Note:Theshoulderboltshouldnotclampthe

platetothehousing.

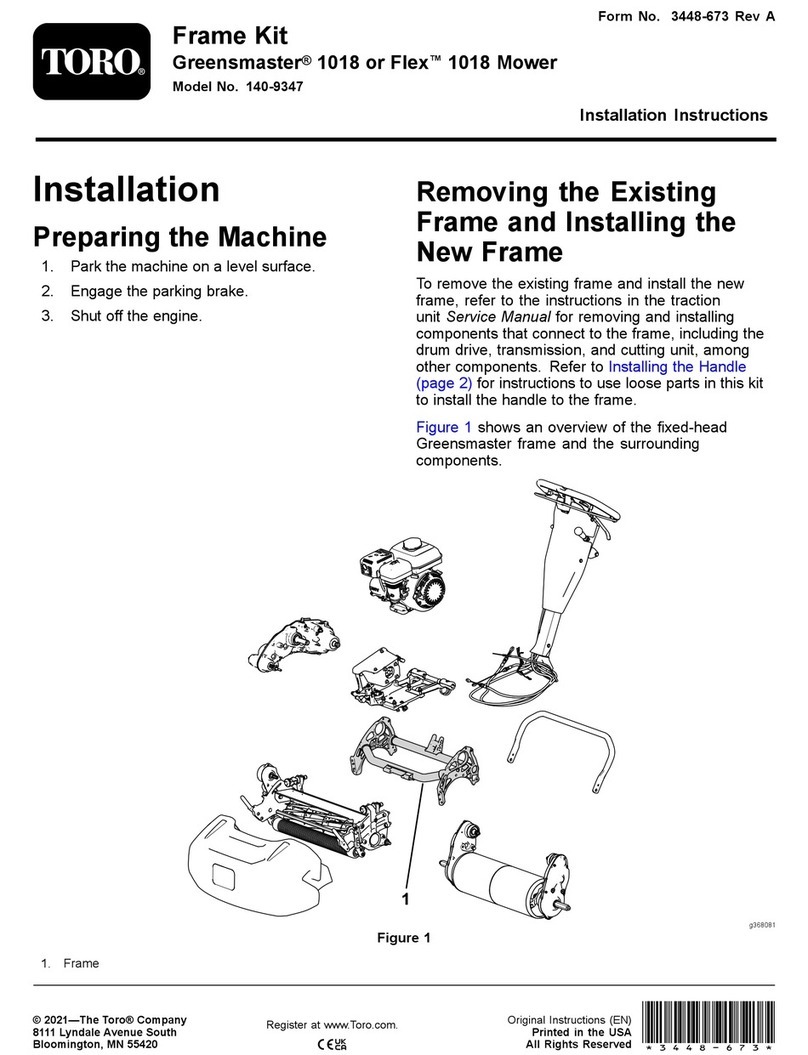

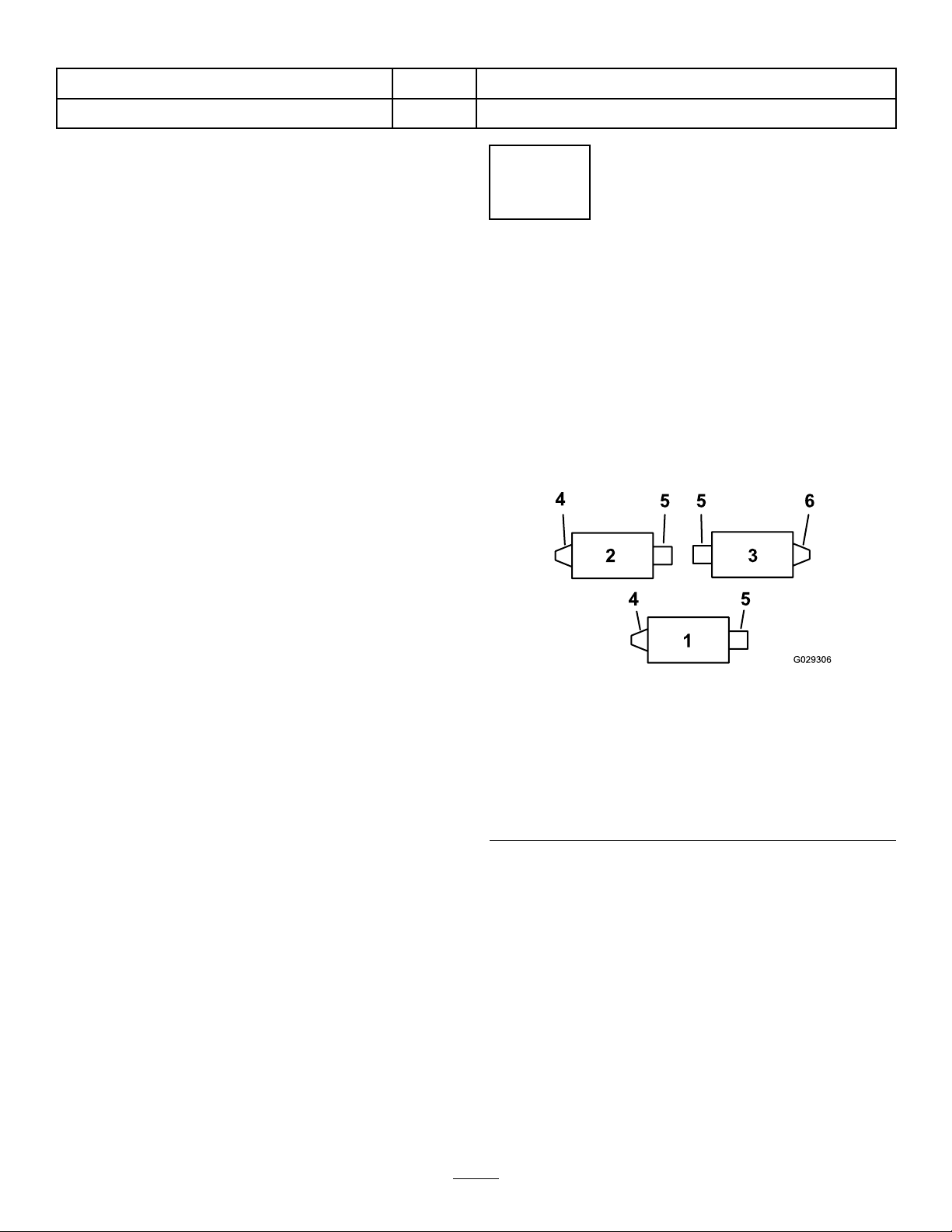

8.Checktoensurethattheroller-brushplateis

paralleltothecutting-unitsideplate.Ifitisnot

parallel,proceedasfollows:

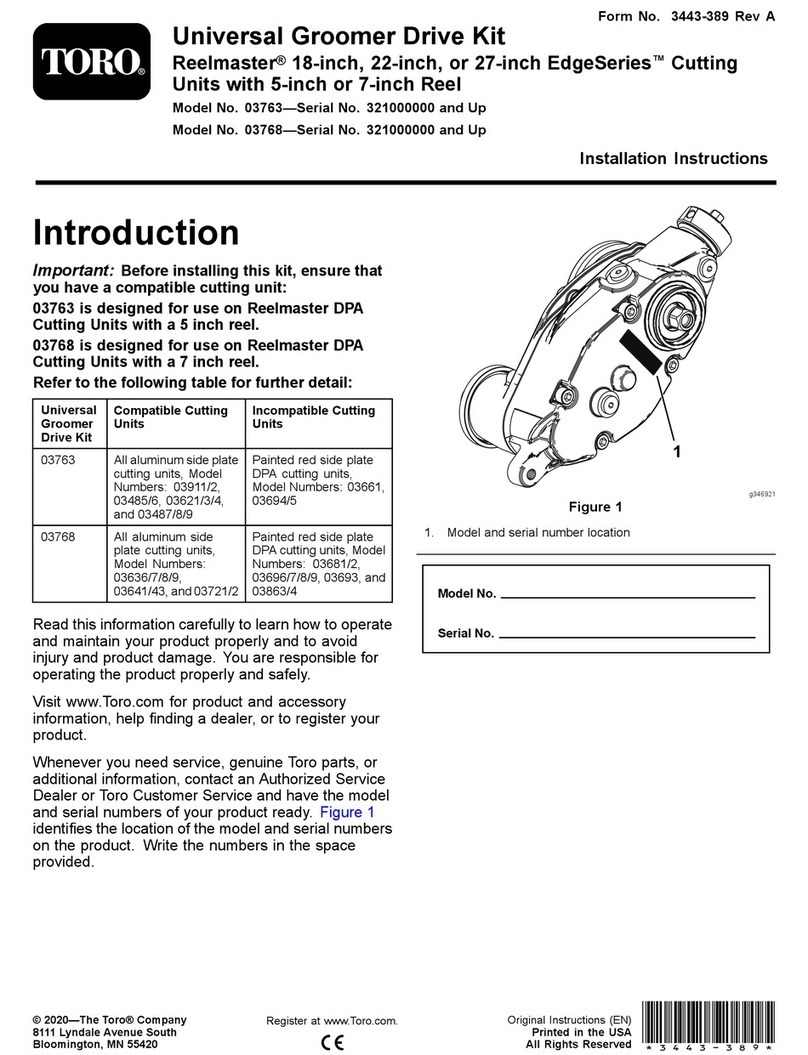

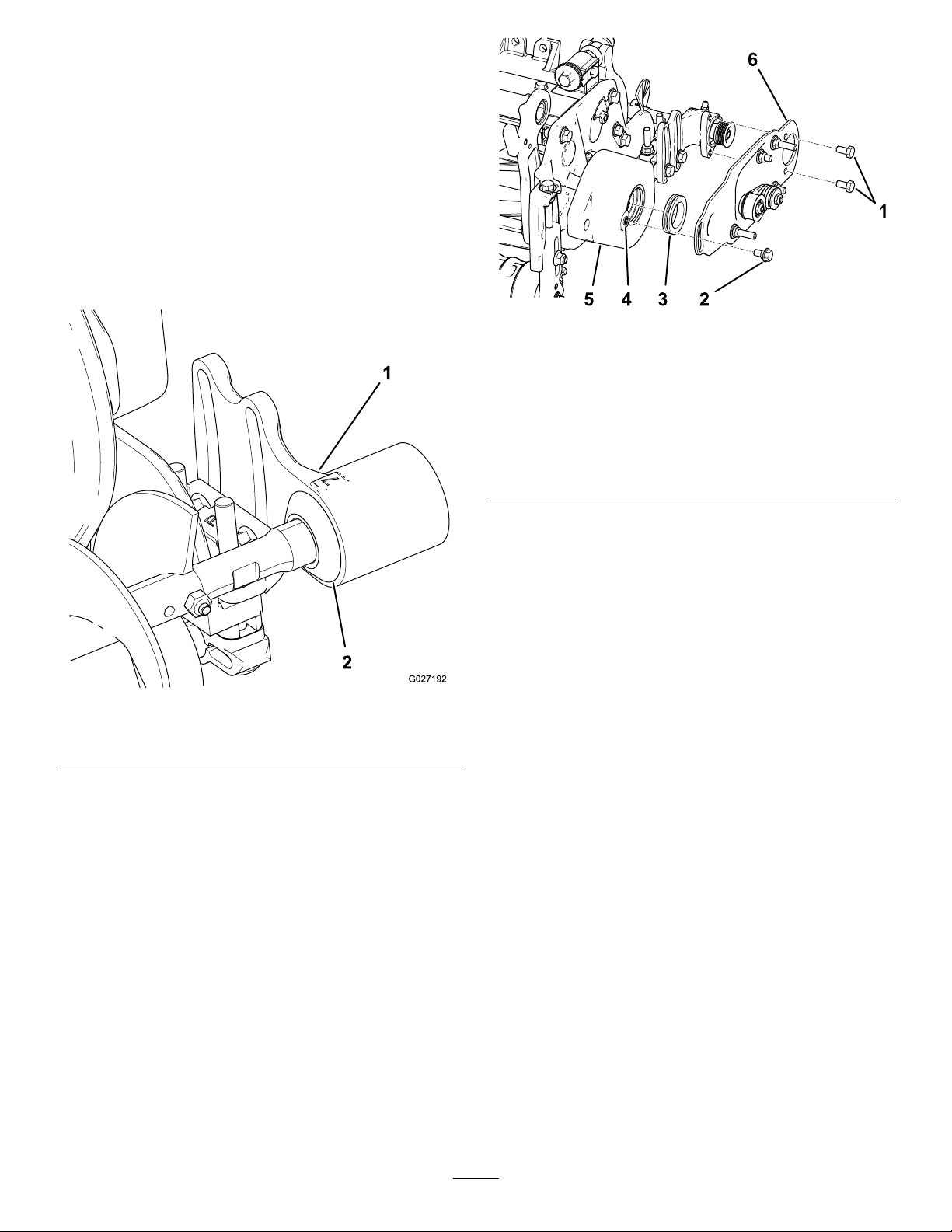

A.Loosenthe2angelocknutssecuring

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure13).

B.Rotatetheroller-brushbearinghousinguntil

thebrushplateisparalleltothecutting-unit

sideplate(Figure13).

C.Tightenthe2angelocknutssecuring

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure13).

g193249

Figure13

1.Loosentheseboltsforpositioningtherollerbrush.

2.Loosenthesenutsformakingtheroller-brushplateparallel.

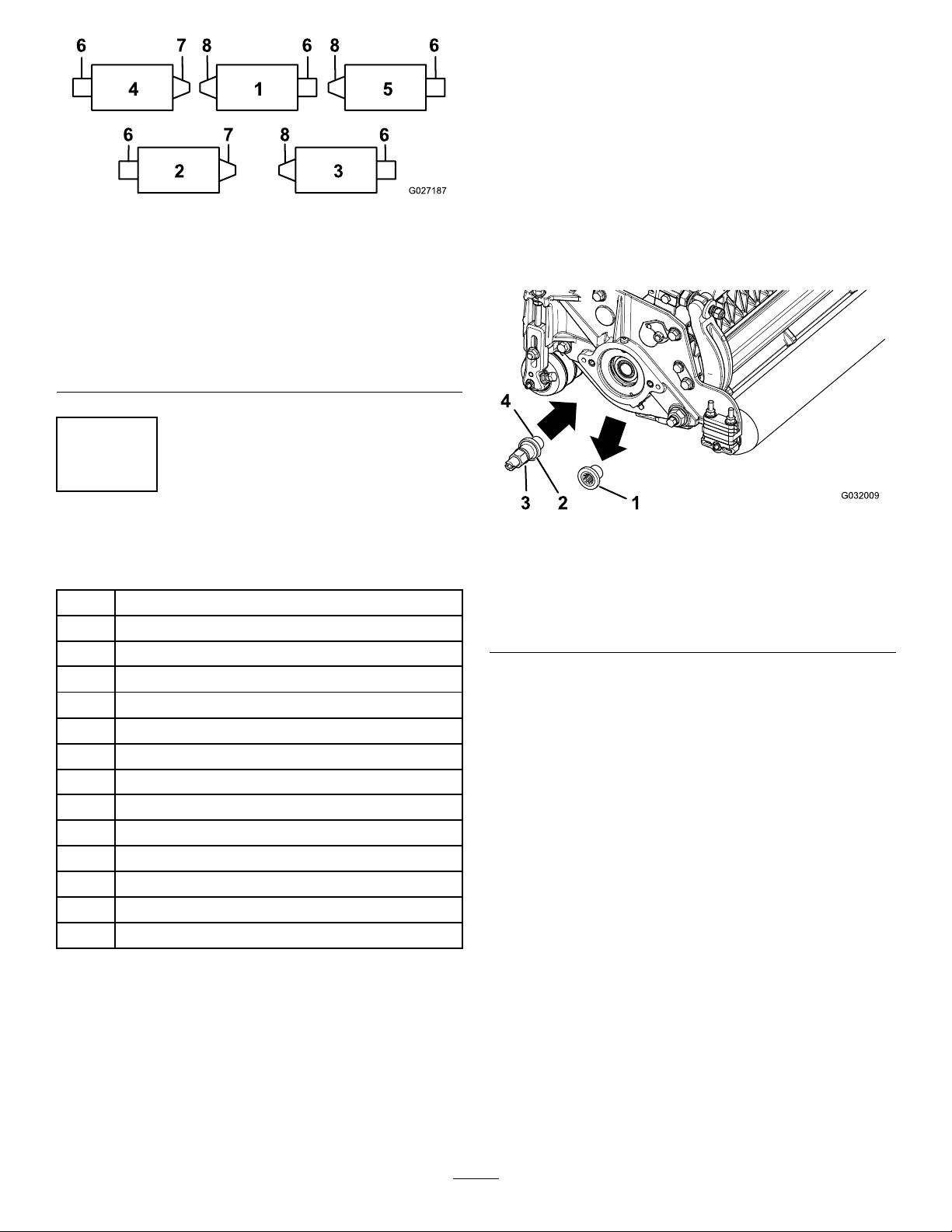

PositioningtheRollerBrush

1.Loosenthe2boltssecuringeachroller-brush

bearinghousingtotheroller-brushmounting

bracket(Figure13).

Note:Theboltsshouldbeloosefromthe

factory.

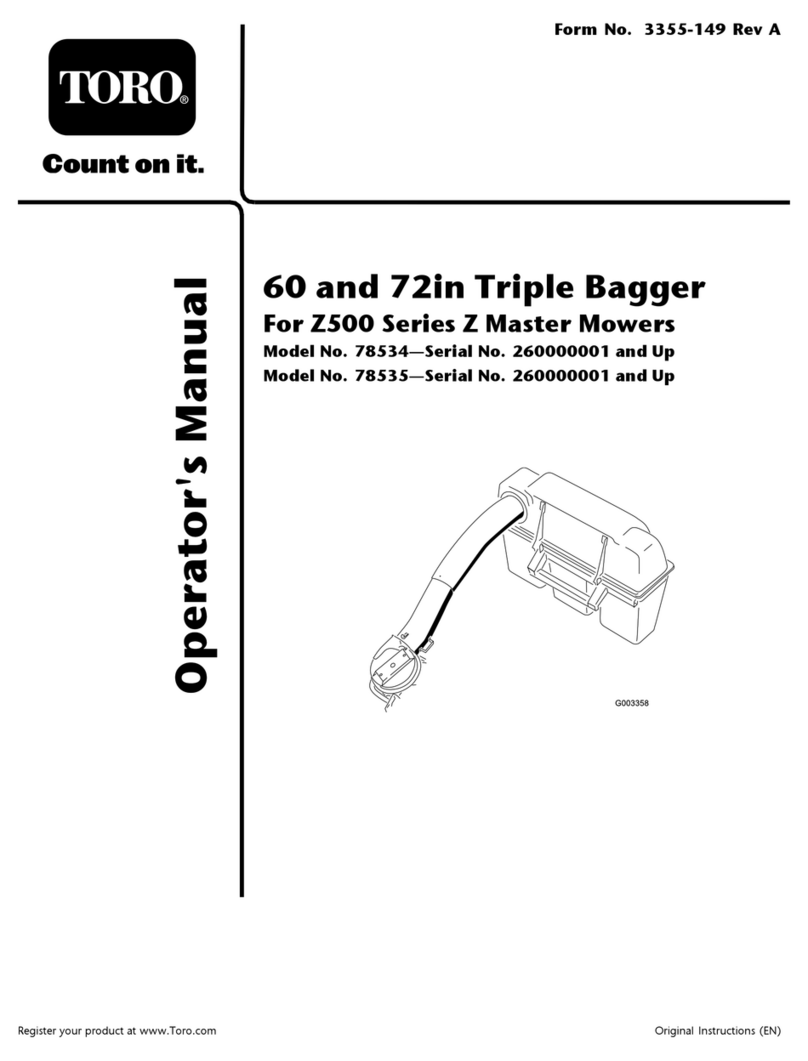

2.Positiontherollerbrushsothatitisjusttouching

orrestingontherearroller(Figure14).

Important:Theroller-brushshaftmustnot

contactthecutting-unitsideplate.

Important:Heavybrushcontactonthe

rollerwillcauseprematurebrushwear.

g027303

Figure14

1.Bearinghousing(some

partsnotshown)

5.Lightcontact

2.Sideplate6.Rearroller

3.Rollerbrush7.Greasetting

4.Ensurethatthereis

clearancehere.

Note:Theroller-brushshaftmustbeparallel

totherearroller.

Important:Positionbothroller-brush

bearinghousingssothattheyareparallel

tothegroundtoensureclearanceforthe

rear-rollergreasetting.

3.Tightenthe2boltssecuringeachroller-brush

bearinghousingtotheroller-brushmounting

brackets.

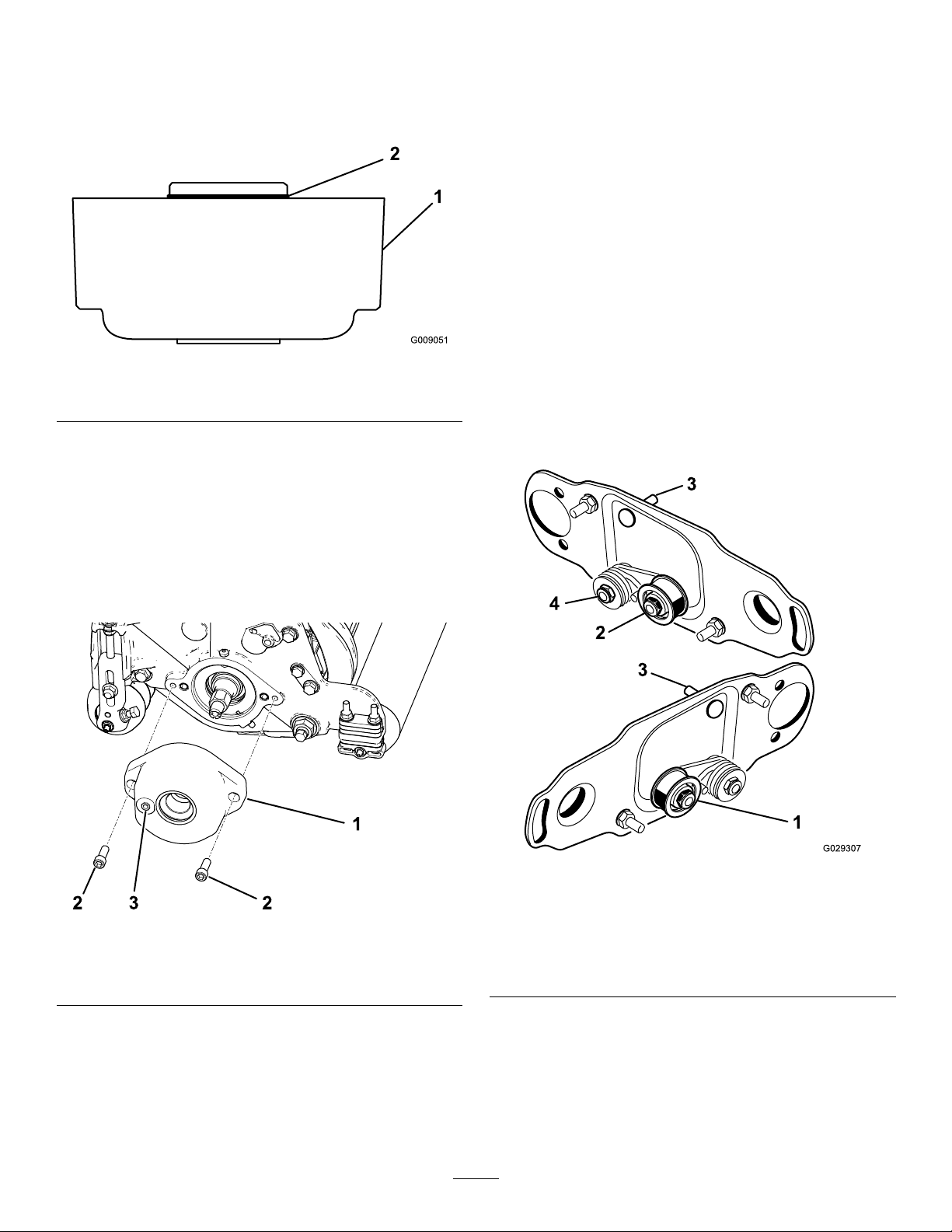

InstallingtheDrivePulley

1.Insertthespacerontotheshaftinthebearing

housing(Figure15).

2.Insertthedrivepulleyintothespacerandonto

thedriveshaft(Figure15).

Note:Ensurethatthepulleytabsarepositioned

intheslotinthedriveshaft.

3.Securethepulleyandspacertothedriveshaft

withaange-headbolt(3/8x2inches);refer

toFigure15.

Note:Torquetheboltto47to54N∙m(35to

40ft-lb).

7