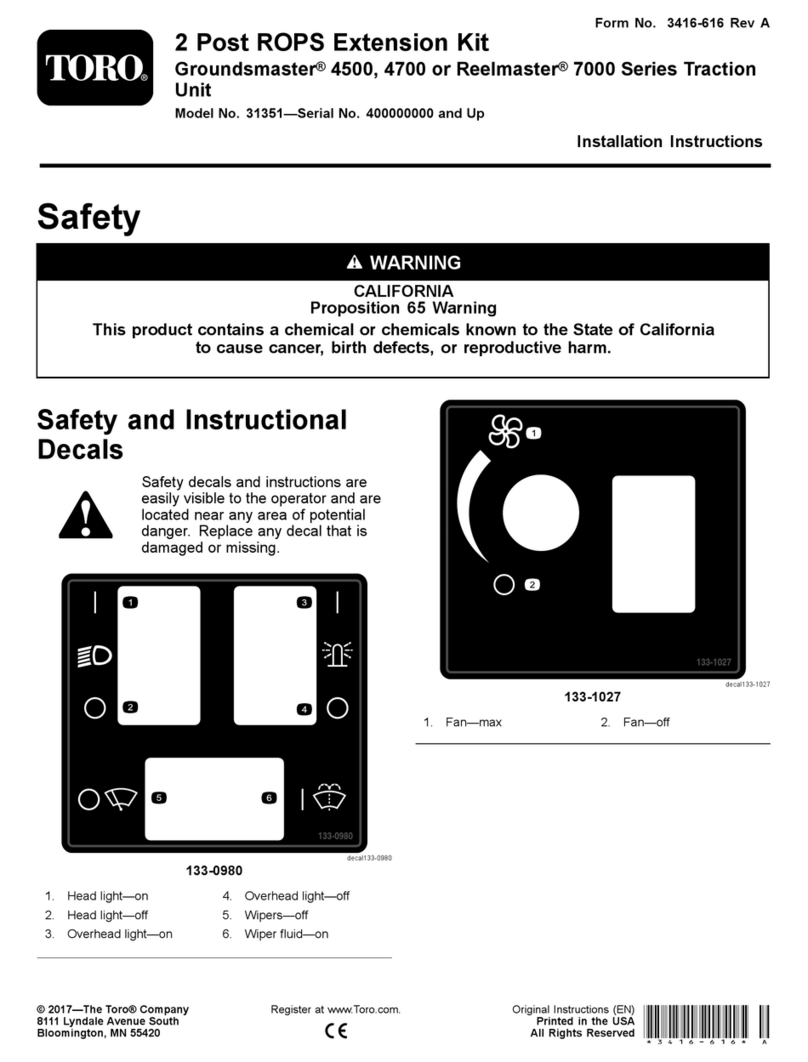

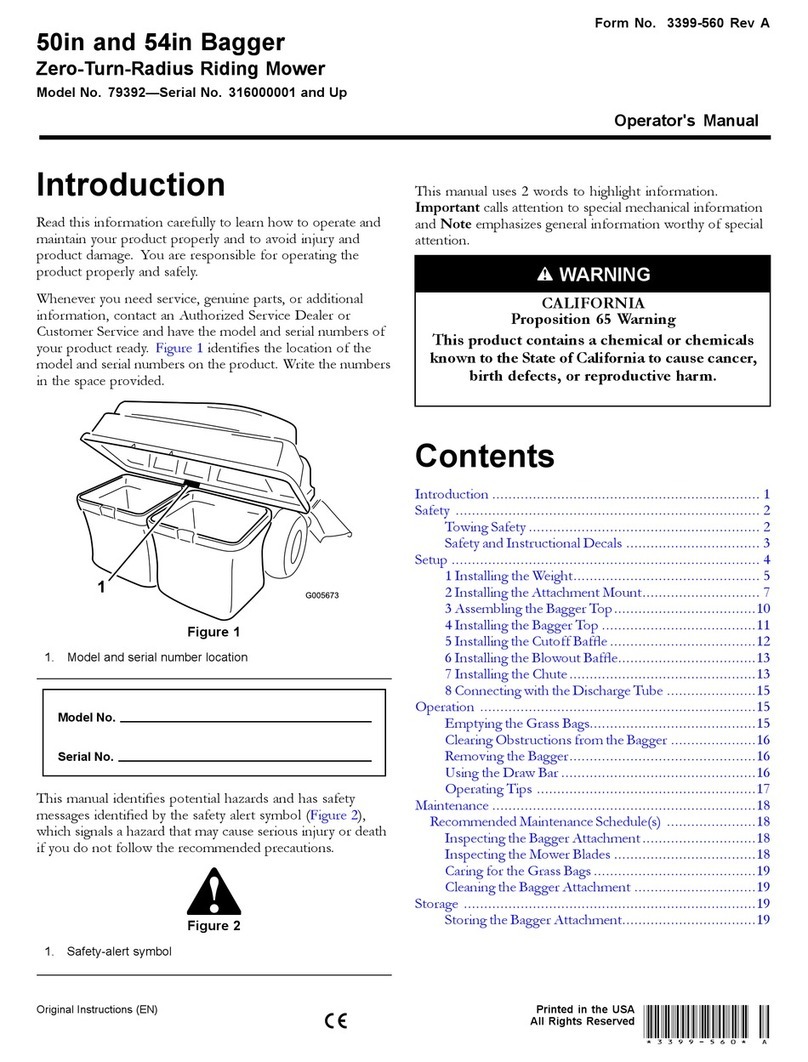

Figure2

1.Bolt,M16x110mm4.L.H.rearlightbracket

2.Existingwashers5.Nut,M16

3.Orangeindicatorsideup

7.InstallthenewM16nutontotheboltandtightento

atorqueof15N-m(11ft-lbs).Donotovertighten

asthiswillmaketheROPSdifculttofold.

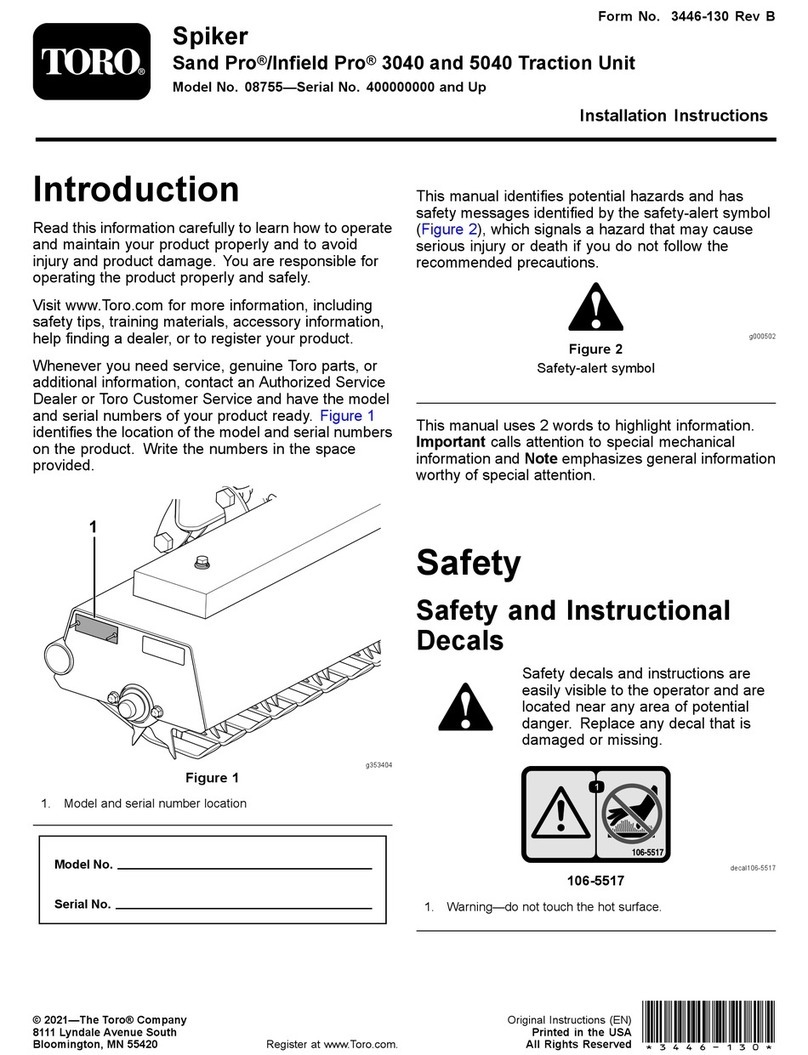

8.RemovetheROPSpivotboltontherightsideof

themower.

9.AligntheupperholeintheR.H.rearlightbracket

withtheholeintheROPSandinsertthenewM16x

110mmbolt(Figure3).Re-usetheexistingwashers.

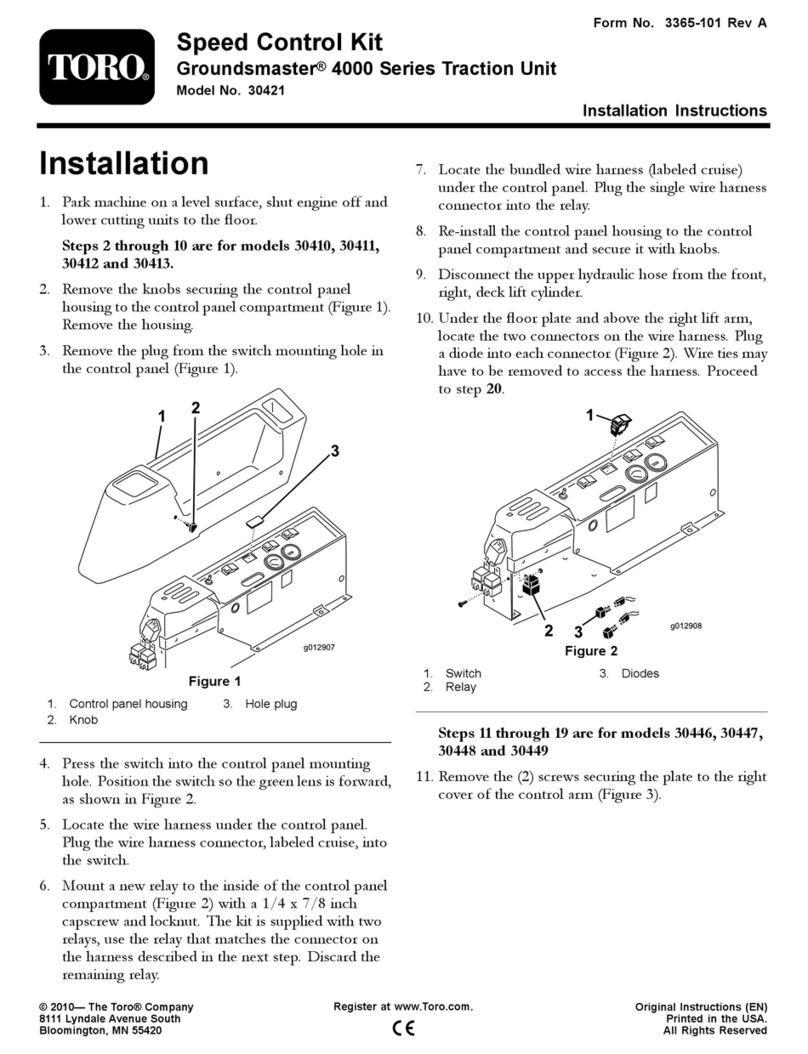

Figure3

1.Nut,M164.Orangeindicatorsideup

2.Existingwashers5.Bolt,M16x110mm

3.R.H.rearlightbracket

10.InstallthenewM16nutontotheboltandtightento

atorqueof15N-m(11ft-lbs).Donotovertighten

asthiswillmaketheROPSdifculttofold.

Note:Ifthereisalreadyabeaconkitttedtothe

rightsideorawastebinkitttedtoleftside,itis

allowabletousethesameboltfortheinstallation.It

isadvisabletousethenewM16nylocnutsprovided

withthiskit.

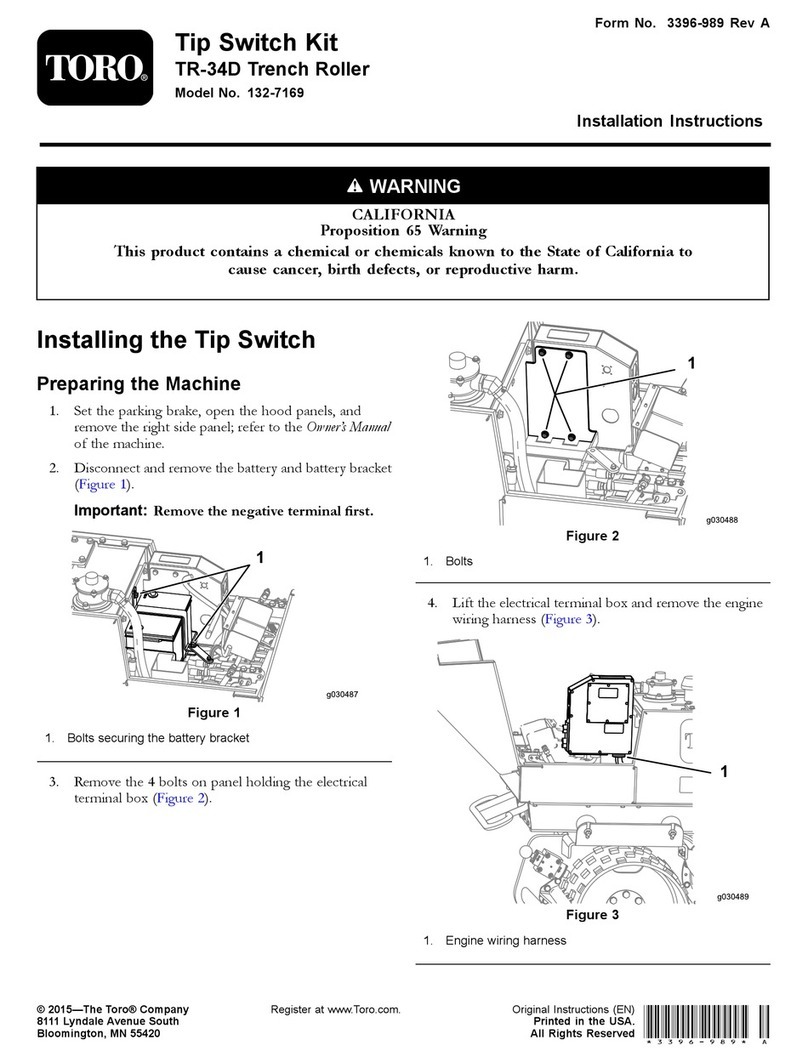

11.FeedallelectricalcablesdownthefrontoftheROPS

frameandontotheelectricalmountpanel.

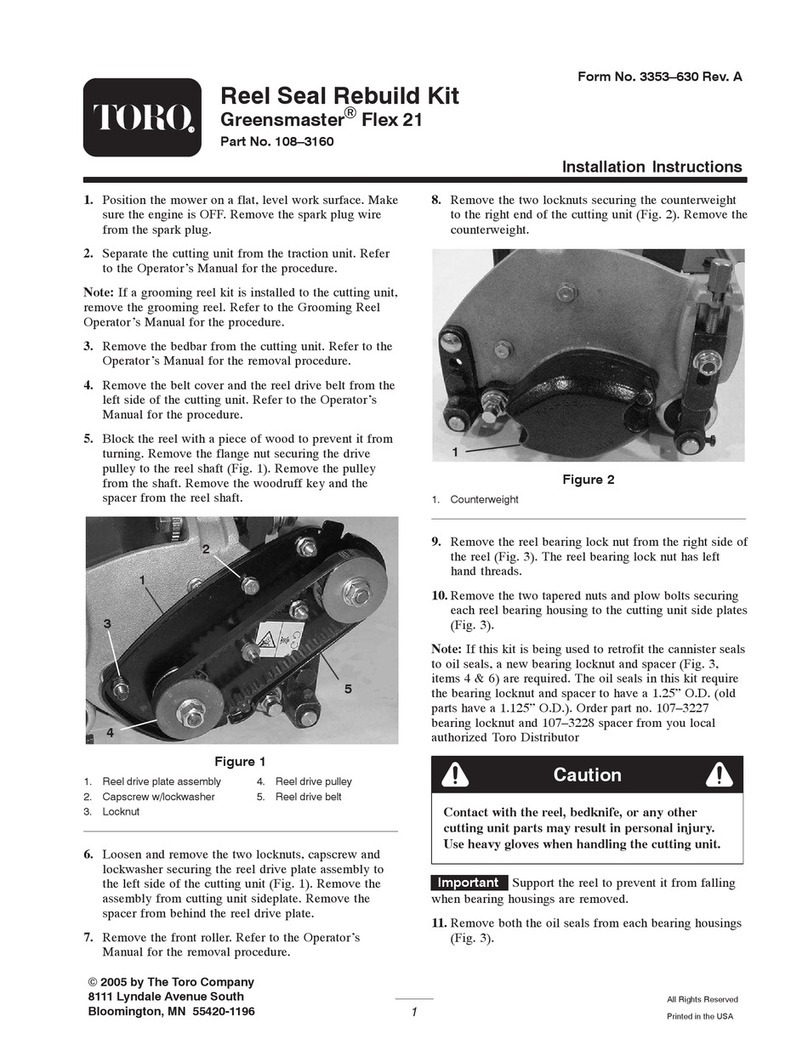

12.Thecablesmustnowbeconnectedtothemain

wiringloomofthemachinewhichislocatedonthe

electricalbulkhead(Figure4).Connectthe4-pin

L.H.rearlightassemblywiringconnectortothe

corresponding4-pinelectricalconnectorontheL.H.

sideofthemainwiringloom.Connectthe4-pin

R.H.rearlightassemblywiringconnectortothe

corresponding4-pinelectricalconnectorontheR.H.

sideofthemainwiringloom.The2-pinelectrical

connectorsontheL.H.andR.H.rearlightassembly

isrequiredforthenumberplatelight.Onlyoneof

the2-Pinelectricalconnectorsareused.

Figure4

1.4-pinL.H.rearlight

assemblyconnectormain

wiringloom

3.4-pinR.H.rearlight

assemblyconnectormain

wiringloom

2.3-pinelectricalpressure

switchcableconnector

mainwiringloom

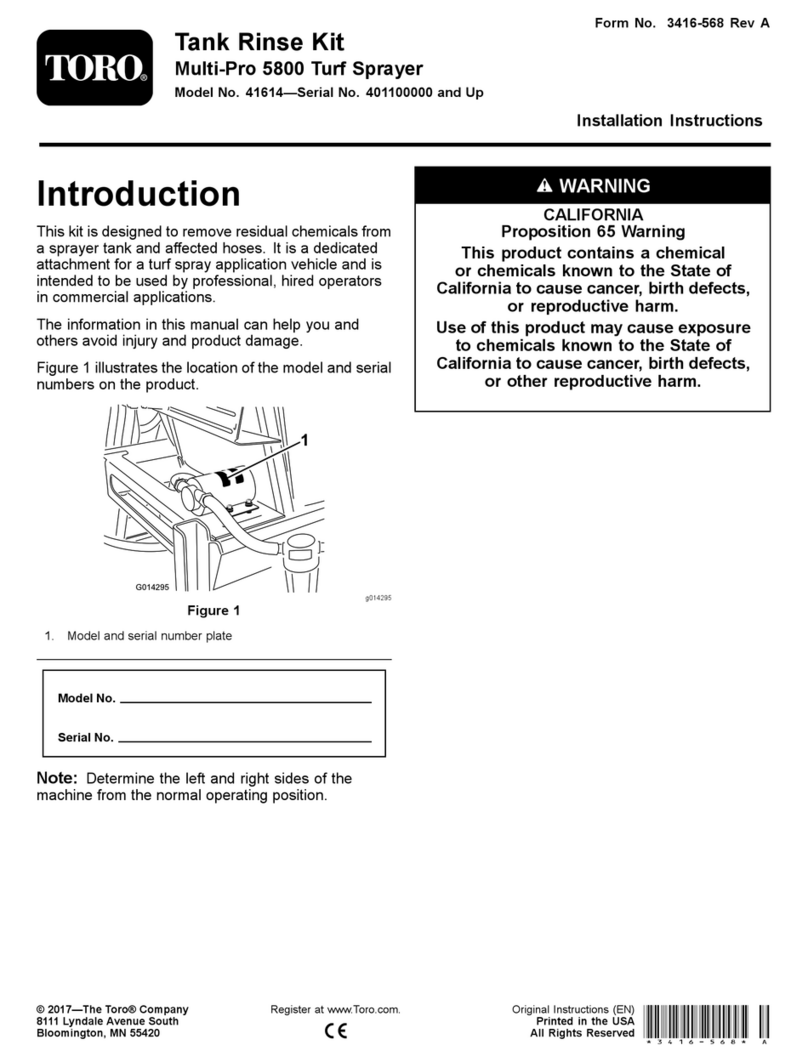

13.Install(2)15ampfusesintothefuseblock.Usethe

1stand3rdreceptaclesfromtheleftendofthefuse

block(Figure5).

3