Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Machine Safety W arnings . . . . . . . . . . . . . . . . . . . . . . 4

Lawn Mower Safety W arnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

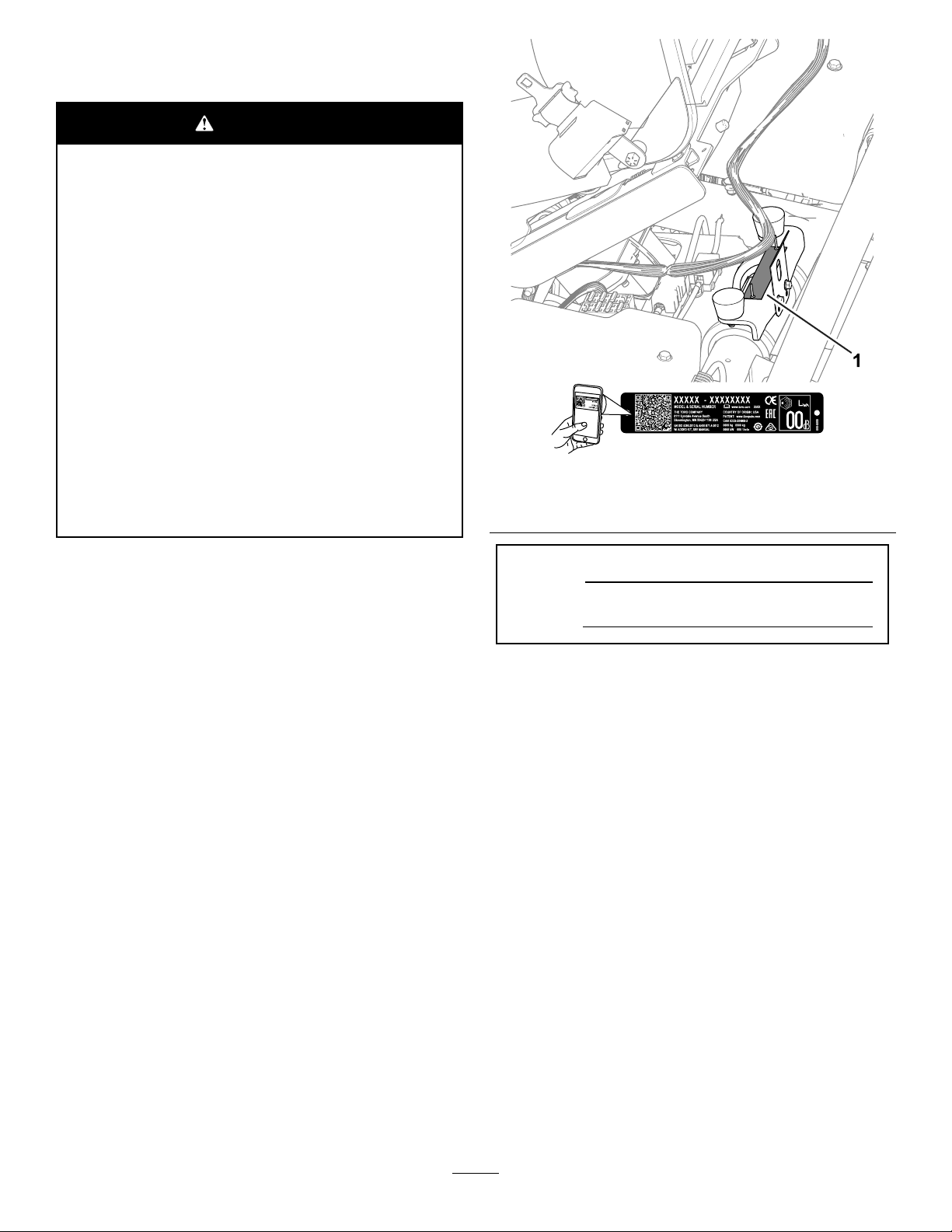

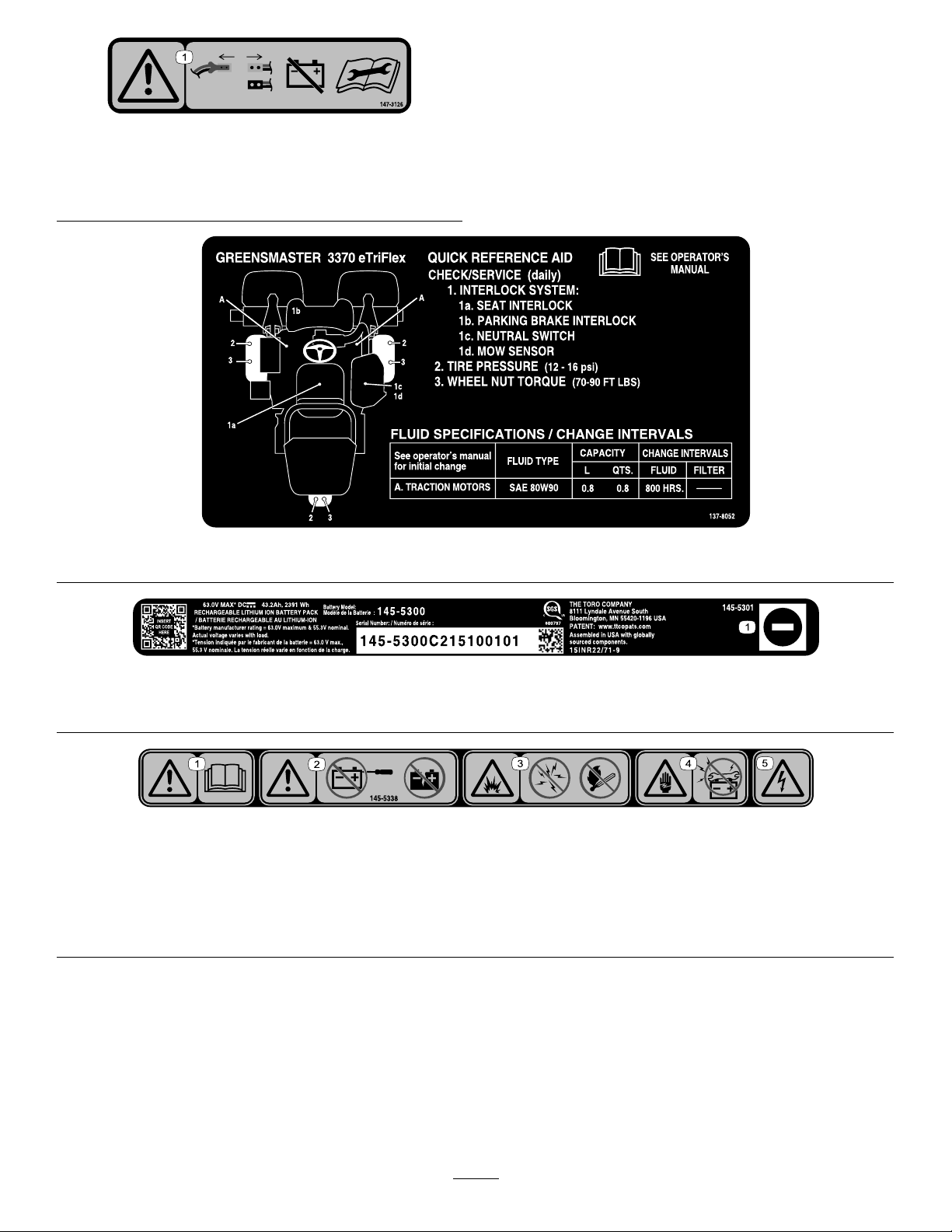

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

1 Installing the Roll Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Installing the Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Installing the Service Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Installing the Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Installing the Grass-Basket Hooks . . . . . . . . . . . . . . . . . 13

6 Installing the Cutting Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Connecting the Main-Power

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Adjusting the Machine Settings . . . . . . . . . . . . . . . . . . . . . . 15

9 Adding Rear W eight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10 Installing the CE/UKCA Decals . . . . . . . . . . . . . . . . . . . . 15

1 1 Reducing the T ire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Mounting the Battery Charger on a

W all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 Charging the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

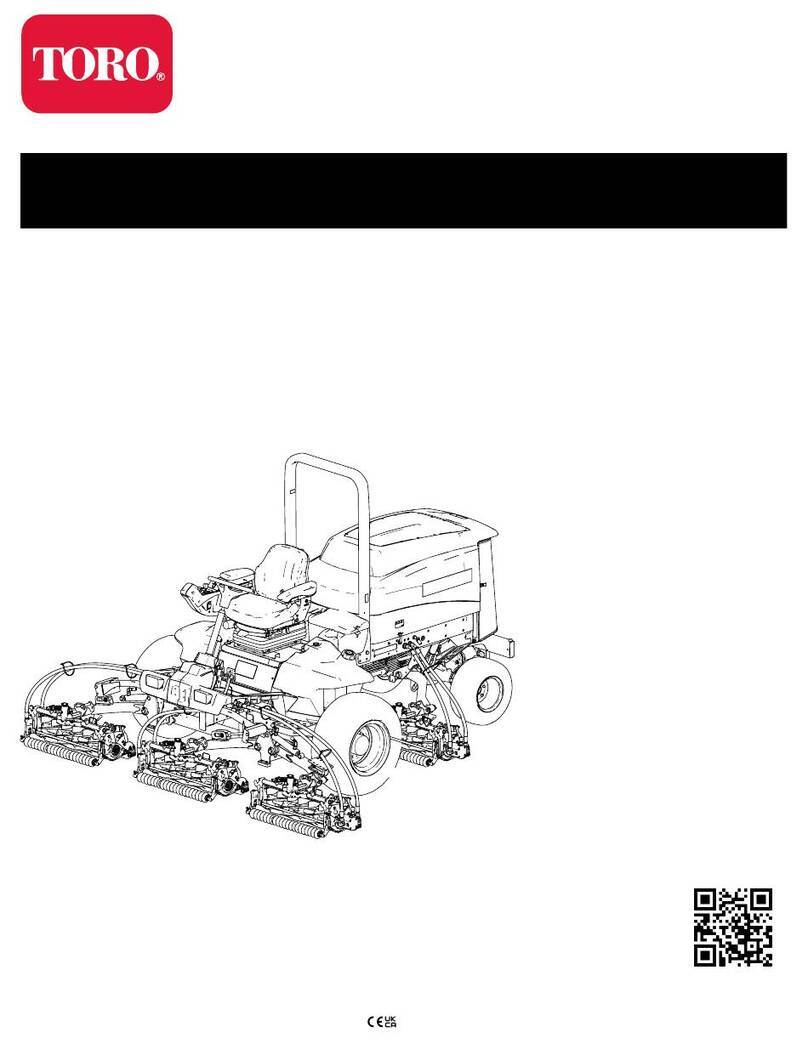

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

InfoCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Identifying the Cutting Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the InfoCenter to Adjust the Machine

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Understanding the InfoCenter Dialog

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

T ilting the Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performing Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 29

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

During Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Breaking in the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

T urning On the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Checking the Machine after T urning On the

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Understanding the Safety-Interlock

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Driving the Machine without Mowing . . . . . . . . . . . . . . . . . 31

Mowing the Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Monitoring the Battery-System Charge

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Shutting Of f the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

After Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

After Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Inspecting and Cleaning after Mowing . . . . . . . . . . . . . . 35

Hauling the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

T owing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Maintaining the Lithium-Ion Batteries . . . . . . . . . . . . . . . . 37

T ransporting the Lithium-Ion Batteries . . . . . . . . . . . . . . 37

Understanding the Lithium-Ion Battery

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Recommended Maintenance Schedule(s) . . . . . . . . . . . 40

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pre-Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Raising the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Raising the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electrical System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Disconnecting or Connecting Power to the

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Locating the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Servicing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Maintaining the Battery Charger . . . . . . . . . . . . . . . . . . . . . . . 46

Drive System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking the T ire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking the T orque of the Wheel

Nuts .............................................................. 47

Changing the T raction-Motor-Gearbox

Fluid .............................................................. 47

Brake Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjusting the Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cutting Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Blade Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Installing and Removing the Cutting

Units .............................................................. 49

Checking the Reel-to-Bedknife Contact . . . . . . . . . . . . 52

Backlapping the Cutting Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preparing the Machine for Storage . . . . . . . . . . . . . . . . . . . 53

Battery Storage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 53

Storing the Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3