Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Slope Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Floor Scraper Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance and Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . 4

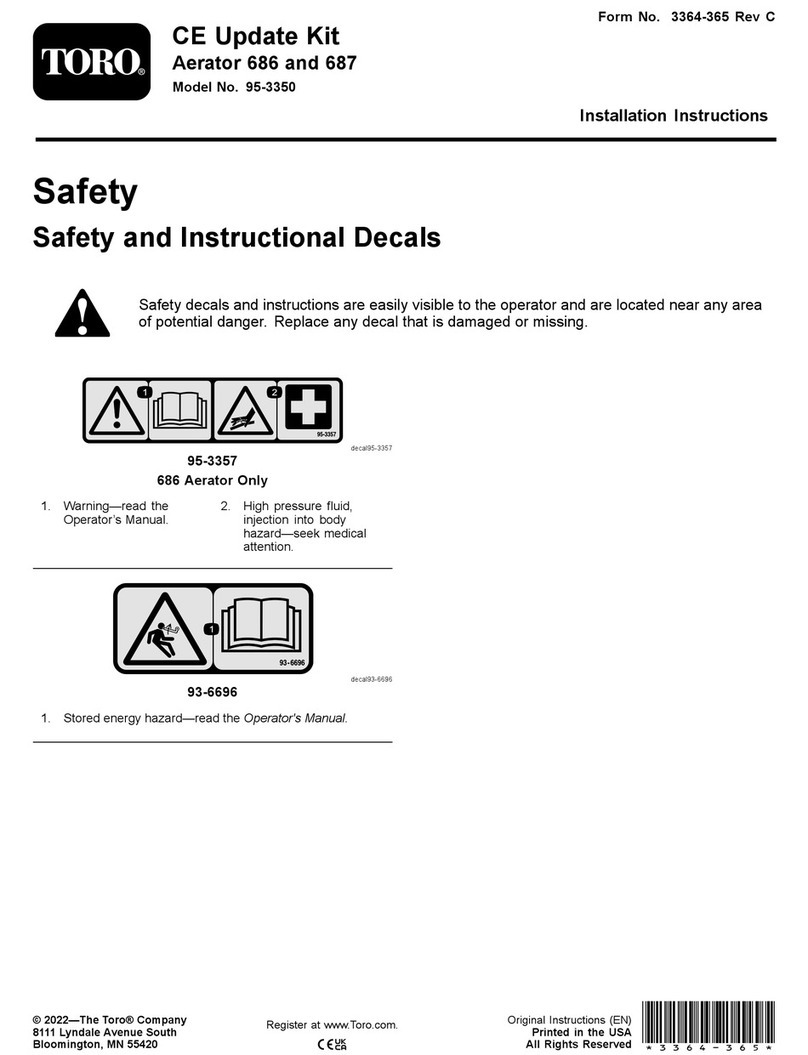

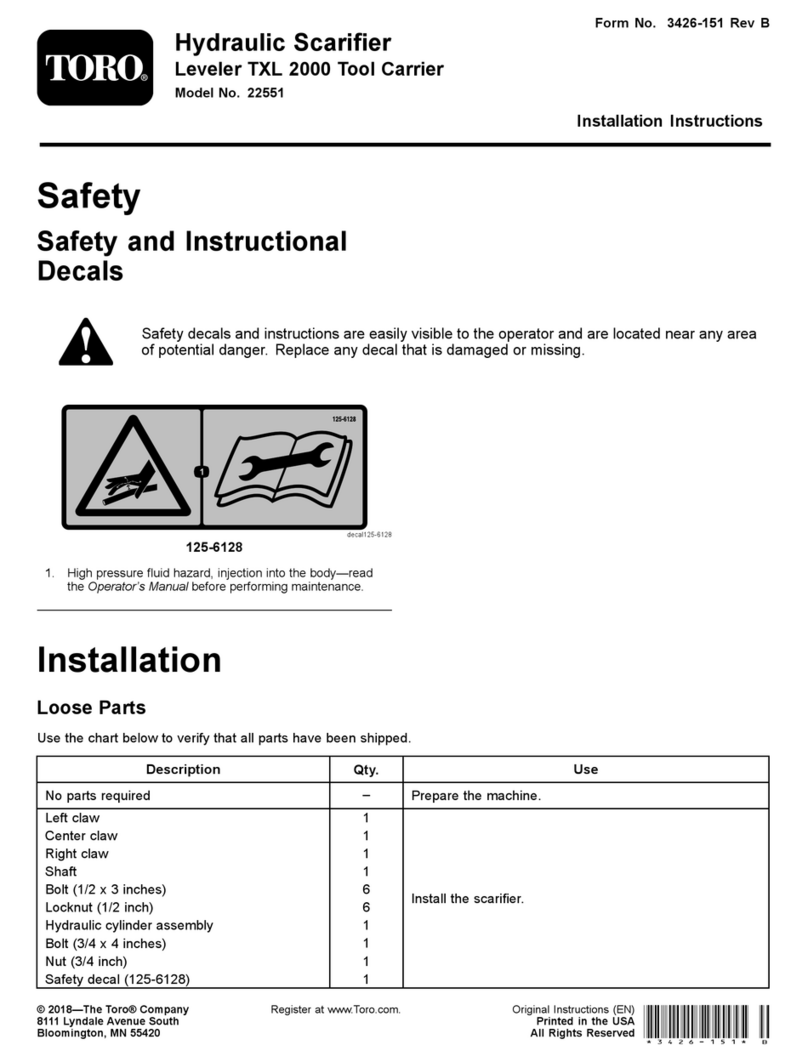

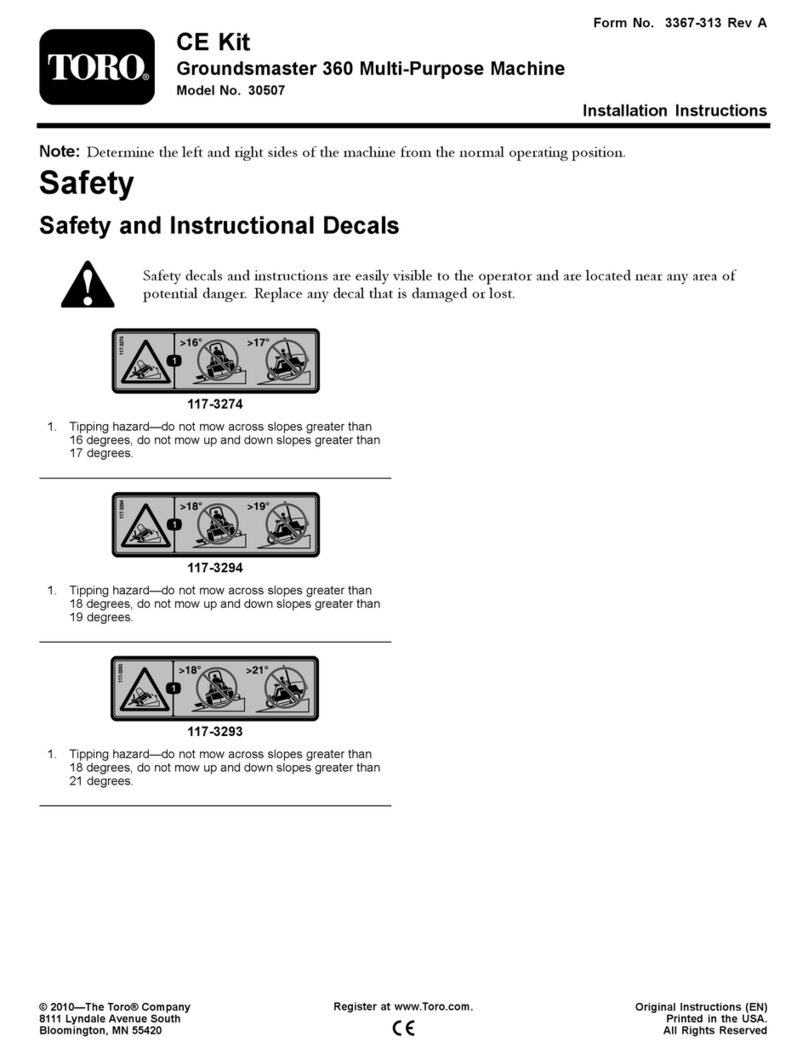

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing and Removing the Attachment . . . . . . . . . . . . . 6

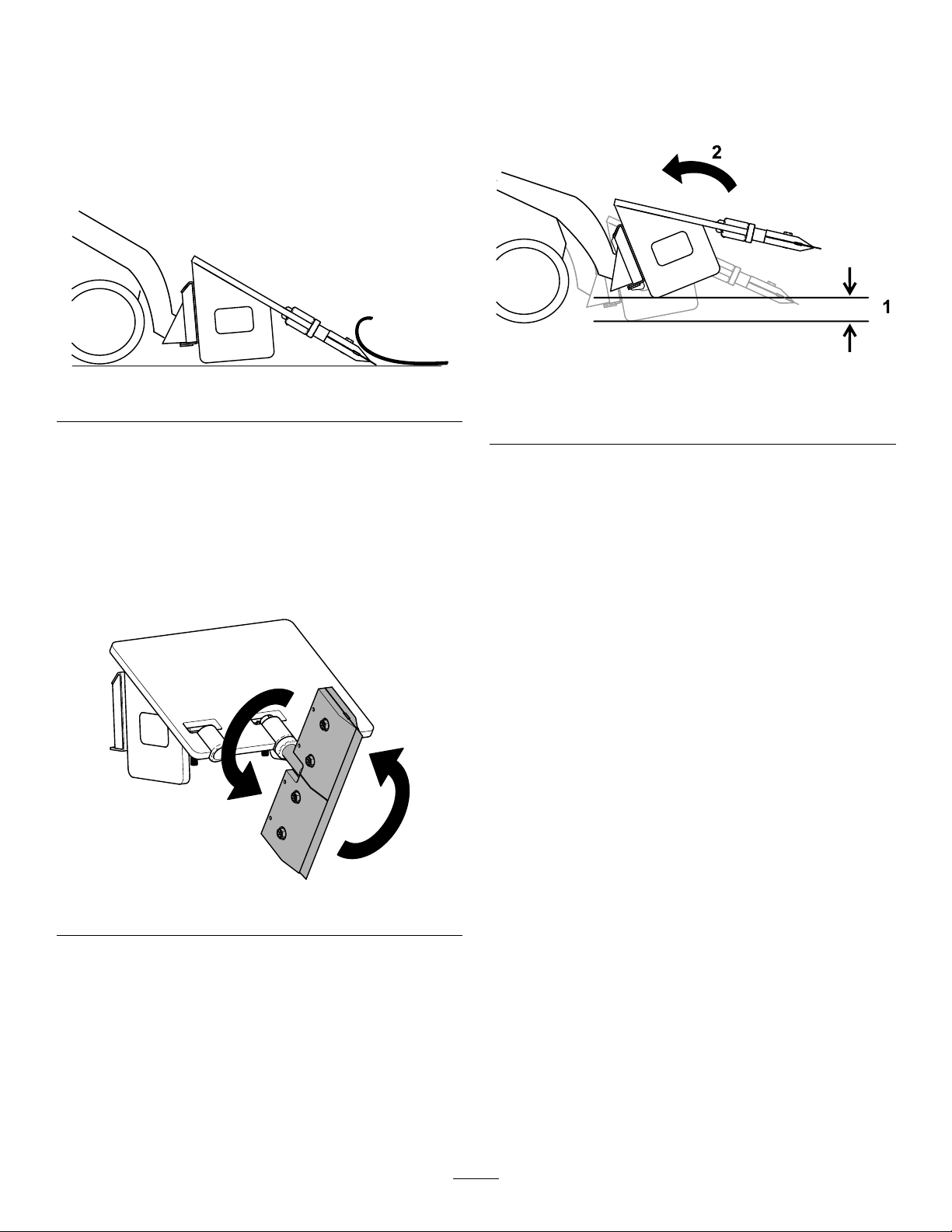

Installing and Removing the Blade

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Selecting a Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing Flooring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

T ransport Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Safety

General Safety

Always follow all safety instructions to avoid serious

injury or death. Using this product for purposes other

than its intended use could prove dangerous to you

and bystanders.

•Do not exceed the rated operating capacity , as the

machine may become unstable, which may result

in loss of control.

•Do not carry a load with the arms raised; always

carry loads close to the ground.

•Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. Operating the machine on any

slope or uneven terrain requires extra caution.

•Operate the machine up and down slopes with

the heavy end of the machine uphill and the

load close to the ground. W eight distribution

changes with attachments. An empty bucket

makes the rear of the machine the heavy end, and

a full bucket makes the front of the machine the

heavy end. Most other attachments make the front

of the machine the heavy end.

•Have the property or work area marked for buried

lines and other objects, and do not dig in marked

areas.

•Read and understand the content of this Operator ’ s

Manual before starting the machine.

•Use your full attention while operating the

machine. Do not engage in any activity that

causes distractions; otherwise, injury or property

damage may occur .

•Never allow children or untrained people to

operate the machine.

•Keep your hands and feet away from the moving

components and attachments.

•Do not operate the machine without the guards

and other safety protective devices in place and

working on the machine.

•Keep bystanders and children out of the operating

area.

•Stop the machine, shut of f the machine, and

remove the key before servicing or unclogging

the machine.

Improperly using or maintaining this machine can

result in injury . T o reduce the potential for injury ,

comply with these safety instructions and always

pay attention to the safety-alert symbol , which

means Caution, W arning, or Danger—personal safety

instruction. Failure to comply with these instructions

may result in personal injury or death.

3