Contents

Safety.......................................................................4

GeneralSafety...................................................4

Engine-EmissionCertication.............................4

SafetyandInstructionalDecals..........................4

Setup......................................................................10

1AdjustingtheSupportRollers..........................11

2ReplacingtheWarningDecalforCE

Compliance....................................................11

3InstallingtheHoodLockforCE

Compliance....................................................11

4InstallingtheCuttingUnits..............................13

5AdjustingtheTurf-Compensation

Spring...........................................................16

6UsingtheCutting-UnitKickstand....................17

7GreasingtheMachine....................................18

8CheckingtheFluidLevels..............................18

9UsingtheGaugeBar......................................18

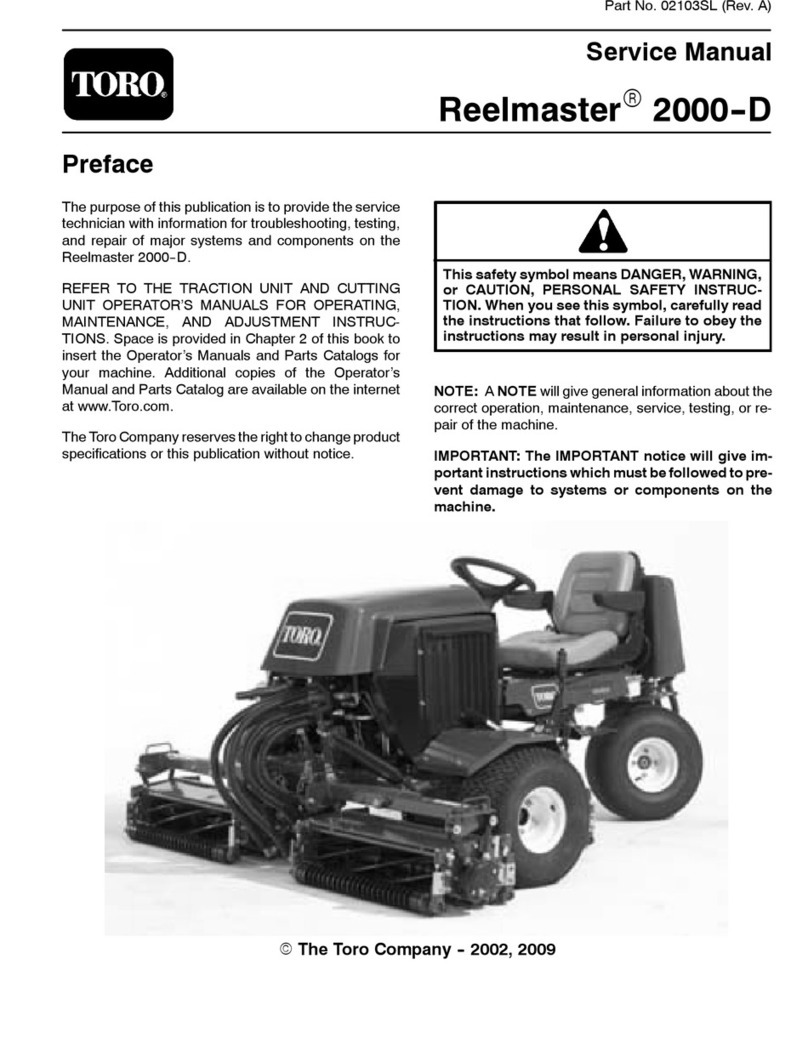

ProductOverview...................................................19

Controls...........................................................19

Specications..................................................26

TractionUnitSpecications..............................26

Attachments/Accessories.................................26

Operation................................................................27

BeforeOperationSafety...................................27

FillingtheFuelTank..........................................27

CheckingtheHydraulicSystem........................28

CheckingtheEngine-OilLevel..........................29

CheckingtheCoolingSystem...........................29

CheckingtheTirePressure...............................30

DuringOperationSafety...................................30

StartingandShuttingOfftheEngine.................31

EngineSpeedSwitch........................................32

CuttingGrasswiththeMachine........................32

DieselParticulateFilterRegeneration...............32

AdjustingtheLift-ArmCounterbalance.............41

AdjustingtheLift-ArmTurnaround

Position.........................................................41

FoldingtheRollBar..........................................42

CheckingtheInterlockSwitches.......................42

AfterOperationSafety......................................43

PushingorTowingtheMachine........................43

HaulingtheMachine.........................................45

IdentifyingtheJackingPoints...........................45

IdentifyingtheTie-DownPoints........................45

OperatingCharacteristics.................................45

OperatingTips.................................................45

Maintenance...........................................................47

RecommendedMaintenanceSchedule(s)...........47

DailyMaintenanceChecklist.............................48

ServiceIntervalChart.......................................49

Pre-MaintenanceProcedures..............................50

Pre-MaintenanceSafety...................................50

RemovingtheHood..........................................50

Lubrication..........................................................51

GreasingtheBearingsandBushings................51

EngineMaintenance...........................................52

EngineSafety...................................................52

ServicingtheAirCleaner..................................52

ServicingtheEngineOil....................................53

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................55

FuelSystemMaintenance...................................56

DrainingtheFuelT ank......................................56

CheckingtheFuelLinesand

Connections..................................................56

ServicingtheWaterSeparator.........................56

ServicingtheFuelFilter....................................56

CleaningtheFuel-IntakeScreen.......................57

ElectricalSystemMaintenance...........................57

ElectricalSystemSafety...................................57

ChargingandConnectingtheBattery...............57

ServicingtheBattery.........................................59

CheckingtheFuses..........................................59

DriveSystemMaintenance..................................60

CheckingtheT orqueoftheWheel

Nuts..............................................................60

CheckingforEnd-PlayinthePlanetary

Drives............................................................60

CheckingthePlanetaryGear-Drive

Lubricant.......................................................61

ChangingthePlanetary-Gear-Drive

Oil.................................................................62

CheckingtheOilLeveloftheRear

Axle...............................................................63

ChangingtheOilintheRearAxle......................63

CheckingtheLubricantintheGearBoxof

theRearAxle................................................63

AdjustingtheTractionDriveforNeutral.............64

CheckingtheRear-WheelToe-In......................64

CoolingSystemMaintenance..............................65

CoolingSystemSafety.....................................65

ServicingtheEngineCoolingSystem...............65

BrakeMaintenance.............................................66

AdjustingtheServiceBrakes............................66

BeltMaintenance................................................67

ServicingtheAlternatorBelt.............................67

HydraulicSystemMaintenance...........................67

HydraulicSystemSafety...................................67

CheckingtheLeveloftheHydraulic

Fluid..............................................................67

ChangingtheHydraulicFluid............................68

ReplacingtheHydraulicFilters.........................69

CheckingtheHydraulicLinesand

Hoses............................................................70

CuttingUnitMaintenance.....................................70

CuttingUnitSafety............................................70

BacklappingtheCuttingUnits...........................70

Storage...................................................................72

PreparingtheTractionUnit...............................72

PreparingtheEngine........................................72

3