ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

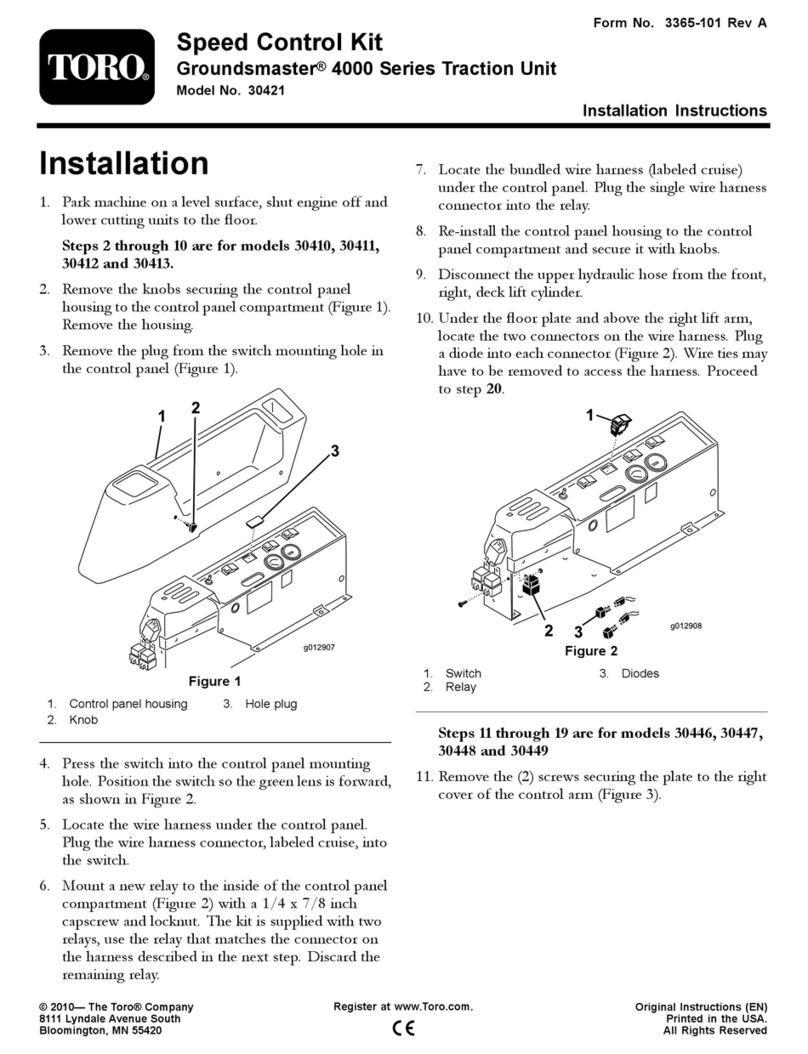

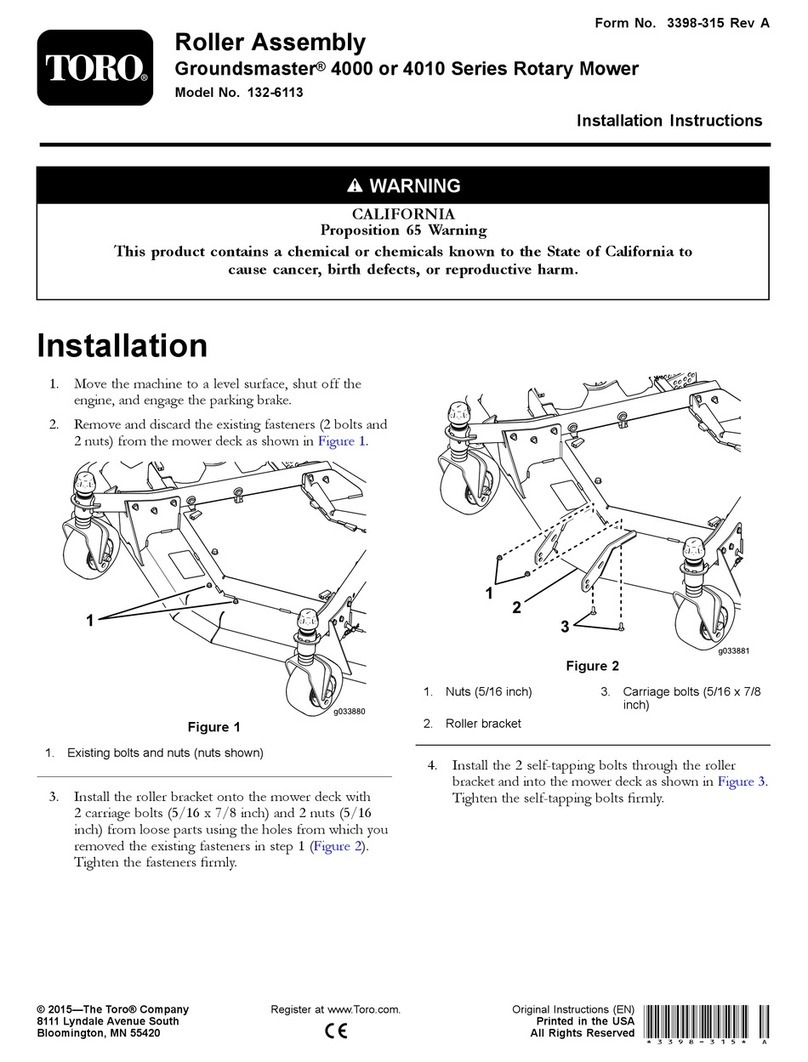

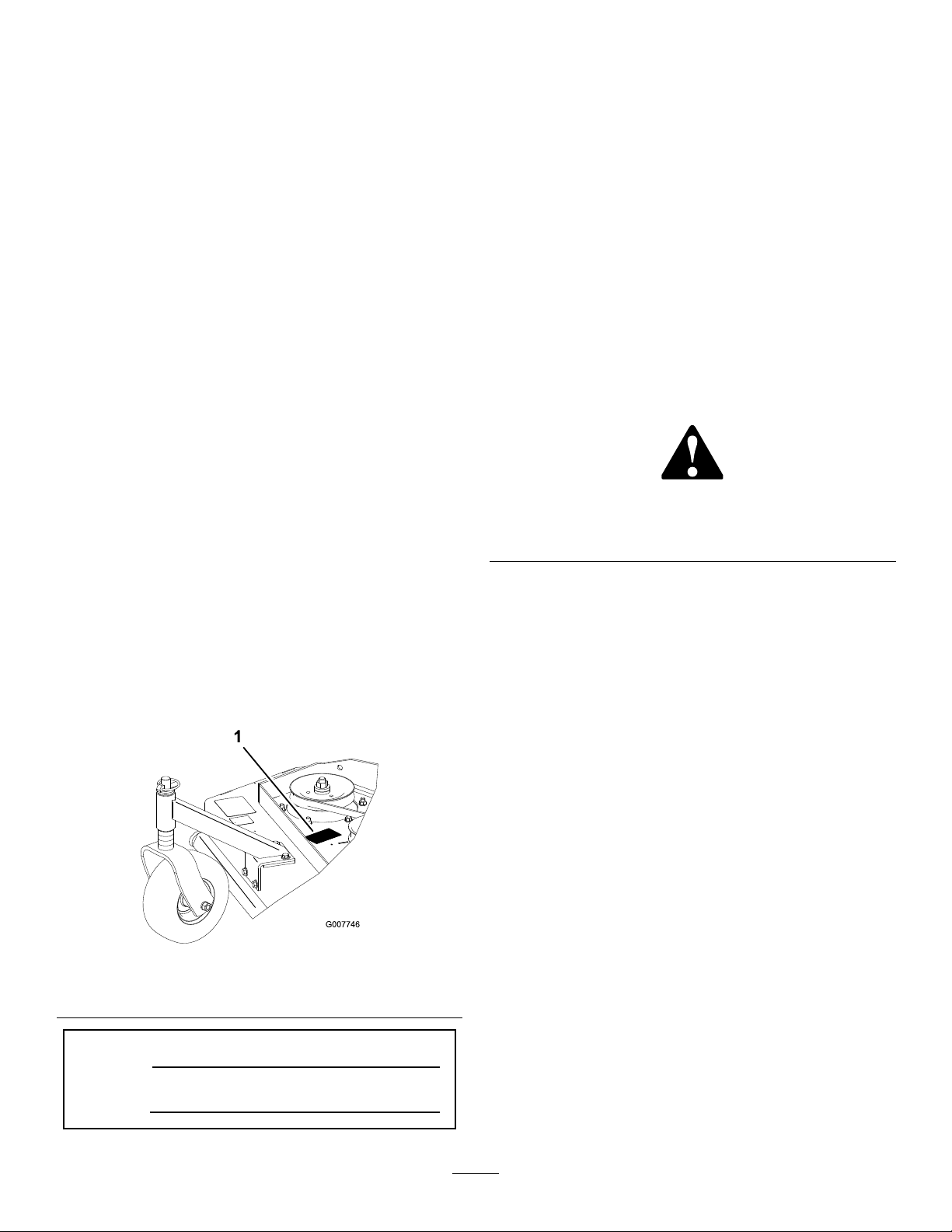

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g007746

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

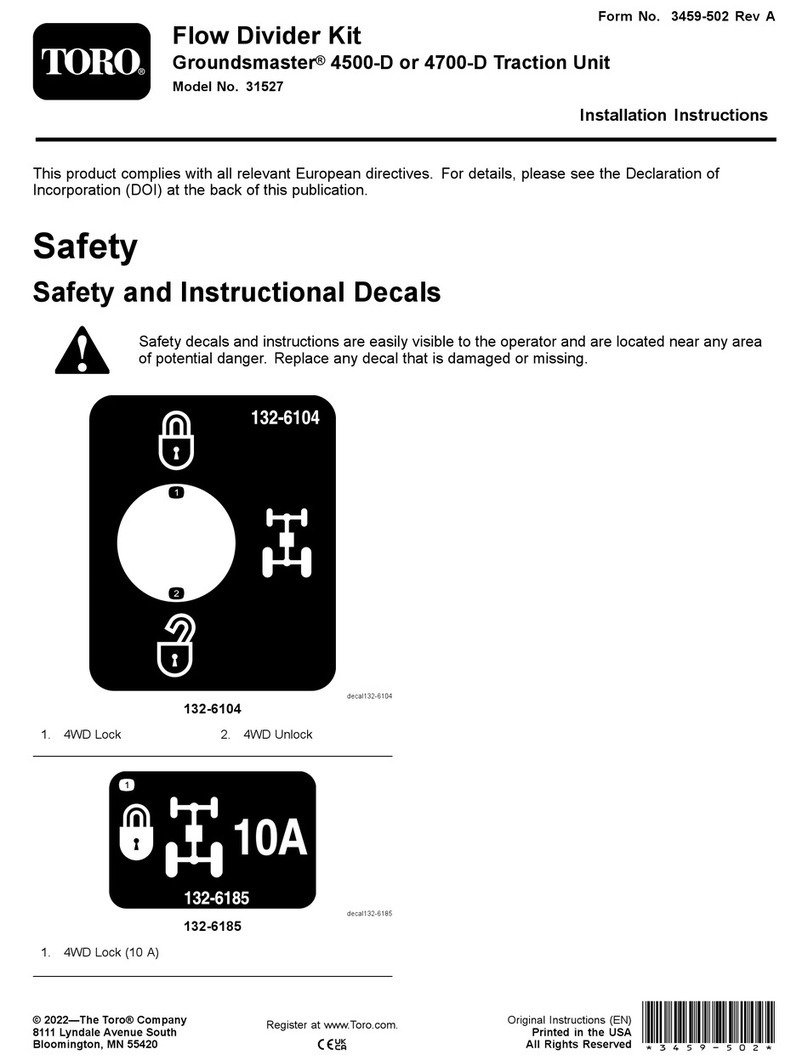

Thesafety-alertsymbol(Figure2)appearsbothin

thismanualandonthemachinetoidentifyimportant

safetymessagesthatyoumustfollowtoavoid

accidents.Thissymbolwillappearwiththeword

Danger,Warning,orCaution.

•Dangerindicatesanimminentlyhazardous

situationwhich,ifnotavoided,willresultindeath

orseriousinjury.

•Warningindicatesapotentiallyhazardous

situationwhich,ifnotavoided,couldresultin

deathorseriousinjury.

•Cautionindicatesapotentiallyhazardoussituation

which,ifnotavoided,mayresultinminoror

moderateinjury.

sa-black

Figure2

Safety-alertsymbol

Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................5

Specications....................................................5

Attachments/Accessories...................................5

Operation..................................................................6

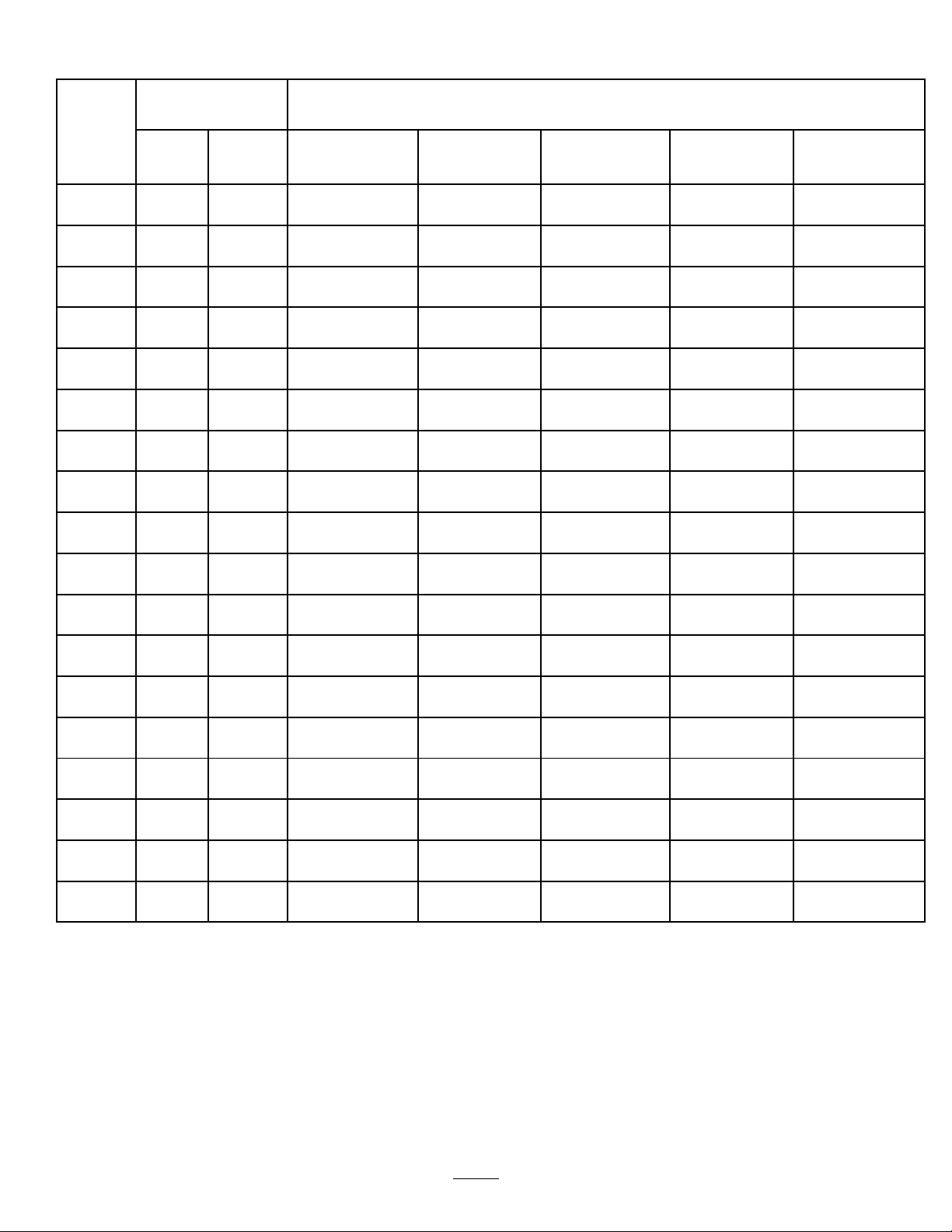

AdjustingtheHeightofCut.................................6

Height-of-CutChart............................................8

Maintenance.............................................................9

RecommendedMaintenanceSchedule(s).............9

Lubrication..........................................................10

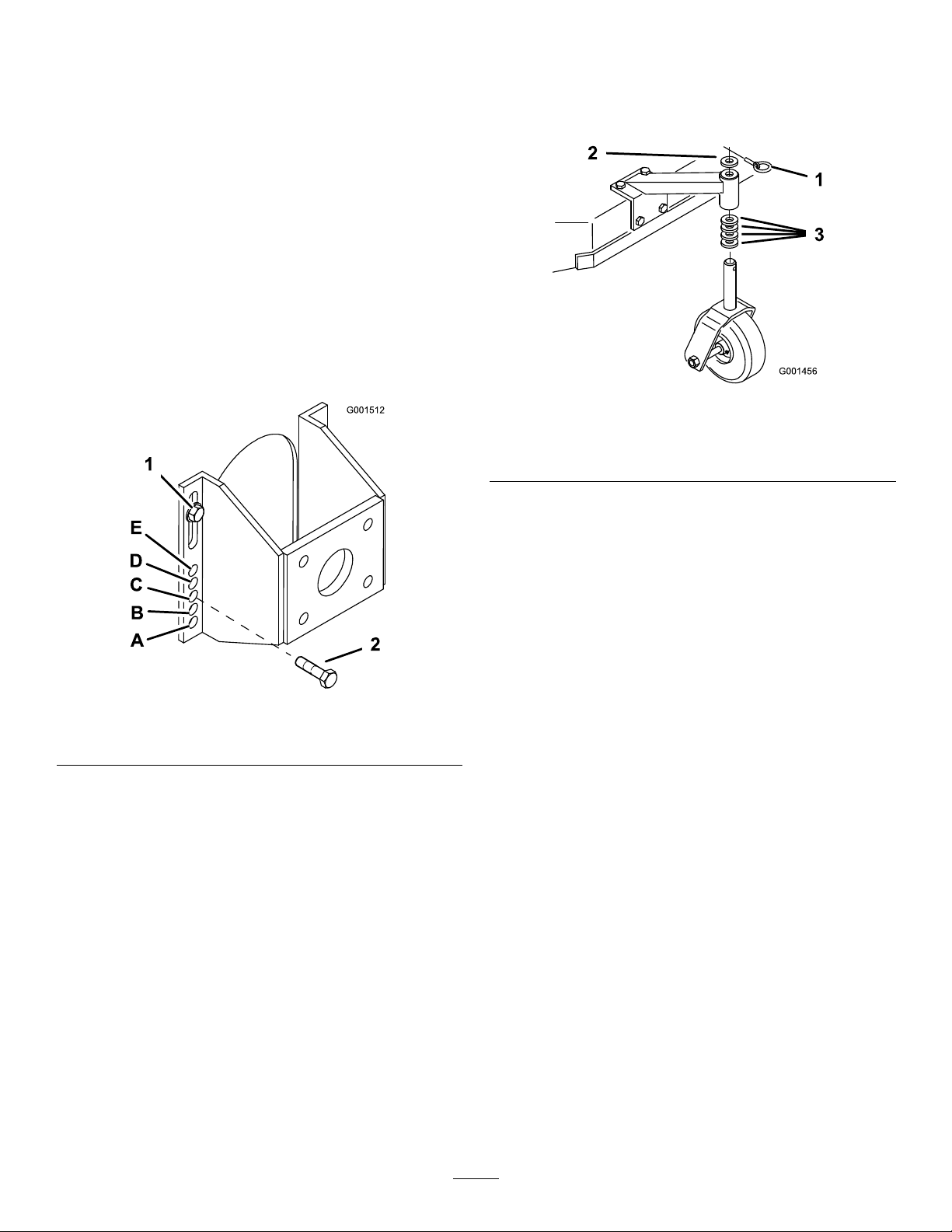

LubricatingtheCasterandWheel

Bearings........................................................10

GreasingtheMower-BeltIdler..........................10

GreasingtheMowerDeck................................10

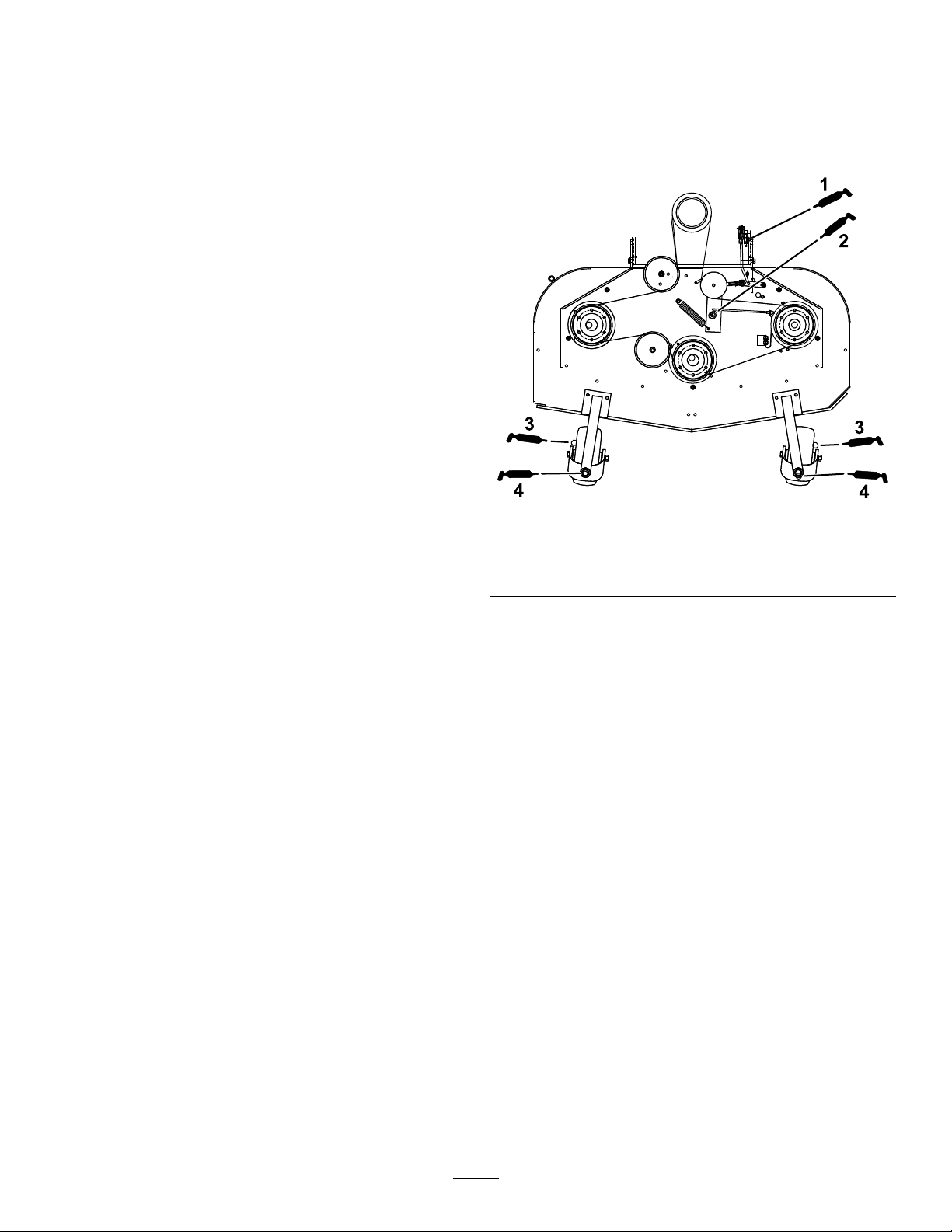

BeltMaintenance.................................................11

CheckingtheBelts.............................................11

ReplacingtheMowerBelt..................................11

AdjustingtheMowerBeltTension......................11

MowerDeckMaintenance....................................14

BladeSafety.....................................................14

ServicingtheCuttingBlades.............................14

AdjustingtheBladeBrake.................................16

Storage...................................................................16

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved