Toro Reelmaster 5010- H User manual

FormNo.3395-552RevA

Verticutter

Reelmaster®5010-HSeriesCuttingUnitwith

5–inchor7–inchReel

ModelNo.03618—SerialNo.315000001andUp

ModelNo.03619—SerialNo.315000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3395-552*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

Introduction

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

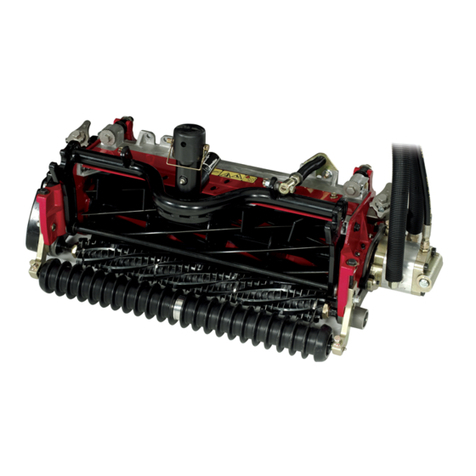

Theverticutterkitsaremountedonaride-onmachineand

areintendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesignedfor

verticuttinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1InspectingtheVerticutter.......................................6

2InstallingtheTransportRollers...............................6

3InstallingtheO-ringandtheGrease

Fitting................................................................6

4InstallingtheShoulderBolt(RM5010–Hybrid

only)..................................................................7

5InstallingtheEnd-WeightKit(Model03618

only)..................................................................7

6AdjustingtheBladeDepth.....................................8

7AdjustingtheRearGrassShield..............................8

8AdjustingtheRollerScrapers..................................9

9AdjustingtheTransportRollers...............................9

10MountingtheVerticutterReel..............................10

ProductOverview.........................................................10

Specications........................................................10

Operation....................................................................11

TrainingPeriod......................................................11

OperatingTips.......................................................11

Maintenance.................................................................12

LubricatingtheVerticutter.......................................12

RemovingtheVerticutterBladesfromthe

Shaft.................................................................12

InstallingtheVerticutterBlades................................13

OptionalBladeSpacing...........................................14

ServicingtheRoller.................................................15

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitoperatorsmanualbeforeoperatingthe

verticutters.

•Read,understand,andfollowallinstructionsinthis

operatorsmanualbeforeoperatingtheverticutters.

•Neverallowchildrentooperatethetractionunitor

verticutters.Donotallowadultstooperatetractionunit

orverticutterswithoutproperinstruction.Onlytrained

operatorswhohavereadthismanualshouldoperatethe

verticutters.

•Neveroperatetheverticutterswhenundertheinuence

ofdrugsoralcohol.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensureverticutteris

insafeoperatingcondition.

•Donotoperateverticutterswhilewearingsandals,tennis

shoes,sneakers,orshorts.Also,donotwearloose

ttingclothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantial,slip-resistant

shoes.Wearingsafetyglasses,safetyshoes,andahelmet

isadvisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbytheverticutterreelblades.Keepall

bystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

verticutterfordamagedparts.Repairanydamagebefore

restartingandoperatingtheverticutter.

•Lowertheverticutterstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Besureverticuttersareinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjustingorstoring

themachine.

3

•Performonlythosemaintenanceproceduresdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedToroDistributor.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

4

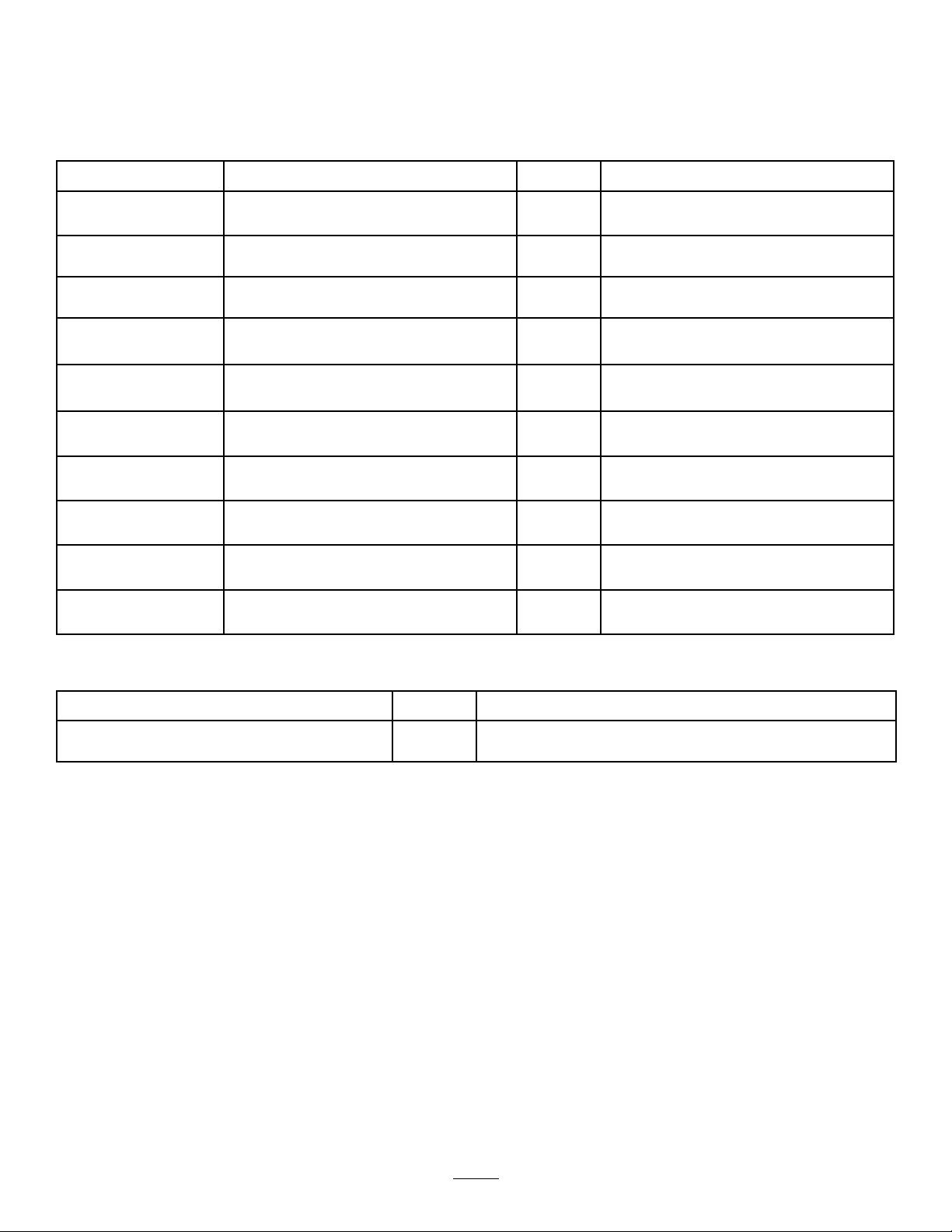

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Verticutter1Inspecttheverticutter.

Transportrollerassembly2

2Cotterpin2Installthetransportrollers.

O-ring1

3Straightgreasetting1InstalltheO-ringandthegreasetting.

4Shoulderbolt5Installtheshoulderbolt

(RM5010–Hybridonly)

5End-weightkit(soldseparately)1Installtheend-weightkit(Model03618

only).

6Nopartsrequired–Adjustthebladedepth.

7Nopartsrequired–Adjustthereargrassshield.

8Nopartsrequired–Adjusttherollerscrapers.

9Nopartsrequired–Adjustthetransportrollers.

10Nopartsrequired–Mounttheverticutterreel.

MediaandAdditionalParts

DescriptionQty.Use

PartsCatalog1

Operator'sManual1Reviewthematerialandsaveitinanappropriateplace.

5

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Whenevertheverticutterhastobetippedtoexpose

theverticutterblades,usethekickstand(suppliedwith

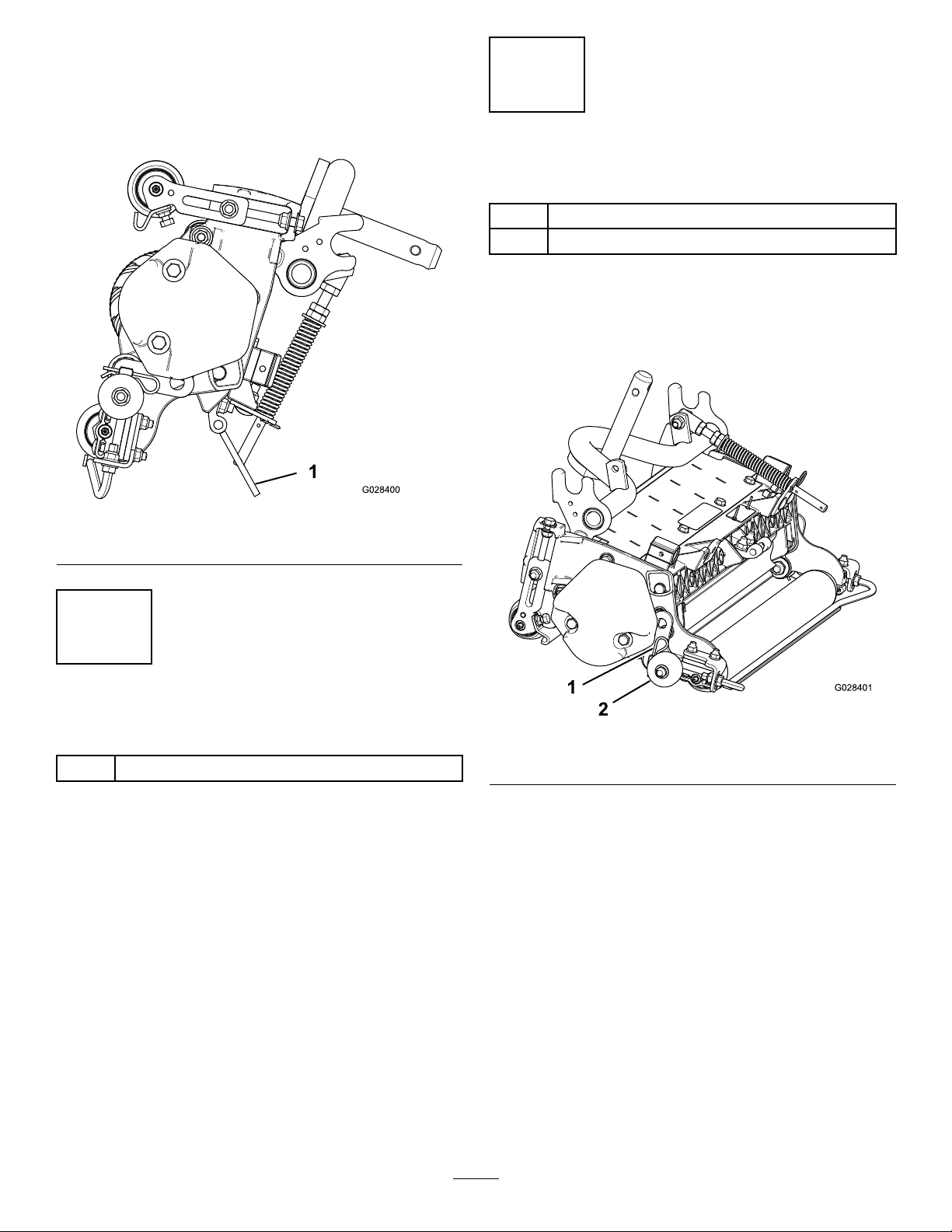

tractionunit);refertoFigure2.

Figure2

1.Kickstand

1

InspectingtheVerticutter

Partsneededforthisprocedure:

1Verticutter

Procedure

Aftertheverticutterisremovedfromthebox,inspectthe

following:

1.Checkeachendofthereelforgrease.Greaseshouldbe

visiblyevidentintheinternalsplinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethatthecarrierframesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

2

InstallingtheTransportRollers

Partsneededforthisprocedure:

2Transportrollerassembly

2Cotterpin

Procedure

Secureatransportrollerbrackettoeachsideplatepinwith

acotterpin(Figure3).

Figure3

1.Cotterpin2.Transportrollerassembly

Note:Therollershouldbepositionedtotherearofthe

verticutter.

6

3

InstallingtheO-ringandthe

GreaseFitting

Partsneededforthisprocedure:

1O-ring

1Straightgreasetting

Procedure

Thegreasettingmustbeinstalledonthereelmotorsideof

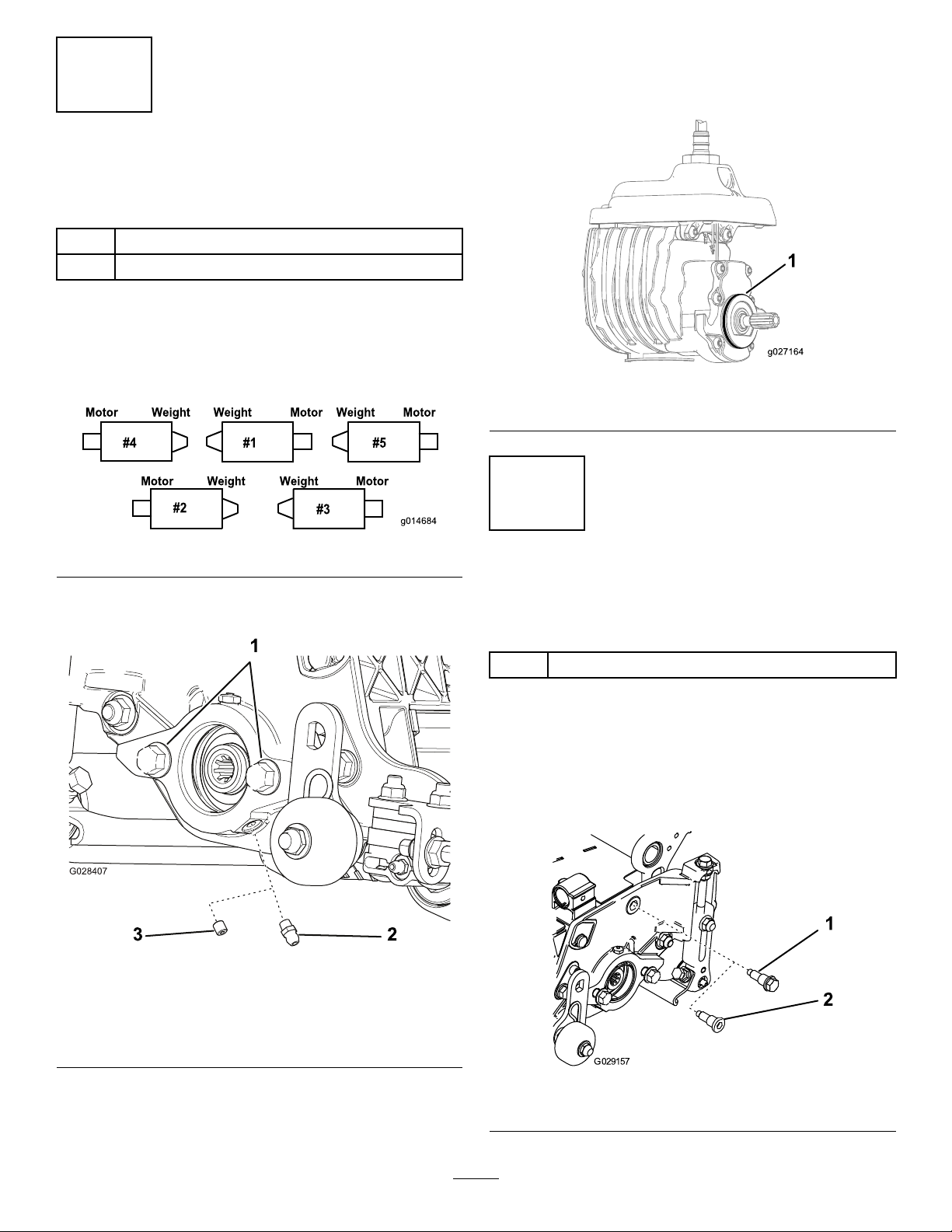

theverticutter.Usethefollowingdiagramtodeterminethe

positionofeachreelmotor(Figure4).

Figure4

1.Removeanddiscardthesetscrewonthereel-motor

side-plate(Figure5).

32

G028407

1

Figure5

1.Capscrews3.Setscrew(removeand

discard)

2.Straightgreasetting

(install)

2.Installthestraightgreasetting(Figure5).

3.Iftherearenoboltsonthereel-motorside-plate,install

them(Figure5).

4.InstalltheO-ringonthereelmotor(Figure6).

Note:Theelectricmotorisshown;thisstepalso

appliestothehydraulicmotor.

Figure6

1.O-ring

4

InstallingtheShoulderBolt

(RM5010–Hybridonly)

Partsneededforthisprocedure:

5Shoulderbolt

Procedure

ForverticuttersbeingmountedonaReelmaster5010–H,

locatedonthereel-motorside-plate(Figure7),mustbe

replacedwiththenewshoulderboltortheelectricreelwill

contacttheexistingbolt.

Figure7

1.Oldbolt2.Newshoulderbolt

7

5

InstallingtheEnd-WeightKit

(Model03618only)

Partsneededforthisprocedure:

1End-weightkit(soldseparately)

Procedure

Buyandinstalltheendweightkitappropriateforthe

congurationofyourmachine(Figure8).

•WeightKitModel03411forelectricreelmotors

•WeightKitModel03412forhydraulicreelmotors

Figure8

1.Endweight(largeweightshown)

Theverticutterscanbeinstalledatanyofthe5locationson

thetractionunit.Figure4showstheorientationofthedrive

motorforeachofthelocations.Foranyofthelocations

requiringthemotortobemountedontherightendofthe

verticutter,installacounterweightontheleftendofthe

verticutter.Forthelocationsrequiringthemotortobe

mountedontheleftend,installacounterweightontheright

endoftheverticutter.

Note:ForModel03619,counterweightsareshipped

installedtotherightendoftheverticutters.Theboltsonthe

leftendaretobeusedforsecuringthemotor.

6

AdjustingtheBladeDepth

NoPartsRequired

Procedure

Note:Themaximumrecommendedbladepenetration

depthsareasfollows:

•Model03618is3mm(1/8inch).

•Model03619is6mm(1/4inch).

1.Placetheverticutterreelonalevelsurface.

2.Place2gaugebars,whichhavethedesireddepthof

bladepenetrationbelowtheground,underthefront

andrearrollersoftheverticutterreeloneachendof

thereel(Figure9).

Figure9

1.Gaugebars2.Adjustingbolts

Note:Theverticutterbladesmustnottouchthe

gaugebars.

3.Turntheadjustingboltoneachheight-of-cutbracket

(Figure9)sothatthereelbladescomeincontactwith

thelevelsurfaceonbothends.

Note:Astheverticutterbladeswear,thediameterof

thereelwilldecreaseandthedepthsettingwillchange.

Checkthedepthsettingperiodicallytoensurethatthe

desiredsettingisachieved.

8

7

AdjustingtheRearGrass

Shield

NoPartsRequired

Procedure

Note:Whenoperatinginturfconditionswheremuchdebris

orunusuallyheavythatchisencountered,opentherear

dischargeshieldtohelpallowthedebristodischargefrom

thereel.

1.Loosentheboltsonthepivotofthegrassshield

(Figure10).

Figure10

1.Reargrassshield2.Pivotbolt

2.Rotatethegrassshieldtothedesiredsetting,and

tightenthebolts(Figure10).

CAUTION

Donotopentherearshieldsothatitishigherthan

leveltoground.

Throwndebriscouldcausepersonalinjury.

8

AdjustingtheRollerScrapers

NoPartsRequired

Procedure

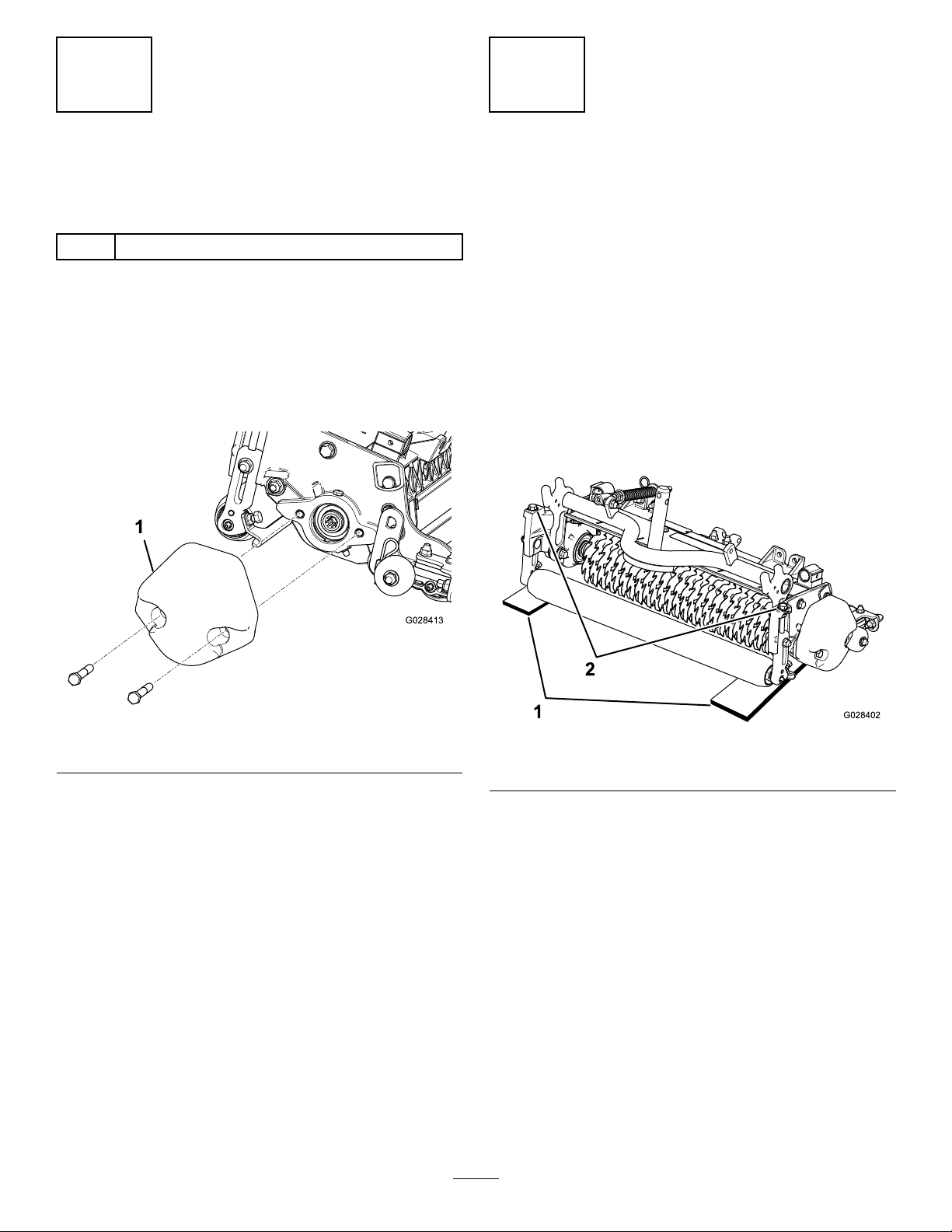

1.Loosentheangenutsthatsecuretherollerscrapers

(Figure11).

Figure11

1.Frontrollerscraper3.Transportroller

2.Rearrollerscraper4.Cotterpin

2.Movethescraperrodsinorouttoattain0.0to0.75

mm(0.0to0.03inch)clearancebetweenthescraper

androller.

3.Ensurethatthescraperrodisparalleltotherollerand

tothelevelsurface.

4.Tightentheangenutstolocktheadjustment.

9

AdjustingtheTransport

Rollers

NoPartsRequired

Procedure

Beforetheverticuttersareloweredtotheshopooror

removedfromthetractionunit,lowerthetransportrollers

(Figure11)toprotectthebladesfromhardsurfacecontact.

1.Removethecotterpinthatsecuresthetransportroller

brackettothesideplatepin.

2.Positionthetransportrollerasfollows:

9

•Lowertherollerbracketbeforetheverticutteris

loweredtotheshopoor.

•Raisetherollerbracketaftertheverticutterisraised

totheoperatingposition.

3.Securethetransportrollerbrackettothesideplatepin

withthecotterpin.

4.Repeattheprocedureontheoppositeendofthe

verticutter.

10

MountingtheVerticutterReel

NoPartsRequired

Procedure

Verticutterreelsaremountedtotractionunitthesameway

cuttingunitsare.RefertoTractionUnitOperator'sManualfor

mountinginstructions.

Installthereelmotorandgreasethesideplateuntilexcess

greaseoozesoutofthereliefvalve(Figure12).

ProductOverview

Specications

ModelNetweight

Withnoendweight:

49.4kg(109lb)

Withsmallendweight

(hydraulicmotor):

52.6kg(116lb)

03618

Withlargeendweight

(electricmotor):

55.8kg(123lb)

0361959.9kg(132lb)

10

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

TrainingPeriod

Beforeoperatingtheverticutterreels,evaluatethe

performanceofthereelatthedesiredsetting.Operateina

clear,unusedareatodetermineifthedesiredresultswillbe

achieved.Adjustasdesired.

OperatingTips

1.Operatethetractionunitatfullthrottle,fullreelspeed

(setting9)andatthedesiredtractionspeed.

2.Themaximumrecommendedbladepenetrationdepths

areasfollows:

•Model03618is3mm(1/8inch).

•Model03619is6mm(1/4inch).

3.Powerrequirementstooperatetheverticutterreelswill

varywithturfandsoilconditions.Travelspeedmay

needtobereducedinsomeconditions.

4.Whenoperatinginturfconditionswheremuchdebris

isencountered,orunusuallyheavythatch,openthe

frontandreardischargeshieldstohelpallowthedebris

todischargefromthereel.

CAUTION

Throwndebriscouldcausepersonalinjury.

Donotopentherearshieldsothatitishigher

thanleveltotheground.

11

Maintenance

LubricatingtheVerticutter

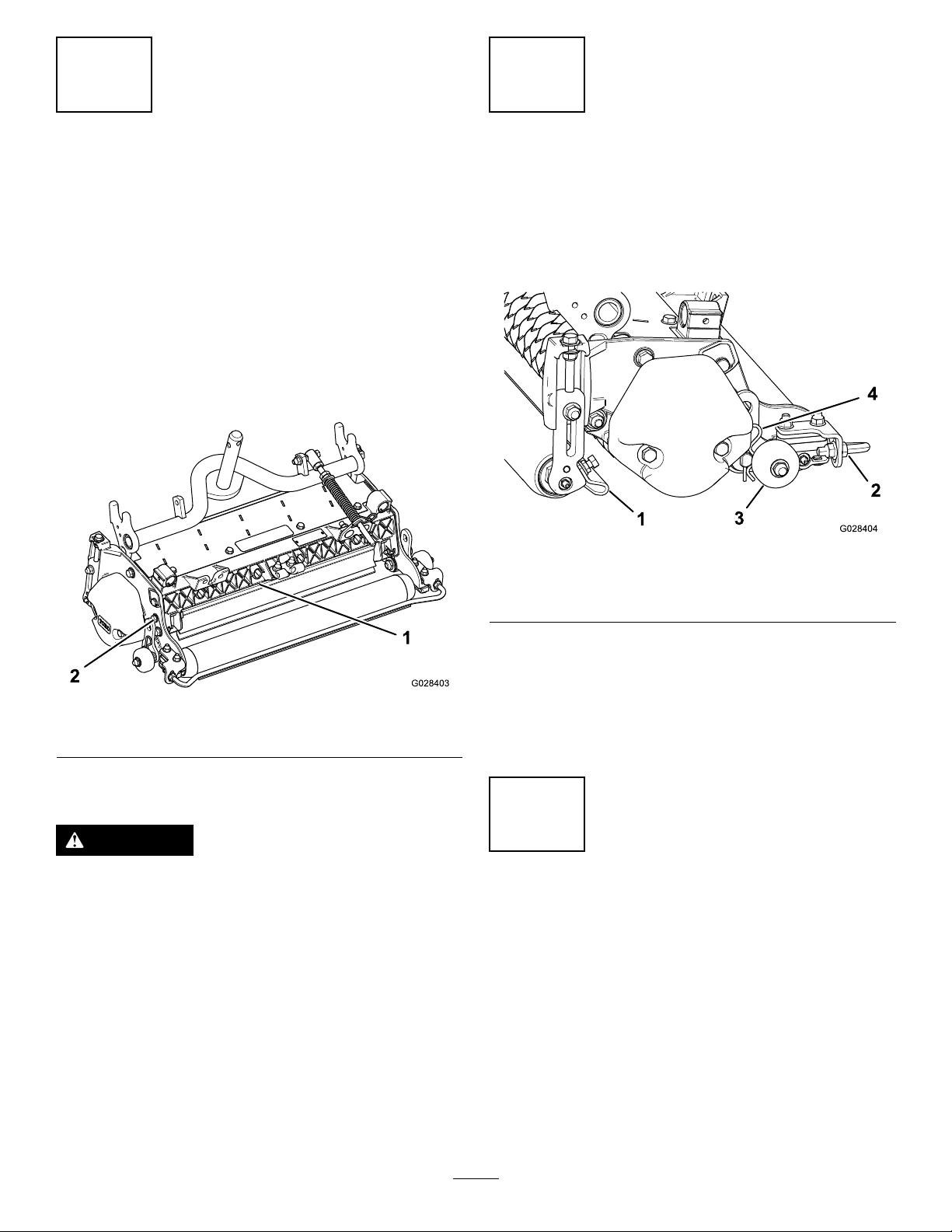

Eachverticutterhas5greasettings(Figure12)thatmustbe

lubricatedweeklywith#2general-purpose,lithium-based

grease.

Thelubricationpointsarethefrontroller(2),therearroller

(2),andthereelmotorsplines(1).

Important:Lubricatingthecuttingunitsimmediately

afterwashinghelpspurgewateroutofthebearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilyouseecleangreasecomingoutof

therollersealsandthebearingreliefvalve(Figure12).

Figure12

1.Reliefvalve

3.Wipeanyexcessgreaseaway.

RemovingtheVerticutter

BladesfromtheShaft

1.Securetheendoftheverticuttershaft,whichhasonly

onewasherandnut,inavise.

2.Onotherendofshaft,rotatethenutcounter-clockwise

andremovethenut.

CAUTION

Thebladesareextremelysharpandmayhave

burrsthatwillcutyourhands.

Usecautionwhenremovingthebladesfrom

theshaft.

3.Removethesmallspacer,thewasher,theblades,and

thelargespacers.Cleanandlubricatethesquareshaft

withalightcoatingofgreasetosimplifytheassembly

(Figure13).

Figure13

1.Shaft4.Smallspacer

2.Nut5.Blade(25formodel03618;

16formodel03619)

3.Washer6.Largespacer(24for

model03618;15formodel

03619)

Important:Donotinverttheverticutterreel

blades.Theorderofdisassemblyisextremely

important.Donotinverttheverticutterreelblades

whendisassemblingorreversetheorderwhen

assemblingthem.Notetheindexholeineach

verticutterblade.Theindexholeisprovidedfor

assemblyinordertoobtaintheproperhelixfor

theverticutterreel.

12

InstallingtheVerticutter

Blades

1.Assembleablade(Figure14).

2.Assemblealargespacer.

3.Donotinvertthereelbladeswhenassemblingthem

onthereelshaft.

Note:Ifthebladesareinverted,thebladesthatare

inuse,(rounded)willbemixedwiththesharpends

ofthebladeswhichwerenotinuse.Thiswillcause

unsatisfactoryperformanceintheverticutterreelunit.

Attentionshouldalwaysbetakenwhendisassembling

theverticutterbladesfromreel.

4.Installthenextbladeclockwisesothattheindex

referencehole(Figure14)isnotalignedwiththerst

bladeholebyoneatoftheshaft.

G017524

Figure14

1.Indexreferencehole

5.Continuetoinstallspacersandbladesinthismanner

untilthefullcomplementofbladeshavebeeninstalled.

Note:Whenproperlyassembled,thebladeswillbe

staggeredinsuchamannerastoappearlikeahelix.

6.Installthesmallspacertotheshaft.

7.ApplyBlueLoctite242tothenut.Installthenutonto

theshaft(machinedsideofthenuttowardthespacer),

andtightenitto109to135N-m(80to100ft-lb).

13

OptionalBladeSpacing

0.50-InchBladeSpacingforModel03618

Tochangethecongurationoftheverticutterfromthestandard0.75-inchspacingtothe0.50-inchspacingrequiresan

additional34spacers,partno.17-1580andanadditional10carbideblades,partno.106-6355,oranadditional10regularblades

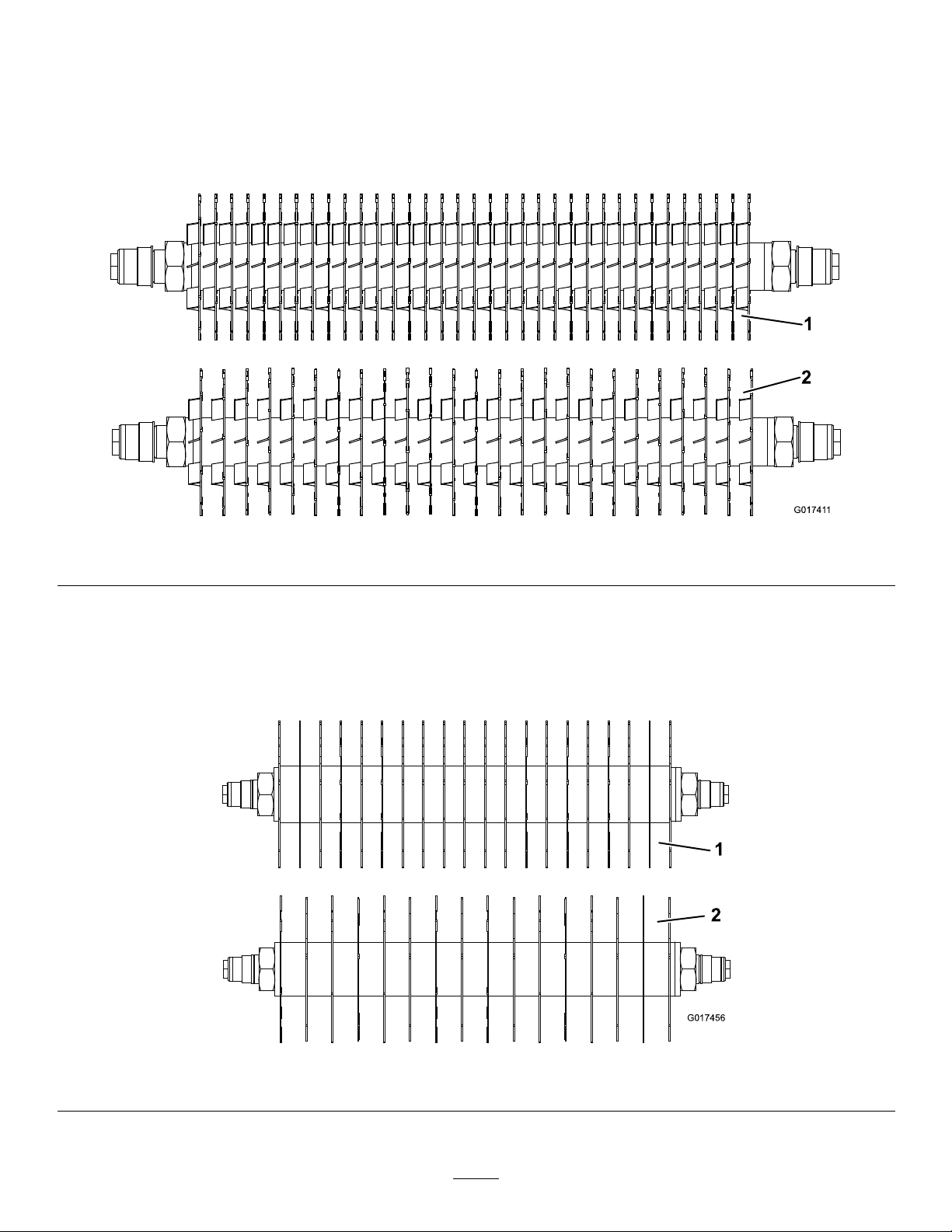

andpartno.17-1590(Figure15).

1

2

Figure15

1.0.50-inchspacing2.0.75-inchspacing

1.00-InchBladeSpacingforModel03619

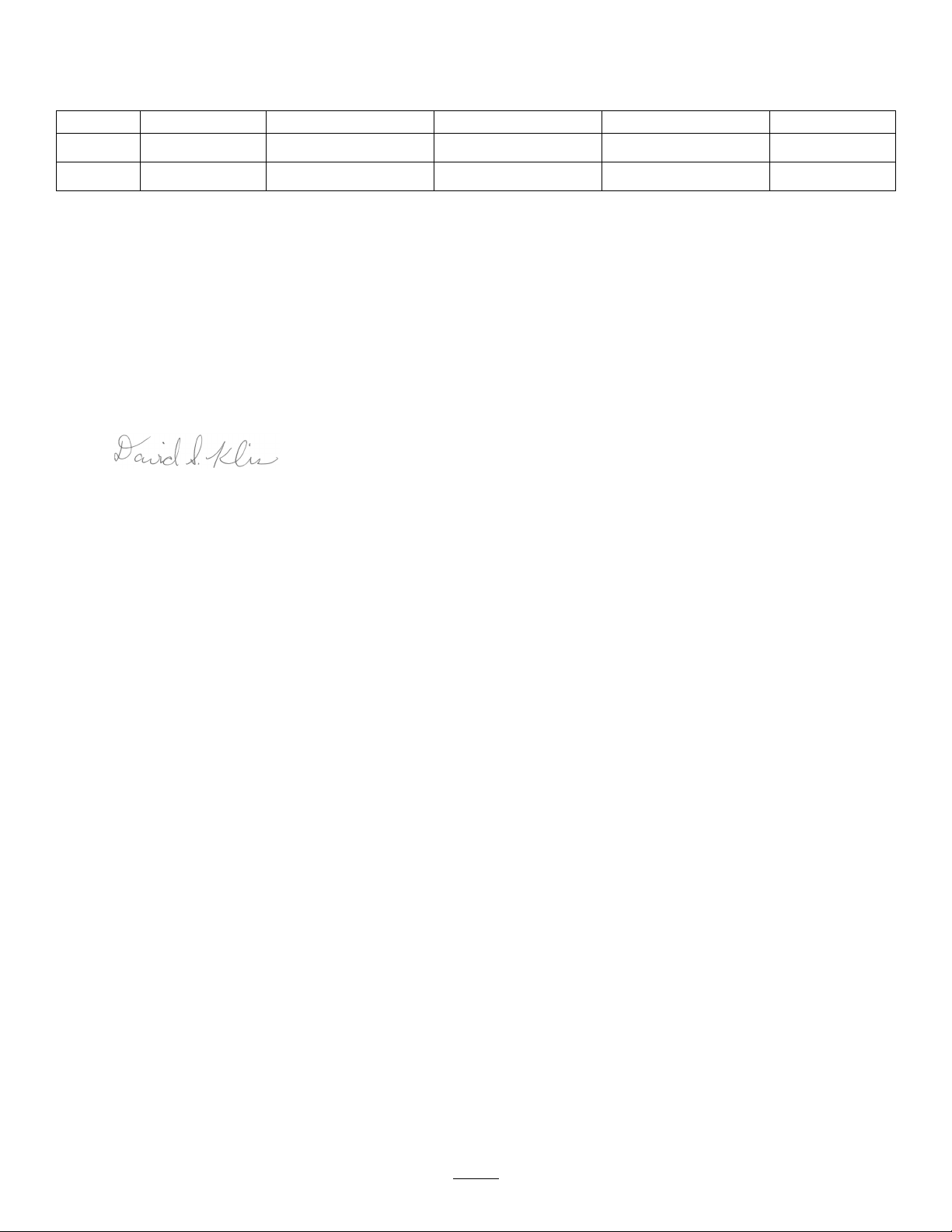

Tochangethecongurationoftheverticutterfromthestandard1.25-inchspacingtothe1.00-inchspacingrequires19new

spacers,partno.93-3092andanadditional4carbideblades,partno.106-8625,oranadditional4regularbladesandpart

no.93-3038-03(Figure16).

G017456

1

2

Figure16

1.1.00-inchspacing2.1.25-inchspacing

14

ServicingtheRoller

ARollerRebuildKit,PartNo.114–5430andaRollerRebuild

ToolKit,PartNo.115–0803(Figure17)areavailablefor

servicingtheroller.TheRollerRebuildKitincludesallthe

bearings,bearingnuts,innersealsandoutersealstorebuilda

roller.TheRollerRebuildToolKitincludesallthetoolsand

theinstallationinstructionsrequiredtorebuildarollerwith

therollerrebuildkit.Refertoyourpartscatalogorcontact

yourAuthorizedToroDistributorforassistance.

Figure17

1.Rebuildkit(PartNo.114–5430)6.Bearingnut

2.Rebuildtoolkit(PartNo.115–0803)7.Innersealtool

3.Innerseal8.Washer

4.Bearing9.Bearing/outersealtool

5.Outerseal

15

Notes:

16

Notes:

17

DeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

03618315000001andUpVerticutter22IN5INVERTICUTTER

[5010HYBRID]Verticutter2006/42/EC

03619315000001andUpVerticutter22IN7INVERTICUTTER

[5010HYBRID]Verticutter2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

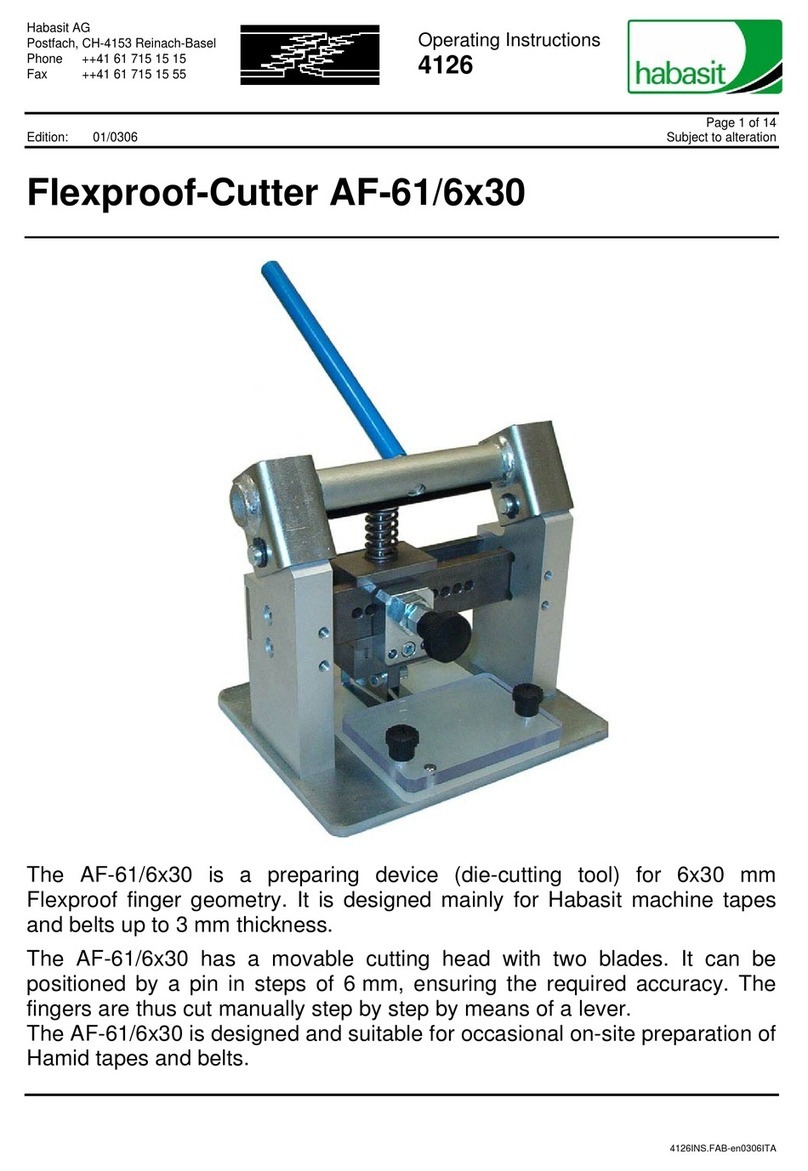

Certied:EUT echnicalContact:

PeterTetteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManagerFax003214581911

8111LyndaleAve.South

Bloomington,MN55420,USA

December11,2014

18

InternationalDistributorList

Distributor:Country:PhoneNumber:Distributor:Country:Phone

Number:

AgrolancKftHungary3627539640MaquiverS.A.Colombia5712364079

BalamaPrimaEngineeringEquip.HongKong85221552163MaruyamaMfg.Co.Inc.Japan81332522285

B-RayCorporationKorea82325512076Mountelda.s.CzechRepublic420255704

220

CascoSalesCompanyPuertoRico7877888383Mountelda.s.Slovakia420255704

220

CeresS.A.CostaRica5062391138MunditolS.A.Argentina54114821

9999

CSSCTurfEquipment(pvt)Ltd.SriLanka94112746100NormaGardenRussia74954116120

CyrilJohnston&Co.NorthernIreland442890813121OslingerTurfEquipmentSAEcuador59342396970

CyrilJohnston&Co.RepublicofIreland442890813121OyHakoGroundandGarden

Ab

Finland35898700733

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala5024423277PerfettoPoland48618208416

ForGarderOUEstonia3723846060PratoverdeSRL.Italy390499128

128

G.Y .K.CompanyLtd.Japan81726325861Prochaska&CieAustria4312785100

GeomechanikiofAthensGreece30109350054RTCohen2004Ltd.Israel97298617979

GolfinternationalTurizmTurkey902163365993RiversaSpain34952837500

GuandongGoldenStarChina862087651338LelyTurfcareDenmark4566109200

HakoGroundandGardenSweden4635100000SolvertS.A.S.France331308177

00

HakoGroundandGardenNorway4722907760SpyprosStavrinidesLimitedCyprus35722434131

HayterLimited(U.K.)UnitedKingdom441279723444SurgeSystemsIndiaLimitedIndia911292299901

HydroturfInt.CoDubaiUnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

HydroturfEgyptLLCEgypt2025194308ToroAustraliaAustralia61395807355

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

4387

ValtechMorocco21253766

3636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalTorocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithToro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailat[email protected].

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevH

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevC

Other manuals for Reelmaster 5010- H

8

This manual suits for next models

2

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

Habasit

Habasit AF-61/6 30 Series operating instructions

CellPath

CellPath TruSlice Digital CBA-0200-00A Instructions for use

SignWarehouse.com

SignWarehouse.com Vinyl Express Cougar 24" owner's manual

Makita

Makita 180 mm 4157KB instruction manual

KINZO

KINZO 29605 manual

ORSI

ORSI Acrobat 4.4 Translation of the original instructions