WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

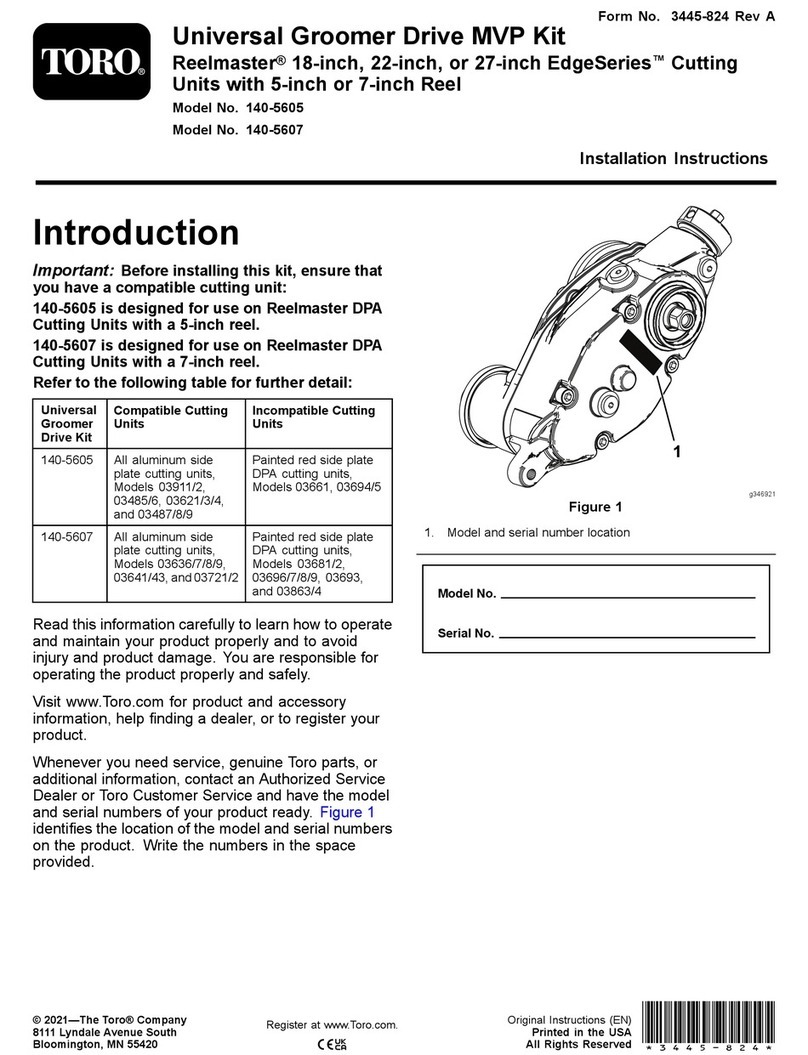

Introduction

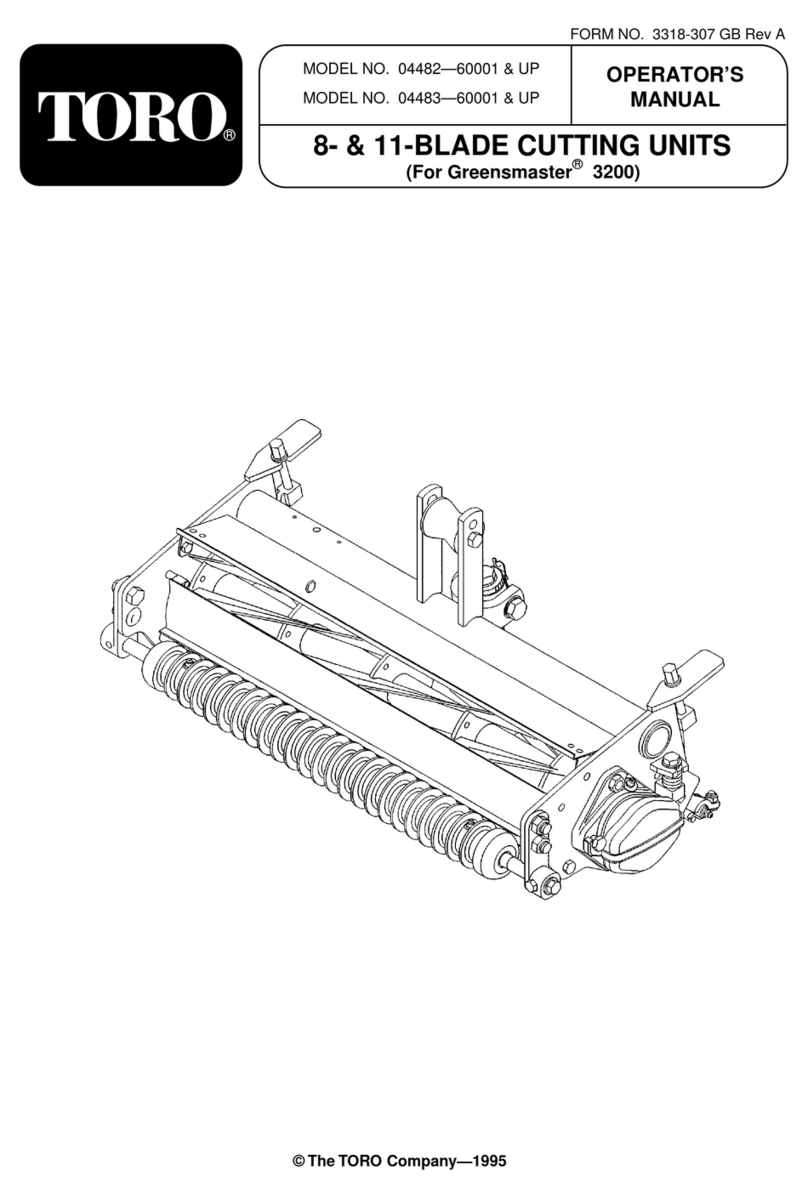

Thisrotary-bladelawnmowerdeckismountedtoaride-on

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarilydesigned

formowinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

mowingbrush,grassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactyourTorodealerandhavethemodel

andserialnumbersofyourproductready.Themodeland

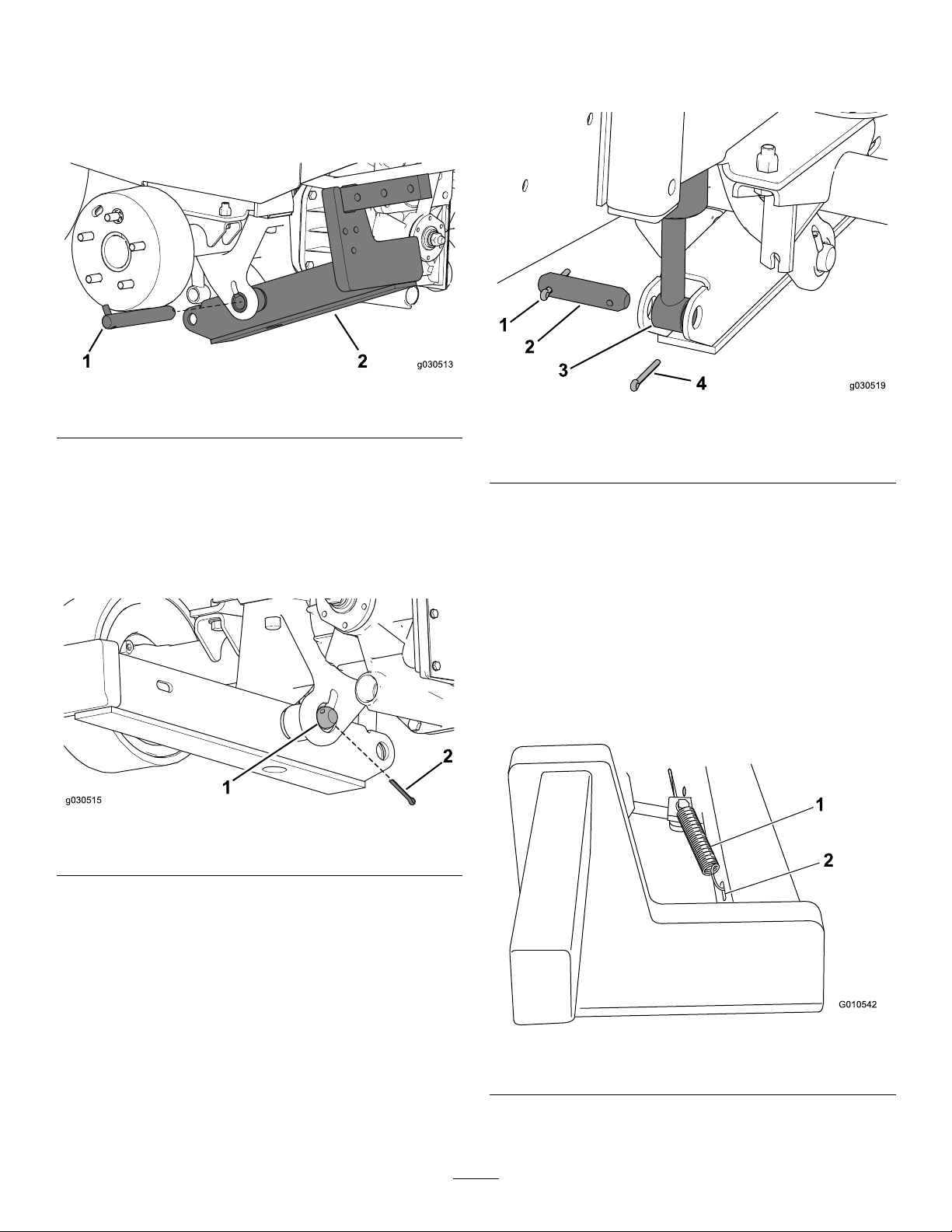

serialnumbersarestampedintoaplatelocatedonthecarrier

framebehindtherightfrontcastorwheel.Writethenumbers

inthespaceprovided.

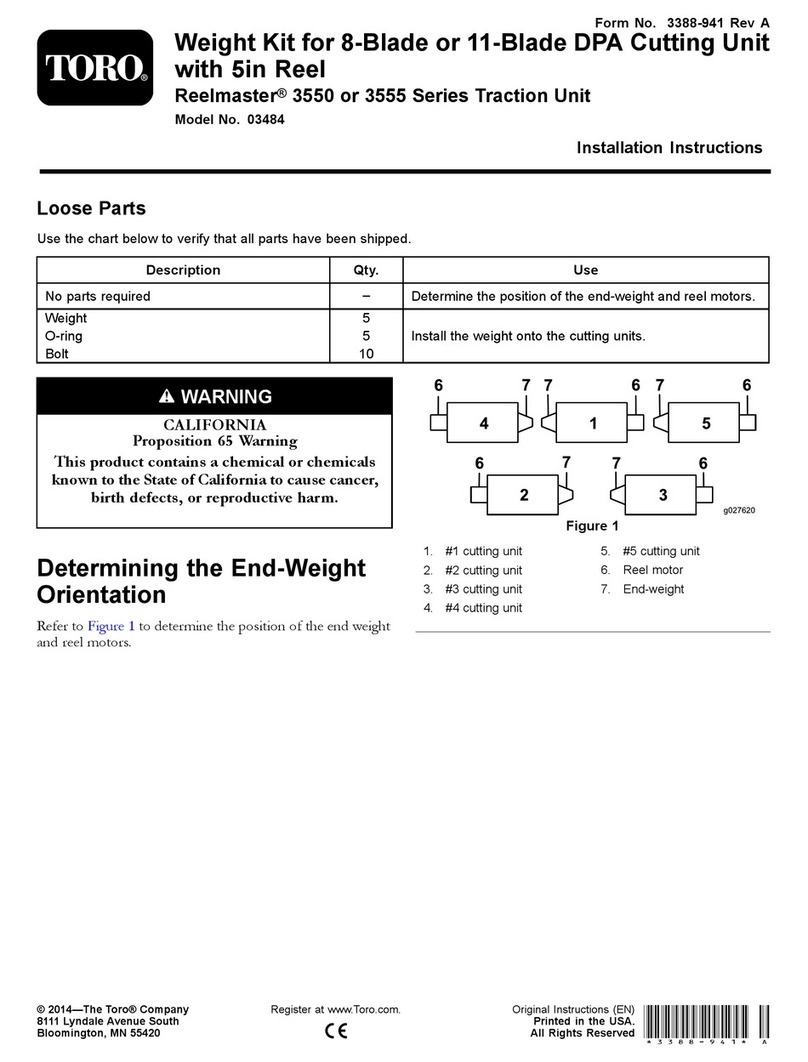

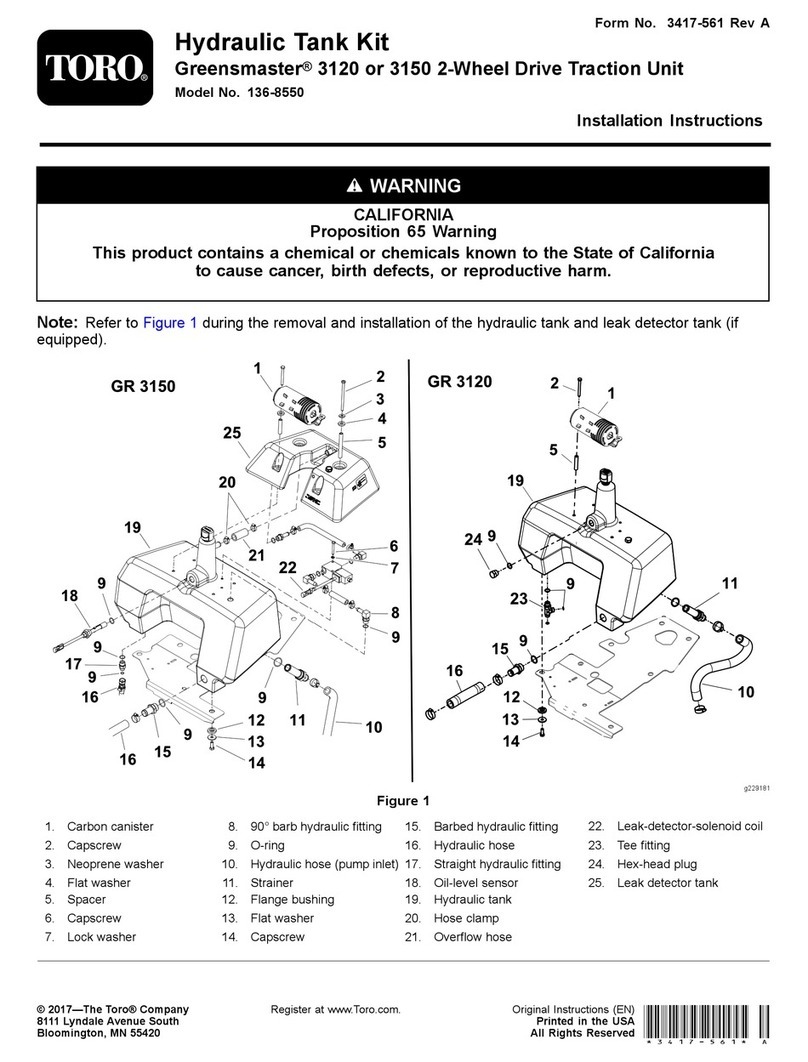

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

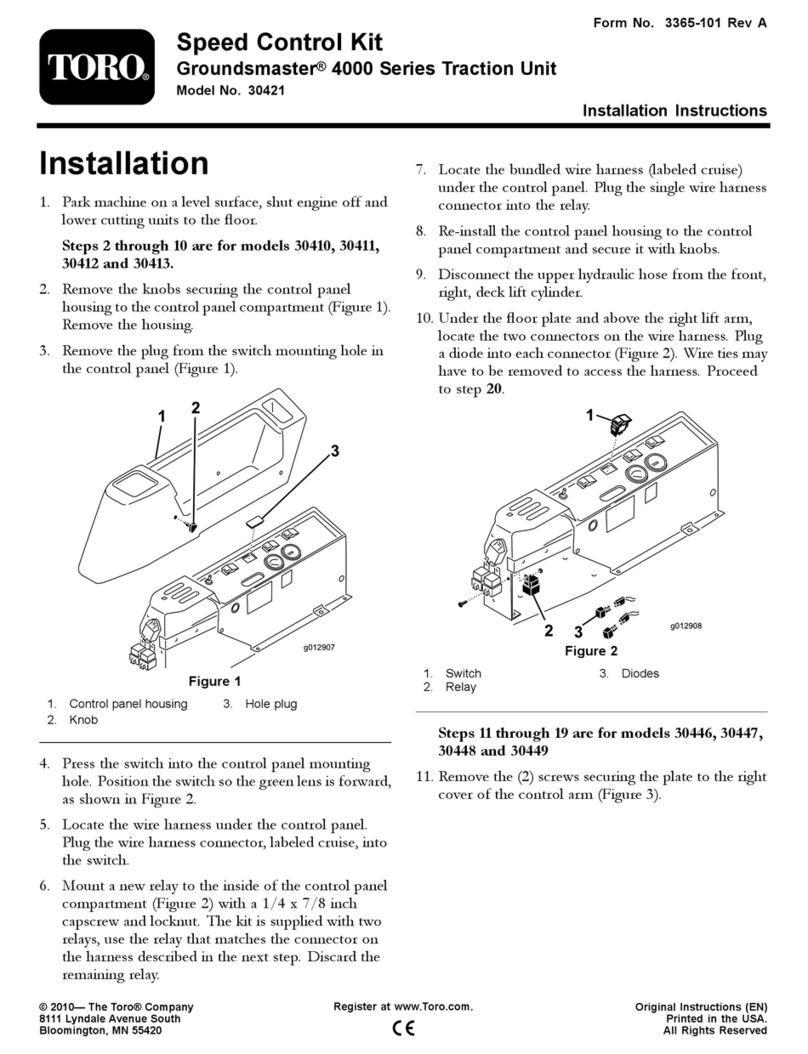

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

ToroMowerSafety..................................................3

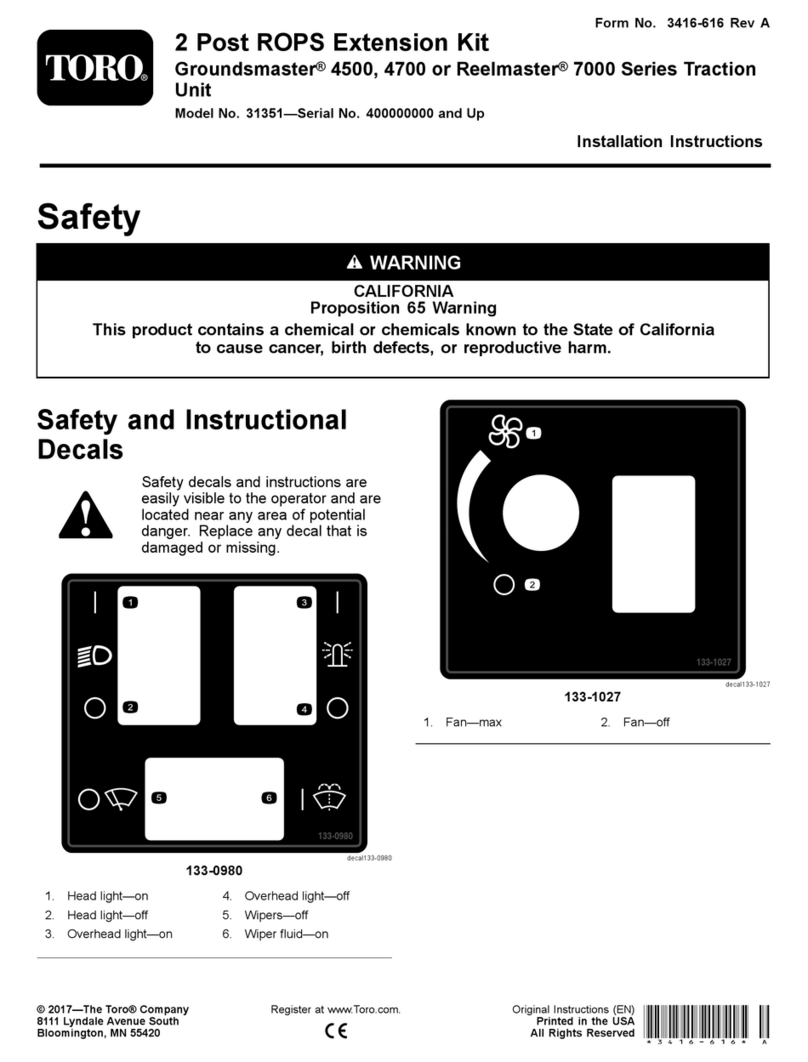

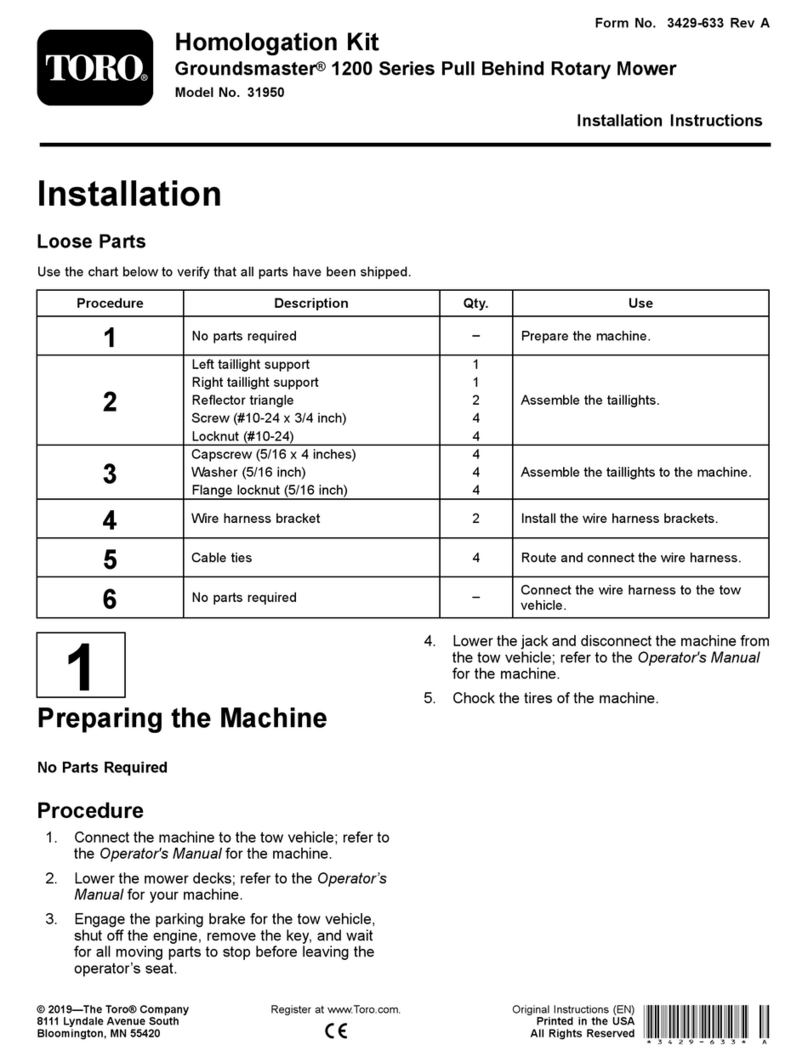

SafetyandInstructionalDecals.................................4

Setup............................................................................6

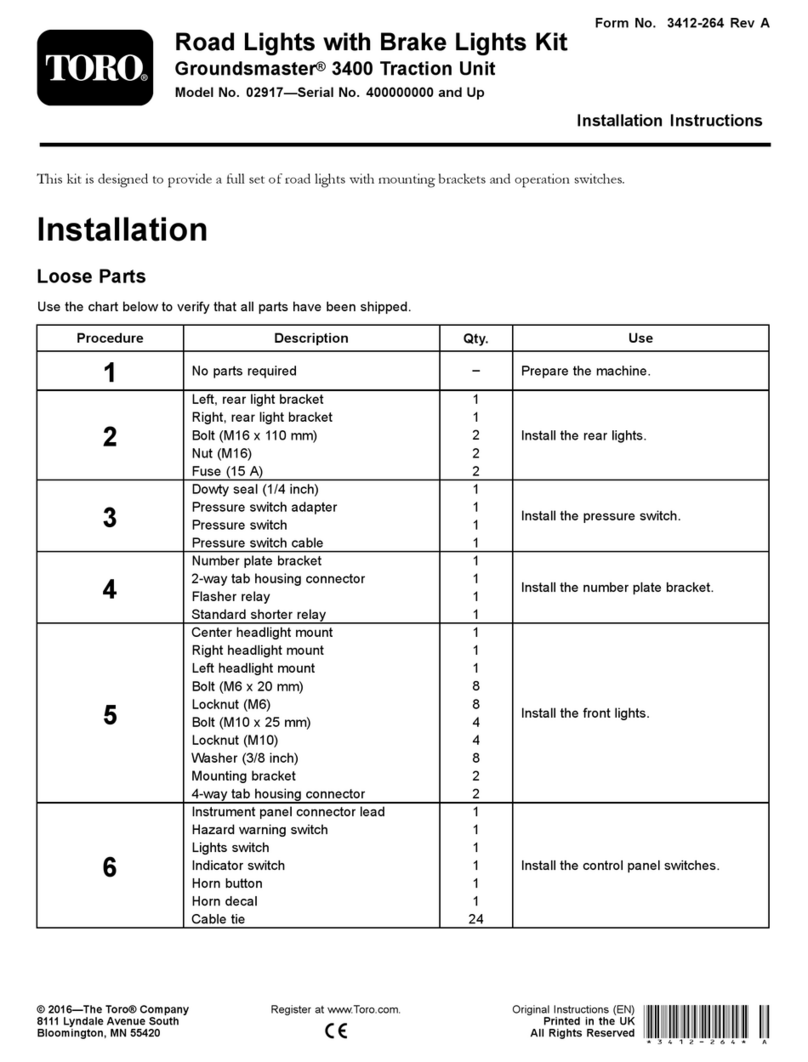

1PreparingtheMachine...........................................6

2InstallingtheCarrierFrame....................................7

3InstallingtheMowerDeck....................................10

4InstallingRearWeight...........................................13

ProductOverview.........................................................13

Specications........................................................13

Attachments/Accessories........................................13

Operation....................................................................14

AdjustingtheHeightofCut.....................................14

AdjustingtheRollers...............................................14

CheckingtheGearboxLubricant..............................15

AdjustingWeightTransfer.......................................15

UsingtheGrassDeector.......................................15

Maintenance.................................................................16

LubricatingtheCastors...........................................16

LubricatingtheMowerDeck....................................16

RemovingtheMowerDeck.....................................17

ServicingtheCasterArms.......................................18

ServicingtheCasterWheel......................................18

CheckingforaBentBlade........................................19

RemovingtheCuttingBlade.....................................19

InspectingandSharpeningtheBlade.........................20

CheckingandCorrectingMismatchof

Blades...............................................................20

ReplacingtheGrassDeector..................................21

AdjustingtheIdlerPulley........................................22

ReplacingtheDriveBelt..........................................23

Troubleshooting...........................................................24

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved