricatingtheCuttingUnit

NoPartsRequired

Procedure

FillallthebearinghousingswithNo.2lithiumgrease.

Note:Thisrequiresasignicantquantityofgrease.

RefertoGreasingtheCuttingUnit(page10).

6

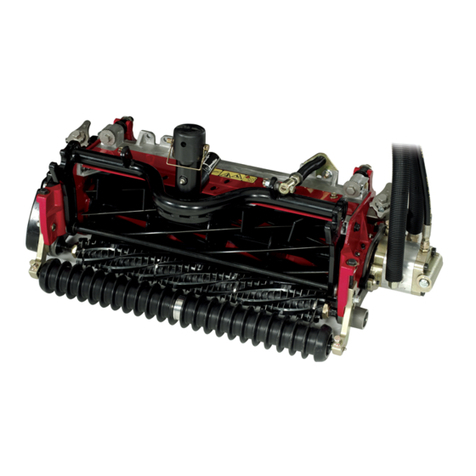

ProductOverview

Specications

200mmcuttingunit254mmcuttingunit

4blade6blade8blade10blade4blade6blade8blade

Modelno.02800028010280202803028100281102812

Weight72kg75kg78kg81kg80.5kg83.5kg90kg

Cylinder

diameter

20cm(8inch)25.4cm(10inch)

Cuttingwidth76.2cm(30inch)76.2cm(30inch)

Heightofcut1.2to8.0cm(0.5to3.15inches)1.2to8.0cm(0.5to3.15inches)

RefertoyourPartsCatalogforalistofrecommendedbladesforyourcuttingunit.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourT oroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonT orogenuineparts.

7

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

OperatingtheCuttingUnit

Whenthemowerissetupwithxedcuttingunits,

theheightofcutisgaugedbytherearrollerand

thecuttingunitisallowedtopivotlaterallytofollow

groundcontours.Thisarrangementisrecommended

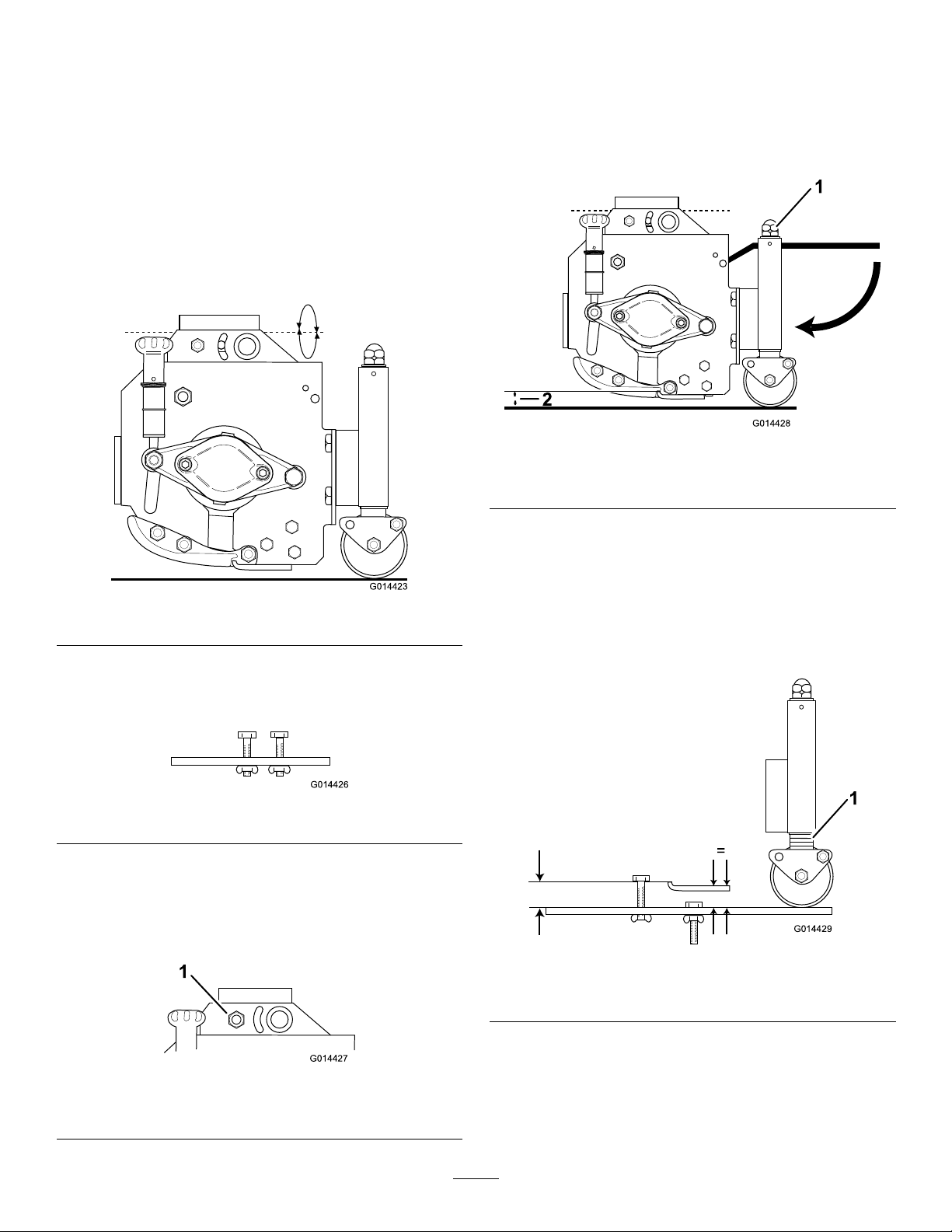

forgeneralmowingrequirements(Figure5).

g014423

Figure5

Heightofcutgauge:Anoptionalheightofcutgauge

isavailabletoassistinachievingaccuratecutheight

settings(Figure6).

g014426

Figure6

AdjustingthePivotKnuckle

SecuretheboltinthefrontxedholepositioninFigure

7asshown.

g014427

Figure7

1.Frontxedholeposition

AdjustingtheHeightofCut

1.Theheightofcutisgaugedbythepositionof

therearroller.Turntheadjustingnutassembly

bothendsclockwisetodecreasetheheightof

cutorcounter-clockwisetoincreasetheheight

ofcut(Figure8).

g014428

Figure8

1.Adjustingnutassembly2.Heightofcut

Important:Donotattempttounlockthe

nuts.

2.Ensurethatallcuttingunitsaresetatthesame

heightofcutbyeitherreferringtotheindicator

ringsorbyusingaheight-of-cutgaugeacross

thefullwidthofeachcuttingunitforgreater

accuracyasshown(Figure9).

g014429

Figure9

1.Indicatorrings

3.Ifthecentercuttingunitproducesahigherheight

ofcutthanthewingcuttingunits,setthecenter

cuttingunitheight-of-cutindicatorringlower

thantheindicatorringofthewingcuttingunits.

8

ClearingtheCutting

Cylinders

WARNING

Neverattempttorotatethecuttingcylinders

byhand.

Theremaybesomeresidualpressureinthe

hydraulicsystem,whichcouldcauseinjury

throughsuddenmovementofthecylinder(s)

whenyoureleasetheblockage.

•Alwayswearprotectiveglovesandusea

suitablestrongwoodenstick.

•Ensurethatthewoodensticktsbetween

thebladesandthroughthecylinderandis

longenoughtoprovidesufcientclearance

andleveragetoreleasetheblockage.

1.Stopthemachineonlevelground.

2.Applytheparkingbrakeanddisengageall

drives.

3.Lowerthecuttingunitstothegroundorsecurely

lockinthedesignatedtransportpositions.

4.Shutofftheengineandremovethekeyto

isolateallpowersourcesandcheckthatthey

arestopped.

5.Releaseallstoredenergydevices.

6.Checkthatallmovingpartsarestationary.

7.Usingasuitablestrongwoodenstick,remove

theblockage.Makesurethatthewoodenstick

isproperlysupportedinthecylinderandavoid

theuseofexcessiveforcetopreventdamage.

8.Ensurethatthewoodenstickisremovedfrom

thecuttingcylinderbeforestartingtheengine.

9.Repairoradjustthecylinderifrequired.

9

Maintenance

CheckingtheCuttingUnit

toBedknifeContact

ServiceInterval:Beforeeachuseordaily

Eachdaybeforeoperatingthemachine,checkthe

cuttingunittobedknifecontact,regardlessifthe

qualityofcuthadpreviouslybeenacceptable.There

mustbelightcontactacrossthefulllengthofthe

cuttingunitandthebedknife.

GreasingtheCuttingUnit

ServiceInterval:Beforeeachuseordaily

GreaseType:No.2lithiumgrease

Lubricatethebearingsandbushingsimmediately

aftereverywashing,regardlessoftheintervallisted.

Replaceanygreaseorgreasettingsthatbecome

damaged.

Greaseallcuttingunitgreasepointsandensurethat

sufcientgreaseisinjectedsuchthatcleangrease

isseentoescapefromtherollerendcaps.This

providesvisibleevidencethattherollersealshave

beenpurgedofgrass,debris,etc.andensures

maximumworkinglife.

Thegreasettinglocationsandquantitiesareas

showninFigure10.

g028858

Figure10

1.–Greaseevery50hours2.–Greasedaily

10

CheckingtheRear-Roller

BearingAdjustment

ServiceInterval:Every50hours

Important:Keeptherollerbearingsinthecutting

unitsingoodadjustmentinordertoensure

maximumworkinglife.Excessiverollerendoat

willcauseprematurebearingdamage.

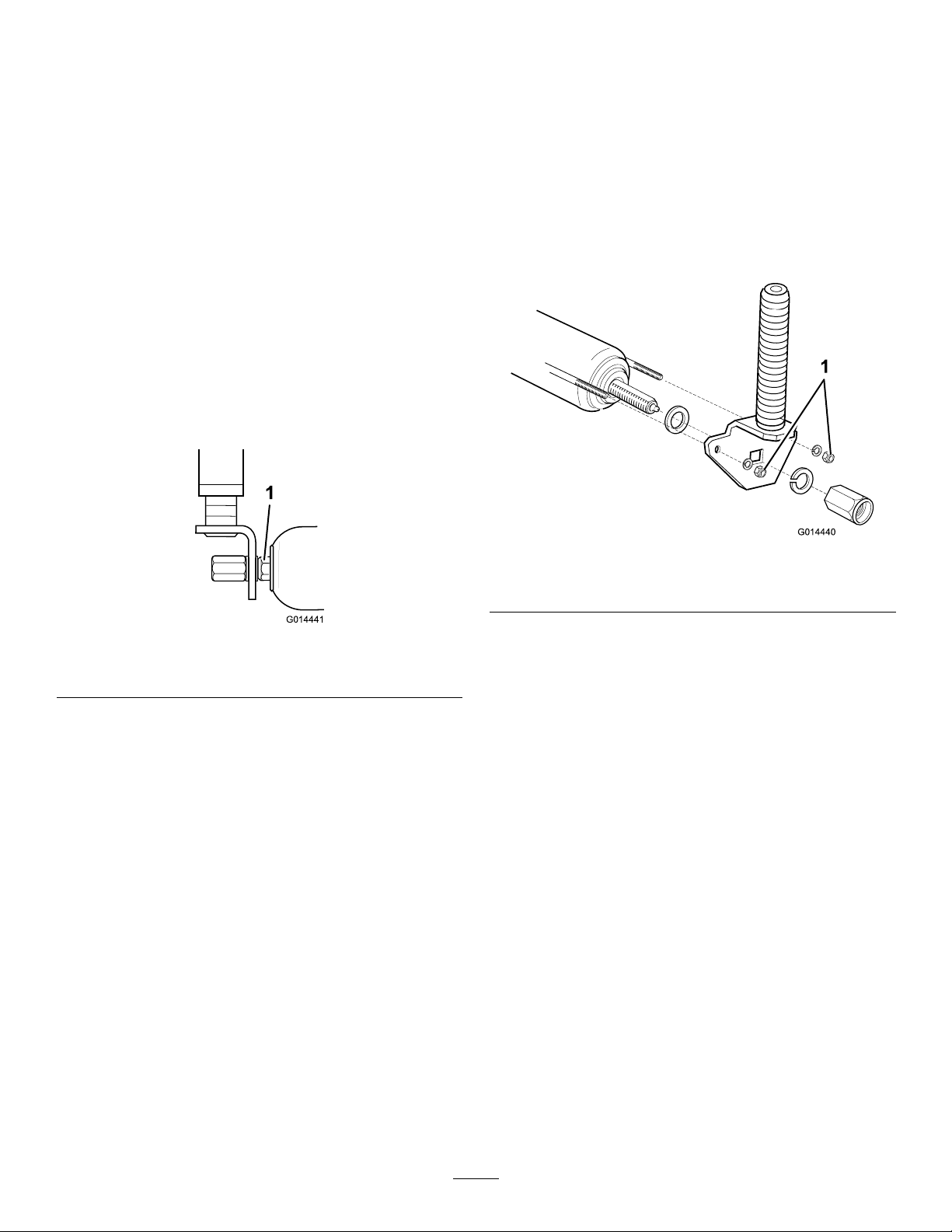

1.Griptherollerandmovefromsidetosideand

upanddown.

2.Ifyouseeexcessivemovement,carefullytighten

thenutsateachendoftherollerjustsufciently

toremoveanyendoat(Figure11).

Note:Therollershouldstillrotatefreelyafter

adjustment.Overtighteningthenutscouldlead

toprematurebearingdamage.

Adjustthenutsanequalamountatbothends

oftheroller.

g014441

Figure11

1.Nut

CheckingRearRoller

ScraperWireTension

ServiceInterval:Every50hours

Adjustthetensionofscraperwiresarecorrectlyto

ensurecorrectoperationandmaximumworkinglife.

1.Carefullytightenthescraperwireretainingnuts

toremoveanyslackfromthescraperwires.

2.Tightenthenuts4fullturnstocorrectlytension

thewire(Figure12).

g014440

Figure12

1.Scraperwireretainingnuts

Note:Donotovertightenthescraperwires.

11

AdjustingtheContact

BetweentheCylinderand

BottomBlade

ServiceInterval:Beforeeachuseordaily

Important:Itisessentialthattherelationship

betweenthebottombladesandthecuttingunits

arekeptingoodadjustmentinordertoensure

goodcuttingperformance,minimumpower

consumption,andprolongedlifeforthecutting

edges.Notmakingtheproperadjustmentsmay

resultinhighermaintenancecostsandalower

qualityofcutthatmayaffectthehealthand

growthofthegrass.

Important:Donotoveradjust.Over-adjusting

maycauseheavycontactbetweenthecylinder

andbottomblade,whichmaycreateveryrapid,

unevenwear,tramlining,wavinessofcutting

edges,increasedcontactpressure,andsignicant

powerabsorption.

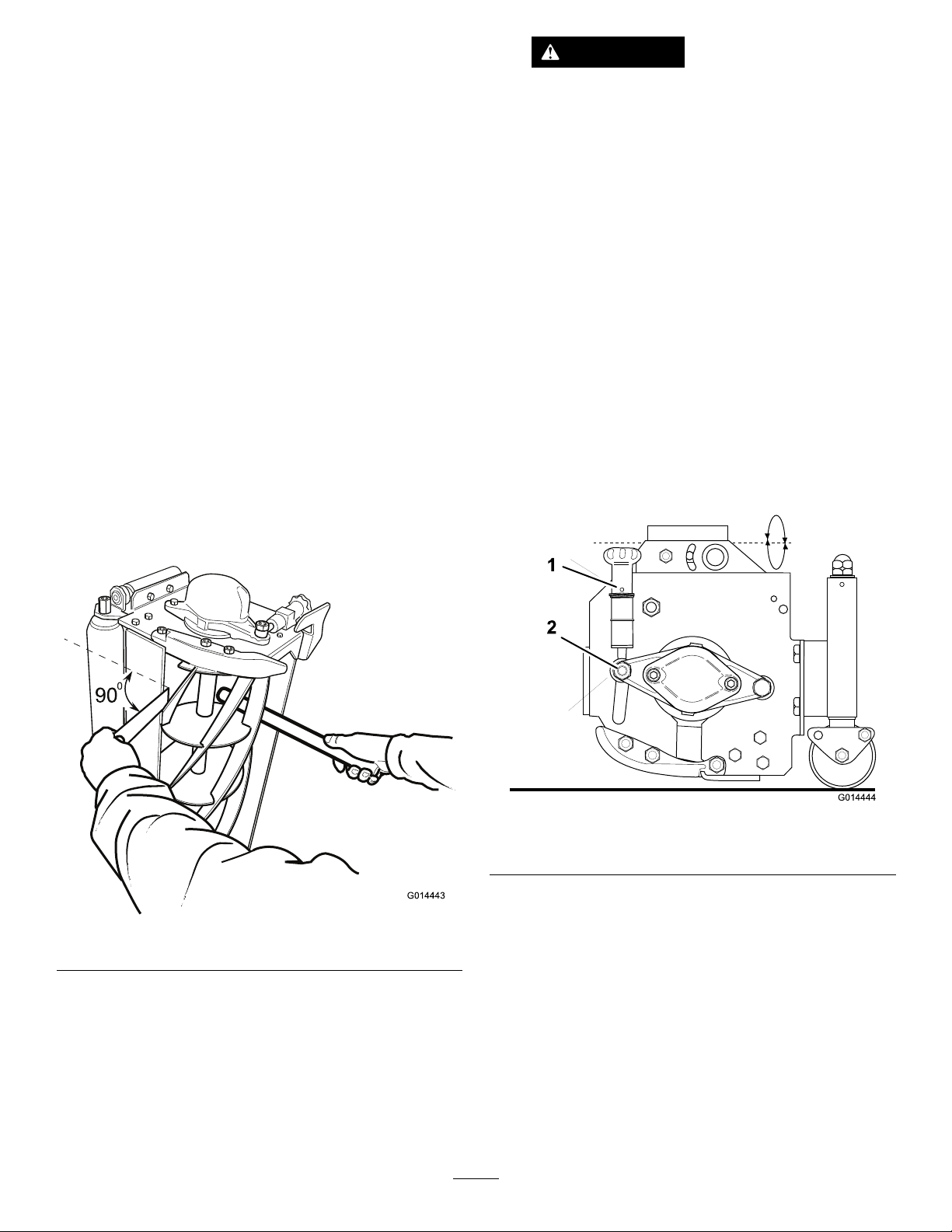

1.Checkthatthecuttingcylinderiscorrectlysetto

thebottombladebyholdingathinpieceofpaper

betweenthecuttingcylinderandthebottom

blade(Figure13).

g014443

Figure13

2.Carefullyrotatethecylinderasshownandcheck

thatthepaperiscutcleanlyatallpointsalong

thelengthoftheblade.Holdthepaperata90

degreerightangletothebottombladetoobtain

thecorrectcuttingaction.

WARNING

Thecuttingcylindersaresharp,and

contactwiththemcancauseinjury.Also,

rotating1ofthecuttingcylindersmay

causeotherstorotate,exposingothers

topotentialinjury.

Takecarewhenservicingthecutting

cylindersandensurethatbystandersare

awayfromthemachineandcuttingunits.

3.Stoptheprocedureifanadjustmentisnot

necessary.Otherwise,loosenthenutonboth

endsofthecuttingunit1/4turn(Figure14).

4.Turnthehandwheeloneachendalternately

whilerotatingthecuttingcylinderbackwarduntil

thebottombladeisineetingcontactwiththe

cylinderalongitsentirelength(Figure14).

5.Checkthecuttingactionalongthelengthofthe

bottombladeusingathinpieceofpaperand

makemarginaladjustmentsasnecessary.

6.Tightenthenutsoneachend(Figure14).

g014444

Figure14

1.Handwheel2.Nut

7.Ifyoucannotobtainagoodcleanpapercut

acrosstheentirelengthofthebottomblade,

backlapthecuttingunit(refertoBacklapping

theCuttingUnit(page13).Inseverecases,

grindingthecuttingcylinderandbottomblade

maybenecessary(refertoGrindingtheCutting

Unit(page13).

12

BacklappingtheCutting

Unit

WARNING

Contactwiththecuttingunitsorothermoving

partscanresultinpersonalinjury.

•Keepyourhandsandclothingawayfrom

thecuttingunitsorothermovingparts.

•Neverattempttoturnthecuttingunitsby

handorfootwhiletheengineisrunning.

Thisprocessisrecommendedforrestoringthesharp

cuttingedgestocylindersandbottombladeswhich

areessentialforgoodqualitygrasscutting.

Thisprocesscanonlyremoveasmallamountof

metaltorestorethecuttingedges.Ifthebladeedges

areseriouslywornordamaged,itwillbenecessaryto

removethecomponentpartsandgrindthem.

1.Turntheengineoffandapplytheparkingbrake.

2.Adjustthecuttingcylinderstothebottomblades

toobtaineetingcontact.

3.Applyamedium-gradedetergent-based

carborundumpastetothecuttingedgesofthe

cylinderswithalonghandledbrush.

80GradeCarborundumPaste

PartNo.

1lb(0.45kg)63-07-088

25lb(11.25kg)63-07-086

g014445

Figure15

4.Ensurethattheareasurroundingthecutting

unitsisclearofpeople.Keepyourhandsand

feetclearofthecuttingcylinderswhilethe

engineisrunning.

5.Sitontheoperatorseat,starttheengine,and

settheenginespeedatidle.

6.Operatethecuttingunitdriveswitchtothe

reverse/backlappositionforaperiodoftime

andlistentothegrindingaction.

g014443

Figure16

7.OperatethecuttingunitdriveswitchtotheOFF

positionandswitchofftheenginewhenthe

grindingactionhasstopped.

8.Thoroughlycleanthebladeedgesandadjustthe

cuttingcylinderstothebottomblades.Check

thatathinpieceofpapercanbecutcleanlyat

allpointsalongthecuttingedgeswhilerotating

thecylindersbyhand.

9.Iffurtherbacklappingisnecessaryrepeatsteps

2through8.

10.Thoroughlyremoveandwashoffalltracesof

thecarborundumpastefromthecylindersand

bottomblades.

GrindingtheCuttingUnit

Grindthecylinderspiraledgesorbottombladeedges

iftheybecomeexcessivelyroundedordistorted.

Replacethebottombladeswhentheyarenearthe

endoftheirwearlife.Grindnewbladesontheir

holderspriortotting.Whengrindingisnecessary,

grindbothcylindersandbottombladesatthesame

time,exceptwhenanewcylinderistted,inwhich

caseitisnecessaryonlytogrindthebottomblade.

Allgrindingoperationsshouldbeperformedby

yourauthorizedT orodistributoronaquality,well

maintainedcylinder/bottombladegrindingmachine.

13

ReplacingtheBottomBlade

RefertoyourPartsCatalogforalistofrecommended

bladesforyourcuttingunit.

Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous.

Suchusecouldvoidtheproductwarranty.

1.Removethebottombladeholderbyremoving

the3xingboltsateachendandremovethem

fromthecuttingunit(Figure17).

g028860

Figure17

2.Removethewornbottombladeanddiscardthe

countersunkscrewsandsecuringnuts.

3.Fitthenewbladetotheholderandloosely

assemblewithnewcountersunkscrewsand

securingnuts(Figure18andFigure19).

4.Tightenthecenterboltstoatorqueof40N·m

(30lb-ft).

5.Tightentheremainingboltstoatorqueof40

N·m(30lb-ft)byworkingfromthecenterout

towardthebladeends.

6.Grindthenewbottombladeonitsholderprior

tottingtothecuttingunit.Adjustthecutting

cylinderpositiontogiveadequateclearancefor

ttingthenewbottombladeholder.

7.Installthebottombladeholderassemblytothe

cuttingunitusingtheoriginalxingboltsand

torquethemto35N·m(26lb-ft).

8.Adjustthecylindertothebottomblade.

g223071

Figure18

1.Bottomblade2.Countersunkscrew

g223072

Figure19

1.Securingnut

14

Notes:

Notes:

Notes:

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

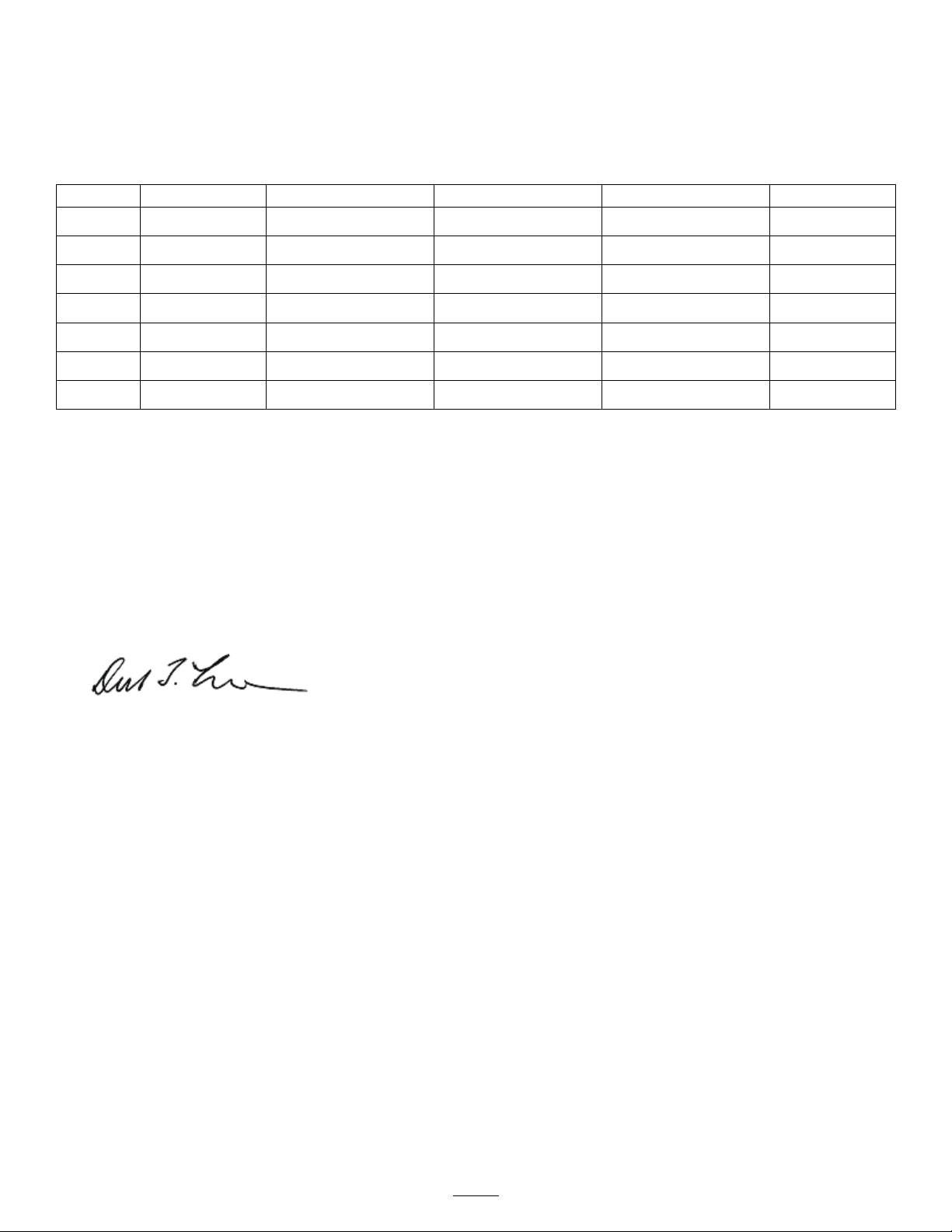

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

02800315000001andUpMK3200mm(8in)4-Blade

CuttingUnit

MK3200MM(8")4-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02801315000001andUpMK3200mm(8in)6-Blade

CuttingUnit

MK3200MM(8")6-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02802315000001andUpMK3200mm(8in)8-Blade

CuttingUnit

MK3200MM(8")8-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02803315000001andUpMK3200mm(8in)10-Blade

CuttingUnit

MK3200MM(8")10-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02810315000001andUpMK3250mm(10in)4-Blade

CuttingUnit

MK3250MM(10")4-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02811314000001andUpMK3250mm(10in)6-Blade

CuttingUnit

MK3250MM(10")6-BLADE

CUTTERUNITCuttingUnit2006/42/EC

02812315000001andUpMK3250mm(10in)8-Blade

CuttingUnit

MK3250MM(10")8-BLADE

CUTTERUNITCuttingUnit2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

DonLackner

Sr.EngineeringManagerTel.+3216386659

8111LyndaleAve.South

Bloomington,MN55420,USA

July5,2017

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailat[email protected].

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0282RevC

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro®Companyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator’sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakespadsand

linings,clutchlinings,blades,reels,bedknives,tines,sparkplugs,

castorwheels,tires,lters,belts,andcertainsprayercomponents

suchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesin

thisproductareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementofItems

andConditionsNotCoveredlters,coolant,andcompletingRecommended

MaintenancearesomeofthenormalservicesT oroproductsrequirethat

areattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedtothe

durationofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlonganimplied

warrantylasts,sotheaboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomersshouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry,province,orstate.Ifforanyreasonyouare

dissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,you

maycontactusatToroWarrantyCompany.

374-0277RevA

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

Silver King

Silver King KutLett SKK2 Technical manual and replacement parts list

GRAPHTEC

GRAPHTEC FC2240 Service manual

QEP

QEP 10-37 owner's manual

EINHELL

EINHELL BT-KF 150 Original operating instructions

Florida Pneumatic

Florida Pneumatic Universal Tool UT8748E General Safety Information & Replacement Parts

Land Pride

Land Pride RC2512 Series Operator's manual