Toro 140-5800 User manual

Other Toro Lawn Mower Accessories manuals

Toro

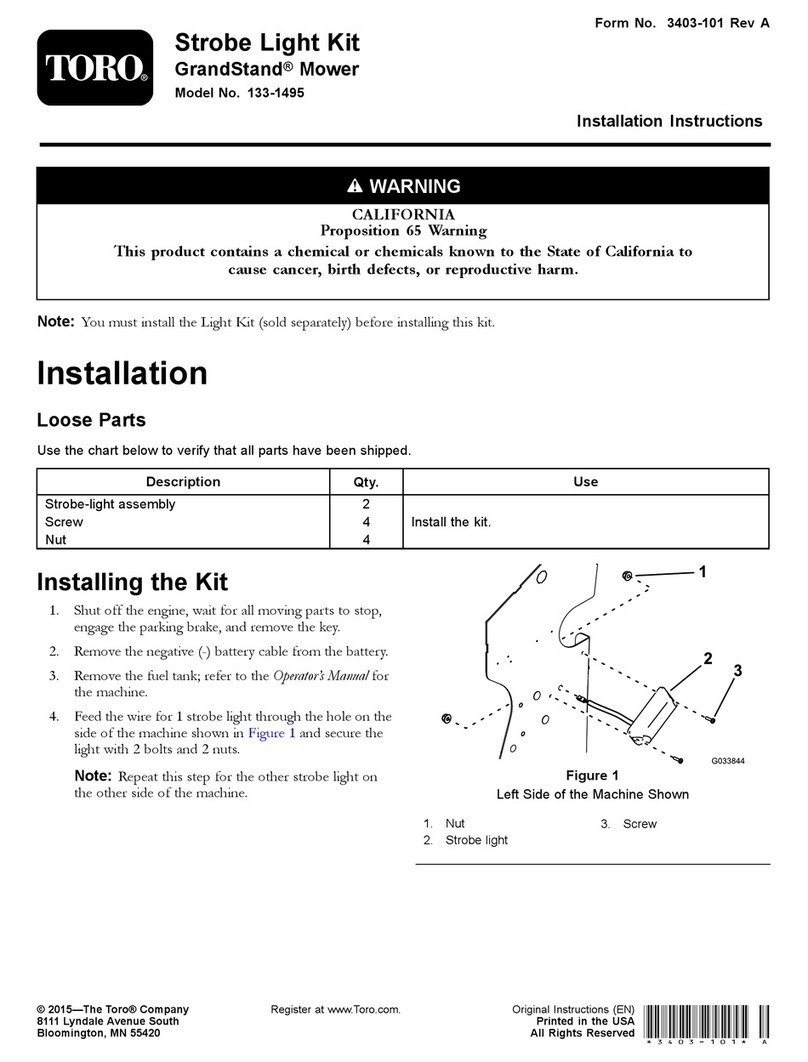

Toro GrandStand 133-1495 User manual

Toro

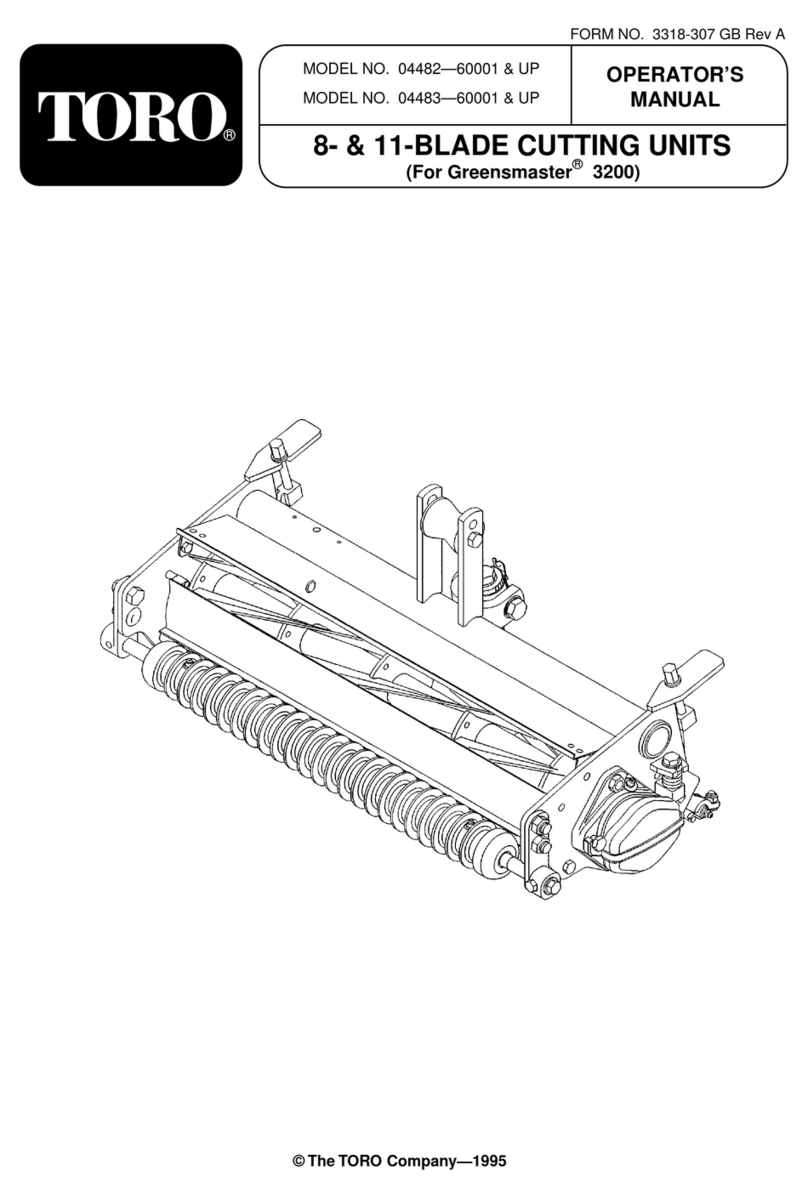

Toro 04482-60001 User manual

Toro

Toro SUPER RECYCLER 59193 User manual

Toro

Toro 79348 User manual

Toro

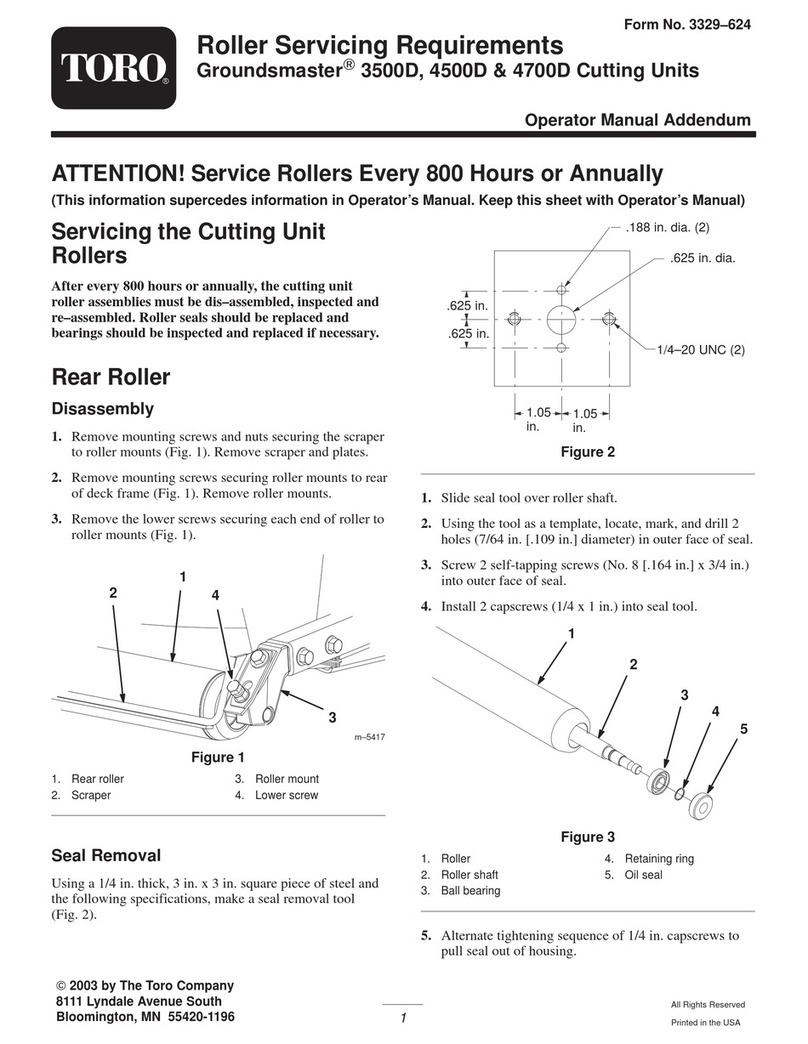

Toro Groundsmaster 3500-D User manual

Toro

Toro ProStripe 560 User manual

Toro

Toro 78534 User manual

Toro

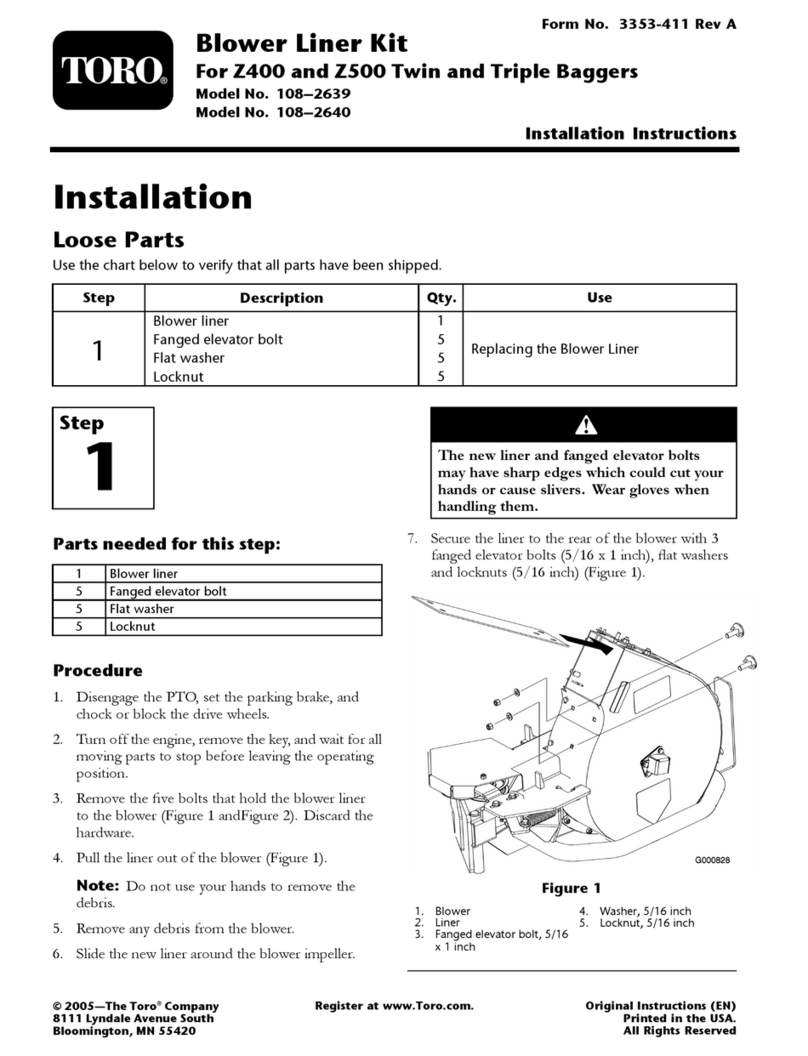

Toro 108-2639 User manual

Toro

Toro 30810 User manual

Toro

Toro 30107 User manual

Toro

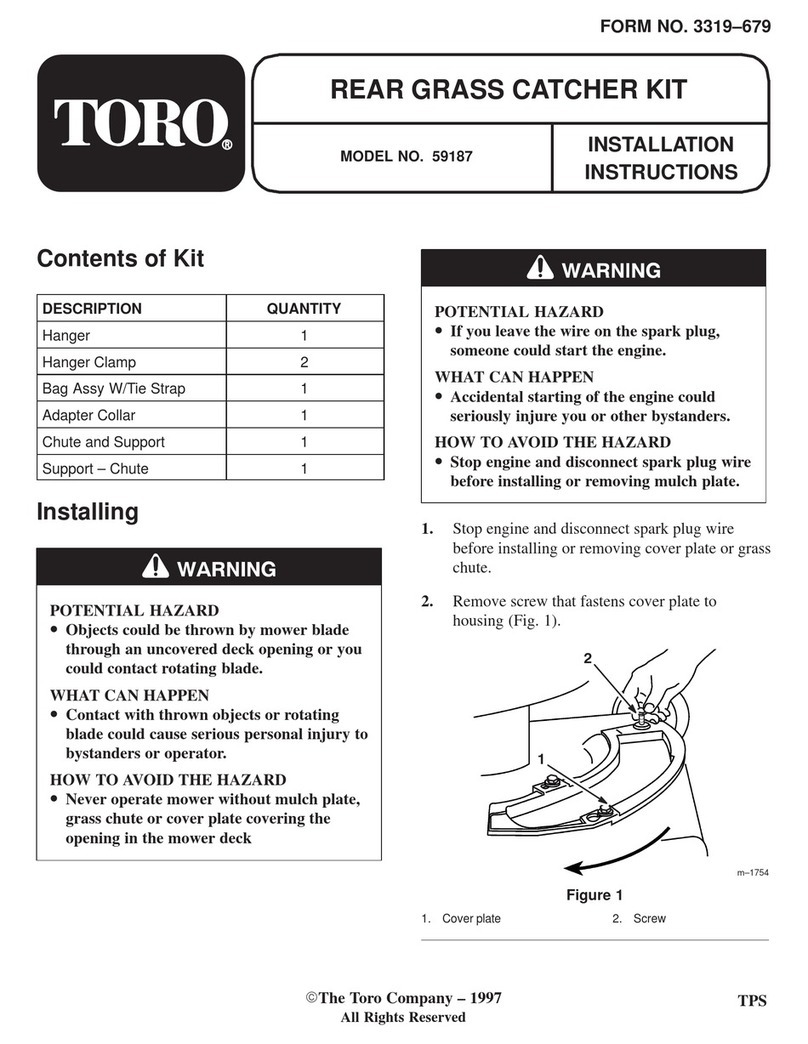

Toro 59187 User manual

Toro

Toro 31200 User manual

Toro

Toro 78490 User manual

Toro

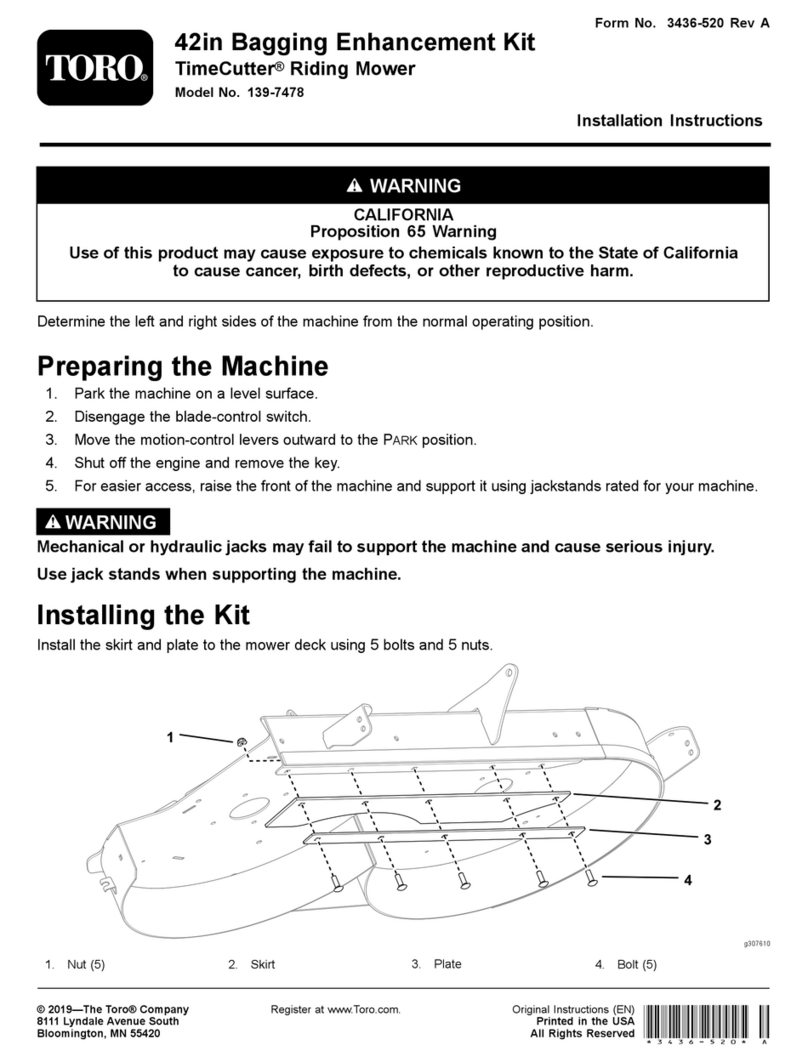

Toro TimeCutter 139-7478 User manual

Toro

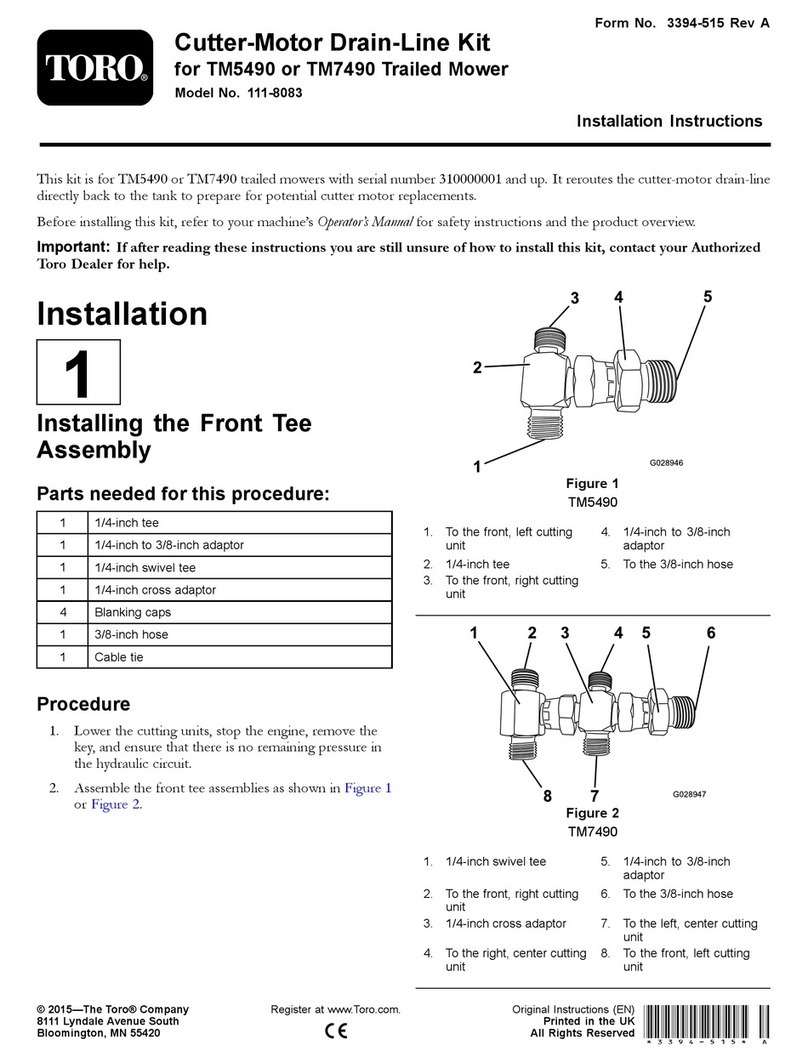

Toro 111-8083 User manual

Toro

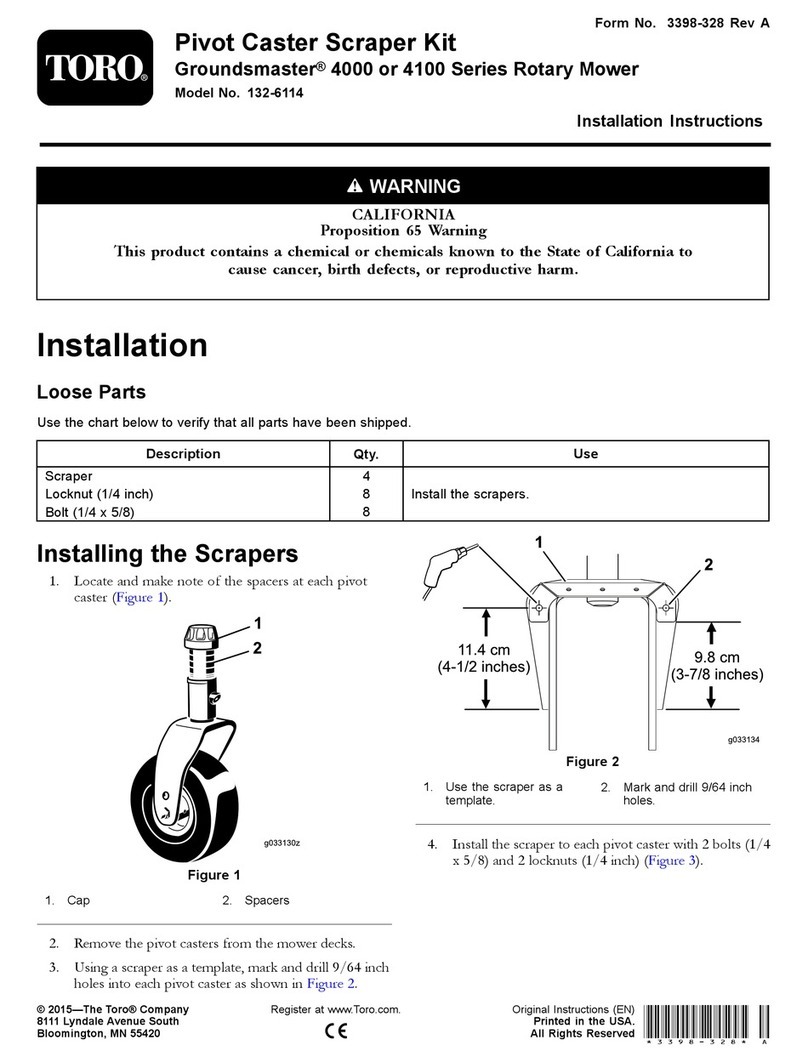

Toro 132-6114 User manual

Toro

Toro 88710 User manual

Toro

Toro 79030 User manual

Toro

Toro Groundsmaster 360 Series User manual

Toro

Toro 144-1848 User manual