Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................7

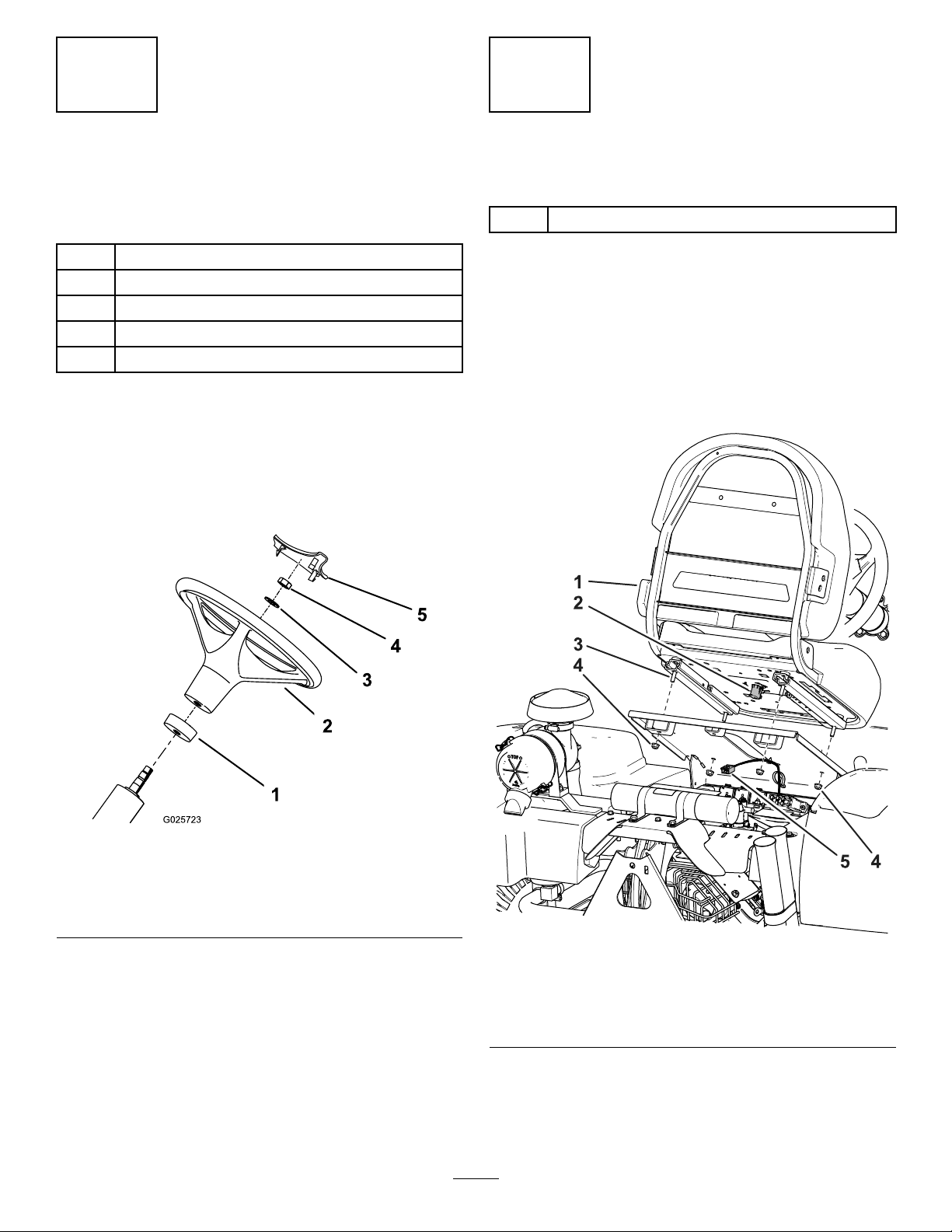

1InstallingtheSteeringWheel............................8

2InstallingtheSeat............................................8

3InstallingtheBattery........................................8

4InstallingtheFrontWeights............................10

5ApplyingtheProductionYearDecaland

CEDecal.......................................................10

ProductOverview....................................................11

Controls............................................................11

Specications..................................................13

Attachments/Accessories.................................13

BeforeOperation.................................................14

BeforeOperationSafety...................................14

FillingtheFuelTank..........................................14

BeforeOperationsChecks................................15

CheckingtheInterlockSystem..........................15

DuringOperation.................................................16

GeneralSafety.................................................16

SlopeSafety.....................................................16

StartingandShuttingOfftheEngine.................17

BreakingintheMachine...................................17

BecomingFamiliarwiththeMachine.................17

AfterOperation....................................................18

AfterOperationSafety......................................18

TowingtheMachine..........................................18

HaulingtheMachine.........................................18

Maintenance...........................................................19

MaintenanceSafety..........................................19

RecommendedMaintenanceSchedule(s)...........19

DailyMaintenanceChecklist.............................20

Pre-MaintenanceProcedures..............................21

LiftingtheMachine...........................................21

Lubrication..........................................................22

GreasingtheMachine.......................................22

EngineMaintenance...........................................23

EngineSafety...................................................23

EngineOilSpecication....................................23

CheckingtheEngine-OilLevel..........................23

ChangingtheEngineOilandFilter....................24

ServicingtheAirCleaner..................................25

ReplacingtheSparkPlugs................................26

FuelSystemMaintenance...................................26

ReplacingtheFuelFilter...................................26

ChangingtheCarbon-CanisterFilter................27

ElectricalSystemMaintenance...........................28

ElectricalSystemSafety...................................28

Jump-StartingtheMachine...............................28

ReplacingFuses...............................................28

MaintainingtheBattery.....................................28

DriveSystemMaintenance..................................29

CheckingtheTirePressure...............................29

TorquingtheWheelLugNuts............................29

AdjustingtheTransportSpeed..........................29

ControlsSystemMaintenance.............................30

AdjustingtheLiftLever.....................................30

HydraulicSystemMaintenance...........................31

HydraulicSystemSafety...................................31

CheckingtheHydraulicLinesand

Hoses............................................................31

HydraulicFluidSpecications...........................31

CheckingtheHydraulic-FluidLevel...................32

ReplacingtheHydraulicFilter...........................33

ChangingtheHydraulicFluid............................33

Cleaning..............................................................34

CleaningandInspectingtheMachine...............34

CleaningtheOilCooler.....................................34

Storage...................................................................35

PreparingtheMachine......................................35

PreparingtheEngine........................................35

PreparingtheBattery........................................35

3