2.Insertthecabletiethroughtheslotsinthe

columnmountbracketsothattheendsare

outward,butdonottiethem.

3.Installthesteering-columnbracketontothe

steeringcolumnwiththemountingbracket,2

carriagebolts,and2angenuts(Figure14).

Important:Ensurethatthetopofthe

steering-columnbracketis21mm(0.83inch)

belowthetopofthesteeringcolumn.

Important:Torquethefastenersto19to24

N∙m(14to18ft-lb).Donotovertightenthe

carriagebolts;otherwise,youmaydeform

thesteering-columnbracket.

8

InstallingtheBrake-Sensor

Bracket

Partsneededforthisprocedure:

1Carriagebolt(#10x5/8inch)

1Locknut(#10)

1Sensorplate

2Flangenut(1/4inch)

1Brake-sensorbracket

2Bolts(1/4x3/4inch)

2Slottedscrew(#6x1inch)

4Washer(#6)

1Brakesensor

2Locknut(#6)

Procedure

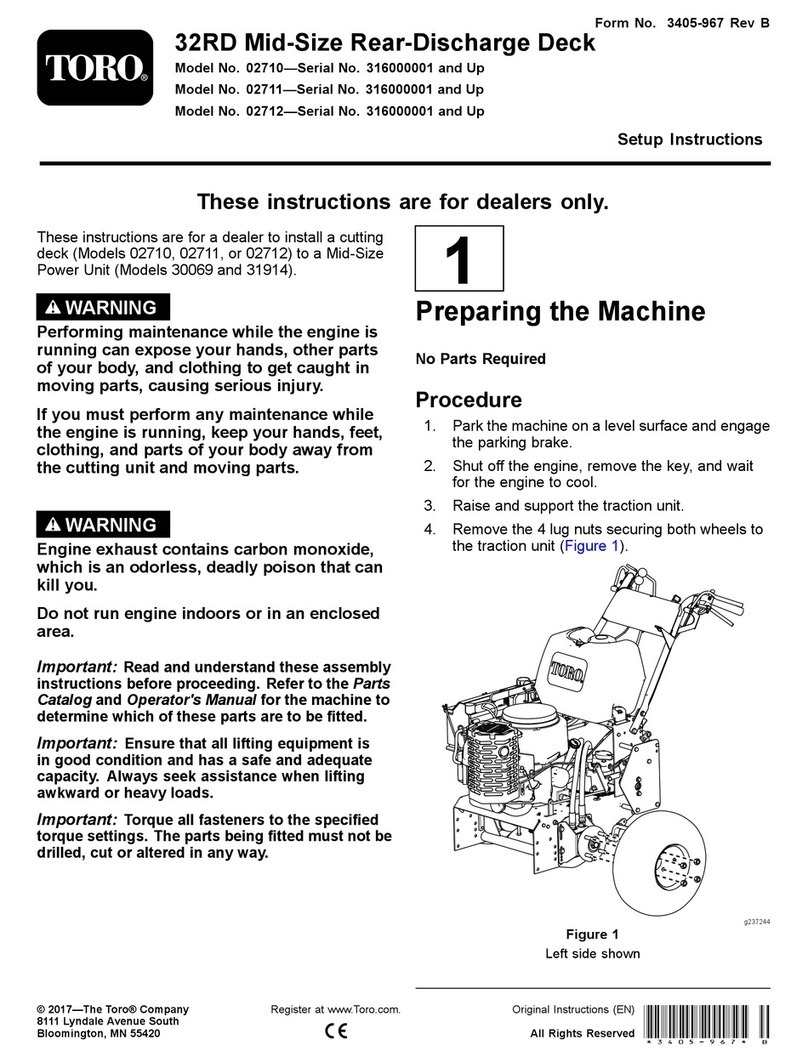

Note:Thisprocedureisonlyformachineswith

halogenheadlights.UseFigure15todetermineifyou

havehalogenheadlights.

g312027

Figure15

1.Halogenheadlight2.LEDheadlight

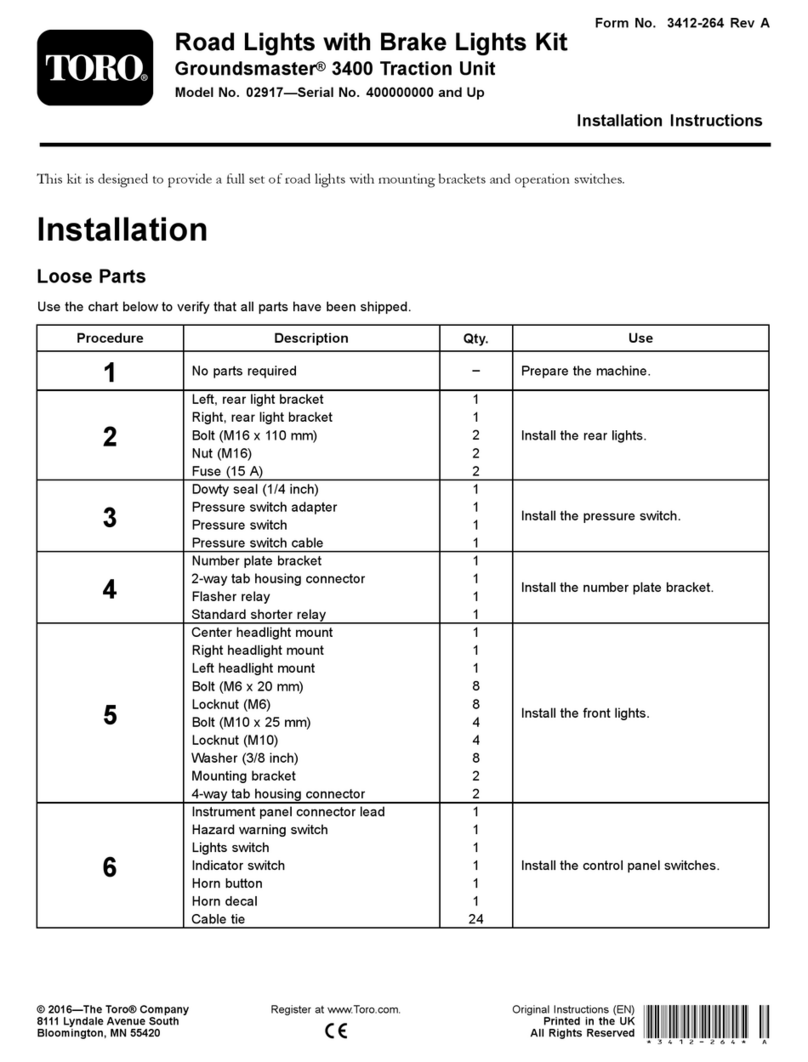

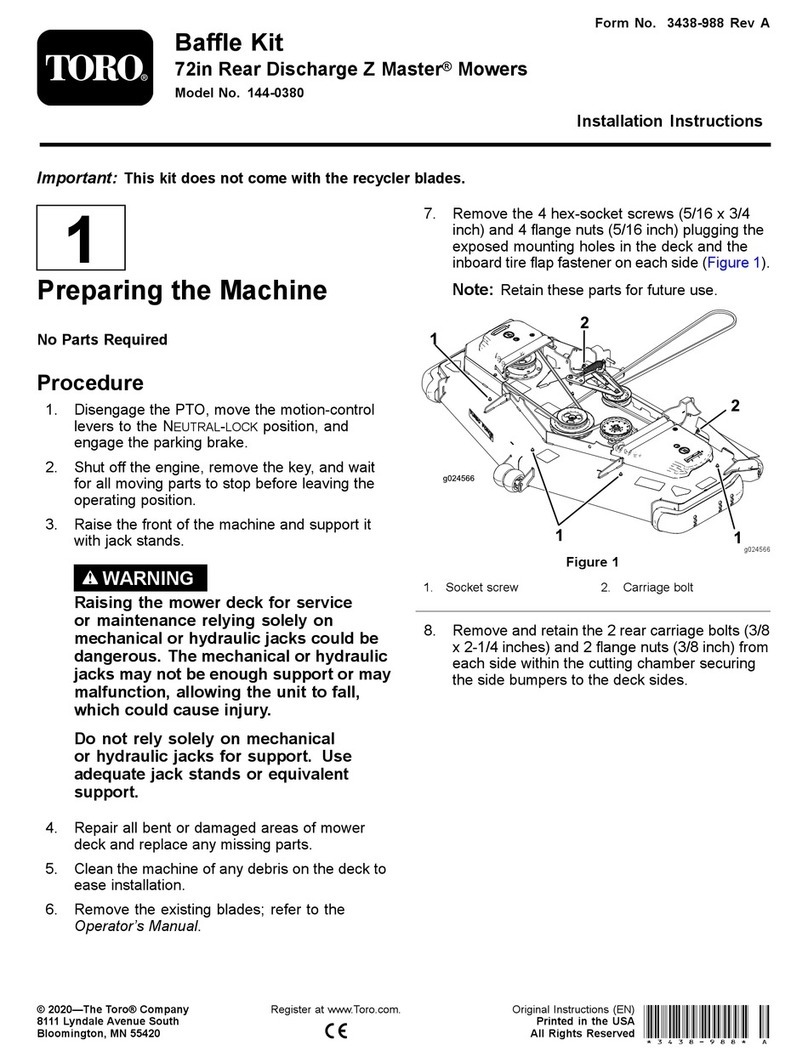

1.Disassembletheproximity-sensorassemblyon

thebrake-pedallever(Figure16)andsetaside

allthepartsexcepttheproximitysensor.

g029761

Figure16

1.Forwardfootrest4.Proximitysensor

2.Carriagebolt(#10x5/8

inch)

5.Brake-pedallever

3.Brake-sensorplate6.Locknut(#10)

2.Assembletheproximity-sensorassemblytothe

brakeleverusingthecarriagebolt(#10x5/8

inch),brake-sensorplate,proximitysensor,and

locknut(#10)asshowninFigure16.

Note:Ensurethatyoudonotovertightenthe

bolts.Overtighteningtheboltswilldamagethe

sensor.

3.Locatethebrake-sensorbracketmountingholes

onthefrontfootrestandlooselyinstallthe

brake-sensorbrackettothefrontfootrestusing2

bolts(1/4x3/4inch)and2angenuts(1/4inch).

Note:Youwillneedtomovethebrake-sensor

bracketupordowntoalignthebrakesensorto

thebrake-sensorplate(Figure17).

10