Toro Greensmaster 3150 Series User manual

FormNo.3397-897RevB

8-Blade,11-Blade,and14-Blade

DPACuttingUnit

Greensmaster®3150or3250-DSeries

TractionUnit

ModelNo.04652—SerialNo.316000001andUp

ModelNo.04654—SerialNo.316000001andUp

ModelNo.04656—SerialNo.316000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3397-897*B

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thiscuttingunitisdesignedforcuttingturfongreens

andsmallfairwaysofgolfcourses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g020063

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

InstallingtheRoller.............................................5

InstallingtheBallStuds.......................................5

InstallingtheHoopLink,OffsetLink,or

ChainLink.......................................................5

RepositioningtheCounterWeights.....................6

AdjustingtheCuttingUnit...................................7

ProductOverview.....................................................8

Specications....................................................8

Attachments/Accessories...................................8

Operation..................................................................8

Maintenance.............................................................9

SupportingtheCuttingUnit.................................9

AdjustingtheBedknife-to-ReelContact..............9

Relief-GrindingtheReel...................................10

AdjustingtheRear-RollerHeight........................11

AdjustingtheHeightofCut...............................12

AdjustingtheCut-OffBar..................................13

ServicingtheBedbar........................................13

CheckingtheTopGrindAngle...........................15

ReelGrindingSpecications.............................15

InstallingtheBedknife.......................................16

BacklappingtheCuttingUnit.............................17

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface,lowerthe

cuttingunits,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

SafeOperatingPractices

•ReadtheOperator’sManualforthetractionunit

andothertrainingmaterialcarefully.Befamiliar

withthecontrols,safetysigns,andtheproper

useoftheequipment.Iftheoperatorormechanic

cannotreadthelanguageofthismanual,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

3

•Wearappropriateclothing,includingeye

protection;substantial,slip-resistantfootwear;

longpants,andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry.

•Inspecttheareawheretheequipmentistobe

usedandremoveallobjects,suchasrocks,toys,

andwire,thatthemachinecanthrow.

•Checkthatoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepyourhandsandfeetawayfromthecutting

units.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyouor

bystanders,resultinginseriouspersonalinjuryor

death.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal104-7729

104–7729

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

hazard;handorfoot—shut

offtheengineandwaitfor

movingpartstostop.

4

Setup

MediaandAdditionalParts

DescriptionQty.Use

Ballstud2Mountthistotheroller.

Operator'sManual1Readbeforeinstallingandoperatingthecuttingunit.

Partscatalog1Usethistoreferencepartnumbers.

InstallingtheRoller

Thecuttingunitisshippedwithoutafrontroller.

Obtainarollerfromyourdealerandinstallitonthe

cuttingunit,asfollows:

1.Removetheplowbolt,washer,andangenut

securingoneoftheheight-of-cutarmstothe

cuttingunitsideplate(Figure3).

g016936

Figure3

1.Height-of-cutarm4.Washer

2.Adjustingscrew5.Flangenut

3.Plowbolt6.Roller-mountingscrew

2.Loosentheroller-mountingscrewsinthe

height-of-cutarms(Figure3).

3.Slidetherollershaftintotheheight-of-cutarm

ontheoppositeendofthecuttingunit(Figure3).

4.Slidetheheight-of-cutarmontotherollershaft

(Figure3).

5.Looselysecuretherollertothecuttingunitwith

theheight-of-cutarmandfastenerspreviously

removed(Figure3).

6.Centertherollerbetweentheheight-of-cutarms.

7.Tightentheroller-mountingscrews(Figure3).

8.Adjusttothedesiredheight-of-cutandtighten

theheight-of-cutarmmountingfasteners.

InstallingtheBallStuds

Installaballstudoneachendofthefrontroller(Figure

4).

g020075

Figure4

1.Ballstud

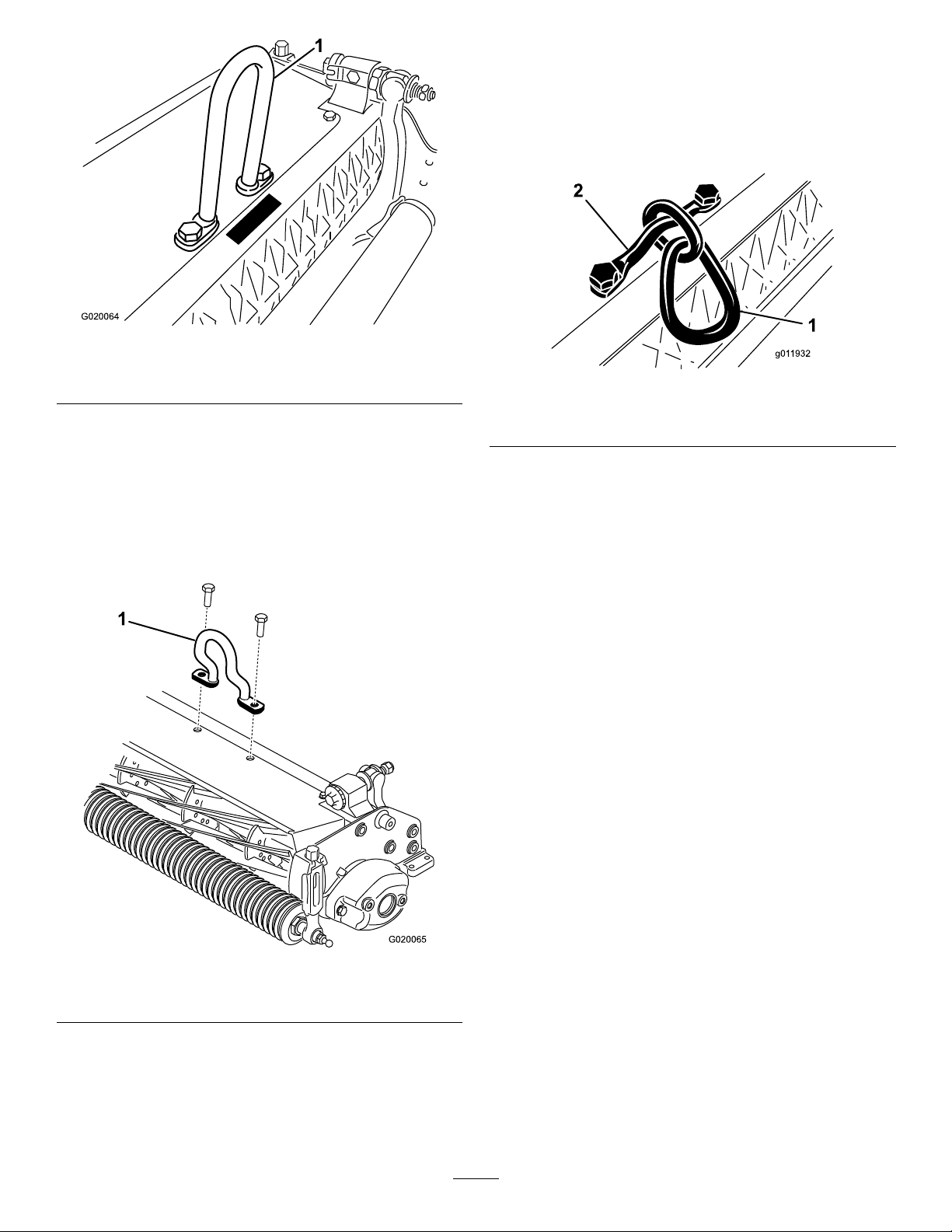

InstallingtheHoopLink,

OffsetLink,orChainLink

Forcuttingunitsmountingonatractionunitwitha

serialnumberpriorto240000001,obtainandinstall

theproperliftlinkasfollows:

Note:The2boltsusedtomounttheliftlinkare

shippedinstalledonthecuttingunit.

•ForGreensmaster3120and3150tractionunits,

installthehooplinksuppliedwiththetractionunit.

Installthehooplinktothetopofthecuttingunit

with2bolts.T orquetheboltsto34to40N∙m(25

to30ft-lb)(Figure5).

5

g020064

Figure5

1.Hooplink

•FortheGreensmaster3250-Dtractionunits,install

theoffsetlinksuppliedwiththetractionunit.

Installtheoffsetlink(Figure6)tothetopofthe

cuttingunitwith2bolts.Torquetheboltsto34to

40N∙m(25to30ft-lb).

Important:Positionthelifthookoffsettoward

thefrontofthecuttingunit.

g020065

Figure6

1.Offsetlifthook

•OptionallyfortheGreensmaster3250-Dtraction

units,youcaninstallthechainLinkandmounting

bracketavailablefromyourauthorizedToro

distributor.

Installthechainlink(Figure7)tothetopofthe

cuttingunitwiththemountingbracketand2bolts.

Torquetheboltsto34to40N∙m(25to30ft-lb).

Note:Whenmountingthecuttingunittothe

tractionunit,hookthewiderendofthechainlink

totheliftarm.

g011932

Figure7

1.Chainlink2.Mountingbracket

RepositioningtheCounter

Weights

Thecuttingunitsareshippedwiththecounterweight

mountedtotheleftendandthemotormounttothe

rightendofthecuttingunit.T ochangethecuttingunit

todifferentpositions,proceedasfollows:

Important:Wheneveryouneedtotipthecutting

unitonitsside,ensurethatyoupropituptoavoid

damagingthebedbar-adjustingbolts;referto

SupportingtheCuttingUnit(page9)

1.Removethe2boltssecuringthecounterweight

totheleftendofthecuttingunit.Removethe

counterweight(Figure9).

2.Removethe2Allenheadboltssecuringthe

motormounttotheleftendofthecuttingunit.

Removethemotormount(Figure8).

3.Applygreasetotheinsidediameterofthedrive

spline(Figure8).

4.Ontheleftendofthecuttingunit,applyalight

coatingofoiltotheO-ringandinstallthemotor

mountwiththe2Allenheadboltspreviously

removed(Figure8).Torquetheboltsto16to

20N∙m(12to15ft-lb).

6

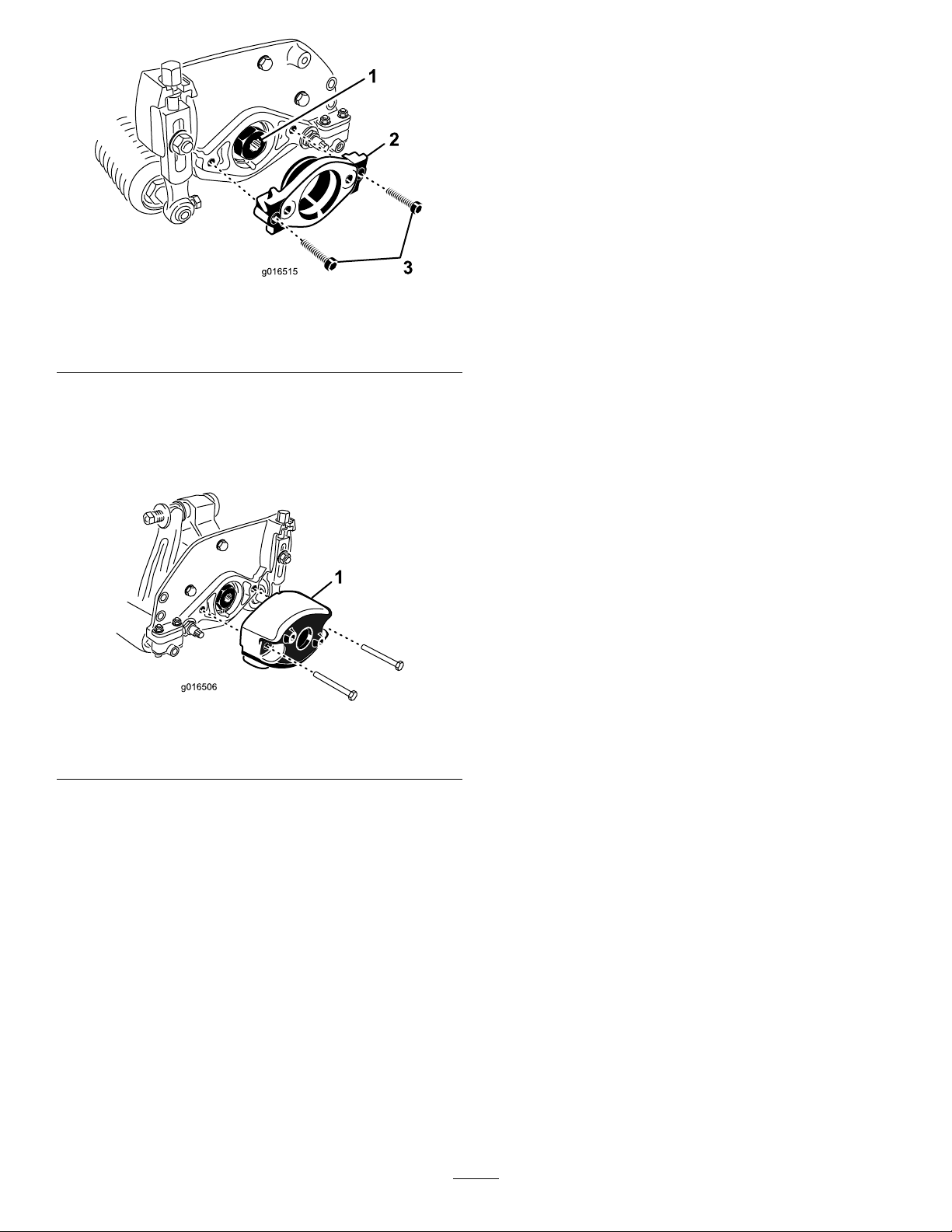

g016515

Figure8

1.Drivespline3.Allenheadbolts

2.Motormount

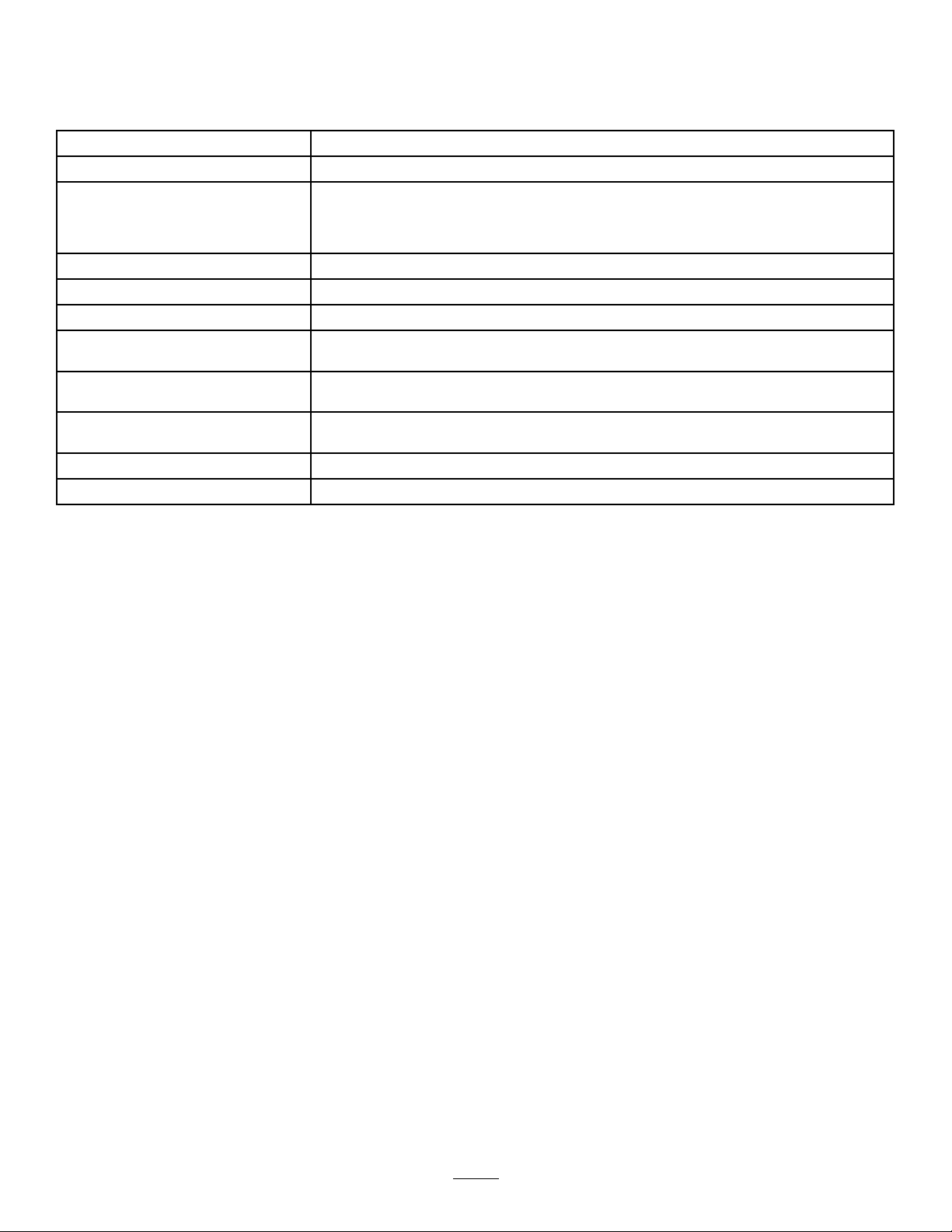

5.Ontherightendofthecuttingunit,applyalight

coatingofoiltotheO-ringandinstallthecounter

weightwiththeboltspreviouslyremoved(Figure

9).T orquetheboltsto16to20N∙m(12to15

ft-lb).

g016506

Figure9

1.Counterweight

AdjustingtheCuttingUnit

1.Supportthecuttingunit;refertoSupportingthe

CuttingUnit(page9).

2.Adjustthebedknifetothereel;refertoAdjusting

theBedknife-to-ReelContact(page9).

3.Adjusttherearrollerheight;refertoAdjusting

theRear-RollerHeight(page11).

4.Adjusttheheightofcut;refertoAdjustingthe

HeightofCut(page12).

5.Adjustthecut-offbar;refertoAdjustingthe

Cut-OffBar(page13).

7

ProductOverview

Specications

TractorsGreensmaster3120,3150,3250-D,and3150-QTractionUnits.

HeightofCutAdjustonthefrontrollerusing2verticalboltsandheld2lockingbolts.

Height-of-CutRangeStandardbenchheight-of-cutrangeis1.6mm(0.062inch)to12.7mm(0.500inch).Bench

height-of-cutrangewiththeHighHeightofCutKitinstalledis7mm(0.285inch)to25mm

(1.00inch).Effectiveheightofcutmayvarydependingonturfconditions,typeofbedknife,

rollers,andattachmentsinstalled.

CuttingWidth53cm(21inches)

ReelBearingsTwosealedstainlesssteel,deepgrooveballbearings

RollersTherearrollerisa5.1cm(2inch)diametersteelfullroller.

BedknifeReplaceablesingleedged,highcarbonsteelbedknifeisfastenedtoamachinedcastiron

bedbarwith13bolts

BedknifeAdjustmentDual-boltadjustmenttothereel;detentscorrespondingto0.018mm(0.0007inch)bedknife

movementforeachindexedposition

GrassShieldNon-adjustableshieldwithadjustablecut-offbartoimprovegrassdischargefromreelin

wetconditions

CounterweightAcastironweightmountedoppositetothedrivemotorbalancesthecuttingunit.

NetWeight8Blade—30kg(65lb),11Blade—31kg(68lb),14Blade—32kg(71lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comfora

listofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

Operation

RefertoyourtractionunitOperator’sManualfordetailedoperationinstructions.Beforeusingthecuttingunit

eachday,adjustthebedknife;refertoAdjustingtheBedknife-to-ReelContact(page9).Testthequalityofcut

bycuttingatestswathbeforeusingthecuttingunitonagreentoensurethatthenishedcutiscorrect.

8

Maintenance

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

SupportingtheCuttingUnit

Wheneveryouneedtotipthecuttingunittoexpose

thebedknife/reel,propuptherearofthecutting

unittoensurethatthenutsonthebackendofthe

bedbar-adjustingboltsarenotrestingonthework

surface(Figure10).

g016511

Figure10

1.Prop(notprovided)2.Bedbar-adjusting-screw

nut(2)

Adjustingthe

Bedknife-to-ReelContact

AdjustingtheBedknifeDaily

Priortomowingeachday,orasrequired,verifyproper

bedknife-to-reelcontact.Performthisprocedure

eventhoughthequalityofcutisacceptable.

1.Lowerthecuttingunitsontoahardsurface,shut

offtheengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,

listeningforreel-to-bedknifecontact.

•Ifnocontactisevident,adjustthebedknife

asfollows:

A.Turnthebedbaradjustingscrews

clockwise(Figure11),1clickatatime,

untilyoufeelandhearlightcontact.

Note:Thebedbaradjustingscrews

havedetentscorrespondingto0.018

mm(0.0007inch)bedknifemovement

foreachindexedposition.

g026076

Figure11

1.Bedbaradjustingscrew

2.Bedbar-adjusting-screwnut(2)

B.Insertalongstripofcuttingperformance

paperbetweenthereelandbedknife,

perpendiculartothebedknife(Figure

12),thenslowlyrotatethereelforward;

itshouldcutthepaper;ifnot,repeat

stepsAandBuntilitdoes.

•Ifexcessivecontact/reeldragisevident,

backlap,refacethefrontofthebedknife,or

grindthecuttingunittoachievethesharp

edgesneededforprecisioncutting(Referto

theToroManualforSharpeningReeland

RotaryMowers,FormNo.09168SL).

Important:Lightcontactispreferredatall

times.Ifyoudonotmaintainlightcontact,

thebedknife/reeledgeswillnotsufciently

self-sharpen,anddullcuttingedgeswill

resultafteraperiodofoperation.Ifyou

maintainexcessivecontact,bedknife/reel

wearwillbeaccelerated,unevenwearcan

result,andthequalityofcutmaydecline.

Note:Asthereelbladescontinuetorunagainst

thebedknife,aslightburrwillappearonthefront

cuttingedgesurfacealongthefulllengthofthe

bedknife.Occasionallyrunaleacrossthefront

edgetoremovethisburrtoimprovecutting.

Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Round

offthesenotchesorlethemushwiththe

cuttingedgeofthebedknifetoensuresmooth

operation.

9

AdjustingtheBedknifetotheReel

Usethisprocedureduringinitialcutting-unitsetupand

aftergrinding,backlapping,ordisassemblingthereel.

Thisisnotadailyadjustment.

1.Positionthecuttingunitonaat,levelwork

surface.

2.Tipthecuttingunittoexposethebedknifeand

reel.

Note:Ensurethatthenutsonthebackofthe

bedbaradjustingboltsarenotrestingonthe

worksurface(Figure10).

3.Rotatethereelsothat1ofthebladescrosses

thebedknifeedgebetweentherstandsecond

bedknifeboltheadslocatedontherightsideof

thecuttingunit.

4.Makeanidentifyingmarkonthebladewhereit

crossesthebedknifeedge.

Note:Thiswillmakelateradjustmentseasier.

5.Inserta0.05mm(0.002inch)shimbetweenthe

bladeandthebedknifeedgeatthepointmarked

instep4.

6.Turntherightbedbaradjustingbolt(Figure11)

untilyoufeellightpressureontheshimwhen

slidingitside-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotate

thereelsothattheclosestbladecrossesthe

bedknifeedgebetweentherstandsecondbolt

heads.

8.Repeatsteps4through6fortheleftsideofthe

cuttingunitandleftbedbaradjustingbolt.

9.Repeatsteps5and6untilthereislightpressure

atthecontactpointsonboththeleftandright

sidesofthecuttingunit.

10.Toobtainlightcontactbetweenthereeland

bedknife,turneachbedbaradjustingbolt

clockwise3clicks.

Note:Eachclickonthebedbaradjustingbolt

movesthebedknife0.018mm(0.0007inches).

Donotovertightentheadjustingbolts.

Turningtheadjustingboltclockwisemoves

thebedknifeedgeclosertothereel.Turning

theadjustingboltcounterclockwisemovesthe

bedknifeedgeawayfromthereel.

11.Insertalongstripofcuttingperformancepaper

betweenthereelandbedknife,perpendicularto

thebedknife(Figure12),thenslowlyrotatethe

reelforward;itshouldcutthepaper;ifnot,turn

eachbedbaradjustingboltclockwise1clicks

andrepeatthisstepuntilitcutsthepaper.

g000487

Figure12

Note:Ifexcessivecontact/reeldragisevident,

backlap,refacethefrontofthebedknife,orgrind

thecuttingunittoachievethesharpedgesneeded

forprecisioncutting(RefertotheToroManualfor

SharpeningReelandRotaryMowers,FormNo.

09168SL).

Relief-GrindingtheReel

Thenewreelhasalandwidthof1.3to1.5mm(0.050

to0.060inch)anda30degreereliefgrind.

Whenthelandwidthgetslargerthan3mm(0.120

inch)wide,dothefollowing:

1.Applya30degreereliefgrindonallreelblades

untilthelandwidthis1.3mm(0.050inch)wide

(Figure13andFigure14).

g028800

Figure13

Model03638

1.30degrees2.1.3mm(0.050inch)

10

g028838

Figure14

Models03639and03641

1.1.3mm(0.050inch)2.30degrees

2.Spingrindthereeltoachieve<0.025mm(0.001

inch)reelrun-out.

Note:Thiscausesthelandwidthtogrow

slightly.

Note:T oextendthelongevityofthesharpnessofthe

edgeofthereelandthebedknife—aftergrindingthe

reeland/orthebedknife—checkthereeltobedknife

contactagainaftercutting2fairways,asanyburrs

willberemoved,whichmaycreateimproperreelto

bedknifeclearanceandthusacceleratewear.

AdjustingtheRear-Roller

Height

Dependingonyourdesiredheight-of-cutrange,you

needtoadjusttherear-rollerbrackets(Figure15or

Figure16)totheloworhighposition:

•Positionthespacerabovethesideplate-mounting

ange(factorysetting)whentheheight-of-cut

settingsrangefrom1.5mmto6mm(1/16inchto

1/4inch)asshowninFigure15.

g014404

Figure15

1.Spacer3.Rollerbracket

2.Sideplate-mountingange

•Positionthespacerbelowthesideplate-mounting

angewhentheheight-of-cutsettingsrangefrom

3mmto25mm(1/8inchto1inch)asshownin

Figure16.

g014405

Figure16

1.Sideplate-mountingange3.Rollerbracket

2.Spacer

1.Raisetherearofthecuttingunitandplacea

blockunderthebedknife.

2.Removethe2nutssecuringeachrollerbracket

andspacertoeachsideplatemountingange.

3.Lowertherollerandboltsfromthesideplate

mountingangesandspacers.

4.Placethespacersontotheboltsaboveorbelow

therollerbrackets,asrequired(Figure15or

Figure16).

5.Securetherollerbracketandspacerstothe

undersideofthemountingangeswiththenuts

previouslyremoved.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnot

required.

11

AdjustingtheHeightofCut

Usethefollowingcharttodeterminewhichbedknifeis

bestsuitedforthedesiredheightofcut.

BedknifePartNo.Height-of-Cut

Edgemax

Micro-cut

(Standard)

115-18801.5to4.7mm(0.062to

0.188inch)

Edgemax

Tournament

(Optional)

115-18813.1to12.7mm(0.125to

0.500inch)

Micro-cut

(Optional)

93-42621.5to4.7mm(0.062to

0.188inch)

Tournament

(Optional)

93-42633.1to12.7mm(0.125to

0.500inch)

Extended

Micro-cut

(Optional)

108-43031.5to4.7mm(0.062to

0.188inch)

Extended

Tournament

(Optional)

108-43023.1to12.7mm(0.125to

0.500inch)

Low-cut

(Optional)

93-42644.7to25.4mm(0.188to

1.00inch)

High-cut

(Optional)

94-63927.9to25.4mm(0.312to

1.00inch)

Fairway

(Optional)

63-86009.5to25.4mm(0.375to

1.00inch)

Fairway

EdgeMax

(optional)

112–74759.5to25.4mm(0.375to

1.00inch)

Note:Forheightsofcutgreaterthan9.5mm(0.375

inch),installthehigh-height-of-cutkit.

AdjustingtheHeight-of-CutGauge

Beforeadjustingtheheightofcut,settheheight-of-cut

gaugeasfollows:

1.Loosenthenutonthegaugebarandsetthe

adjustingbolttothedesiredheightofcut(Figure

17).

Note:Thedistancebetweenthebottomofthe

boltheadandthefaceofbaristheheightofcut.

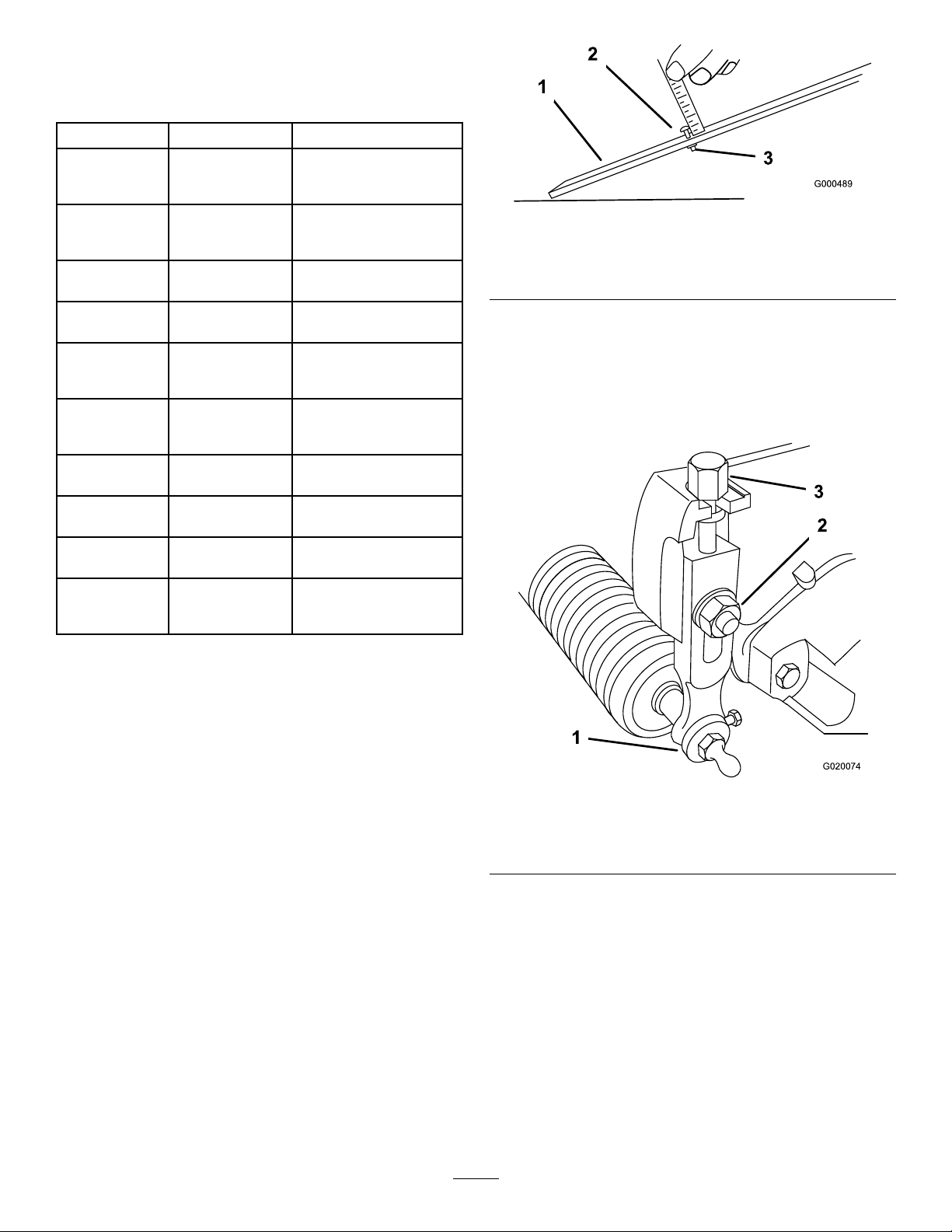

g000489

Figure17

1.Gaugebar3.Nut

2.Height-adjustingbolt

2.Tightenthenut.

AdjustingtheHeightofCut

1.Loosenthelocknutssecuringtheheight-of-cut

armstothecutting-unitsideplates(Figure18).

g020074

Figure18

1.Height-of-cutarm3.Adjustingbolt

2.Locknut

2.Hooktheboltheadoftheheight-of-cutgauge

ontotherightsideofthecuttingedgeofthe

bedknifeandresttherearendofthebaronto

therearoftheroller(Figure19).

12

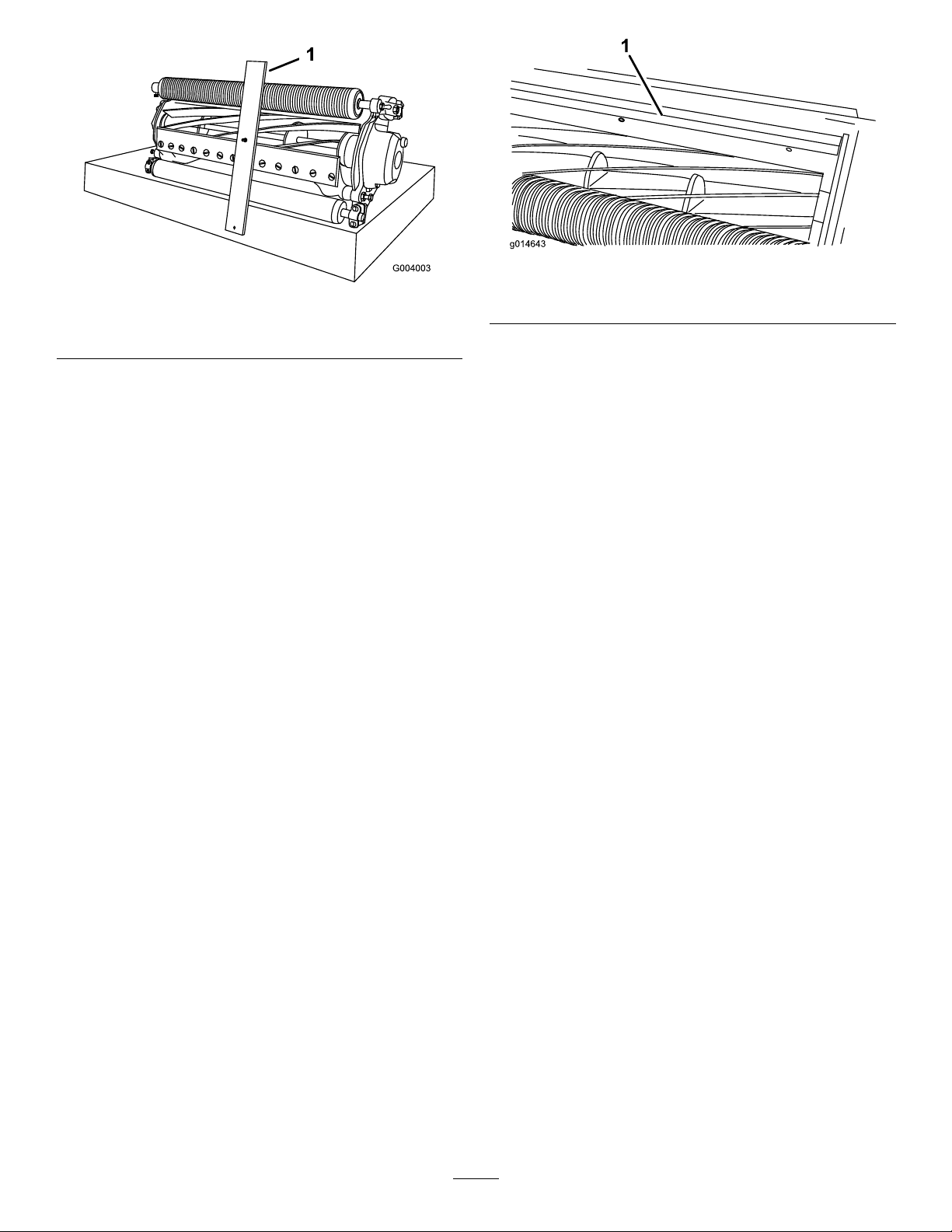

g004003

Figure19

1.Gaugebar

3.Rotatetheadjustingboltuntiltherollercontacts

thefrontofthegaugebar.

4.Repeatsteps2and3fortheleftside.

5.Adjustbothendsoftherolleruntiltheentire

rollerisparalleltothebedknife.

Important:Whensetproperly,therear

andfrontrollerswillcontactthegauge

barandtheboltwillbesnugagainstthe

bedknife.Thisensuresthattheheightofcut

isidenticalatbothendsofthebedknife.

6.Tightenthenutstosecuretheadjustment

enoughtoremoveplayfromthewasher.

7.Verifythattheheight-of-cutsettingiscorrect;

repeatthisprocedureifnecessary.

AdjustingtheCut-OffBar

Adjustthecut-offbartoensurethattheclippingsare

cleanlydischargedfromthereelarea,asfollows:

Note:Thebarisadjustabletocompensatefor

changesinturfconditions.Adjustthebarcloserto

thereelwhentheturfisextremelydry.Bycontrast,

adjustthebarfurtherawayfromthereelwhentheturf

conditionsarewet.Thebarshouldbeparalleltothe

reeltoensureoptimumperformance.Adjustitafter

thereelissharpenedonareelgrinder.

1.Loosentheboltssecuringthetopbar(Figure

20)tothecuttingunit.

g014643

Figure20

1.Cut-offbar

2.Inserta1.5mm(0.060inch)feelergauge

betweenthetopofthereelandthebarthen

tightenthebolts.

Important:Ensurethatthebarandreelare

equaldistanceapartacrossthecomplete

reel.

Note:Adjustthegapasneededforyourturf

conditions.

ServicingtheBedbar

Onlyaproperlytrainedmechanicshouldservicethe

bedbarandbedknifetopreventdamagetothereel,

bedbar,orbedknife.Ideally,takethecuttingunitto

yourauthorizedT orodistributorforservice.Referto

theServiceManualforyourtractionunitforcomplete

instructions,specialtools,anddiagramsforservicing

thebedknife.Shouldyoueverneedtoremove

orassemblethebedbaryourself,instructionsare

providedbelow,asarethespecicationsforservicing

thebedknife.

Important:Alwaysfollowthebedknife

proceduresdetailedinyourServiceManualwhen

servicingthebedknife.Failuretoinstallandgrind

thebedknifecorrectlycanleadtodamagetothe

reel,bedbar,orbedknife.

13

RemovingtheBedbar

1.Turnthebedbaradjustingscrew,

counterclockwise,tobackthebedknife

awayfromthereel(Figure21).

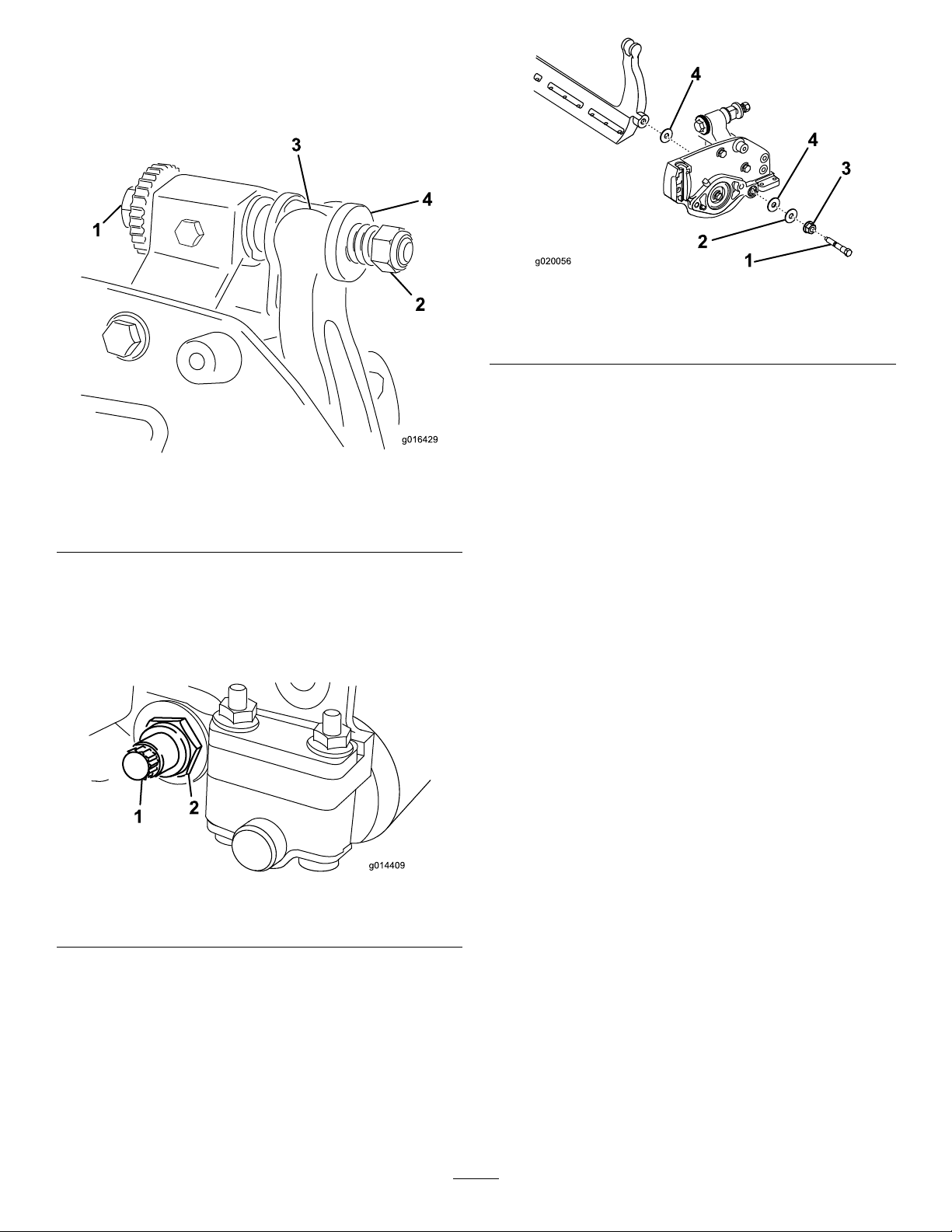

g016429

Figure21

1.Bedbar-adjustingscrew3.Bedbar

2.Spring-tensionnut4.Washer

2.Backoutthespring-tensionnutuntilthewasher

isnolongertensionedagainstthebedbar

(Figure21).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure22).

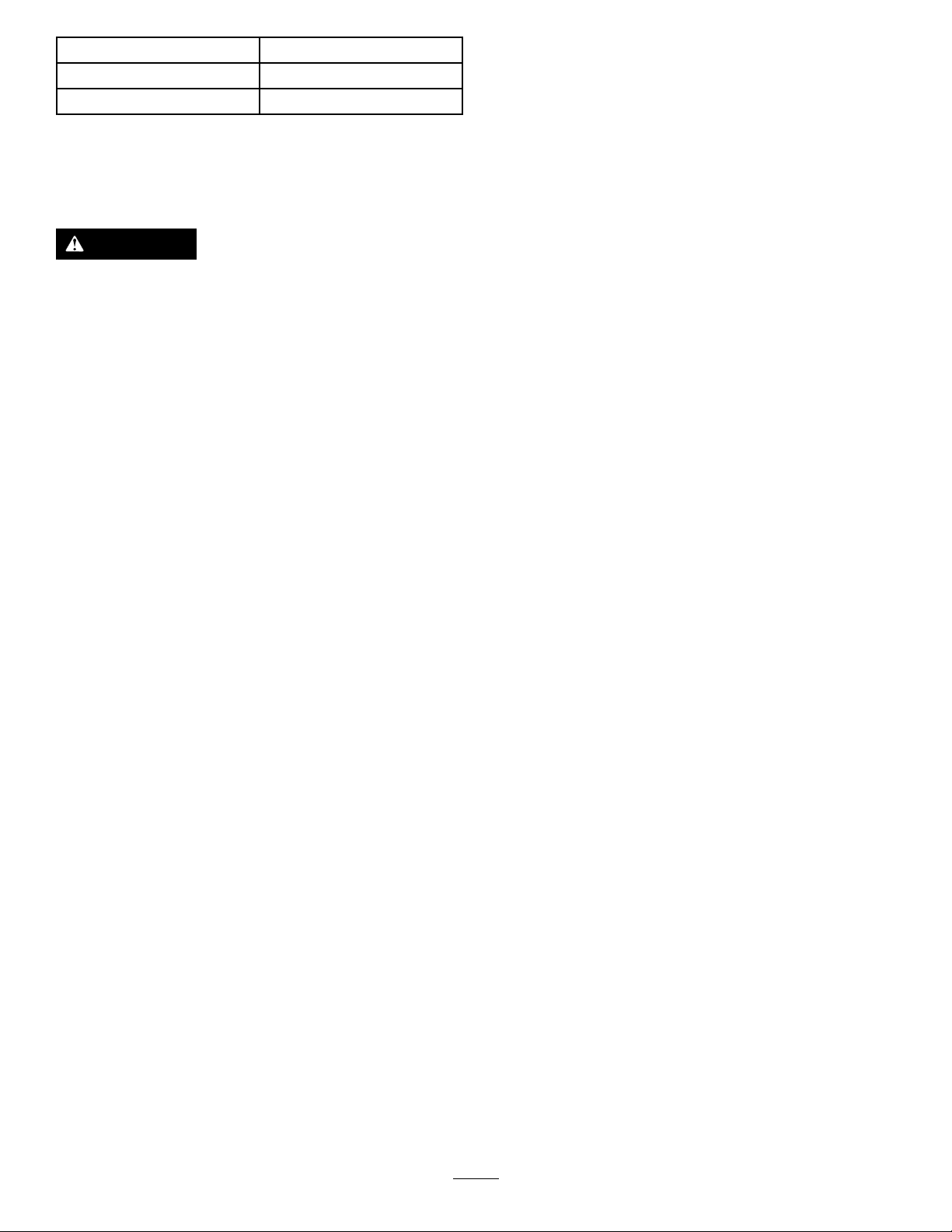

g014409

Figure22

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingthebedbar

tobepulleddownwardandremovedfromthe

cuttingunit(Figure22).

Accountforthe2nylonwashersand1steel

washeroneachendofthebedbar(Figure23).

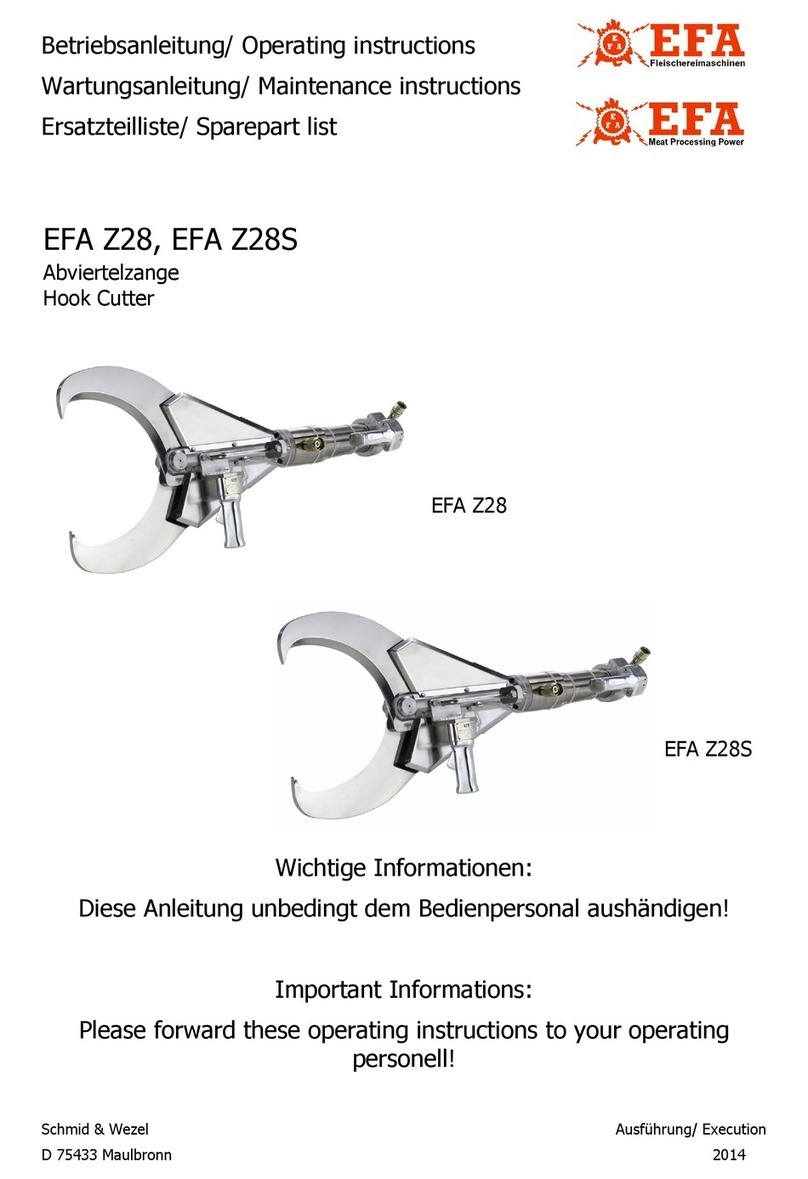

g020056

Figure23

1.Bedbarbolt3.Nylonwasher

2.Nut4.Steelwasher

AssemblingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewashersandthebedbar-adjusting

screw(Figure21).

2.Securethebedbartoeachsideplatewiththe

bedbarbolts(nutsonbolts)and3washers(6

total).

3.Positionanylonwasheroneachsideofthe

side-plateboss.Placeasteelwasheroutside

eachofthenylonwashers(Figure23).

4.Torquethebedbarboltsto27to36N∙m(240to

320inch-lb).

5.Tightenthelocknutsuntilyouremovetheend

playfromsteelwashers,butyouareableto

rotatethembyhand.Thewashersontheinside

mayhaveagap.

Important:Donotovertightenthelocknuts

ortheywilldeectthesideplates.

6.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackitoff1/2turn(Figure24).

14

g016470

Figure24

1.Spring-tensionnut2.Spring

7.Adjustthebedknifetothereel;refertoAdjusting

theBedknife-to-ReelContact(page9).

CheckingtheTopGrind

Angle

Theanglethatyouusetogrindyourbedknivesis

veryimportant.

Usetheangleindicatorandtheangle-indicatormount

tochecktheanglethatyourgrinderproducesand

thencorrectforanygrinderinaccuracy.

1.Placetheangleindicatoronthebottomsideof

thebedknifeasshowninFigure25.

g034113

Figure25

1.Bedknife(vertical)2.Angleindicator

2.PresstheAltZerobuttonontheangleindicator.

3.Placetheangle-indicatormountontheedge

ofthebedknifesothattheedgeofthemagnet

mateswiththeedgeofthebedknife(Figure26).

Note:Thedigitaldisplayshouldbevisiblefrom

thesamesideduringthisstepasitwasinstep1.

g034114

Figure26

1.Angle-indicatormount3.Bedknife

2.Edgeofthemagnetmated

withtheedgeofthe

bedknife

4.Angleindicator

4.Placetheangleindicatoronthemountasshown

inFigure26.

Note:Thisistheanglethatyourgrinder

produces,andshouldbewithin2degreesofthe

recommendedtopgrindangle.

ReelGrinding

Specications

ReelDiameter(New)128.5mm(5.06inches)

ServiceLimit-ReelDiameter114.3mm(4.50inches)

ReelShaftDiameter(OD)34.9mm(1.375inches)

BladeReliefAngle30°

BladeReliefAngleRange28–32°

BladeLandWidth1mm(0.040inch)

BladeLandWidthRange0.8to1.2mm(0.030to0.050

inch)

ServiceLimit-ReelDiameter

Taper

0.25mm(0.010inch)

15

InstallingtheBedknife

1.Removetherust,scale,andcorrosionfromthe

bedbarsurfaceandapplyathinlayerofoilto

thebedbarsurface.

2.Cleanthescrewthreads.

3.Applythread-lockingcompoundtothescrews

andinstallthebedknifetothebedbar.

g255045

Figure27

1.Bedbar3.Screw

2.Bedknife

4.Torquethe2outerscrewsto1N∙m(10in-lb).

5.Workingformthecenterofthebedknife,torque

thescrewsto23to28N∙m(200to250in-lb).

g255046

Figure28

1.Bednifescrewtool3.Torqueto23to28N∙m

(200to250in-lb).

2.Installandtorquethese

rstto1N∙m(10in-lb).

6.Grindthebedknife.

BedknifeSpecications

BedknifeScrews

Torque:23to28N∙m(200to250in-lb)

Installationtool:TOR510880

Installationorder:

g254874

Figure29

BedknifeGrindingSpecications

g032182

Figure30

1.Reliefangle4.Frontface

2.Topface5.Frontangle

3.Removeburr

16

Standardbedknifereliefangle3°minimum

Extendedbedknifereliefangle7°minimum

FrontAngleRange13°to17°

BacklappingtheCutting

Unit

DANGER

Contactwiththereelorothermovingparts

canresultinpersonalinjury.

Keepyourngers,hands,andclothingaway

fromthereelsorothermovingparts.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrush

forbacklapping.PartNo.29-9100Handle

assemblycompleteorindividualpartsare

availablefromyourlocalauthorizedToro

distributor.

1.Positionthemachineonaclean,levelsurface,

lowerthecuttingunits,stoptheengine,engage

theparkingbrake,andremovetheignitionkey.

2.Removethereelmotorsfromthecuttingunits

anddisconnectandremovethecuttingunits

fromtheliftarms.

3.Connectthebacklappingmachinetothecutting

unitbyinsertingapieceof3/8inchsquarestock

intothesplinedcouplingintheendofthecutting

unit.

Note:Additionalinstructionsandprocedures

onBacklappingareavailableinyourtraction

unitOperator’sManualandtheToroSharpening

ReelandRotaryMowersManual,FormNumber

80-300PT.

Note:Forabettercuttingedge,runale

acrossthefrontfaceofthebedknifeandreel

whenthelappingoperationiscompleted.This

willremoveanyburrsorroughedgesthatmay

havebuiltuponthecuttingedge.

17

Notes:

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

04652316000001andUp8-BladeDPAReelMower8BLADECUTTINGUNIT

NGDPA8-BladeDPAReelMower2006/42/EC,

2000/14/EC

04654316000001andUp11-BladeDPAReelMower11BLADECUTTING

UNITNGDPA11-BladeDPAReelMower2006/42/EC,

2000/14/EC

04656316000001andUp14-BladeDPAReelMower14BLADECUTTING

UNITNGDPA14-BladeDPAReelMower2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHeckel

Sr.EngineeringManagerTel.+3216386659

8111LyndaleAve.South

Bloomington,MN55420,USA

May9,2018

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevD

This manual suits for next models

7

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

Cembre

Cembre B-TC650NA Operation and maintenance manual

EFA

EFA Z28S Operating Instructions, Maintenance instructions, Spare Part List

Kasanova

Kasanova GRA-TECH WIS000001-2 user manual

HSGM

HSGM HSG-00-VW operating instructions

Battipav

Battipav Queen 180 operating instructions

Westfalia

Westfalia 82 64 28 instruction manual