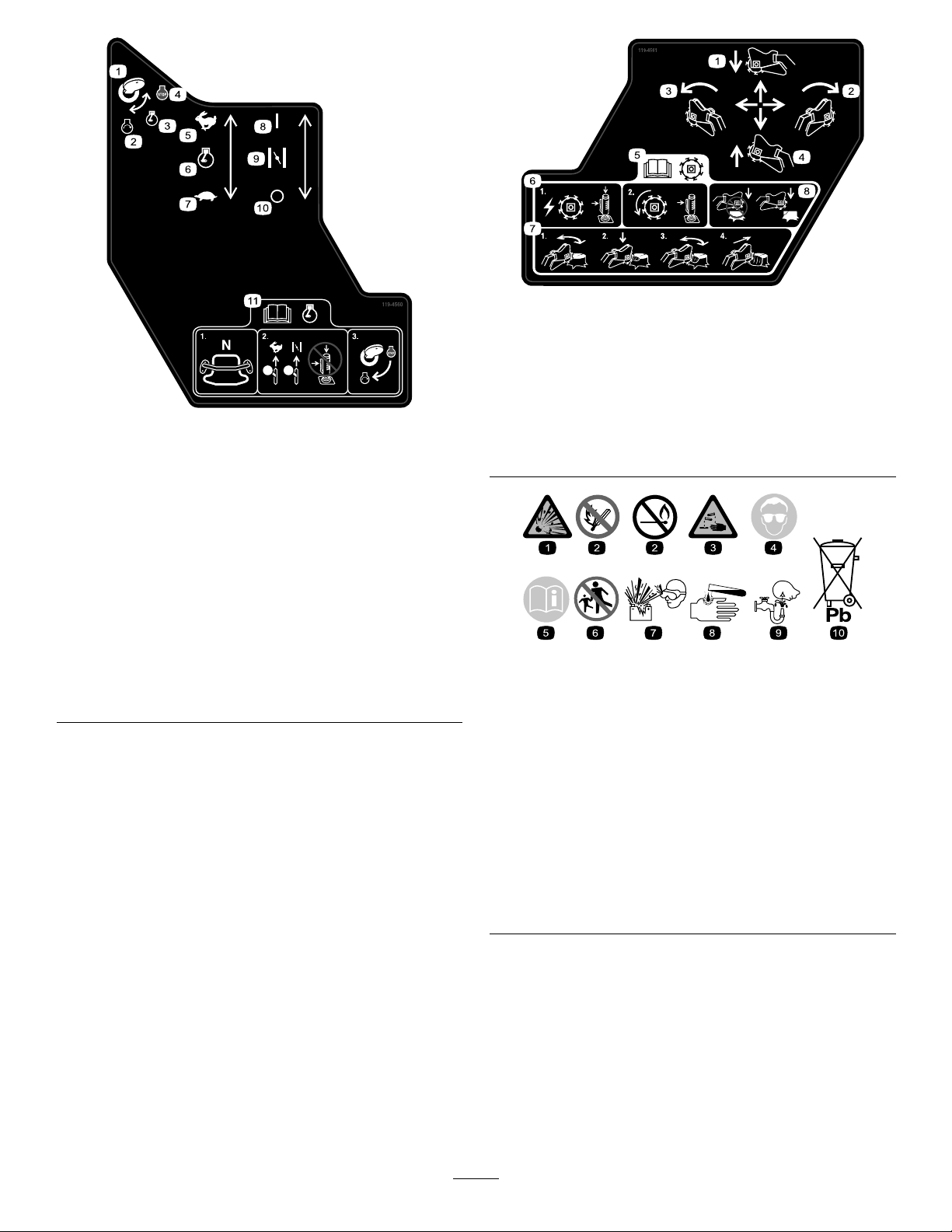

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralbeforestartingthe

engine.Onlystarttheenginefromtheoperator's

position.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine'sstability.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerthegrinder,disengage

thehydraulics,andshutofftheenginebeforeleaving

theoperator'spositionforanyreason.

•Keephandsandfeetawayfromthemovinggrinder

wheelandteeth.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyone

entersthearea.

•Neverleavearunningmachineunattended.Always

lowerthegrinder,stoptheengine,andremovethe

keybeforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytothe

operator.Failuretomaintainadequatedistancefrom

trees,walls,andotherbarriersmayresultininjury

asthemachinebacksupduringoperationifthe

operatorisnotattentivetothesurroundings.Only

operatetheunitinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Beforedigging,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthemachine

andkeephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

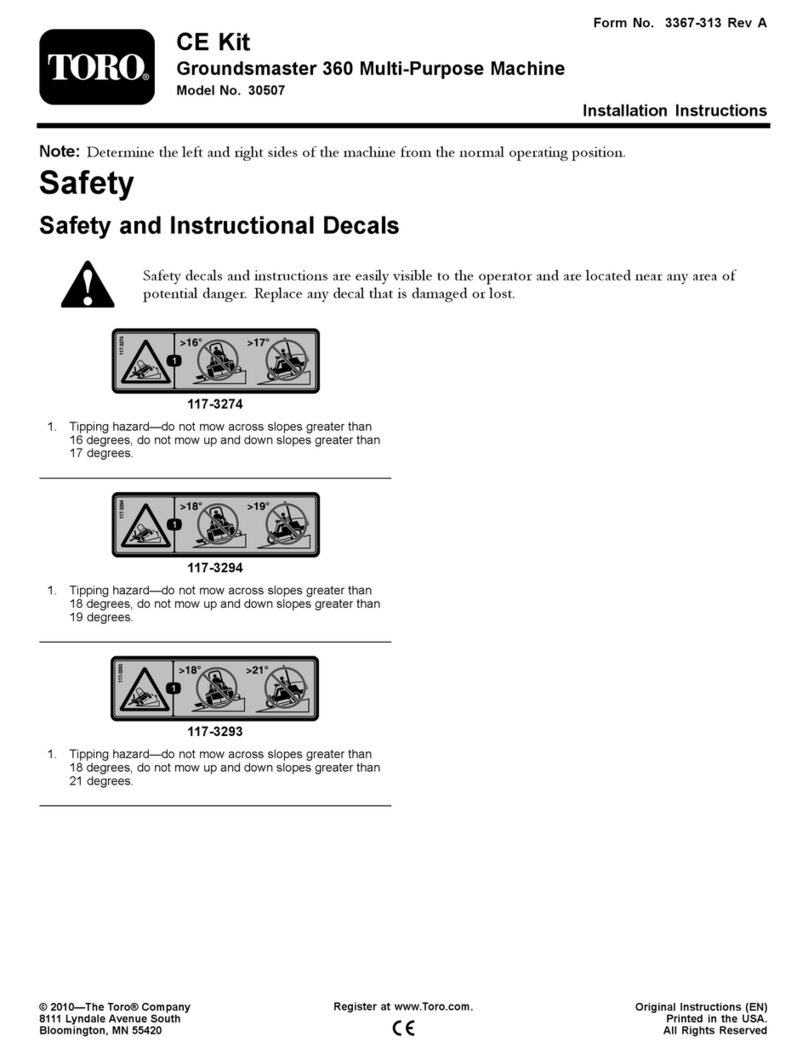

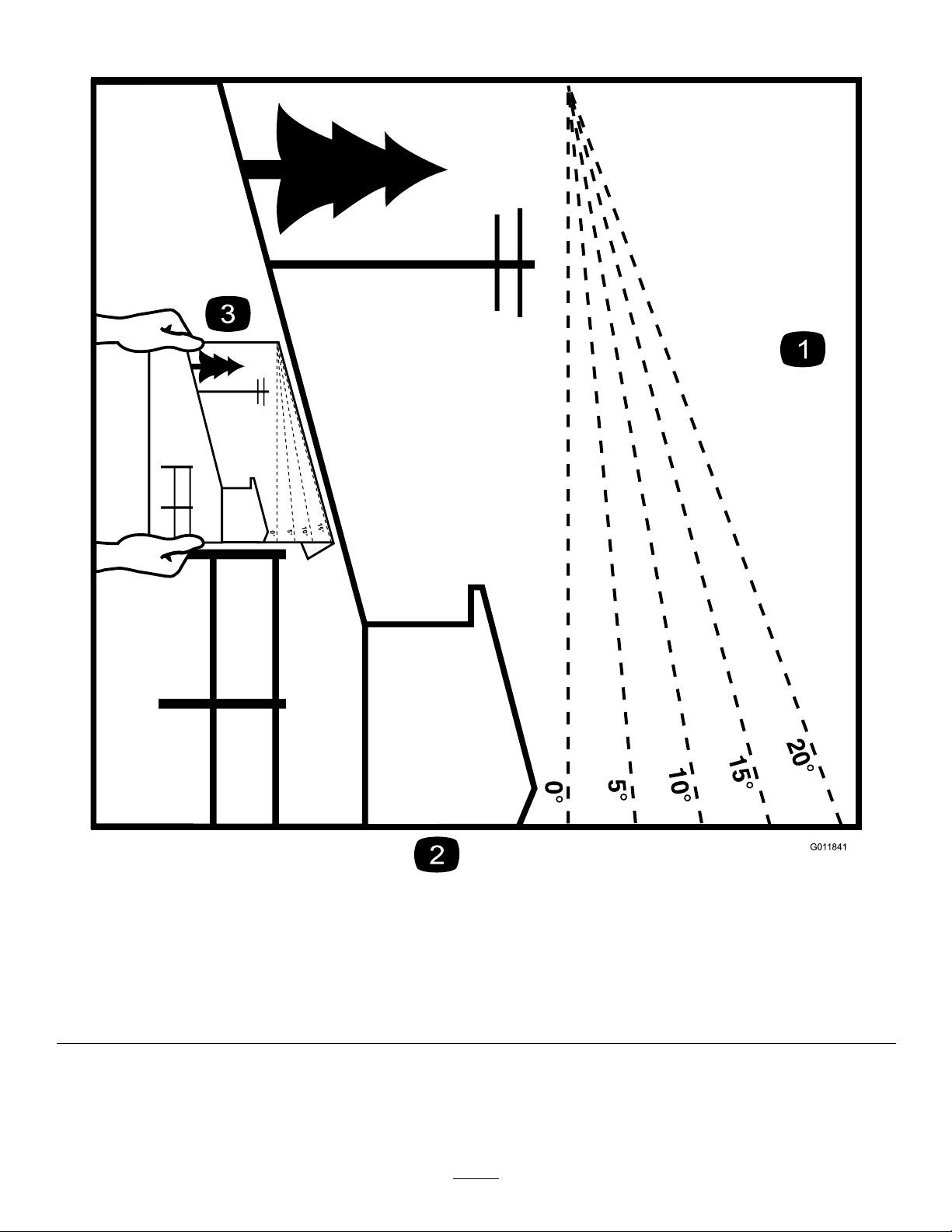

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Allslopesrequireextracaution.

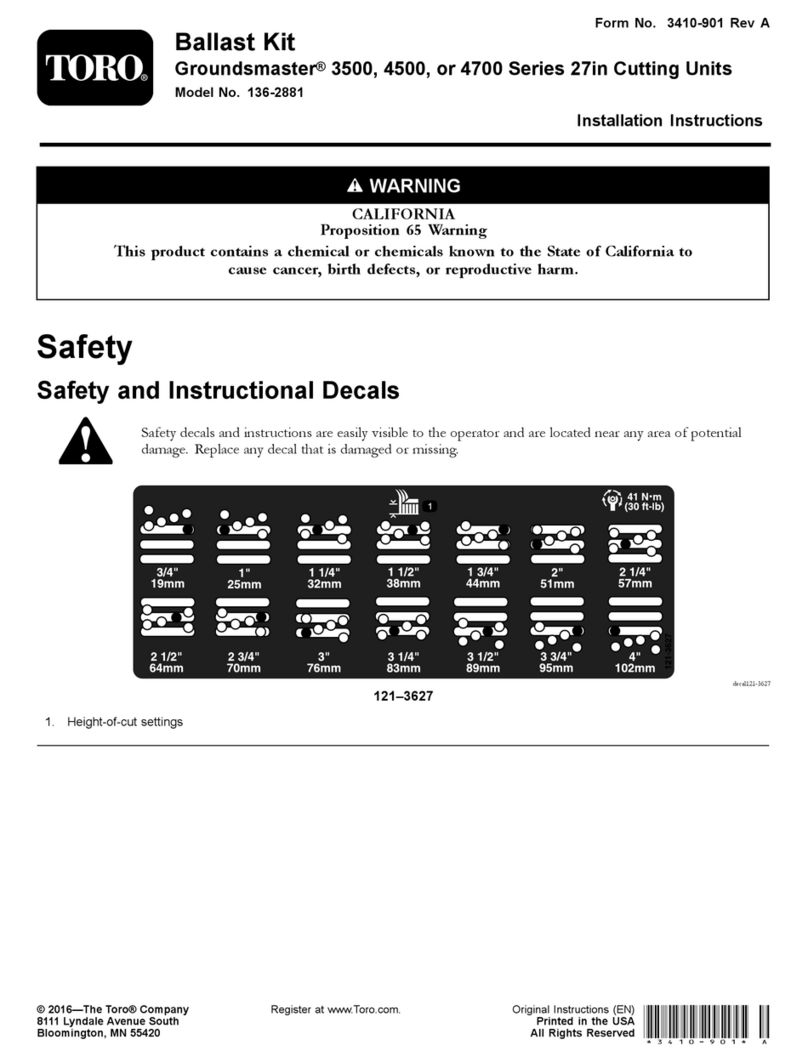

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinthefollowing

table.

FrontFacing

Uphill

RearFacingUphillSideFacingUphill

12°18°16°

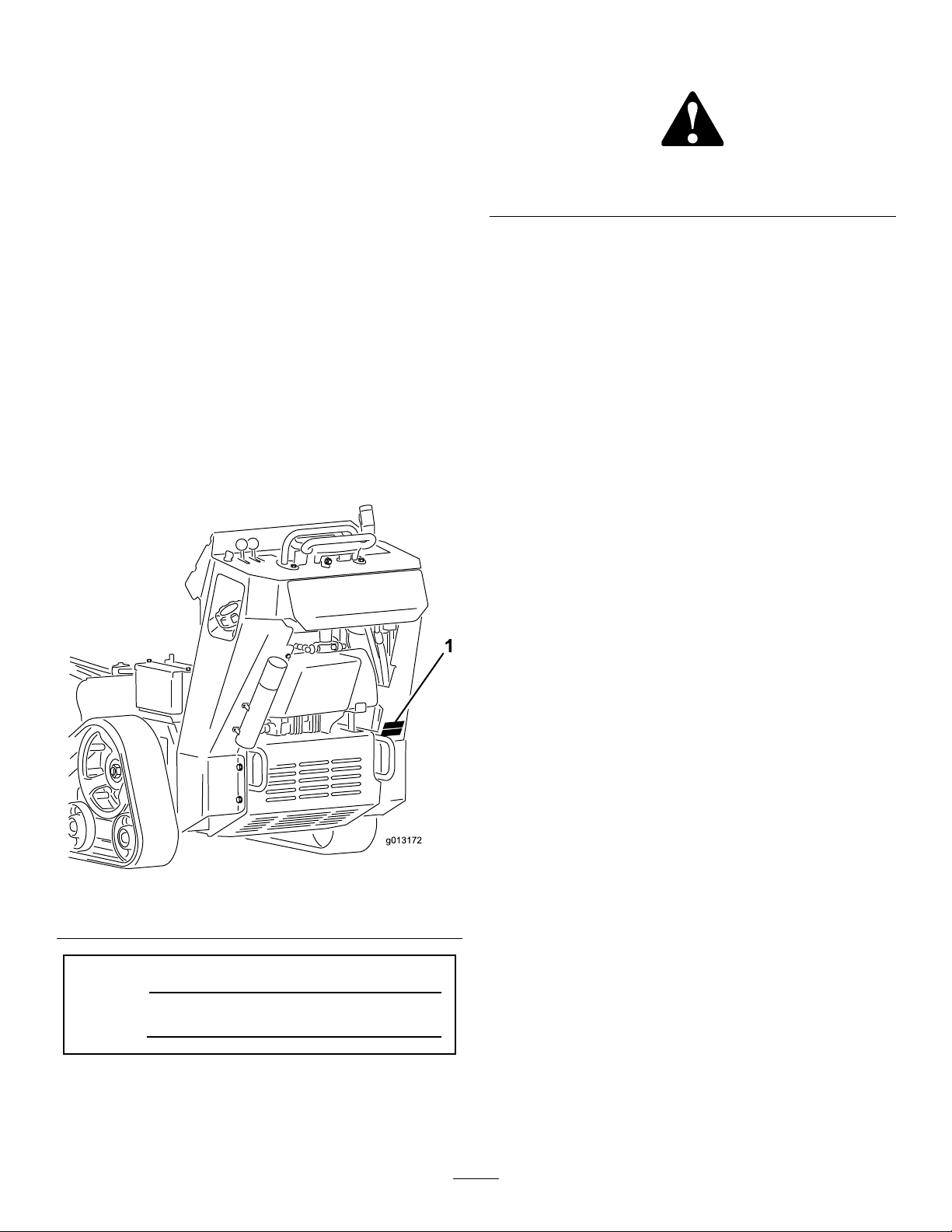

Note:SeealsotheSlopeIndicator(page7).

•Operateupanddownslopeswiththefrontend

ofthemachineuphill.

•Removeobstaclessuchasrocks,treelimbs,etc.

fromtheworkarea.Watchforholes,ruts,orbumps,

asuneventerraincouldoverturnthemachine.Tall

grasscanhideobstacles.

•UseonlyToro-approvedaccessories.Accessoriescan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedaccessories.

•Keepallmovementsonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

5