4

SAFETY INSTRUCTIONS

Improper use or maintenance of the machine can

result in injury. To reduce the potential for injury,

comply with the following safety instructions.

BEFORE OPERATING

1. Owners of this Aerator must give operators and

employees full operation and safety instructions before

allowing them to operate this machine and at least

annually thereafter. An operator who has not read and

fully understood all operating and safety instructions is

not qualified to operate this machine. Become familiar

with all controls and know how to stop quickly. A free

replacement manual is available by sending complete

Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, Minnesota 55420-1196 USA

2. Do not allow children to operate the machine. Do

not allow adults to operate the machine without proper

instruction.

3. Remove all debris or other objects that might

interfere with operation. Keep all bystanders away from

the work area.

4. Locate and mark all under ground obstructions

such as irrigation components, electrical or telephone

lines.

5. Make sure tractor is in neutral and hand brake

applied before starting. Refer to Tractor Operator's

Manual for safe starting procedures.

6. To maintain full steering control, add front end

weights to tractor. Refer to Tractor Operator's Manual

for weight requirements.

7. Keep all shields and safety devices in place. If a

shield, safety device or decal is damaged, repair or

replace it before operation is commenced. Also tighten

any loose nuts, bolts and screws to assure machine is

in safe operating condition.

8. Do not operate machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing which could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, ear protection

and a helmet is advisable and may be required by

some local ordinances and insurance regulations.

WHILE OPERATING

9. Keep all bystanders and pets away from the work

area.

10. Using the machine demands attention, and to

prevent loss of control:

A. Use only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not transport machine close to a sand trap,

ditch, creek or other hazard.

D. Reduce speed on side hills and before making

sharp turns to prevent tipping or loss of control.

E. Look behind the aerator before backing up.

11. If the tines strike a solid object or the machine

vibrates abnormally, shut the engine off. Remove key

from ignition switch. Check aerator and traction unit for

damage. Repair any damage before restarting the

engine and operating the tines. Be sure tines are in

good condition and all bolts are tight.

12. Before leaving machine unattended, disengage

power to aerator, lower aerator and set parking brake.

Stop engine.

13. Never dismount while tractor is in motion. Never

get on or off tractor while engine is running and PTO

drive shaft is engaged. Never step over PTO shaft to

reach other side of aerator - walk around the machine.

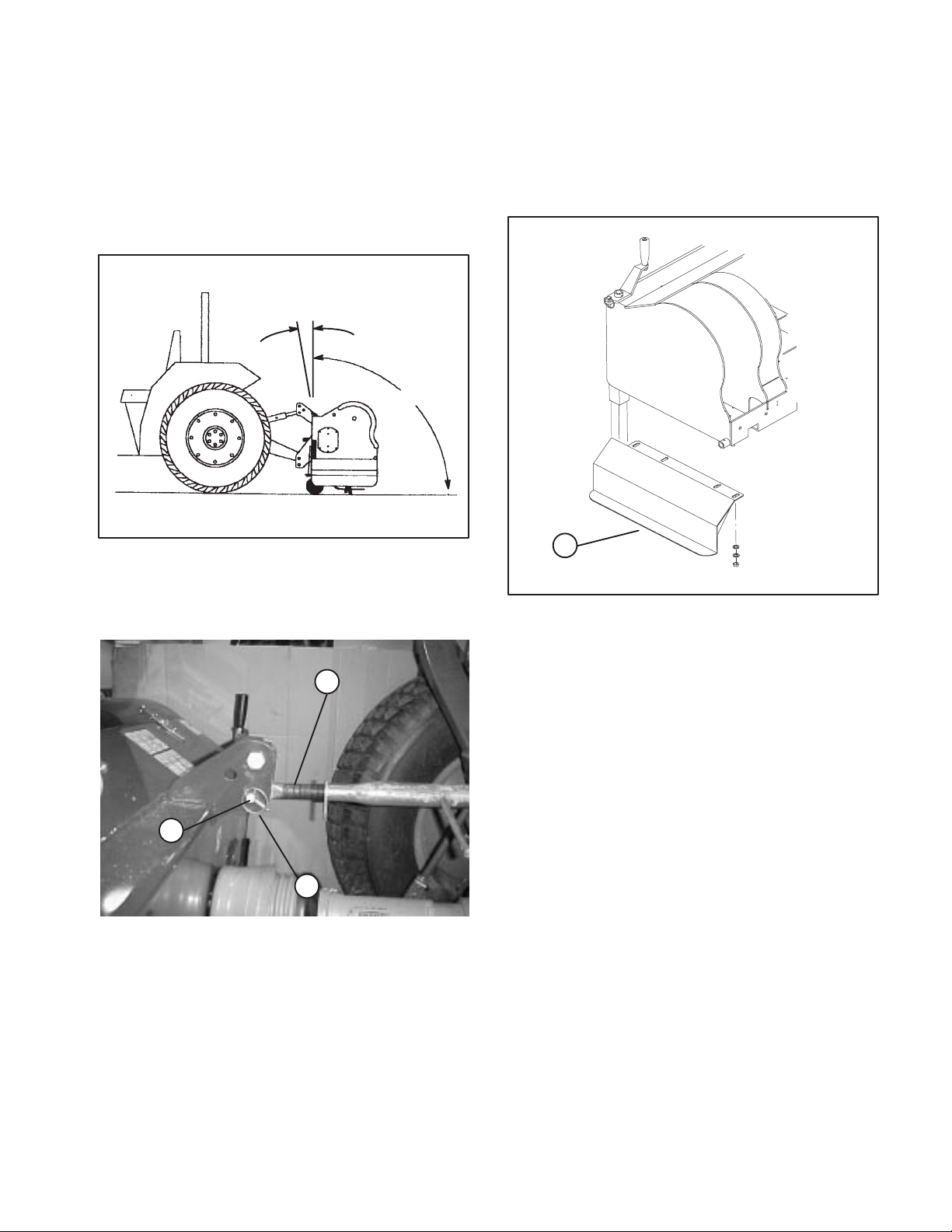

14. Park aerator on a level surface, install rear

support/safety stand and chock roller before

disconnecting from tractor.

15. If it is necessary to probe below the soil surface,

use a non conductive material to prevent electrical

shock in case electrical wires are present.

TRANSPORTING

16. Be sure you are in compliance with all regulations

regarding transporting equipment on the public roads

and highways.

17. Ensure that all reflectors and lights required are in

place and are clean and visible by overtaking and

oncoming traffic.

18. Never allow anyone to ride on the machine during

transport.

19. Reduce speed on rough roads and surfaces.

20. Independent brakes should ALWAYS be locked

together when on the road.

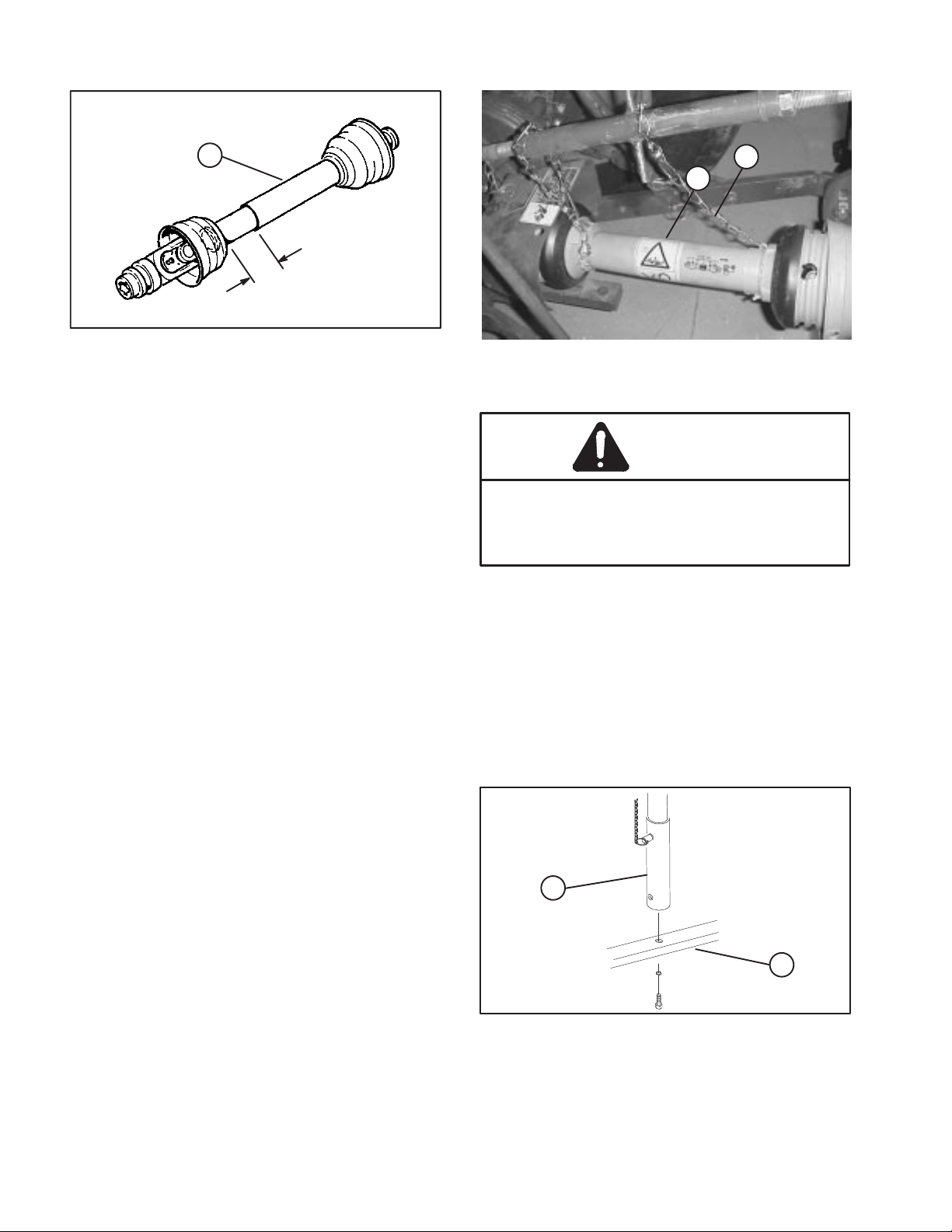

PTO SHAFT

21. For all PTO shaft steel parts (tubes, bearings, joints

etc). disassembly or repairs, it is highly advisable to

contact your local Toro distributor. Removal of

components for repairs and re-assembly may

damage some parts if not carried out correctly using

special tools available in a dealer's workshop.

22. The PTO shaft should not be used without the

guards supplied, with partial protection, with damaged

guard or without the special anti-rotation chains

correctly hooked, so as to permit the maximum angle

of the PTO shaft without breaking the chains.