AdjustingtheBedknifeafter

Grinding,Backlapping,or

Disassembly

Usethisprocedureduringinitialcutting-unitsetupand

aftergrinding,backlapping,ordisassemblingthereel.

Thisisnotadailyadjustment.

Note:Thisprocedurecanbeperformedwiththe

cuttingunitinstalledtothetractionunit.

Note:ForeFlexcuttingunits,thereel-to-bedknife

contacthasasignicantimpactonenergy

consumption.Verylightcontactisbestforcutting

performanceandbatteryconsumption.

1.Shutoffthetractionunit.

2.Accessthecuttingunit;refertoAccessingthe

CuttingUnit(page6).

3.Rotatethereelsothat1ofthebladescrosses

thebedknifeedgebetweentherstandsecond

bedknifescrewheadslocatedontherightside

ofthecuttingunit.

4.Makeanidentifyingmarkonthebladewhereit

crossesthebedknifeedge.

Note:Thiswillmakelateradjustmentseasier.

5.Inserta0.05mm(0.002inch)shim(T oroPart

No.140-5531)betweenthebladeandthe

bedknifeedgeatthepointmarkedinstep4.

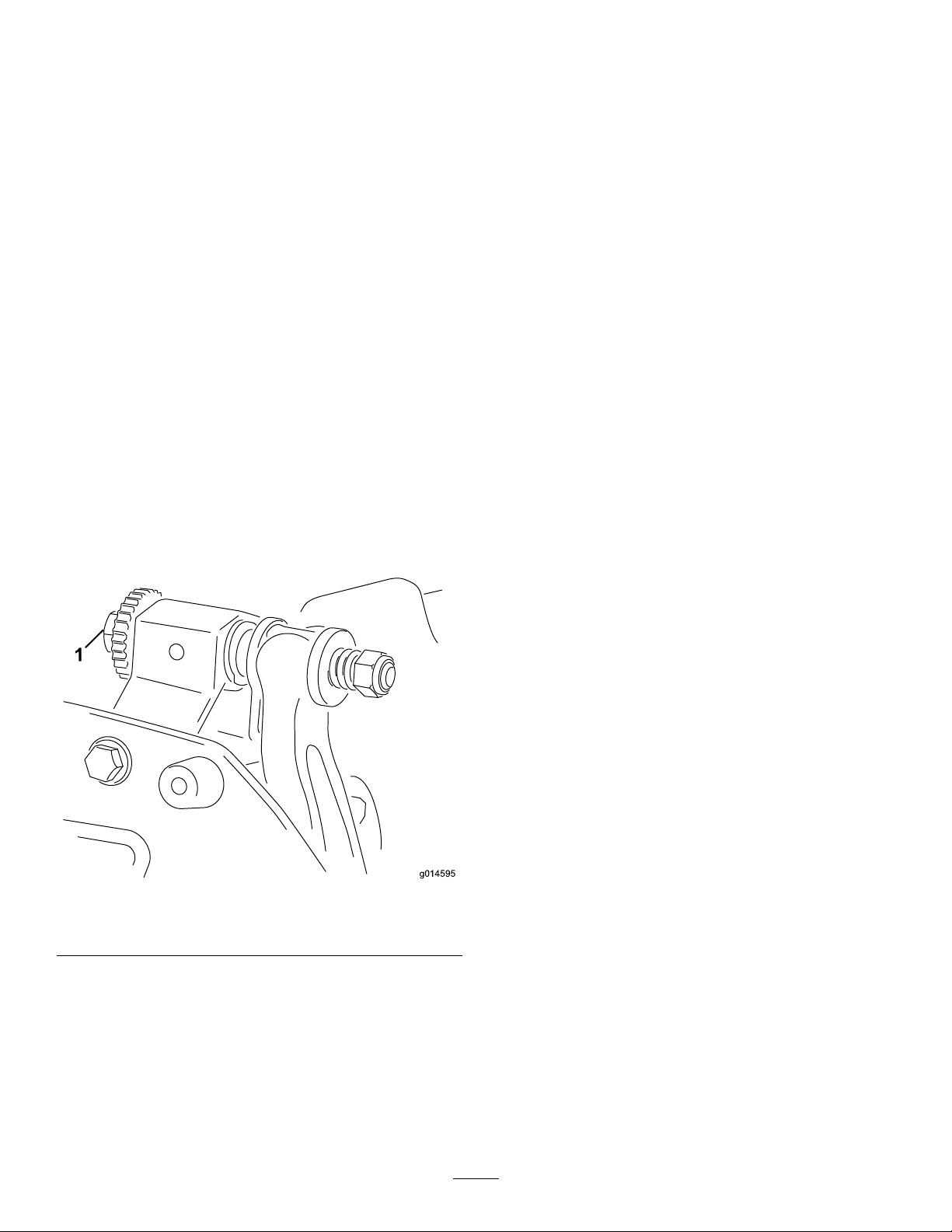

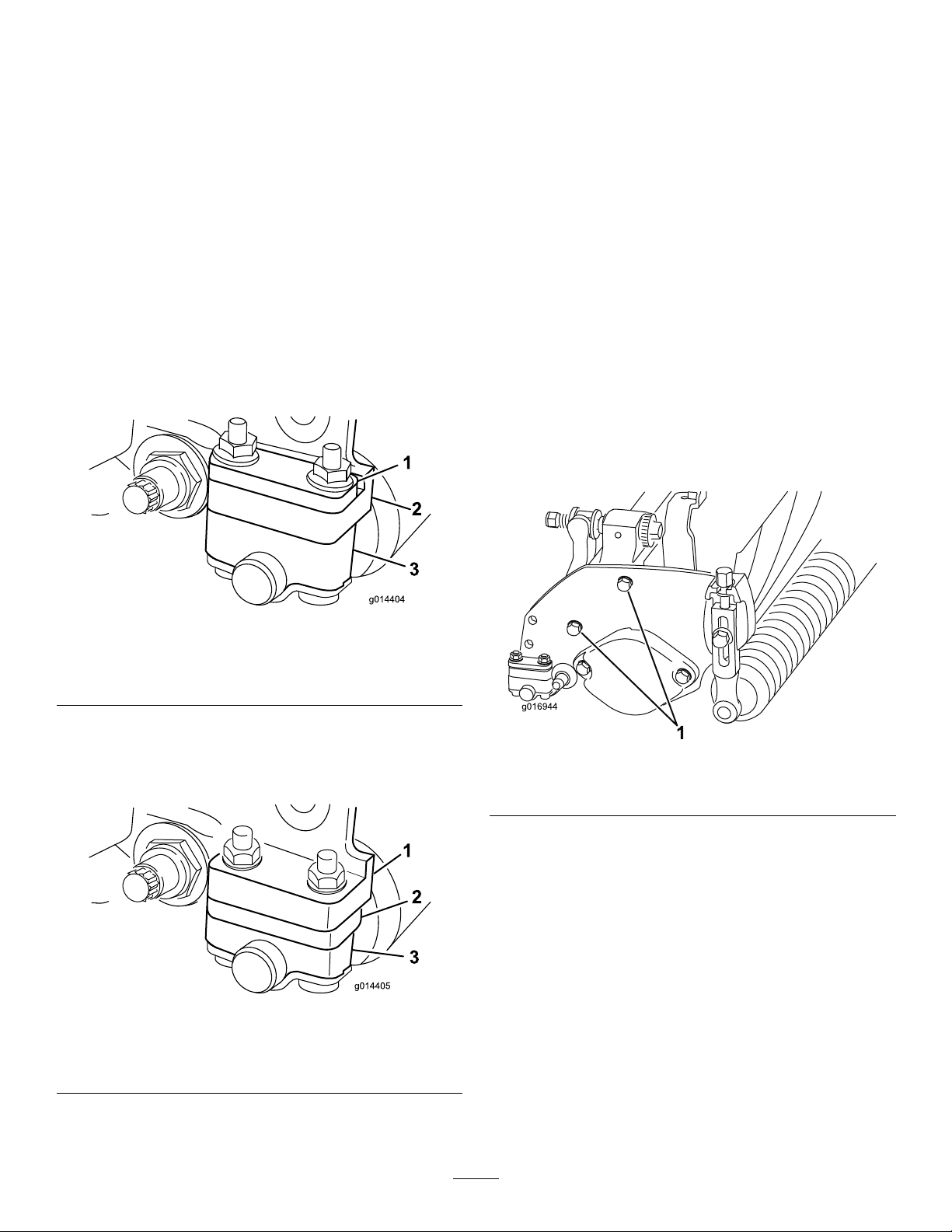

6.Turntherightbedbaradjustingscrew(Figure8)

untilyoufeellightpressureontheshimwhen

slidingitside-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotate

thereelsothattheclosestbladecrossesthe

bedknifeedgebetweentherstandsecond

screwheads.

8.Repeatsteps4through6fortheleftsideofthe

cuttingunitandleftbedbaradjustingscrew.

9.Repeatsteps5and6untilthereislightpressure

atthecontactpointsonboththeleftandright

sidesofthecuttingunit.

10.Toobtainlightcontactbetweenthereeland

bedknife,turneachbedbaradjustingscrew

clockwise3clicks.

Note:Eachclickonthebedbaradjustingscrew

movesthebedknife0.018mm(0.0007inches).

Donotovertightentheadjustingscrews.

Turningtheadjustingscrewclockwisemoves

thebedknifeedgeclosertothereel.Turningthe

adjustingscrewcounterclockwisemovesthe

bedknifeedgeawayfromthereel.

11.Insertalongstripofcuttingperformancepaper

(ToroPartNo.125-5610)betweenthereeland

bedknife,perpendiculartothebedknife(Figure

9),thenslowlyrotatethereelforward;itshould

cutthepaper;ifnot,turneachbedbaradjusting

screwclockwise1clicksandrepeatthisstep

untilitcutsthepaper.

g310820

Figure9

Note:Ifexcessivecontactorreeldragisevident,

youmaybacklap,refacethefrontofthebedknife,

orgrindthecuttingunittoachievethesharpedges

neededforprecisioncutting(RefertotheToroManual

forSharpeningReelandRotaryMowers,FormNo.

09168SL).

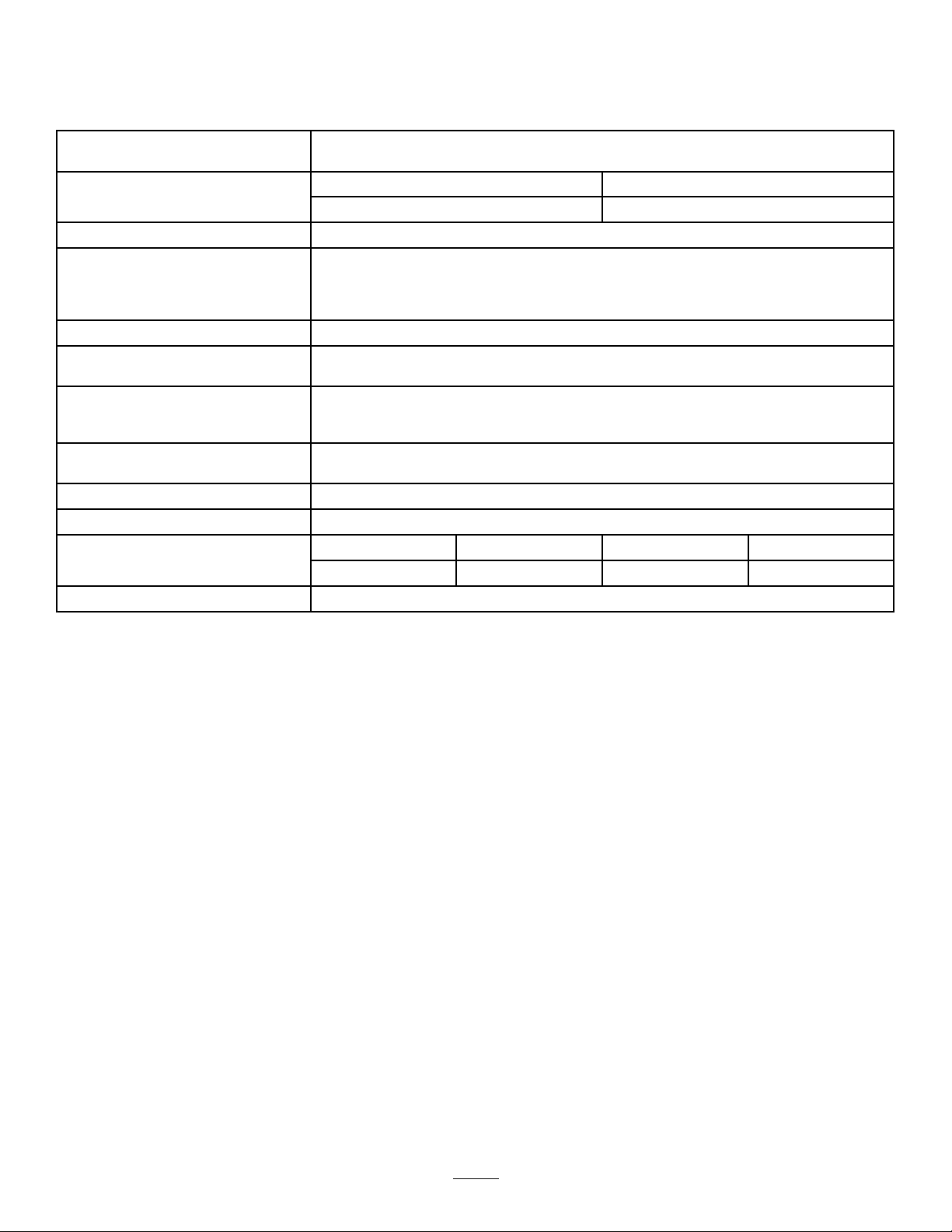

SettingtheCuttingUnitto

MatchTurfConditions

Usethefollowingtabletodeterminetheproper

bedknifethatisneededtomatchyourturfconditions.

ContactyourauthorizedTorodistributortoacquire

additionalbedknivesandrollers.

RefertoAdjustingtheClipRate(page11)for

instructionstosettheappropriatecliprateforyour

turfconditions.

RecommendedBedknife/HeightofCutChart

BedknifeHeightofCut

EdgemaxMicro-cut

(Standard)

1.5to4.7mm(0.062–0.188inch)

EdgemaxT ournament

(Optional)

3.1to12.7mm(0.125–0.500inch)

Micro-cut(Optional)1.5to4.7mm(0.062–0.188inch)

Tournament(Optional)3.1to12.7mm(0.125–0.500inch)

ExtendedMicro-cut

(Optional)

1.5to4.7mm(0.062–0.188inch)

ExtendedT ournament

(Optional)

3.1to12.7mm(0.125–0.500inch)

Low-cut(Optional)4.7to25.4mm(0.188–1.00inch)

8